ASTM F1826-00(2021)

(Specification)Standard Specification for Live Line and Measuring Telescoping Tools

Standard Specification for Live Line and Measuring Telescoping Tools

ABSTRACT

This specification covers mechanical and electrical testing and acceptance criteria for live line and measuring telescoping tools. It shall be used for design, routine, and acceptance testing. It does not cover multiple section or extendable section clampsticks. Mechanical test methods shall include horizontal bending deflection test, free fall impact test, tension test, and vertical deflection test. Measuring device tool need not to comply with mechanical strength requirements of this specification. Electrical test methods shall include electrical design test and electrical withstand test.

SCOPE

1.1 This specification covers mechanical and electrical testing and acceptance criteria for telescoping live line tools.

1.1.1 A tool designed only for use as a measuring device need not comply with mechanical strength requirements of this specification.

1.2 The use and maintenance of this equipment is beyond the scope of this specification.

1.3 This specification does not cover multiple section or extendable section clampsticks.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains to Section 9 only. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1826 −00 (Reapproved 2021)

Standard Specification for

Live Line and Measuring Telescoping Tools

This standard is issued under the fixed designation F1826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers mechanical and electrical test- 3.1 Definitions— Terminology used in this specification is

ing and acceptance criteria for telescoping live line tools.

in accordance with Definitions F819.

1.1.1 A tool designed only for use as a measuring device

3.2 Definitions of Terms Specific to This Standard:

need not comply with mechanical strength requirements of this

3.2.1 acceptance test, n—one made at the option of the

specification.

purchaser to verify that a product meets design criteria.

1.2 The use and maintenance of this equipment is beyond

3.2.2 design test, n—one made on a sample treated as

the scope of this specification.

representative of an industrial product. These tests generally

1.3 This specification does not cover multiple section or

will not be repeated in quantity production.

extendable section clampsticks.

3.2.3 dimensional check, n—measurements made to verify

1.4 The values stated in SI units are to be regarded as that a product complies with the dimension stated by the

standard. The values given in parentheses after SI units are

manufacturer.

provided for information only and are not considered standard.

3.2.4 hydrophobic, adj—lacking affinity for water.

1.5 The following safety hazards caveat pertains to Section

3.2.5 routine test, n—a type of test made regularly on

9 only. This standard does not purport to address all of the

production material.

safety concerns, if any, associated with its use. It is the

3.2.6 telescoping live line tool, n—an extendable multiple

responsibility of the user of this standard to establish appro-

section FRP tool designed to carry an attachment to perform

priate safety, health, and environmental practices and deter-

mechanical tasks.

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

3.2.7 telescoping measuring tool, n—anextendablemultiple

dance with internationally recognized principles on standard- section FRP tool designed only to measure vertical heights.

ization established in the Decision on Principles for the

3.2.8 visual inspection, n—a visual check made to detect

Development of International Standards, Guides and Recom-

manufacturing defects.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Significance and Use

2. Referenced Documents

4.1 This specification shall be used for design, routine, and

acceptance testing of live line and measuring telescoping tools.

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and

5. Ordering Information

DielectricStrengthofSolidElectricalInsulatingMaterials

at Commercial Power Frequencies

5.1 Include the following information when ordering tele-

F819 Terminology Relating to Electrical Protective Equip-

scoping live line or measuring tools, or both:

ment for Workers

5.1.1 Quantity.

5.1.2 Catalog number.

This specification is under the jurisdiction of ASTM Committee F18 on

NOTE 1—Live line tools may also be designed as a measuring tool.

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.35 on Tools & Equipment.

5.1.3 Tested to meet ASTM Specification F1826 design

Current edition approved June 1, 2021. Published June 2021. Originally

tests.

approvedin1997.Lastpreviouseditionapprovedin2016asF1826–00(2016).DOI:

10.1520/F1826-00R21.

6. Workmanship, Finish, and Appearance

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 The external and internal surfaces shall have hydropho-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bic abilities.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1826−00 (2021)

FIG. 1Horizontal Test Set-Up

NOTE 1—For details of Fig. 4, see Figs. 5-10.

