ASTM E384-22

(Test Method)Standard Test Method for Microindentation Hardness of Materials

Standard Test Method for Microindentation Hardness of Materials

SIGNIFICANCE AND USE

5.1 Hardness tests have been found to be very useful for materials evaluation, quality control of manufacturing processes and research and development efforts. Hardness, although empirical in nature, can be correlated to tensile strength for many metals and alloys, and is also an indicator of machinability, wear resistance, toughness and ductility.

5.2 Microindentation tests are utilized to evaluate and quantify hardness variations that occur over a small distance. These variations may be intentional, such as produced by localized surface hardening, for example, from shot blasting, cold drawing, flame hardening, induction hardening, etc., or from processes such as carburization, nitriding, carbonitriding, etc.; or, they may be unintentional variations due to problems, such as decarburization, localized softening in service, or from compositional/microstructural segregation problems. Low test forces also extend hardness testing to materials too thin or too small for macroindentation tests. Microindentation tests permit hardness testing of specific phases or constituents and regions or gradients too small for evaluation by macroindentation tests.

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average and standard deviation are calculated, as needed or as required.

5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances. To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must be carefully constructed to accurately apply the test forces exactly at the desired location and must have a high-quality optical syste...

SCOPE

1.1 This test method covers determination of the microindentation hardness of materials.

1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 9.8 × 10-3 to 9.8 N (1 to 1000 gf).

1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how these factors affect the precision, bias, repeatability, and reproducibility of test results.

1.4 Information pertaining to the requirements for direct verification and calibration of the testing machine and the requirements for the manufacture and calibration of Vickers and Knoop reference hardness test blocks are in Test Method E92.

Note 1: While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Sep-2022

- Technical Committee

- E04 - Metallography

- Drafting Committee

- E04.05 - Microindentation Hardness Testing

- Current Stage

Relations

- Effective Date

- 01-Nov-2019

- Refers

ASTM C1327-15(2019) - Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics - Effective Date

- 01-Jul-2019

- Effective Date

- 01-Apr-2018

- Effective Date

- 01-Apr-2018

- Effective Date

- 01-Jun-2015

- Effective Date

- 01-Apr-2015

- Effective Date

- 01-Jan-2015

- Effective Date

- 01-Nov-2014

- Effective Date

- 01-Oct-2014

- Effective Date

- 01-Oct-2014

- Effective Date

- 01-May-2014

- Refers

ASTM E766-14 - Standard Practice for Calibrating the Magnification of a Scanning Electron Microscope - Effective Date

- 01-Jan-2014

- Effective Date

- 01-Jan-2014

- Effective Date

- 01-Aug-2013

- Effective Date

- 01-May-2013

ASTM E384-22 - Standard Test Method for Microindentation Hardness of Materials

REDLINE ASTM E384-22 - Standard Test Method for Microindentation Hardness of Materials

