ASTM B956-07e1

(Specification)Standard Specification for Welded Copper and Copper-Alloy Condenser and Heat Exchanger Tubes with Integral Fins

Standard Specification for Welded Copper and Copper-Alloy Condenser and Heat Exchanger Tubes with Integral Fins

ABSTRACT

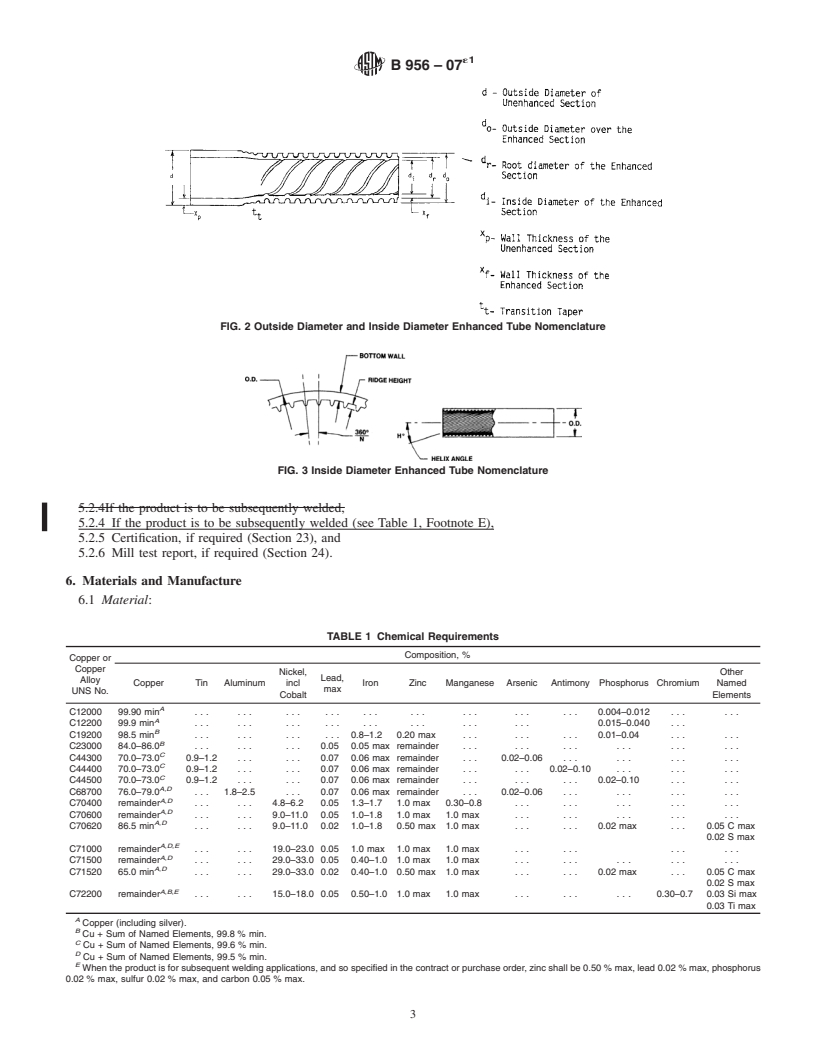

This specification establishes the requirements for forge-welded copper and copper alloy with integral fins for use in surface condenser, evaporator, and heat exchanger. The product shall be welded tube of one of the following Copper or Copper Alloy UNS Nos.: C12000, C12200, C19200, C23000, C44300, C44400, C44500, C68700, C70400, C70600, C70620, C71000, C71500, C71520, and C72200. The material heat identification or traceability shall be specified if required. The product shall be manufactured by cold forming to produce an integral enhanced surface for improved heat transfer and shall typically be furnished with unenhanced ends, but may be furnished with enhanced ends or stripped ends. Temper conditions (annealed, WO61 or light cold-worked, WC55) for the tubes and the enhanced and unenhanced sections of the tubes are given. The material shall conform to the chemical composition requirements prescribed for copper, tin, aluminum, nickel, cobalt, lead, iron, zinc, manganese, arsenic, antimony, phosphorus, chromium, and other elements such as carbon, sulfur, silicon, and titanium as determined by chemical analysis. Requirements for grain size, dimensions, mass, and mechanical properties including tensile strength and yield strength as determined by tension test are detailed. The performance requirements including expansion, flattening, and reverse bend tests; mercurous nitrate test or ammonia vapor test; and nondestructive tests such as eddy-current, hydrostatic, and pneumatic tests are detailed as well.

