ASTM D149-97a

(Test Method)Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies

Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies

SCOPE

1.1 This test method covers procedures for the determination of dielectric strength of solid insulating materials at commercial power frequencies, under specified conditions.

1.2 Unless otherwise specified, the tests shall be made at 60 Hz. However, this test method may be used at any frequency from 25 to 800 Hz. At frequencies above 800 Hz dielectric heating may be a problem.

1.3 This test method is intended to be used in conjunction with any ASTM standard or other document that refers to this test method. References to this document should specify the particular options to be used (see 5.5).

1.4 It may be used at various temperatures, and in any suitable gaseous or liquid surrounding medium.

1.5 This test method is not intended for measuring the dielectric strength of materials that are fluid under the conditions of test.

1.6 This test method is not intended for use in determining intrinsic dielectric strength, direct-voltage dielectric strength, or thermal failure under electrical stress (see Test Method D3151).

1.7 This test method is most commonly used to determine the dielectric breakdown voltage through the thickness of a test specimen (puncture). It may also be used to determine dielectric breakdown voltage along the interface between a solid specimen and a gaseous or liquid surrounding medium (flashover). With the addition of instructions modifying Section 12, this test method may be used for proof testing.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7. Also see Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 149 – 97a

Standard Test Method for

Dielectric Breakdown Voltage and Dielectric Strength of

Solid Electrical Insulating Materials at Commercial Power

Frequencies

This standard is issued under the fixed designation D 149; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.8 This test method is similar to IEC Publication 243-1. All

procedures in this method are included in IEC 243-1. Differ-

1.1 This test method covers procedures for the determina-

ences between this method and IEC 243-1 are largely editorial.

tion of dielectric strength of solid insulating materials at

,

2 3 1.9 This standard does not purport to address all of the

commercial power frequencies, under specified conditions.

safety concerns, if any, associated with its use. It is the

1.2 Unless otherwise specified, the tests shall be made at 60

responsibility of the user of this standard to establish appro-

Hz. However, this test method may be used at any frequency

priate safety and health practices and determine the applica-

from 25 to 800 Hz. At frequencies above 800 Hz dielectric

bility of regulatory limitations prior to use. Specific hazard

heating may be a problem.

statements are given in Section 7. Also see Note 1.

1.3 This test method is intended to be used in conjunction

with any ASTM standard or other document that refers to this

2. Referenced Documents

test method. References to this document should specify the

2.1 ASTM Standards:

particular options to be used (see 5.5).

D 374 Test Methods for Thickness of Solid Electrical Insu-

1.4 It may be used at various temperatures, and in any

lation

suitable gaseous or liquid surrounding medium.

D 618 Practice for Conditioning Plastics and Electrical

1.5 This test method is not intended for measuring the

Insulating Materials for Testing

dielectric strength of materials that are fluid under the condi-

D 877 Test Method for Dielectric Breakdown Voltage of

tions of test.

Insulating Liquids Using Disk Electrodes

1.6 This test method is not intended for use in determining

D 1711 Terminology Relating to Electrical Insulation

intrinsic dielectric strength, direct-voltage dielectric strength,

D 2413 Methods for Preparation and Electrical Testing of

or thermal failure under electrical stress (see Test Method

Insulating Paper and Board Impregnated with a Liquid

D 3151).

Dielectric

1.7 This test method is most commonly used to determine

D 3151 Test Method for Thermal Failure of Solid Electrical

the dielectric breakdown voltage through the thickness of a test

Insulating Materials Under Electric Stress

specimen (puncture). It may also be used to determine dielec-

D 3487 Specification for Mineral Insulating Oil Used in

tric breakdown voltage along the interface between a solid

Electrical Apparatus

specimen and a gaseous or liquid surrounding medium (flash-

D 5423 Specification for Forced-Convection Laboratory

over). With the addition of instructions modifying Section 12,

Ovens for Electrical Insulation

this test method may be used for proof testing.

2.2 IEC Standard:

Pub. 243-1 Methods of Test for Electrical Strength of Solid

This test method is under the jurisdiction of ASTM Committee D-9 on 8

Insulating Materials—Part 1: Tests at Power Frequencies

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.12 on Electrical Tests.

Current edition approved Sept. 10, 1997. Published January 1998. Originally

published as D 149 – 22 T. Last previous edition D 149 – 97.

