ASTM F1825-03(2019)

(Specification)Standard Specification for Clampstick Type Live Line Tools

Standard Specification for Clampstick Type Live Line Tools

ABSTRACT

This specification applies to the clampstick type live line tools to ensure manufacturing processes and materials are compatible and no deterioration of components occur during the assembly process. Neither the FRP tube and rod, foam filling, or the bonding adhesive shall deteriorate during the prescribed mechanical and electrical test. The external surface of the FRP shall be uniform, symmetrical, and free of abrasions, scratches, blemishes, and surface defects. The mechanical design test and electrical design test procedures are presented in details.

SCOPE

1.1 This specification applies to the Clampstick type live line tools to ensure manufacturing processes and materials are compatible and no deterioration of components occur during the assembly process.

1.2 This specification establishes the technical characteristics for clampsticks.

1.3 This specification applies to clampsticks both hollow and foam-filled.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following safety hazards caveat pertains only to the test portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicable of regulatory limitations prior to use.

1.6 The use, maintenance, and in-service testing of this equipment is beyond the scope of this specification.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1825 −03 (Reapproved 2019)

Standard Specification for

Clampstick Type Live Line Tools

This standard is issued under the fixed designation F1825; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F819 Terminology Relating to Electrical Protective Equip-

ment for Workers

1.1 This specification applies to the Clampstick type live

line tools to ensure manufacturing processes and materials are

3. Terminology

compatible and no deterioration of components occur during

the assembly process.

3.1 Definitions—Terminology used in this specification is in

accordance with Terminology F819.

1.2 This specification establishes the technical characteris-

tics for clampsticks.

3.2 Definitions of Terms Specific to This Standard:

1.3 This specification applies to clampsticks both hollow 3.2.1 clampstick, n—a live line tool having a hand control

with latching stops at the butt end mechanically connected by

and foam-filled.

an insulating rod to a hook that retracts into a slotted ferrule at

1.4 The values stated in SI units are to be regarded as the

the head end.

standard. The values given in parentheses are for information

3.2.1.1 Discussion—Clampsticks are used by qualified

only.

workersforhigh-voltageapplicationofhotlineclamps,ground

1.5 The following safety hazards caveat pertains only to the

clamps, operation of energized apparatus and the like. Clamp-

test portions of this specification: This standard does not

sticks are sometimes referred to as “shotgun sticks” or “grip all

purport to address all of the safety concerns, if any, associated

sticks”. Clampsticks are designed to provide insulation to the

with its use. It is the responsibility of the user of this standard

user while performing the above operations.

to establish appropriate safety, health, and environmental

3.2.2 design test, n—a test made on a sample treated as

practices and determine the applicable of regulatory limita-

representative of an industrial product. This test will not

tions prior to use.

generally be repeated in quantity production.

1.6 The use, maintenance, and in-service testing of this

equipment is beyond the scope of this specification.

3.2.3 electrical test, n—a test to ensure that a product meets

1.7 This international standard was developed in accor- minimum electrical requirements of a standard.

dance with internationally recognized principles on standard-

3.2.4 FRP insulating tubes and rods, n—fiberglass rein-

ization established in the Decision on Principles for the

forced plastic (FRP) products manufactured so that the tubes

Development of International Standards, Guides and Recom-

and rods produced will meet the electrical and mechanical

mendations issued by the World Trade Organization Technical

requirements of this specification.

Barriers to Trade (TBT) Committee.

3.2.5 hand control, n—lower control of the clampstick and

connected to hook by an FRP rod.

2. Referenced Documents

3.2.6 head ferrule, n—a nonmetallic structural part with

2.1 ASTM Standards:

slots to accept clamp bases of standard size and allow the

F711 Specification for Fiberglass-Reinforced Plastic (FRP)

closing motion of the hook.

Rod and Tube Used in Live Line Tools

3.2.7 mechanical test, n—a test to ensure that a product

meets minimum mechanical requirements of a standard.

This specification is under the jurisdiction of ASTM Committee F18 on

3.2.8 rear stop, n—a device or devices that stop the rear-

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.35 on Tools & Equipment.

ward motion of the hand control when the tool has reached its

Current edition approved Aug. 15, 2019. Published August 2019. Originally

fully retracted position.

approved in 1997. Last previous edition approved in 2013 as F1825 – 03(2013).