Frequently Asked Questions

ASTM E384-22 is a standard published by ASTM International. Its full title is "Standard Test Method for Microindentation Hardness of Materials". This standard covers: SIGNIFICANCE AND USE 5.1 Hardness tests have been found to be very useful for materials evaluation, quality control of manufacturing processes and research and development efforts. Hardness, although empirical in nature, can be correlated to tensile strength for many metals and alloys, and is also an indicator of machinability, wear resistance, toughness and ductility. 5.2 Microindentation tests are utilized to evaluate and quantify hardness variations that occur over a small distance. These variations may be intentional, such as produced by localized surface hardening, for example, from shot blasting, cold drawing, flame hardening, induction hardening, etc., or from processes such as carburization, nitriding, carbonitriding, etc.; or, they may be unintentional variations due to problems, such as decarburization, localized softening in service, or from compositional/microstructural segregation problems. Low test forces also extend hardness testing to materials too thin or too small for macroindentation tests. Microindentation tests permit hardness testing of specific phases or constituents and regions or gradients too small for evaluation by macroindentation tests. 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average and standard deviation are calculated, as needed or as required. 5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances. To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must be carefully constructed to accurately apply the test forces exactly at the desired location and must have a high-quality optical syste... SCOPE 1.1 This test method covers determination of the microindentation hardness of materials. 1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 9.8 × 10-3 to 9.8 N (1 to 1000 gf). 1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how these factors affect the precision, bias, repeatability, and reproducibility of test results. 1.4 Information pertaining to the requirements for direct verification and calibration of the testing machine and the requirements for the manufacture and calibration of Vickers and Knoop reference hardness test blocks are in Test Method E92. Note 1: While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials. 1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 Hardness tests have been found to be very useful for materials evaluation, quality control of manufacturing processes and research and development efforts. Hardness, although empirical in nature, can be correlated to tensile strength for many metals and alloys, and is also an indicator of machinability, wear resistance, toughness and ductility. 5.2 Microindentation tests are utilized to evaluate and quantify hardness variations that occur over a small distance. These variations may be intentional, such as produced by localized surface hardening, for example, from shot blasting, cold drawing, flame hardening, induction hardening, etc., or from processes such as carburization, nitriding, carbonitriding, etc.; or, they may be unintentional variations due to problems, such as decarburization, localized softening in service, or from compositional/microstructural segregation problems. Low test forces also extend hardness testing to materials too thin or too small for macroindentation tests. Microindentation tests permit hardness testing of specific phases or constituents and regions or gradients too small for evaluation by macroindentation tests. 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average and standard deviation are calculated, as needed or as required. 5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances. To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must be carefully constructed to accurately apply the test forces exactly at the desired location and must have a high-quality optical syste... SCOPE 1.1 This test method covers determination of the microindentation hardness of materials. 1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 9.8 × 10-3 to 9.8 N (1 to 1000 gf). 1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how these factors affect the precision, bias, repeatability, and reproducibility of test results. 1.4 Information pertaining to the requirements for direct verification and calibration of the testing machine and the requirements for the manufacture and calibration of Vickers and Knoop reference hardness test blocks are in Test Method E92. Note 1: While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials. 1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM E384-22 is classified under the following ICS (International Classification for Standards) categories: 19.060 - Mechanical testing. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM E384-22 has the following relationships with other standards: It is inter standard links to ASTM E766-14(2019), ASTM C1327-15(2019), ASTM E2554-18, ASTM E2554-18e1, ASTM E7-15, ASTM E2587-15, ASTM C1327-15, ASTM E7-14, ASTM E2587-14e1, ASTM E2587-14, ASTM E177-14, ASTM E766-14, ASTM E766-14e1, ASTM C1326-13, ASTM E177-13. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM E384-22 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E384 − 22

Standard Test Method for

Microindentation Hardness of Materials

This standard is issued under the fixed designation E384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

1.1 This test method covers determination of the microin-

2.1 ASTM Standards:

dentation hardness of materials.

C1326Test Method for Knoop Indentation Hardness of

Advanced Ceramics

1.2 This test method covers microindentation tests made

withKnoopandVickersindentersundertestforcesintherange C1327Test Method for Vickers Indentation Hardness of

-3

from 9.8 × 10 to 9.8 N (1 to 1000 gf). Advanced Ceramics

E3Guide for Preparation of Metallographic Specimens

1.3 This test method includes an analysis of the possible

E7Terminology Relating to Metallography

sourcesoferrorsthatcanoccurduringmicroindentationtesting

E92Test Methods for Vickers Hardness and Knoop Hard-

and how these factors affect the precision, bias, repeatability,

ness of Metallic Materials

and reproducibility of test results.

E140Hardness Conversion Tables for Metals Relationship

1.4 Information pertaining to the requirements for direct

Among Brinell Hardness, Vickers Hardness, Rockwell

verification and calibration of the testing machine and the

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

requirements for the manufacture and calibration of Vickers

scope Hardness, and Leeb Hardness

and Knoop reference hardness test blocks are in Test Method

E175Terminology of Microscopy (Withdrawn 2019)

E92.

E177Practice for Use of the Terms Precision and Bias in

NOTE1—WhileCommitteeE04isprimarilyconcernedwithmetals,the

ASTM Test Methods

test procedures described are applicable to other materials.

E691Practice for Conducting an Interlaboratory Study to

1.5 Units—The values stated in SI units are to be regarded

Determine the Precision of a Test Method

asstandard.Nootherunitsofmeasurementareincludedinthis

E766Practice for Calibrating the Magnification of a Scan-

standard.

ning Electron Microscope

1.6 This standard does not purport to address all of the

E1268Practice for Assessing the Degree of Banding or

safety concerns, if any, associated with its use. It is the

Orientation of Microstructures

responsibility of the user of this standard to establish appro-

E2554Practice for Estimating and Monitoring the Uncer-

priate safety, health, and environmental practices and deter-

tainty of Test Results of a Test Method Using Control

mine the applicability of regulatory limitations prior to use.

