ASTM D5508-94a

(Test Method)Standard Test Method for Determination of Residual Acrylonitrile Monomer in Styrene-Acrylonitrile Copolymer Resins and Nitrile-Butadiene Rubber by Headspace-Capillary Gas Chromatography (HS-CGC)

Standard Test Method for Determination of Residual Acrylonitrile Monomer in Styrene-Acrylonitrile Copolymer Resins and Nitrile-Butadiene Rubber by Headspace-Capillary Gas Chromatography (HS-CGC)

SCOPE

1.1 This test method covers the determination of the residual acrylonitrile (RAN) content in nitrile-butadiene rubbers (NBR), styrene-acrylonitrile (SAN) copolymers, and rubber-modified acrylonitrile-butadiene-styrene (ABS) resins.

1.2 Any components that can generate acrylonitrile in the headspace procedure will constitute an interference. The presence of 3-hydroxypropionitrile in latices limits this procedure to any rubbers and resins.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given Notes 4 and 5.

Note 1--There is no current ISO equivalent test method for residual acrylonitrile (RAN) determinations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5508 – 94a An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Residual Acrylonitrile Monomer in Styrene-

Acrylonitrile Copolymer Resins and Nitrile-Butadiene

Rubber by Headspace-Capillary Gas Chromatography (HS-

CGC)

This standard is issued under the fixed designation D 5508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope AN from other volatiles that may be present. The AN response

is measured using a nitrogen-specific detector (NPD). The raw

1.1 This test method covers the determination of the re-

data signal is converted to a relative RAN concentration

sidual acrylonitrile (RAN) content in nitrile-butadiene rubbers

through a standard addition calculation.

(NBR), styrene-acrylonitrile (SAN) copolymers, and rubber-

modified acrylonitrile-butadiene-styrene (ABS) resins.

4. Significance and Use

1.2 Any components that can generate acrylonitrile in the

4.1 A measurement of the residual acrylonitrile in nitrile

headspace procedure will constitute an interference. The pres-

rubbers (NBR), styrene-acrylonitrile copolymers or ABS ter-

ence of 3-hydroxypropionitrile in latices limits this procedure

polymers will determine the polymer’s suitability for various

to dry rubbers and resins.

applications.

1.3 This standard does not purport to address all of the

4.2 Under optimum conditions, the minimum level of de-

safety concerns, if any, associated with its use. It is the

tection of RAN in NBR, SAN, or ABS terpolymers is approxi-

responsibility of the user of this standard to establish appro-

mately 50 ppb.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

5. Apparatus

tionary statements are given Note 4 and Note 5.