DOI: 10.1520/F1825-03R19.

3.2.9 retract lock, n—a locking means that allows the hand

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

control to be positioned and releaseably latched between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

safety stop and rear stop and prevents movement toward the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. safety stop.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

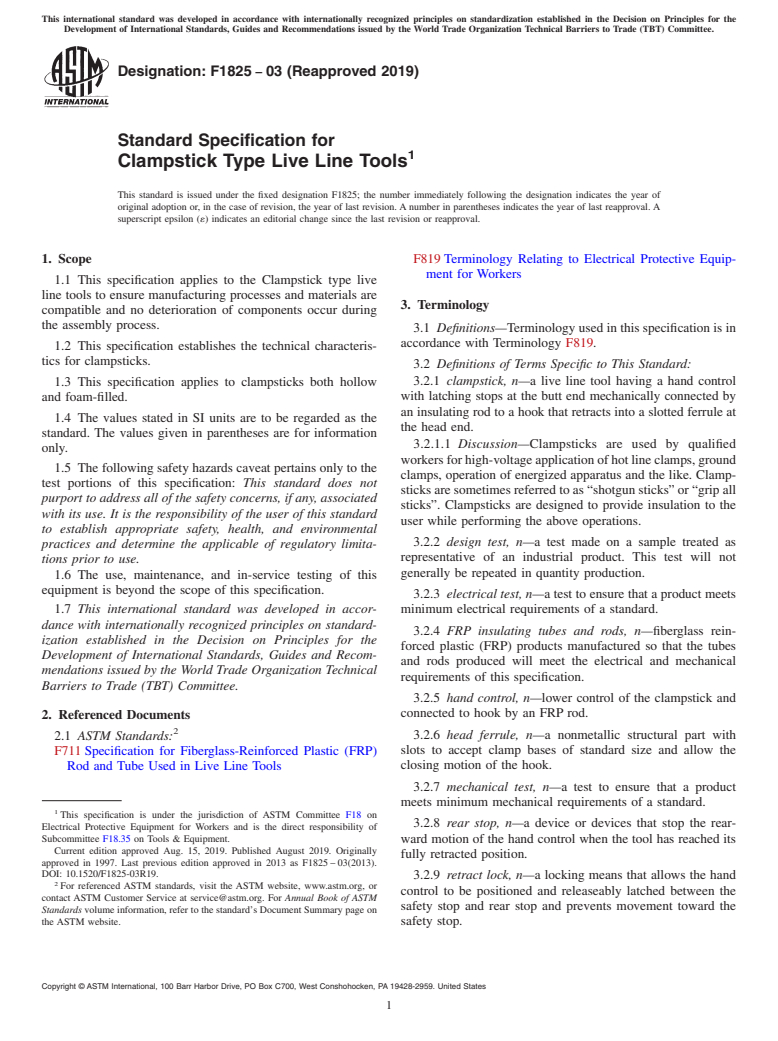

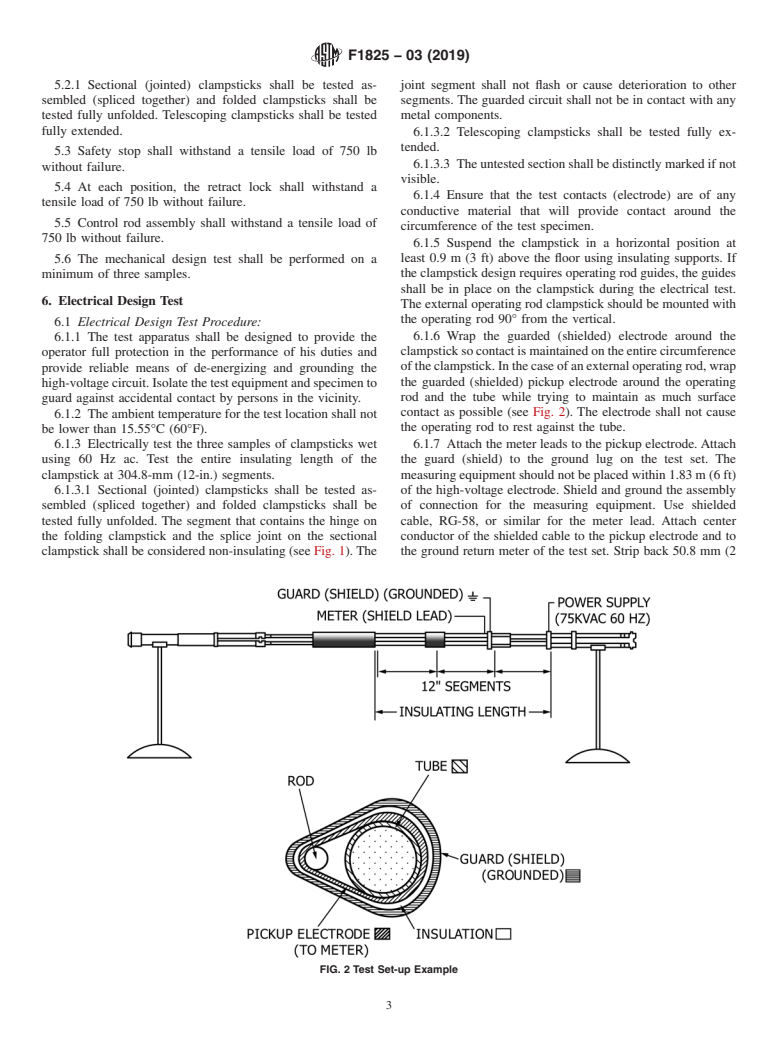

F1825 − 03 (2019)

3.2.10 safety stop, n—a releasable latch that automatically 4.8 The hook shall be designed to enter a 1.42-cm (0.560-

and positively engages at partial retract to fully capture a in.) inside diameter, minimum eye. The ferrule shall be

device. designed to swallow an eye with a 3.96-cm (1.560-in.) outside

diameter and a 1.19-cm (0.470-in.) maximum diameter cross-

3.2.11 visual inspection, n—a visual check made to detect

section and with a 2.29 cm (0.900-in.) outside diameter

defects that impede the performance of product(s).

maximum shank or flange.

4. Materials and Manufacture

4.9 Hook opening shall accept a 20-mm ( ⁄4-in.) diameter

rod.

4.1 Neither the FRP tube and rod, foam filling, or the

bonding adhesive shall deteriorate during the prescribed me- 4.10 Hook retraction from safety stop (intermediate posi-

chanical and electrical test of this specification. tion) shall be 11.73 cm (4.62 in.) minimum.

4.11 The end slots of head ferrule must accept a clamp base

4.2 The external surface of the FRP shall be uniform,