Chart Techniques

1.7 This international standard was developed in accor-

E2587Practice for Use of Control Charts in Statistical

dance with internationally recognized principles on standard-

Process Control

ization established in the Decision on Principles for the

2.2 ISO Standard:

Development of International Standards, Guides and Recom-

ISO/IEC 17025 General Requirements for the Competence

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. of Testing and Calibration Laboratories

1 2

This test method is under the jurisdiction of ASTM Committee E04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallography and is the direct responsibility of Subcommittee E04.05 on Micro- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

indentation Hardness Testing. With this revision the test method was expanded to Standards volume information, refer to the standard’s Document Summary page on

include the requirements previously defined in E28.92, Standard Test Method for the ASTM website.

Vickers Hardness Testing of Metallic Material that was under the jurisdiction of The last approved version of this historical standard is referenced on

E28.06 www.astm.org.

Current edition approved Oct. 1, 2022. Published November 2022. Originally Available from International Organization for Standardization (ISO), 1, ch. de

approved in 1969. Last previous edition approved in 2017 as E384–17. DOI: la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

10.1520/E0384-22 www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E384 − 22

3. Terminology 3.3 Formulae—The formulae presented in 3.3.1 – 3.3.4 for

calculating microindentation hardness are based upon an ideal

3.1 Definitions—For definitions of terms used in this test

tester and conditions. The measured value of the microinden-

method, see Terminology E7.

tation hardness of a material is subjected to several sources of

3.2 Definitions of Terms Specific to This Standard:

errors. Based on Eq 1-9, variations in the applied force,

3.2.1 calibrating, v—determining the values of the signifi-

geometrical variations between diamond indenters, and human

cant parameters by comparison with values indicated by a

errorsinmeasuringindentationlengthswillaffecttheprecision

reference instrument or by a set of reference standards.

ofthecalculatedmaterialhardness.Themagnitudeoftheerror

3.2.2 Knoop hardness number, HK, n—an expression of that variations of each of these parameters have on the

hardness obtained by dividing the force applied to the Knoop

calculated value of a microindentation measurement is dis-

indenter by the projected area of the permanent impression cussed in Section 10.

made by the indenter.

3.3.1 For Knoop hardness tests, in practice, test loads are in

grams-forceandindentationdiagonalsareinmicrometers.The

3.2.3 Knoop indenter, n—a rhombic-based pyramidal-

Knoop hardness number is calculated using the following:

shaped diamond indenter with edge angles of/ A = 172° 30'

3 3 2

and/ B = 130° 0' (see Fig. 1).

HK 51.000 310 3 P/A 51.000 310 3 P/ c 3 d (1)

~ ! ~ !

p p

3.2.4 microindentation hardness test, n—a hardness test

or

using a calibrated machine to force a diamond indenter of

HK 514229 3 P/d (2)

specific geometry into the surface of the material being

evaluated,inwhichthetestforcesrangefrom1to1000gf(9.8 /B

tan

-3

×10 to9.8N),andtheindentationdiagonal,ordiagonals,are 2

c 5 (3)

p

measured with a light microscope after load removal; for any

/A

2tan

microindentation hardness test, it is assumed that the indenta- 2

tion does not undergo elastic recovery after force removal.

where:

NOTE 2—Use of the term microhardness should be avoided because it

P = force, gf,

implies that the hardness, rather than the force or the indentation size, is

d = length of long diagonal, µm,

very low.

A = projected area of indentation, µm

p

3.2.5 verifying, v—checking or testing the instrument to

/A = included longitudinal edge angle, 172° 30’

assure conformance with the specification.

