ASTM D4629-96

(Test Method)Standard Test Method for Trace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence Detection

Standard Test Method for Trace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence Detection

SCOPE

1.1 This test method covers the determination of the trace total nitrogen naturally found in liquid hydrocarbons boiling in the range from approximately 50°C to 400°C, with viscosities between approximately 0.2 and 10 cSt (mm /s) at room temperature. This test method is applicable to naphthas, distillates, and oils containing 0.3 to 100 mg/kg total nitrogen.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Sections 5.2, 5.4, 5.5, 5.10, and 6.0.

1.3 The values stated in acceptable SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 4629 – 96

Designation: 379/88

Standard Test Method for

Trace Nitrogen in Liquid Petroleum Hydrocarbons by

Syringe/Inlet Oxidative Combustion and

Chemiluminescence Detection

This standard is issued under the fixed designation D 4629; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope method can be used to determine bound nitrogen in process

feeds and may also be used to control nitrogen compounds in

1.1 This test method covers the determination of the trace

finished products which fall within the scope of the test

total nitrogen naturally found in liquid hydrocarbons boiling in

method.

the range from approximately 50°C to 400°C, with viscosities

between approximately 0.2 and 10 cSt (mm /s) at room

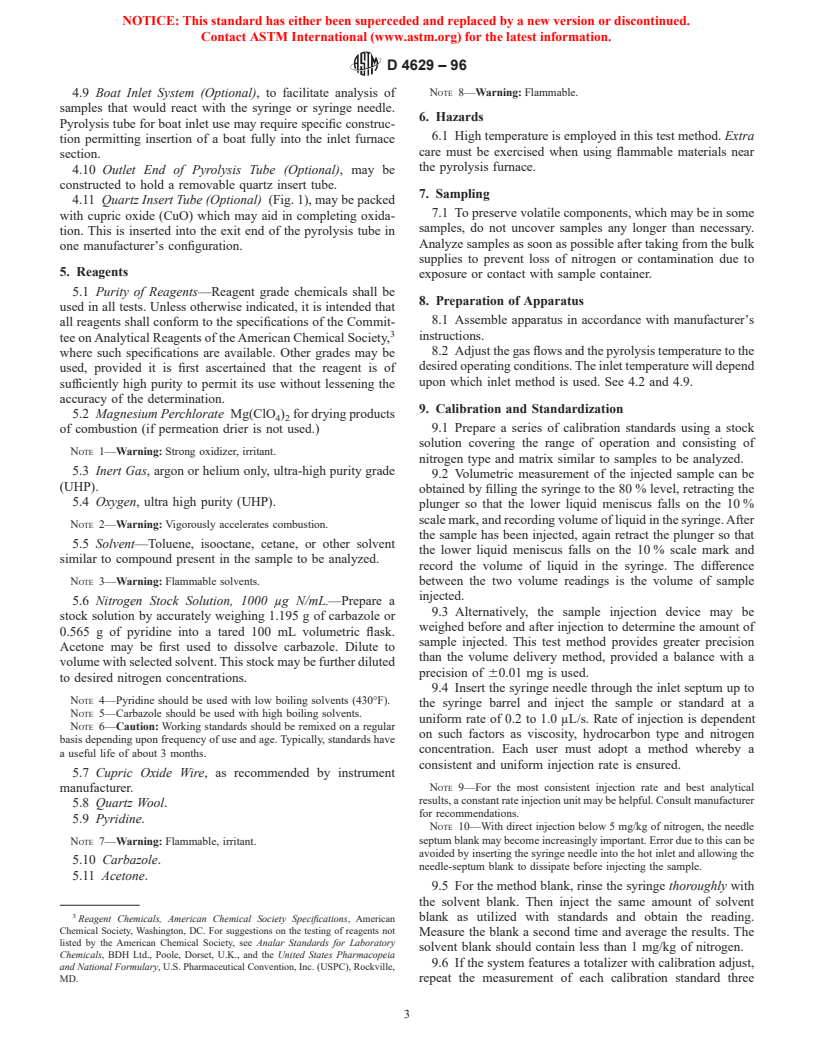

4. Apparatus (Figs. 1-3)

temperature. This test method is applicable to naphthas, distil-

4.1 Furnace, electric, held at a temperature sufficient to

lates, and oils containing 0.3 to 100 mg/kg total nitrogen.

volatilize and pyrolyze all of the sample and oxidize the

1.2 This standard does not purport to address all of the

organically bound nitrogen to NO. Furnace temperature(s) for

safety concerns, if any, associated with its use. It is the

petroleum substances shall be as recommended by the manu-

responsibility of the user of this standard to establish appro-

facturer.

priate safety and health practices and determine the applica-

4.2 Combustion Tube, fabricated from quartz. The inlet end

bility of regulatory limitations prior to use. See Sections 5.2,

of the tube holds a septum for syringe entry of the sample and

5.4, 5.5, 5.10, and 6.0.

has a side arm for introduction of oxygen (O ) and inert gas.