SCOPE

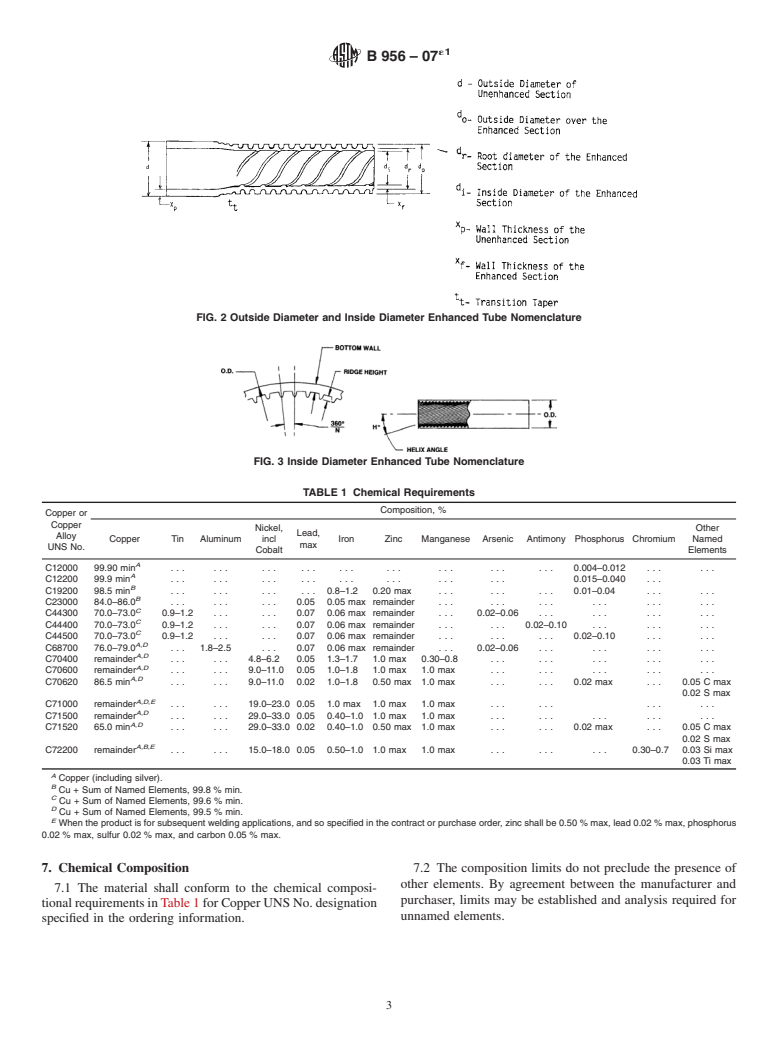

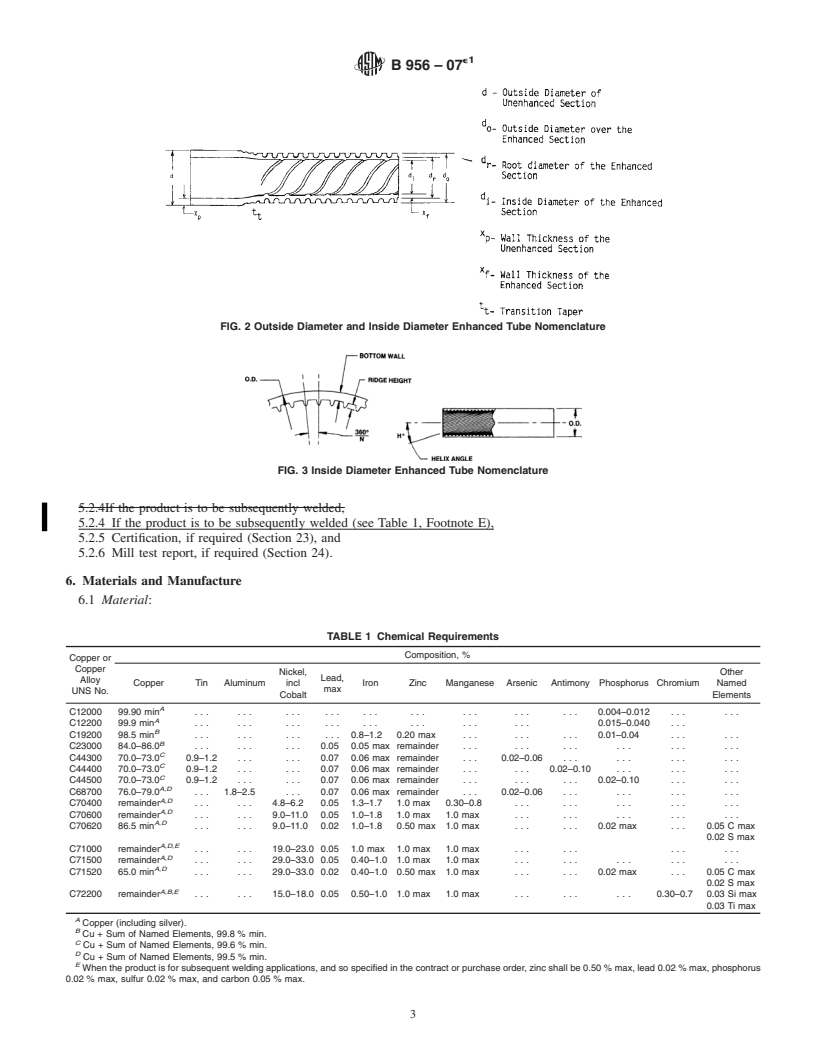

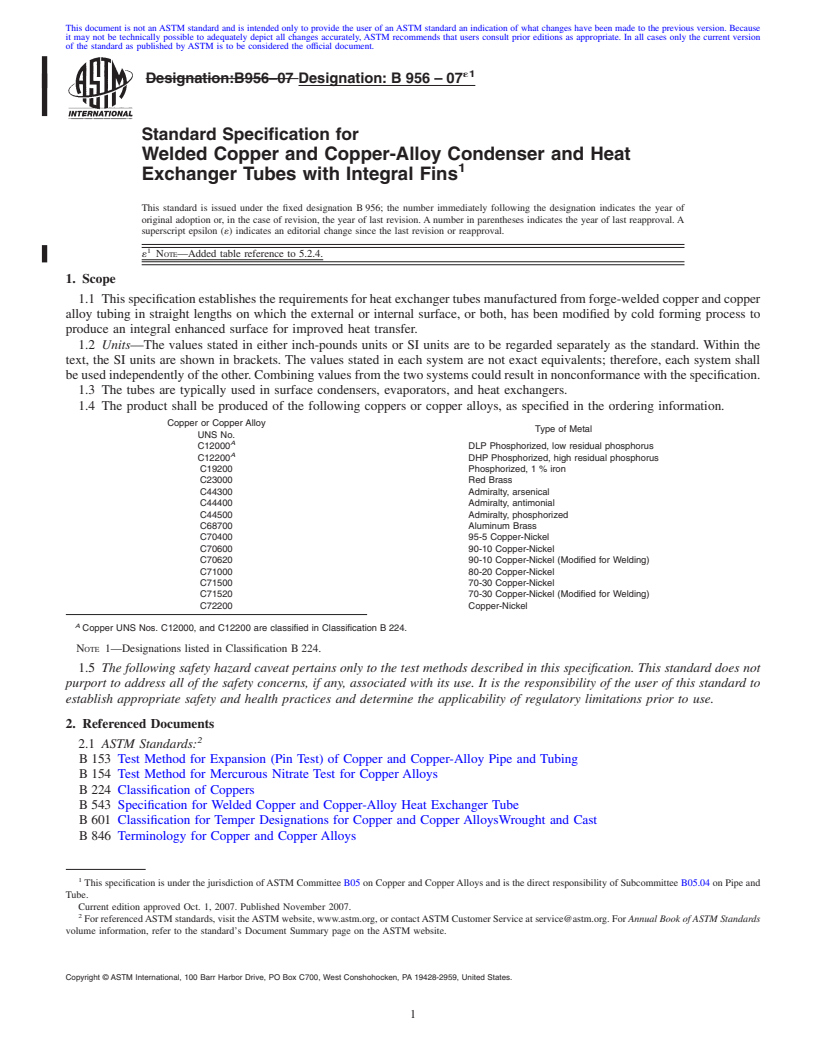

1.1 This specification establishes the requirements for heat exchanger tubes manufactured from forge-welded copper and copper alloy tubing in straight lengths on which the external or internal surface, or both, has been modified by cold forming process to produce an integral enhanced surface for improved heat transfer.