FIG. 4Typical AC Test Set-Up

FIG. 2Position of Stick Prior to Release for Free Fall Test

8. Tests to Be Conducted

8.1 Mechanical:

Test Type

Visual Routine/Acceptance

Dimensional Design/Acceptance

Horizontal Bending Deflection Design

Free Fall Impact Design

Tension Design

Vertical Deflection Design

8.2 Electrical:

Test Type

Leakage Current Design

Withstand Routine/Acceptance

FIG. 3Block Edge of Telescoping Stick to Obtain Correct 30.48

cm (12 in.) Centerline to Centerline Measurement

9. Mechanical Test Methods

9.1 Visual Inspection—In accordance with the manufactur-

6.2 The external and internal surfaces shall be free of any

abrasions, scratches, blemishes and surface defects that may

capture an impurity and impair the dielectric integrity of the

product.

6.3 After a finish coating, such as paint, has been applied,

the material shall meet all physical, electrical, and mechanical

properties.

6.4 Measuring units on telescoping tools shall be readable

and clearly legible on all sections designed for measuring.

7. Sampling

7.1 Design Test—Perform the test on a minimum of three

samples. The design test will be used to qualify a specific item

and normally will not be repeated during production.

7.2 Routine Test—Perform the test on all pieces delivered to

the purchaser.

7.3 Acceptance Tests—A test made at the option of the

purchaser. FIG. 5Assembly Detail

F1826−00 (2021)

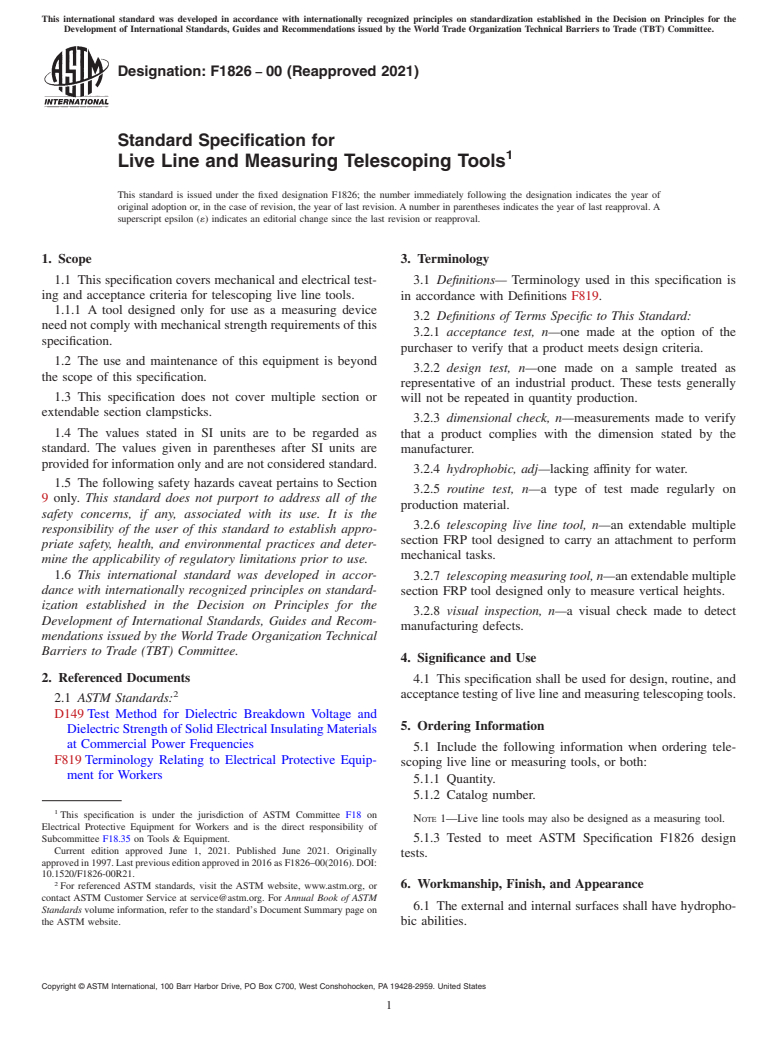

FIG. 8Brass Electrode Detail

FIG. 6Electrode Detail

bonding between fibers and resin, air bubbles, foreign bodies,

or particles. Check all operational components for fit and

function.

9.2 Dimensional Values—The manufacturer, upon request

by the purchaser, shall furnish product dimensional values to

the customer.