1.3 The values stated in acceptable SI units are to be

The construction is such that the inert gas sweeps the inlet zone

regarded as the standard.

transporting all of the volatilized sample into a high tempera-

2. Summary of Test Method ture oxidation zone. The oxidation section shall be large

enough (see Fig. 1 and Fig. 3) to ensure complete oxidation of

2.1 The sample of liquid petroleum hydrocarbon is injected

the sample. Fig. 1 and Fig. 3 depict conventional pyrolysis

into a stream of inert gas (helium or argon). The sample is

tubes. Other configurations are acceptable if precision is not

vaporized and carried to a high temperature zone where oxygen

degraded.

is introduced and organic and bound nitrogen is converted to

4.3 Drier Tube—The reaction products include water vapor

nitric oxide (NO). The NO contacts ozone and is converted to

that must be eliminated prior to measurement by the detector.

excited nitrogen oxide (NO ). The light emitted as the excited

This can be accomplished with a magnesium perchlorate

NO decays is detected by a photomultiplier tube and the

Mg(ClO ) scrubber or a membrane drying tube (permeation

resulting signal is a measure of the nitrogen contained in the 4

drier), or both.

sample.

4.4 Chemiluminescent Detector, capable of measuring light

3. Significance and Use emitted from the reaction between NO and ozone.

4.5 Totalizer, having variable attenuation, and capable of

3.1 Some process catalysts used in petroleum and chemical

measuring, amplifying and integrating the current from the

refining may be poisoned when even trace amounts of nitrog-

chemiluminescent detector. The amplified or integrated output

enous materials are contained in the feedstocks. This test

signal shall be applied to a digital display and to strip chart

recorder if desired.

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03.0B on Spectrometric Methods. The apparatus described in (4.1-4.11) is manufactured in several variations by

Current edition approved Apr. 10, 1996. Published June 1996. Originally the Antek Instruments Inc. of Houston, TX and Dohrmann Division, Xertex Corp.

e1

published as D 4629 – 86. Last previous edition D 4629 – 91 (1995) . of Santa Clara, CA. Both have been found to meet all essential requirements.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D4629–96

FIG. 1 Quartz Pyrolysis Tube

FIG. 2 Typical Instrument Block Diagram

FIG. 3 Quartz Pyrolysis Tube

4.6 Microlitre Syringe, of 5, 10, 25, 50, or 250 μL capacity 4.8 Constant Rate Injector System (Optional), capable of

capable of accurately delivering microlitre quantities is re- delivering a sample at a precisely controlled rate may have

quired. The needle should be long enough to reach the hottest

independent signal processing and data display capabilities

portion of inlet section furnace when injecting the sample.

(optional).

4.7 Recorder (Optional).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D4629–96

NOTE 8—Warning: Flammable.

4.9 Boat Inlet System (Optional), to facilitate analysis of

samples that would react with the syringe or syringe needle.

6. Hazards

Pyrolysis tube for boat inlet use may require specific construc-

6.1 High temperature is employed in this test method. Extra

tion permitting insertion of a boat fully into the inlet furnace

care must be exercised when using flammable materials near

section.

the pyrolysis furnace.

4.10 Outlet End of Pyrolysis Tube (Optional), may be

constructed to hold a removable quartz insert tube.

7. Sampling

4.11 Quartz Insert Tube (Optional) (Fig. 1), may be packed

7.1 To preserve volatile components, which may be in some

with cupric oxide (CuO) which may aid in completing oxida-

samples, do not uncover samples any longer than necessary.

tion. This is inserted into the exit end of the pyrolysis tube in

Analyze samples as soon as possible after taking from the bulk

one manufacturer’s configuration.

supplies to prevent loss of nitrogen or contamination due to

5. Reagents

exposure or contact with sample container.

5.1 Purity of Reagents—Reagent grade chemicals shall be

8. Preparation of Apparatus

used in all tests. Unless otherwise indicated, it is intended that

8.1 Assemble apparatus in accordance with manufacturer’s

all reagents shall conform to the specifications of the Commit-

instructions.

tee on Analytical Reagents of the American Chemical Society,

8.2 Adjust the gas flows and the pyrolysis temperature to the

where such specifications are available. Other grades may be

desired operating conditions. The inlet temperature will depend

used, provided it is first ascertained that the reagent is of

upon which inlet method is used. See 4.2 and 4.9.

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

9. Calibration and Standardization

5.2 Magnesium Perchlorate Mg(ClO ) for drying products

4 2

9.1 Prepare a series of calibration standards using a stock

of combustion (if permeation drier is not used.)

solution covering the range of operation and consisting of

NOTE 1—Warning: Strong oxidizer, irritant.

nitrogen type and matrix similar to samples to be analyzed.

5.3 Inert Gas, argon or helium only, ultra-high purity grade

9.2 Volumetric measurement of the injected sample can be

(UHP).

obtained by filling the syringe to the 80 % level, retracting the

5.4 Oxygen, ultra high purity (UHP).

plunger so that the lower liquid meniscus falls on the 10 %

scale mark, and recording volume of liquid in the syringe. After

NOTE 2—Warning: Vigorously accelerates combustion.

the sample has been injected, again retract the plunger so that

5.5 S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.