1.2 Units—The values stated in either inch-pounds units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information. Copper or Copper Alloy

UNS No.Type of Metal C12000ADLP Phosphorized, low residual phosphorus

C12200ADHP Phosphorized, high residual phosphorus

C19200Phosphorized, 1 % iron C23000Red Brass C44300Admiralty, arsenical C44400Admiralty, antimonial C44500Admiralty, phosphorized C68700Aluminum Brass C7040095-5 Copper-Nickel C7060090-10 Copper-Nickel C7062090-10 Copper-Nickel (Modified for Welding) C7100080-20 Copper-Nickel C7150070-30 Copper-Nickel C7152070-30 Copper-Nickel (Modified for Welding) C72200Copper-Nickel

A Copper UNS Nos. C12000, and C12200 are classified in Classification B 224.

Note 1—Designations listed in Classification B 224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: B 956 – 07

Standard Specification for

Welded Copper and Copper-Alloy Condenser and Heat

1

Exchanger Tubes with Integral Fins

This standard is issued under the fixed designation B 956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Added table reference to 5.2.4.

1. Scope not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

1.1 This specification establishes the requirements for heat

standard to establish appropriate safety and health practices

exchanger tubes manufactured from forge-welded copper and

and determine the applicability of regulatory limitations prior

copper alloy tubing in straight lengths on which the external or

to use.

internal surface, or both, has been modified by cold forming

process to produce an integral enhanced surface for improved

2. Referenced Documents

heat transfer.

2

2.1 ASTM Standards:

1.2 Units—The values stated in either inch-pounds units or

B 153 Test Method for Expansion (Pin Test) of Copper and

SI units are to be regarded separately as the standard. Within

Copper-Alloy Pipe and Tubing

the text, the SI units are shown in brackets. The values stated

B 154 Test Method for Mercurous Nitrate Test for Copper

in each system are not exact equivalents; therefore, each

Alloys

system shall be used independently of the other. Combining

B 224 Classification of Coppers

values from the two systems could result in nonconformance

B 543 Specification for Welded Copper and Copper-Alloy

with the specification.

Heat Exchanger Tube

1.3 The tubes are typically used in surface condensers,

B 601 Classification for Temper Designations for Copper

evaporators, and heat exchangers.

and Copper Alloys—Wrought and Cast

1.4 The product shall be produced of the following coppers

B 846 Terminology for Copper and Copper Alloys

or copper alloys, as specified in the ordering information.

B 858 Test Method for Ammonia Vapor Test for Determin-

Copper or Copper Alloy

Type of Metal

ing Susceptibility to Stress Corrosion Cracking in Copper

UNS No.

A

C12000 DLP Phosphorized, low residual phosphorus

Alloys

A

C12200 DHP Phosphorized, high residual phosphorus

E8 Test Methods for Tension Testing of Metallic Materials

C19200 Phosphorized, 1 % iron

E29 Practice for Using Significant Digits in Test Data to

C23000 Red Brass

C44300 Admiralty, arsenical

Determine Conformance with Specifications

C44400 Admiralty, antimonial

E53 Test Method for Determination of Copper in Unal-

C44500 Admiralty, phosphorized

loyed Copper by Gravimetry

C68700 Aluminum Brass

C70400 95-5 Copper-Nickel

E54 Test Methods for Chemical Analysis of Special

C70600 90-10 Copper-Nickel

3

Brasses and Bronzes

C70620 90-10 Copper-Nickel (Modified for Welding)

E62 Test Methods for Chemical Analysis of Copper and

C71000 80-20 Copper-Nickel

C71500 70-30 Copper-Nickel

Copper Alloys (Photometric Methods)

C71520 70-30 Copper-Nickel (Modified for Welding)

E112 Test Methods for Determining Average Grain Size

C72200 Copper-Nickel

E118 Test Methods for Chemical Analysis of Copper-

A

Copper UNS Nos. C12000, and C12200 are classified in Classification B 224.

Chromium Alloys

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

NOTE 1—Designations listed in Classification B 224.

nation of Copper and Copper-Alloy Tubes

1.5 The following safety hazard caveat pertains only to the

test methods described in this specification. This standard does

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

Standards volume information, refer to the standard’s Document Summary page on

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

the ASTM website.

3

and Tube.

