ASTM B1011/B1011M-22

(Specification)Standard Specification for Cobalt Alloy Spring Wire

Standard Specification for Cobalt Alloy Spring Wire

SCOPE

1.1 This specification covers cold-drawn cobalt alloy spring wire intended especially for the manufacture of springs.

1.1.1 This specification requires capability properties after age hardening test samples of the cold worked spring wire to ensure final mechanical properties are satisfied. The spring is typically age hardened after fabrication to increase its strength. However, mechanical properties cannot be obtained from finished springs.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 Unless the order specifies an “M” designation, the material shall be furnished to inch-pound units.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B1011/B1011M −22

Standard Specification for

1

Cobalt Alloy Spring Wire

ThisstandardisissuedunderthefixeddesignationB1011/B1011M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E92 Test Methods for Vickers Hardness and Knoop Hard-

ness of Metallic Materials

1.1 This specification covers cold-drawn cobalt alloy spring

E354 Test Methods for Chemical Analysis of High-

wire intended especially for the manufacture of springs.

Temperature,Electrical,Magnetic,andOtherSimilarIron,

1.1.1 This specification requires capability properties after

Nickel, and Cobalt Alloys

age hardening test samples of the cold worked spring wire to

E527 Practice for Numbering Metals and Alloys in the

ensure final mechanical properties are satisfied. The spring is

Unified Numbering System (UNS)

typically age hardened after fabrication to increase its strength.

3

2.2 NACE Standard:

However, mechanical properties cannot be obtained from

NACE MR0175/ISO 15156 Petroleum and natural gas

finished springs.

industries—Materials for use in H2S-containing environ-

1.2 The values stated in either SI units or inch-pound units

ments in oil and gas production

are to be regarded separately as standard. The values stated in

4

2.3 SAE Standard:

each system may not be exact equivalents; therefore, each

J 1086 Numbering Metals and Alloys

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3. Ordering Information

with the standard.

3.1 It is the responsibility of the purchaser to specify all

1.3 Unless the order specifies an “M” designation, the

requirements that are necessary for material ordered under this

material shall be furnished to inch-pound units.

specification. Such requirements may include, but are not

1.4 This international standard was developed in accor-

limited to the following:

dance with internationally recognized principles on standard-

3.1.1 Quantity (weight or number of pieces),

ization established in the Decision on Principles for the

3.1.2 Name of material,

Development of International Standards, Guides and Recom-

3.1.3 Melt method (see 5.1),

mendations issued by the World Trade Organization Technical

3.1.4 Finish (see 5.4),

Barriers to Trade (TBT) Committee.

3.1.5 Dimension(s) with tolerance(s),

3.1.6 UNS designation (Table 1),

2. Referenced Documents

3.1.7 ASTM designation and date of issue,

2

2.1 ASTM Standards:

3.1.8 Special requirements and any supplementary require-

B880 Specification for General Requirements for Chemical

ments(suchasS1forNACEMR0175/ISO15156service),and

Check Analysis Limits for Nickel, Nickel Alloys and

3.1.9 Packaging (see 5.5).

Cobalt Alloys

NOTE 1—A typical ordering description is as follows:

E8/E8M Test Methods for Tension Testing of Metallic Ma-

2000 lb [900 kg] Cobalt Alloy Spring Wire, cold-drawn and stearate

terials

coated, 0.032-in. [0.82 mm] diameter, in 100-lb [45 kg] 16-in. [0.4 m]

E18 Test Methods for Rockwell Hardness of Metallic Ma-

coils, UNS R30035, to ASTM B1011/B1011M, dated ____.

terials

4. General Requirements for Delivery

4.1 Spring wire shall be shipped in suitable packing and

1

This specification is under the jurisdiction of ASTM Committee B02 on

shall include a shipping tag or label to include size, alloy,

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

purchase order number, heat or batch number and other

Current edition approved April 1, 2022. Published April 2022. Originally

approved in 2019. Last previous edition approved in 2019 as B1011/B1011M – 19.