1.22 cm (0.480 in.) max width to a depth of 0.76 cm (0.300 in.)

symmetrical, and free of abrasions, scratches, blemishes, and

min.

surface defects.

4.12 Foam-filled clampsticks shall be sealed at both ends.

4.3 Any defect that may capture an impurity or impair the

dielectric integrity of the product shall be cause for rejection.

4.13 Foam-filled FRP tube and solid FRP rod used in the

manufacturing of clampsticks shall meet all requirements of

4.4 FRProd or tube material to which a finish coating, such

Specification F711.

as paint, is applied must meet all physical, electrical, and

mechanical requirements after the coating is applied. 4.14 Hollow tube shall meet all requirements of Specifica-

tion F711 except mechanical aging and shall withstand 75 %

4.5 Theexternalsurfacesofallcompositematerialpartsand

crushing strength of the foam-filled tube of equal outside

fittings shall be uniform and free of projections or flaws that

diameter listed in Specification F711.

present a hazard to the operator.

5. Mechanical Design Test

4.6 Moving parts must operate properly without binding at

temperatures from –40°C (–40°F) to 48.9°C (120°F).

5.1 FRP tube and rod shall meet all mechanical specifica-

tions and requirements of Specification F711.

4.7 Retract lock and safety stop must be separate and so

arranged that release of retract lock or forward motion of 5.2 The complete clampstick shall withstand a torque load

control shall not release safety st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.