Bartnikas, R., Chapter 3, “High Voltage Measurements,” Electrical Properties

of Solid Insulating Materials, Measurement Techniques, Vol. IIB, Engineering Annual Book of ASTM Standards, Vol 10.01.

Dielectrics, R. Bartnikas, Editor, ASTM STP 926, ASTM, Philadelphia, 1987. Annual Book of ASTM Standards, Vol 08.01.

3 6

Nelson, J. K., Chapter 5, “Dielectric Breakdown of Solids,” Electrical Annual Book of ASTM Standards, Vol 10.03.

Properties of Solid Insulating Materials: Molecular Structure and Electrical Annual Book of ASTM Standards, Vol 10.02.

Behavior, Vol. IIA, Engineering Dielectrics, R. Bartnikas and R. M. Eichorn, Available from the International Electrotechnical Commission, Geneva, Swit-

Editors, ASTM STP 783, ASTM, Philadelphia, 1983. zerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 149

2.3 ANSI Standard: environmental situations. This test method is useful for process

C68.1 Techniques for Dielectric Tests, IEEE Standard No. control, acceptance or research testing.

4 5.3 Results obtained by this test method can seldom be used

directly to determine the dielectric behavior of a material in an

3. Terminology actual application. In most cases it is necessary that these

results be evaluated by comparison with results obtained from

3.1 Definitions:

other functional tests or from tests on other materials, or both,

3.1.1 dielectric breakdown voltage (electric breakdown

in order to estimate their significance for a particular material.

voltage), n—the potential difference at which dielectric failure

5.4 Three methods for voltage application are specified in

occurs under prescribed conditions, in an electrical insulating

Section 12: Method A, Short-Time Test; Method B, Step-by-

material located between two electrodes. (See also Appendix

Step Test; and Method C, Slow Rate-of-Rise Test. Method A is

X1.)

the most commonly-used test for quality-control tests. How-

3.1.1.1 Discussion—The term dielectric breakdown voltage

ever, the longer-time tests, Methods B and C, which usually

is sometimes shortened to “breakdown voltage.”

will give lower test results, may give more meaningful results

3.1.2 dielectric failure (under test), n— an event that is

when different materials are being compared with each other. If

evidenced by an increase in conductance in the dielectric under

a test set with motor-driven voltage control is available, the

test limiting the electric field that can be sustained.

slow rate-of-rise test is simpler and preferable to the step-by-

3.1.3 dielectric strength, n—the voltage gradient at which

step test. The results obtained from Methods B and C are

dielectric failure of the insulating material occurs under spe-

comparable to each other.

cific conditions of test.

5.5 Documents specifying the use of this test method shall

3.1.4 electric strength, n—see dielectric strength.

also specify:

3.1.4.1 Discussion—Internationally, “electric strength” is

5.5.1 Method of voltage application,

used almost universally.

5.5.2 Voltage rate-of-rise, if slow rate-of-rise method is

3.1.5 flashover, n—a disruptive electrical discharge at the

specified,

surface of electrical insulation or in the surrounding medium,

5.5.3 Specimen selection, preparation, and conditioning,

which may or may not cause permanent damage to the

5.5.4 Surrounding medium and temperature during test,

insulation.

5.5.5 Electrodes,

3.1.6 For definitions of other terms relating to solid insulat-

5.5.6 Wherever possible, the failure criterion of the current-

ing materials, refer to Terminology D 1711.

sensing element, and

5.5.7 Any desired deviations from the recommended proce-

4. Summary of Test Method

dures as given.

4.1 Alternating voltage, at a commercial power frequency

5.6 If any of the requirements listed in 5.5 are missing from

(60 Hz, unless otherwise specified) is applied to a test

the specifying document, then the recommendations for the

specimen. The voltage is increased from zero or from a level

several variables shall be followed.

well below the breakdown voltage, in one of three prescribed

5.7 Unless the items listed in 5.5 are specified, tests made

methods of voltage application, until dielectric failure of the

with such inadequate reference to this test method are not in

test specimen occurs.

conformance with this test method. If the items listed in 5.5 are

4.2 Most commonly, the test voltage is applied using simple

not closely controlled during the test, the precisions stated in

test electrodes on opposite faces of specimens. The specimens

15.2 and 15.3 may not be realized.

may be molded or cast, or cut from flat sheet or plate. Other

5.8 Variations in the failure criteria (current setting and

electrode and specimen configurations may be used to accom-

response time) of the current sensing element significantly

modate the geometry of the sample material, or to simulate a

affect the test results.

specific application for which the material is being evaluated.