DOI: 10.1520/B1011_B1011M-22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from NACE International (NACE), 15835 ParkTen Pl., Houston,TX

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 77084, http://www.nace.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

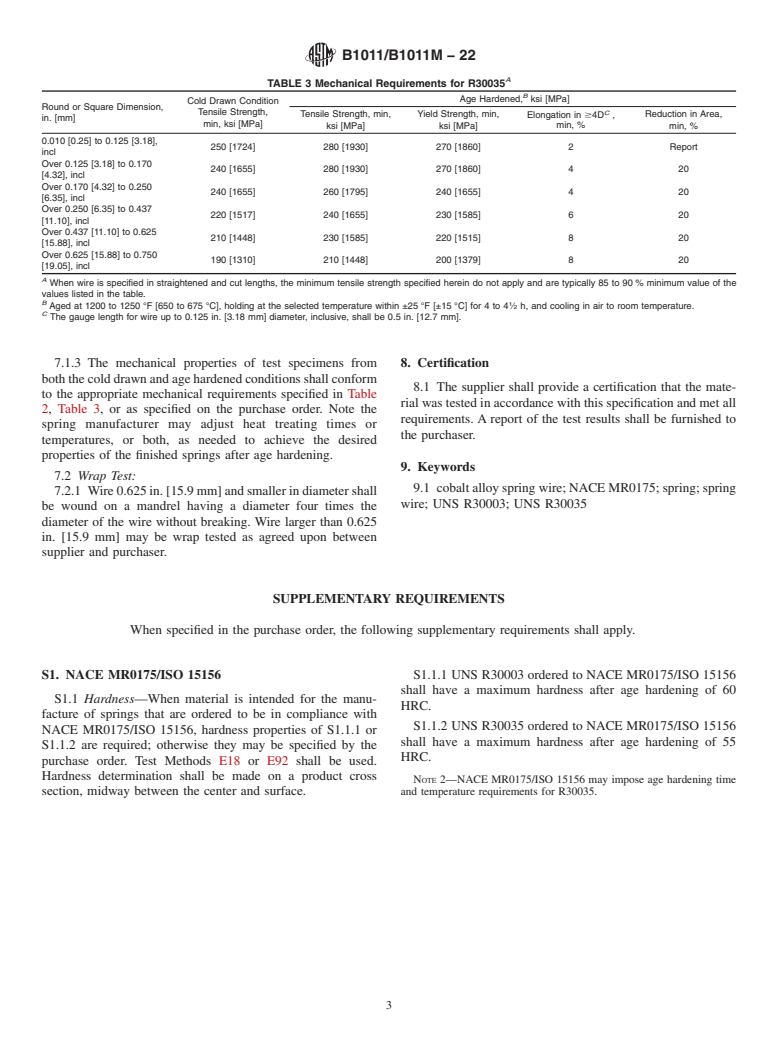

B1011/B1011M−22

TABLE 1 Chemical Requirements

B

Composition, %

UNS Carbon Manganese Phosphorus Sulfur Silicon Cobalt Chromium Nickel Molybdenum Iron Other

A

Designation Elements

C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B1011/B1011M − 19 B1011/B1011M − 22

Standard Specification for

1

Cobalt Alloy Spring Wire

This standard is issued under the fixed designation B1011/B1011M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers cold-drawn cobalt alloy spring wire intended especially for the manufacture of springs.

1.1.1 This specification requires capability properties after age hardening test samples of the cold worked spring wire to ensure

final mechanical properties are satisfied. The spring is typically age hardened after fabrication to increase its strength. However,

mechanical properties cannot be obtained from finished springs.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 Unless the order specifies an “M” designation, the material shall be furnished to inch-pound units.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E18 Test Methods for Rockwell Hardness of Metallic Materials

E92 Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

E354 Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and

Cobalt Alloys

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3

2.2 SAE Standard:

J 1086 Numbering Metals and Alloys

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2019April 1, 2022. Published December 2019April 2022. Originally approved in 2019. Last previous edition approved in 2019 as

B1011/B1011M – 19. DOI: 10.1520/B1011_B1011M-19.10.1520/B1011_B1011M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