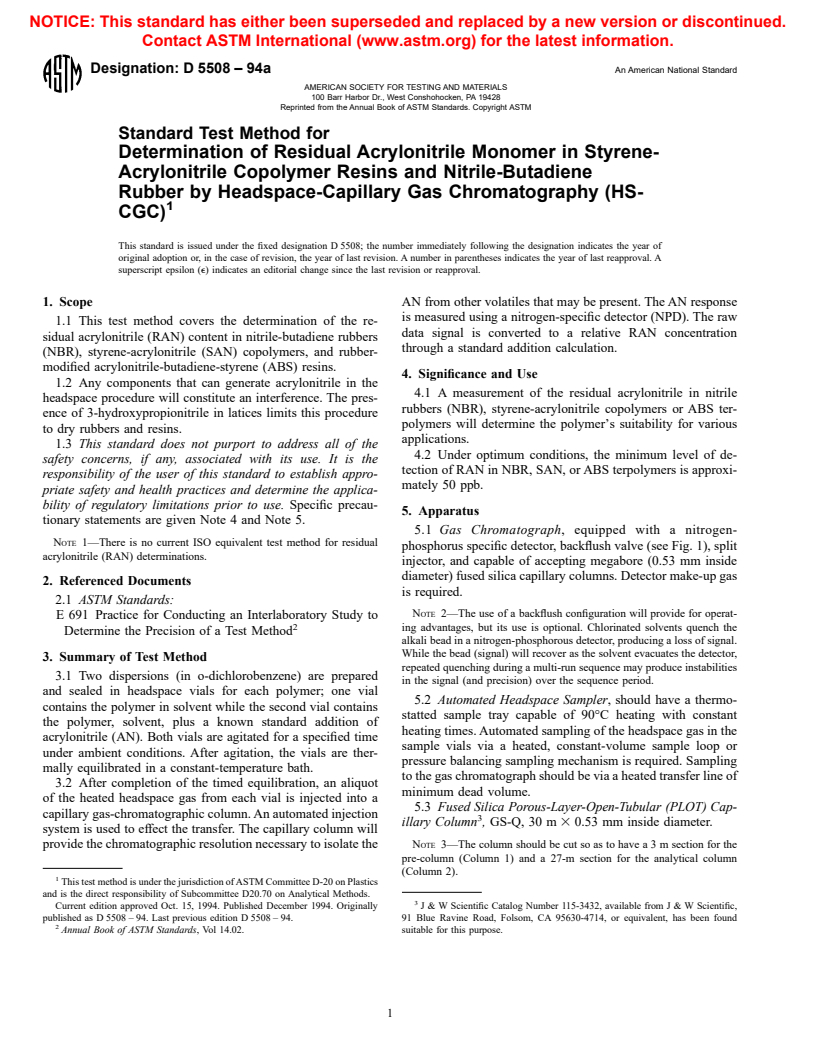

5.1 Gas Chromatograph, equipped with a nitrogen-

NOTE 1—There is no current ISO equivalent test method for residual

phosphorus specific detector, backflush valve (see Fig. 1), split

acrylonitrile (RAN) determinations.

injector, and capable of accepting megabore (0.53 mm inside

diameter) fused silica capillary columns. Detector make-up gas

2. Referenced Documents

is required.

2.1 ASTM Standards:

NOTE 2—The use of a backflush configuration will provide for operat-

E 691 Practice for Conducting an Interlaboratory Study to

ing advantages, but its use is optional. Chlorinated solvents quench the

Determine the Precision of a Test Method

alkali bead in a nitrogen-phosphorous detector, producing a loss of signal.

While the bead (signal) will recover as the solvent evacuates the detector,

3. Summary of Test Method

repeated quenching during a multi-run sequence may produce instabilities

3.1 Two dispersions (in o-dichlorobenzene) are prepared

in the signal (and precision) over the sequence period.

and sealed in headspace vials for each polymer; one vial

5.2 Automated Headspace Sampler, should have a thermo-

contains the polymer in solvent while the second vial contains

statted sample tray capable of 90°C heating with constant

the polymer, solvent, plus a known standard addition of

heating times. Automated sampling of the headspace gas in the

acrylonitrile (AN). Both vials are agitated for a specified time

sample vials via a heated, constant-volume sample loop or

under ambient conditions. After agitation, the vials are ther-

pressure balancing sampling mechanism is required. Sampling

mally equilibrated in a constant-temperature bath.

to the gas chromatograph should be via a heated transfer line of

3.2 After completion of the timed equilibration, an aliquot

minimum dead volume.

of the heated headspace gas from each vial is injected into a

5.3 Fused Silica Porous-Layer-Open-Tubular (PLOT) Cap-

capillary gas-chromatographic column. An automated injection

illary Column , GS-Q, 30 m 3 0.53 mm inside diameter.

system is used to effect the transfer. The capillary column will

provide the chromatographic resolution necessary to isolate the NOTE 3—The column should be cut so as to havea3m section for the

pre-column (Column 1) and a 27-m section for the analytical column

(Column 2).

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Oct. 15, 1994. Published December 1994. Originally J & W Scientific Catalog Number 115-3432, available from J & W Scientific,

published as D 5508 – 94. Last previous edition D 5508 – 94. 91 Blue Ravine Road, Folsom, CA 95630-4714, or equivalent, has been found

Annual Book of ASTM Standards, Vol 14.02. suitable for this purpose.

D 5508

7.2 All test specimens should be taken from the interior of

the polymer-test unit to minimize the contribution of surface

effects on the residual-acrylonitrile level.

7.3 Keep all polymer-test units in sealed containers. Ana-

lyze test-specimen solutions immediately after preparation.

Report any analysis delays along with the test results.

8. Calibration

8.1 Preparation of External Standard Solutions:

8.1.1 Tare (to the nearest 0.1 mg) a 25-mL volumetric flask

containing 10 mL of o-dichlorobenzene (DCB).

8.1.2 Weigh (to the nearest 0.1 mg) into the 25-mL volu-

FIG. 1 Configuration of Eight-Port Valve Backflush Assembly

metric flask 40 6 5 mg of AN. Dilute to the mark with DCB.

Label this solution as the “external-standard master solution”.