9.3 Mechanical Tests:

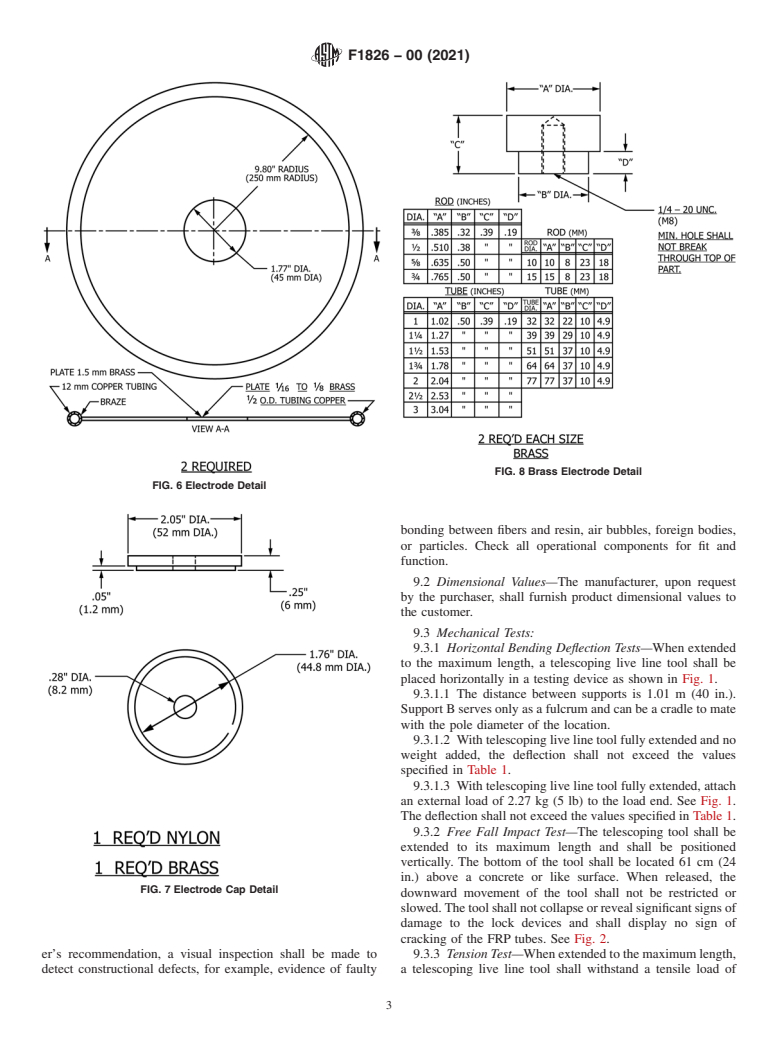

9.3.1 Horizontal Bending Deflection Tests—When extended

to the maximum length, a telescoping live line tool shall be

placed horizontally in a testing device as shown in Fig. 1.

9.3.1.1 The distance between supports is 1.01 m (40 in.).

Support B serves only as a fulcrum and can be a cradle to mate

with the pole diameter of the location.

9.3.1.2 With telescoping live line tool fully extended and no

weight added, the deflection shall not exceed the values

specified in Table 1.

9.3.1.3 With telescoping live line tool fully extended, attach

an external load of 2.27 kg (5 lb) to the load end. See Fig. 1.

The deflection shall not exceed the values specified in Table 1.

9.3.2 Free Fall Impact Test—The telescoping tool shall be

extended to its maximum length and shall be positioned

vertically. The bottom of the tool shall be located 61 cm (24

in.) above a concrete or like surface. When released, the

FIG. 7Electrode Cap Detail

downward movement of the tool shall not be restricted or

slowed.Thetoolshallnotcollapseorrevealsignificantsignsof

damage to the lock devices and shall display no sign of

cracking of the FRP tubes. See Fig. 2.

er’s recommendation, a visual inspection shall be made to 9.3.3 Tension Test—Whenextendedtothemaximumlength,

detect constructional defects, for example, evidence of faulty a telescoping live line tool shall withstand a tensile load of

F1826−00 (2021)

thetool.Withoutadditionalrestraint,thedeflection Datthetop

of the fully extended tool shall not exceed the values given in

Table 2.

10. Electrical Design Test Specimen Preparation

10.1 Three telescoping tools shall each have a specimen cut

fromeachtelescopingsection.Eachspecimenshallbe300mm

(12 in.) in length.

10.2 Conditioning Prior to Electrical Tests:

10.2.1 Prior to the first or initial electrical test, the sample

shall be cleaned inside and out with a suitable solvent, as

recommended by the manufacturer, specifically a solvent that

neither destroys the materials from which the tube is made nor

leaves any residue on the surface of the sample.

10.2.2 All tests shall be made before and after exposu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.