5.9 Appendix X1. contains a more complete discussion of

the significance of dielectric strength tests.

5. Significance and Use

5.1 The dielectric strength of an electrical insulating mate- 6. Apparatus

rial is a property of interest for any application where an

6.1 Voltage Source—Obtain the test voltage from a step-up

electrical field will be present. In many cases the dielectric

transformer supplied from a variable sinusoidal low-voltage

strength of a material will be the determining factor in the

source. The transformer, its voltage source, and the associated

design of the apparatus in which it is to be used.

controls shall have the following capabilities:

5.2 Tests made as specified herein may be used to provide

6.1.1 The ratio of crest to root-mean-square (rms) test

part of the information needed for determining suitability of a

voltage shall be equal to 2 6 5 % (1.34 to 1.48), with the

=

material for a given application; and also, for detecting changes

test specimen in the circuit, at all voltages greater than 50 % of

or deviations from normal characteristics resulting from pro-

the breakdown voltage.

cessing variables, aging conditions, or other manufacturing or

6.1.2 The capacity of the source shall be sufficient to

maintain the test voltage until dielectric breakdown occurs. For

most materials, using electrodes similar to those shown in

Table 1, an output current capacity of 40 mA is usually

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036. satisfactory. For more complex electrode structures, or for

D 149

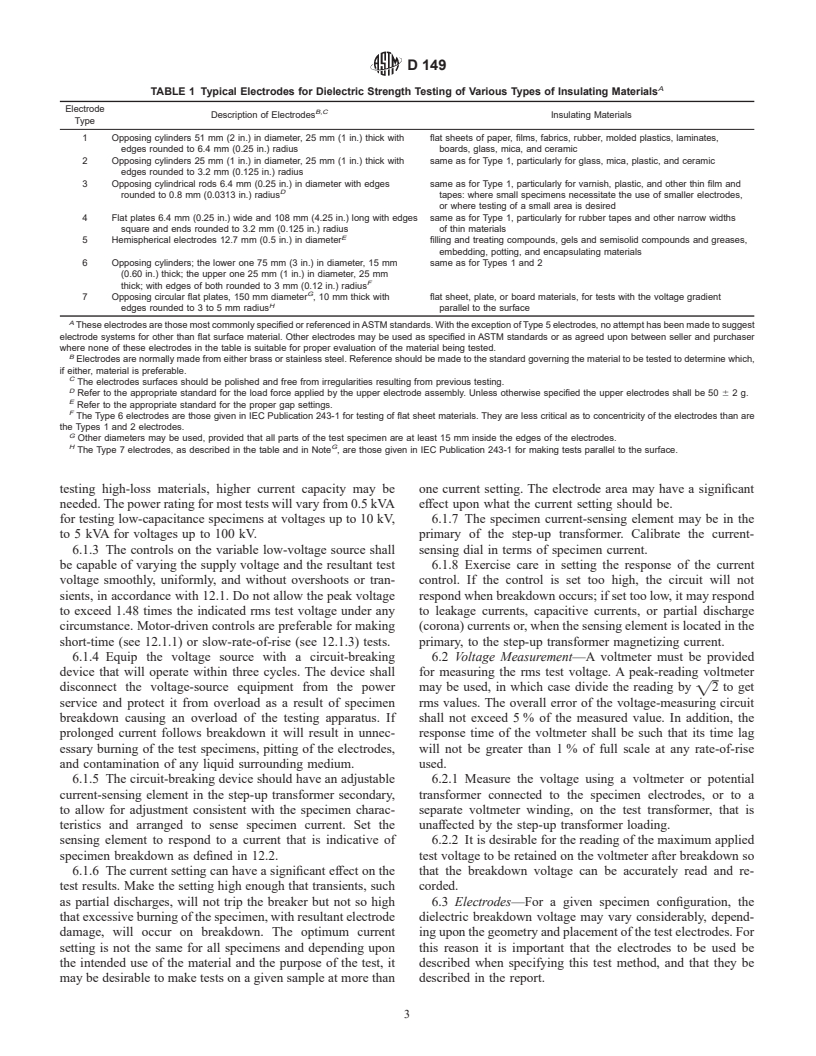

A

TABLE 1 Typical Electrodes for Dielectric Strength Testing of Various Types of Insulating Materials