Withdrawn. The last approved version of this historical standard is referenced

Current edition approved Oct. 1, 2007. Published November 2007.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

B956–07

E 255 Practice for Sampling Copper and CopperAlloys for 5.2 The following options are available and shall be speci-

the Determination of Chemical Composition fied at the time placing the order, when required:

E 478 Test Methods for Chemical Analysis of Copper

5.2.1 When heat identification or traceability is required,

Alloys

5.2.2 Whether a pressure test is to be used instead of the

E 527 Practice for Nu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:B956–07 Designation: B 956 – 07

Standard Specification for

Welded Copper and Copper-Alloy Condenser and Heat

1

Exchanger Tubes with Integral Fins

This standard is issued under the fixed designation B 956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Added table reference to 5.2.4.

1. Scope

1.1 Thisspecificationestablishestherequirementsforheatexchangertubesmanufacturedfromforge-weldedcopperandcopper

alloy tubing in straight lengths on which the external or internal surface, or both, has been modified by cold forming process to

produce an integral enhanced surface for improved heat transfer.

1.2 Units—The values stated in either inch-pounds units or SI units are to be regarded separately as the standard. Within the

text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy

Type of Metal

UNS No.

A

C12000 DLP Phosphorized, low residual phosphorus

A

C12200 DHP Phosphorized, high residual phosphorus

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty, arsenical

C44400 Admiralty, antimonial

C44500 Admiralty, phosphorized

C68700 Aluminum Brass

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

A

Copper UNS Nos. C12000, and C12200 are classified in Classification B 224.

NOTE 1—Designations listed in Classification B 224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B 154 Test Method for Mercurous Nitrate Test for Copper Alloys

B 224 Classification of Coppers

B 543 Specification for Welded Copper and Copper-Alloy Heat Exchanger Tube

B 601 Classification for Temper Designations for Copper and Copper AlloysWrought and Cast

B 846 Terminology for Copper and Copper Alloys

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2007. Published November 2007.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

B956–07

B 858 Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E 54 Test Methods for Chemical Analysis of Special Brasses and Bronzes

E 62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E 112 Test Methods for Determining Average Grain Size

E 118 Test Methods for Chemical Analysis of Copper-Chromium Alloys

E 243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E 255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E 478 Test Methods for Chemical Analysis of Copper Alloys

E 527 Practice for Numbering Metals and Alloys in the Unifie

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:B956–07 Designation: B 956 – 07

Standard Specification for

Welded Copper and Copper-Alloy Condenser and Heat

1

Exchanger Tubes with Integral Fins

This standard is issued under the fixed designation B 956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Added table reference to 5.2.4.

1. Scope

1.1 Thisspecificationestablishestherequirementsforheatexchangertubesmanufacturedfromforge-weldedcopperandcopper

alloy tubing in straight lengths on which the external or internal surface, or both, has been modified by cold forming process to

produce an integral enhanced surface for improved heat transfer.

1.2 Units—The values stated in either inch-pounds units or SI units are to be regarded separately as the standard. Within the

text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems could result in nonconformance with the specification.

1.3 The tubes are typically used in surface condensers, evaporators, and heat exchangers.

1.4 The product shall be produced of the following coppers or copper alloys, as specified in the ordering information.

Copper or Copper Alloy

Type of Metal

UNS No.

A

C12000 DLP Phosphorized, low residual phosphorus

A

C12200 DHP Phosphorized, high residual phosphorus

C19200 Phosphorized, 1 % iron

C23000 Red Brass

C44300 Admiralty, arsenical

C44400 Admiralty, antimonial

C44500 Admiralty, phosphorized

C68700 Aluminum Brass

C70400 95-5 Copper-Nickel

C70600 90-10 Copper-Nickel

C70620 90-10 Copper-Nickel (Modified for Welding)

C71000 80-20 Copper-Nickel

C71500 70-30 Copper-Nickel

C71520 70-30 Copper-Nickel (Modified for Welding)

C72200 Copper-Nickel

A

Copper UNS Nos. C12000, and C12200 are classified in Classification B 224.

NOTE 1—Designations listed in Classification B 224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

B 154 Test Method for Mercurous Nitrate Test for Copper Alloys

B 224 Classification of Coppers

B 543 Specification for Welded Copper and Copper-Alloy Heat Exchanger Tube

B 601 Classification for Temper Designations for Copper and Copper AlloysWrought and Cast

B 846 Terminology for Copper and Copper Alloys

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2007. Published November 2007.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

B956–07

B 858 Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E112 Test Methods for Determining Average Grain Size

E118 Test Methods for Chemical Analysis of Copper-Chromium Alloys

E 243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E 255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E 478 Test Methods for Chemical Analysis of Copper Alloys

E 527 Practice for Numbering Metals and Alloys in the Unified Numbe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.