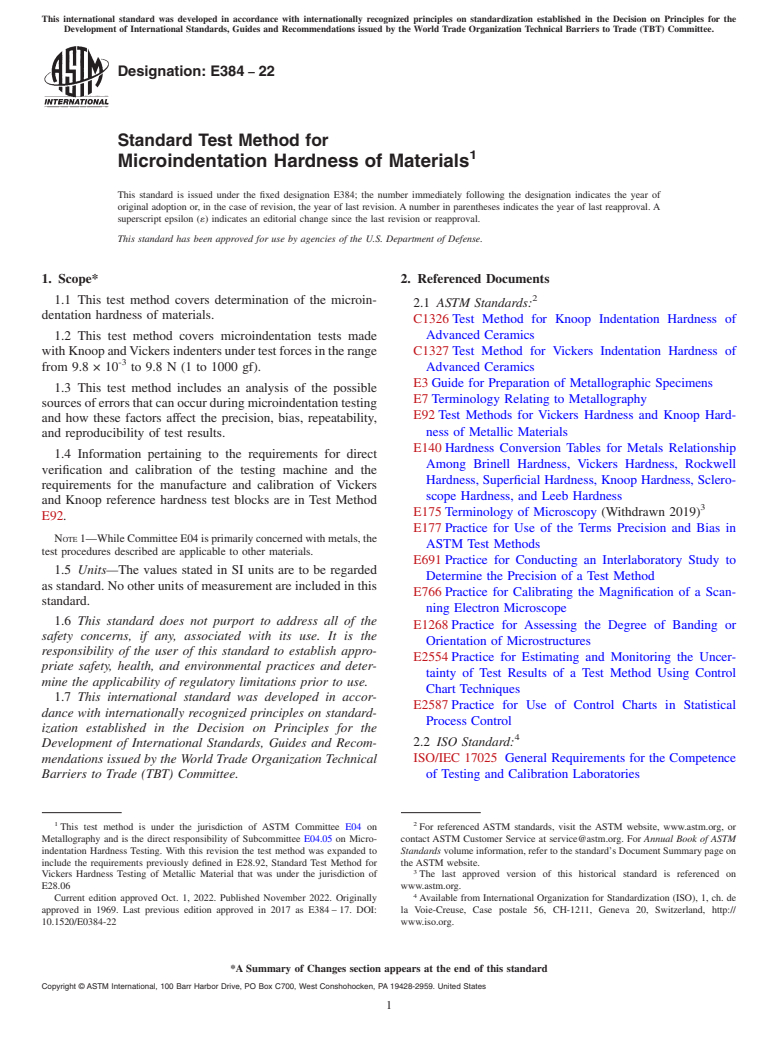

/B = included transverse edge angle, 130° 0’ (see Fig. 1

and,

3.2.6 Vickers hardness number, HV, n—an expression of

c = indenter constant relating projected area of the inden-

hardness obtained by dividing the force applied to a Vickers p

tation to the square of the length of the long diagonal,

indenterbythesurfaceareaofthepermanentimpressionmade

ideally 0.07028.

by the indenter.

3.2.7 Vickers indenter, n—a square-based pyramidal-shaped 3.3.2 The Knoop hardness, kgf/mm is determined as fol-

diamond indenter with face angles of 136° (see Fig. 2). lows:

FIG. 1 Knoop Indenter

E384 − 22

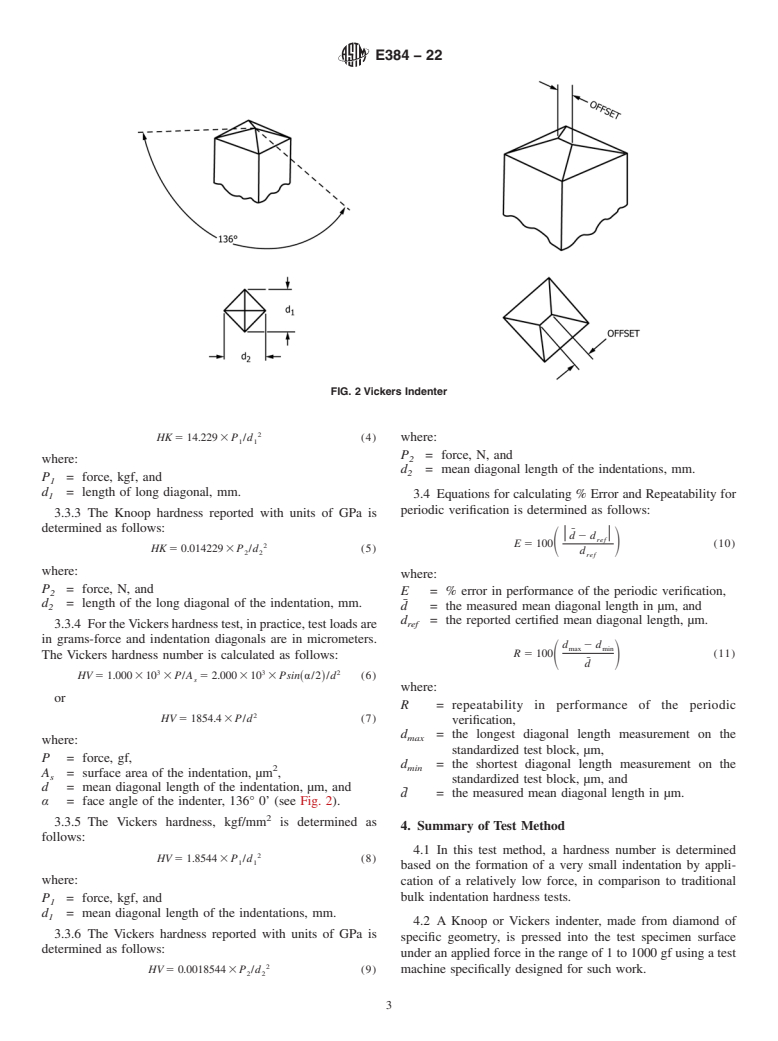

FIG. 2 Vickers Indenter

HK 514.229 3 P /d (4) where:

1 1

P = force, N, and

where:

d = mean diagonal length of the indentations, mm.

P = force, kgf, and

d = length of long diagonal, mm.

3.4 Equations for calculating % Error and Repeatability for

periodic verification is determined as follows:

3.3.3 The Knoop hardness reported with units of GPa is

determined as follows:

¯

d 2 d

? ref?

2 E 5100S D (10)

HK 50.014229 3 P /d (5)

2 2 d

ref

where:

where:

P = force, N, and

2 E = % error in performance of the periodic verification,

d = length of the long diagonal of the indentation, mm. ¯

d = the measured mean diagonal length in µm, and

d = the reported certified mean diagonal length, µm.

ref

3.3.4 FortheVickershardnesstest,inpractice,testloadsare

in grams-force and indentation diagonals are in micrometers.

d 2 d

max min

R 5100 (11)

The Vickers hardness number is calculated as follows:

S D

¯

d

3 3 2

HV 51.000 310 3 P/A 52.000 310 3 Psin α/2 /d (6)

~ !

s

where:

or

R = repeatability in performance of the periodic

HV 51854.4 3 P/d (7)

verification,

d = the longest diagonal length measurement on the

max

where:

standardized test block, µm,

P = force, gf,

d = the shortest diagonal length measurement on the

2 min

A = surface area of the indentation, µm ,

s

standardized test block, µm, and

d = mean diagonal length of the indentation, µm, and

¯

d = the measured mean diagonal length in µm.

α = face angle of the indenter, 136° 0’ (see Fig. 2).

3.3.5 The Vickers hardness, kgf/mm is determined as

4. Summary of Test Method

follows:

4.1 In this test method, a hardness number is determined

HV 51.8544 3 P /d (8)

1 1

based on the formation of a very small indentation by appli-

where:

cation of a relatively low force, in comparison to traditional

bulk indentation hardness tests.

P = force, kgf, and

d = mean diagonal length of the indentations, mm.

4.2 A Knoop or Vickers indenter, made from diamond of

3.3.6 The Vickers hardness reported with units of GPa is

specific geometry, is pressed into the test specimen surface

determined as follows:

under an applied force in the range of 1 to 1000 gf using a test

HV 50.0018544 3 P /d (9) machine specifically designed for such work.

2 2

E384 − 22

4.3 The size of the indentation is measured using a light metrically identical as a function of depth and there will be

microscope equipped with a filar type eyepiece, or other type variations in Knoop hardness, particularly at test forces <200

of measuring device (see Terminology E175). gf, over the force range defined in 1.2 (and above this range);

consequently, Knoop hardness is not normally used to define

4.4 The Knoop hardness number is based upon the force

bulk hardness, except at 500 gf where E140 gives conversions

divided by the projected area of the indentation. The Vickers

toothertestscales,andKnooptestsshouldnotbeperformedat

hardnessnumberisbasedupontheforcedividedbythesurface

test forces above 1000 gf. The majority of Knoop tests of case

area of the indentation.