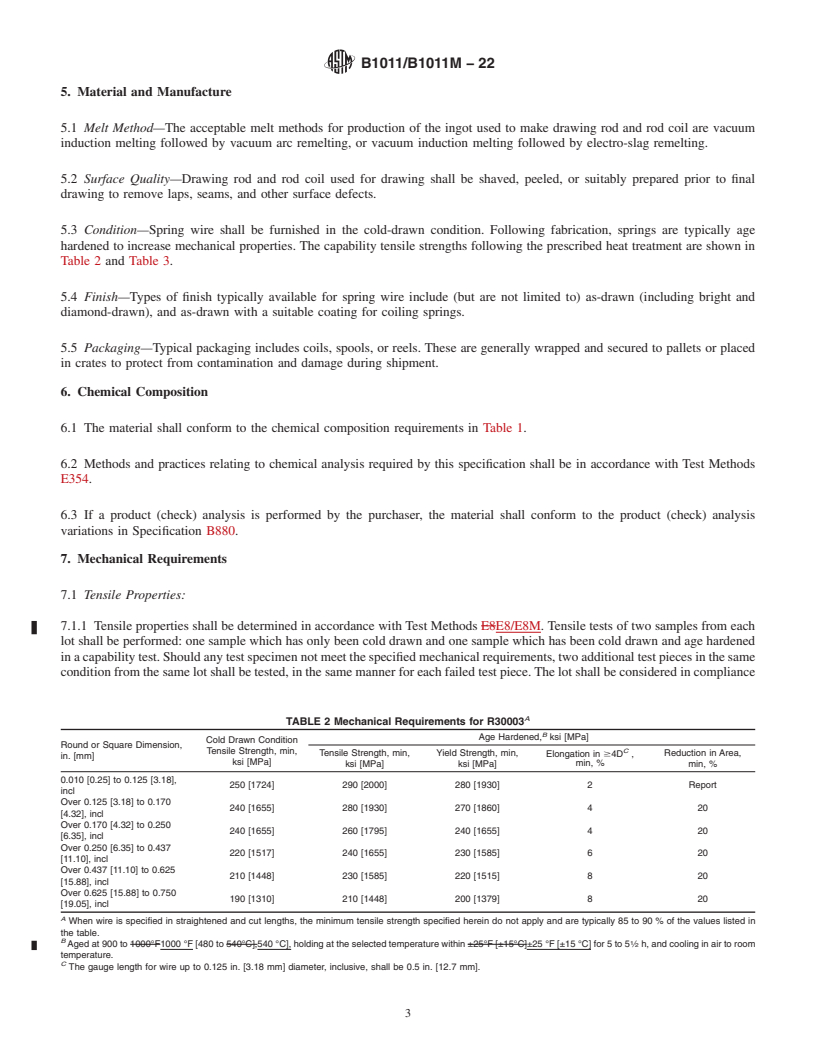

B1011/B1011M − 22

3

2.2 NACE International Standard:

NACE MR0175/ISO 15156 Petroleum and natural gas industries—Materials for use in H2S-containing environments in oil and

gas production

4

2.3 SAE Standard:

J 1086 Numbering Metals and Alloys

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to the following:

3.1.1 Quantity (weight or number of pieces),

3.1.2 Name of material,

3.1.3 Melt method (see 5.1),

3.1.4 Finish (see 5.4),

3.1.5 Dimension(s) with tolerance(s),

3.1.6 UNS designation (Table 1),

3.1.7 ASTM designation and date of issue,

3.1.8 Special requirements and any supplementary requirements (such as S1 for NACE MR0175/ISO 15156 service), and

3.1.9 Packaging (see 5.5).

NOTE 1—A typical ordering description is as follows:

2000 lb [900 kg] Cobalt Alloy Spring Wire, cold-drawn and stearate coated, 0.032-in. [0.82 mm] diameter, in 100-lb [45 kg] 16-in. [0.4 m] coils, UNS

R30035, to ASTM B1011/B1011M, dated ____.

NOTE 1—A typical ordering description is as follows:

2000 lb [900 kg] Cobalt Alloy Spring Wire, cold-drawn and stearate coated, 0.032-in. [0.82 mm] diameter, in 100-lb [45 kg] 16-in. [0.4 m] coils, UNS

R30035, to ASTM B1011/B1011M, dated ____.

4. General Requirements for Delivery

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.