8.1.3 Add 1 mL of the “external-standard master solution”

5.4 Variable Restrictor.

to a clean 10-mL volumetric flask containing 2 mL of DCB.

5.5 Data-Recording Device—A strip-chart recorder, record-

Dilute to the mark with additional DCB. Label this solution as

ing integrator, or computer-based data system is suitable.

the “external-standard working solution”.

5.6 Wrist-Action Shaker.

8.1.4 Prepare fresh “master” and “working” solutions each

5.7 Balance, analytical, 0.1-mg readability.

week and keep refrigerated at 4°C using parafilm “M” to seal

5.8 Headspace Vials, 20-mL capacity.

volumetric stoppers.

5.9 Aluminum Crimp Caps, 20-mm diameter.

8.2 Generation of the External-Standard Calibration Curve:

5.10 Septa, TFE-fluorocarbon-faced silicone construction,

20-mm diameter.

NOTE 7—A new external-standard calibration curve should be gener-

5.11 Crimper, for 20-mm crimp caps.

ated each week to account for any changes in the AN response due to NPD

bead fluctuations.

6. Reagents and Materials

8.2.1 Transfer 5 mL of DCB into seven clean headspace

6.1 Purity of Reagents—Chemicals of the highest purity

vials, using a volumetric pipet.

shall be used in all tests. Solvents should have a minimum of

8.2.2 Add 0 (solvent blank), 1, 5, 10, 20, 60, or 100 mL of

volatile impurities. Other grades should only be used after

the “external-standard working solution”, respectively, to the

ascertaining that the reagent is free of interferences.

vials.

6.2 Observe all health and safety recommendations for each

8.2.3 Seal each vial immediately after addition with a

chemical, as prescribed by the manufacturer.

septum and crimp cap.

6.3 Acrylonitrile, 99+%.

8.2.4 Establish the instrument parameters as listed in Annex

A1.

NOTE 4—Warning: Acrylonitrile is an OSHA-regulated carcinogen

and should not be released into the laboratory atmosphere. All work 8.2.5 Obtain the peak-area values for AN in each of the

involving acrylonitrile should be carried out in a hood or with proper

standards.

personal protection to minimize human exposure.

9. Procedure

6.4 o-Dichlorobenzene.

9.1 Determine the Target AN Weight for Polymer Test Units:

NOTE 5—Warning: o-Dichlorobenzene is moderately toxic and should

9.1.1 Weigh (to the nearest 0.1 mg) into a clean headspace

only be handled in a hood or with proper personal protection to limit

vial 400 6 10 mg of polymer. Add 5 mL of DCB, using a

human exposure.

volumetric pipet. Seal vial with septum and crimp cap.

NOTE 6—Each lot of o-dichlorobenzene should be analyzed under the

same instrumental conditions as the NBR samples to ensure that impuri- 9.1.2 Place the vial on a wrist-action shaker, set at maxi-

ties are not present that will interfere with the acrylonitrile peak.

mum agitation for 16 h under ambient conditions.

9.1.3 Analyze the sample under the same instrument param-

7. Sampling and Storage

eters as was used to generate the external-standard calibration

7.1 The polymer test unit (sample) submitted for analysis

curve.

should be supplied in the form of a 1 ⁄4 in. (45 mm) cube.

9.1.4 Obtain the peak-area value for AN.

9.2 Preparation of AN Standard-Addition Solution:

NOTE 8—The following steps in preparing the AN standard addition

PE Number N930-2823, available from PE XPRESS, Perkin-Elmer Corp., 761

solution are given as an illustration only. Depending on the target weights

Main Ave., Norwalk, CT 06859-0156, or equivalent, has been found suitable for this

purpose. involved, the AN concentration of these solutions may need to be adjusted.

Mettler AE163, available from Mettler-Toledo, Inc., P.O. Box 71, Hightstown,

9.2.1 Tare (to the nearest 0.1 mg) a 25-mL volumetric flask

NJ 08520, or equivalent, has been found suitable for this purpose.

containing 10 mL of DCB.

Aldrich Catalog Number 11 021-3, available from Aldrich Chemical Co., 1001

West Saint Paul Ave., Milwaukee, WI 53233, or equivalent has been found suitable

9.2.2 Weigh (to the nearest 0.1 mg) into the 25-mL volu-

for this purpose.

metric flask 165 6 10 mg of AN. Dilute to the mark with DCB.

B & J Brand, available from Baxter Diagnostics Inc., Scientific Products

Label this solution as the “AN master solution”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.