Electrode

B,C

Description of Electrodes Insulating Materials

Type

1 Opposing cylinders 51 mm (2 in.) in diameter, 25 mm (1 in.) thick with flat sheets of paper, films, fabrics, rubber, molded plastics, laminates,

edges rounded to 6.4 mm (0.25 in.) radius boards, glass, mica, and ceramic

2 Opposing cylinders 25 mm (1 in.) in diameter, 25 mm (1 in.) thick with same as for Type 1, particularly for glass, mica, plastic, and ceramic

edges rounded to 3.2 mm (0.125 in.) radius

3 Opposing cylindrical rods 6.4 mm (0.25 in.) in diameter with edges same as for Type 1, particularly for varnish, plastic, and other thin film and

D

rounded to 0.8 mm (0.0313 in.) radius tapes: where small specimens necessitate the use of smaller electrodes,

or where testing of a small area is desired

4 Flat plates 6.4 mm (0.25 in.) wide and 108 mm (4.25 in.) long with edges same as for Type 1, particularly for rubber tapes and other narrow widths

square and ends rounded to 3.2 mm (0.125 in.) radius of thin materials

E

5 Hemispherical electrodes 12.7 mm (0.5 in.) in diameter filling and treating compounds, gels and semisolid compounds and greases,

embedding, potting, and encapsulating materials

6 Opposing cylinders; the lower one 75 mm (3 in.) in diameter, 15 mm same as for Types 1 and 2

(0.60 in.) thick; the upper one 25 mm (1 in.) in diameter, 25 mm

F

thick; with edges of both rounded to 3 mm (0.12 in.) radius

G

7 Opposing circular flat plates, 150 mm diameter , 10 mm thick with flat sheet, plate, or board materials, for tests with the voltage gradient

H

edges rounded to 3 to 5 mm radius parallel to the surface

A

These electrodes are those most commonly specified or referenced in ASTM standards. With the exception of Type 5 electrodes, no attempt has been made to suggest

electrode systems for other than flat surface material. Other electrodes may be used as specified in ASTM standards or as agreed upon between seller and purchaser

where none of these electrodes in the table is suitable for proper evaluation of the material being tested.

B

Electrodes are normally made from either brass or stainless steel. Reference should be made to the standard governing the material to be tested to determine which,

if either, material is preferable.

C

The electrodes surfaces should be polished and free from irregularities resulting from previous testing.

D

Refer to the appropriate standard for the load force applied by the upper electrode assembly. Unless otherwise specified the upper electrodes shall be 50 6 2g.

E

Refer to the appropriate standard for the proper gap settings.

F

The Type 6 electrodes are those given in IEC Publication 243-1 for testing of flat sheet materials. They are less critical as to concentricity of the electrodes than are

the Types 1 and 2 electrodes.

G

Other diameters may be used, provided that all parts of the test specimen are at least 15 mm inside the edges of the electrodes.

H G

The Type 7 electrodes, as described in the table and in Note , are those given in IEC Publication 243-1 for making tests parallel to the surface.

testing high-loss materials, higher current capacity may be one current setting. The electrode area may have a significant

needed. The power rating for most tests will vary from 0.5 kVA effect upon what the current setting should be.

for testing low-capacitance specimens at voltages up to 10 kV, 6.1.7 The specimen current-sensing element may be in the

to 5 kVA for voltages up to 100 kV. primary of the step-up transformer. Calibrate the current-

6.1.3 The controls on the variable low-voltage source shall sensing dial in terms of specimen current.

be capable of varying the supply voltage and the resultant test 6.1.8 Exercise care in setting the response of the current

voltage smoothly, uniformly, and without overshoots or tran- control. If the control is set too high, the circuit will not

sients, in accordance with 12.1. Do not allow the peak voltage respond when breakdown occurs; if set too low, it may respond

to exceed 1.48 times the indicated rms test voltage under any to leakage currents, capacitive currents, or partial discharge

circumstance. Motor-driven controls are preferable for making

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.