hardness variations are conducted at forces from 100gf to 500

4.5 It is assumed that elastic recovery does not occur when

gf. If the test is being conducted to meet a specified bulk

the indenter is removed after the loading cycle, that is, it is

hardness value, such as HRC, then most such tests will be

assumed that the indentation retains the shape of the indenter

conducted with Knoop at a 500 gf load. Because of the large

aftertheforceisremoved,butthisisnotalwaystrue.InKnoop

difference between the long and short Knoop diagonals, the

testing, it is assumed that the ratio of the long diagonal to the

Knoopindenterisoftenbettersuitedfordeterminingvariations

shortdiagonaloftheimpressionisthesameasfortheindenter,

of hardness over very small distances compared to the Vickers

7.114, but this is not always true due to elastic recovery.

indenter. Vickers and Knoop tests at forces ≤25 gf are

susceptible to imprecision due to the difficulty in measuring

5. Significance and Use

extremely small indents (<20 µm) by light microscopy with

5.1 Hardness tests have been found to be very useful for

high precision and reproducibility.Tests made at forces≤25 gf

materials evaluation, quality control of manufacturing pro-

should be considered to be qualitative in nature. Likewise, test

cesses and research and development efforts. Hardness, al-

forces that create indents <20 µm in length should be avoided

thoughempiricalinnature,canbecorrelatedtotensilestrength

whenever possible and should be considered to be qualitative

for many metals and alloys, and is also an indicator of

innature.Thesuccessofthespecimenpreparationprocedurein

machinability, wear resistance, toughness and ductility.

removing preparation-induced damage can, and will, influence

testresults;thisproblembecomesmorecriticalasthetestforce

5.2 Microindentationtestsareutilizedtoevaluateandquan-

decreases.

tify hardness variations that occur over a small distance.These

variations may be intentional, such as produced by localized

6. Apparatus

surface hardening, for example, from shot blasting, cold

drawing, flame hardening, induction hardening, etc., or from

6.1 Test Machine—The test machine must support the test

processes such as carburization, nitriding, carbonitriding, etc.;

specimen and control the movement of the indenter into the

or, they may be unintentional variations due to problems, such

specimenunderapreselectedtestforce,andshouldhavealight

as decarburization, localized softening in service, or from

optical microscope to select the desired test locations and to

compositional/microstructural segregation problems. Low test

measure the size of the indentations produced by the test. The

forces also extend hardness testing to materials too thin or too

planeofthesurfaceofthetestspecimenmustbeperpendicular

smallformacroindentationtests.Microindentationtestspermit

to the axis of the indenter and the direction of the force

hardness testing of specific phases or constituents and regions

application.Theplaneofthetestspecimensurfacemustbeflat,

orgradientstoosmallforevaluationbymacroindentationtests.

and free of surface relief, in order to obtain valid, usable test

data. The hardness test machine must meet the verification

5.3 Because microindentation hardness tests will reveal

requirements defined in Test Method E92.

hardnessvariationsthatcommonlyexistwithinmostmaterials,

6.1.1 Force Application—The test machine shall be capable

a single test value may not be representative of the bulk

of applying the test forces according to the following:

hardness. Vickers tests at 1000 gf can be utilized for determi-

6.1.1.1 The time from the initial application of the force

nation of the bulk hardness, but, as for any hardness test, it is

recommended that a number of indents are made and the until the full test force is reached shall not exceed 10 s.

6.1.1.2 Theindentershallcontactthespecimenatavelocity

average and standard deviation are calculated, as needed or as

required. between 15 µm/s and 70 µm/s. Indenter velocity is not usually

adjustable by the user.

5.4 Microindentation hardness testing is generally per-

6.1.1.3 The full test force shall be applied for 10s to 15 s

formedtoquantifyvariationsinhardnessthatoccuroversmall

unless otherwise specified.

distances.To determine these differences requires a very small

6.1.1.4 For some applications it may be necessary to apply

physicalindentation.Testersthatcreateindentsatverylowtest

the test force for longer times. In these instances the tolerance

forcesmustbecarefullyconstructedtoaccuratelyapplythetest

for the time of the applied force is 62s.

forces exactly at the desired location and must have a high-

6.1.2 Vibration Control—During the entire test cycle, the

quality optical system to precisely measure the diagonal (or

test machine should be protected from shock or vibration. To

diagonals) of the small indents. Test forces in the upper range

minimize vibrations, the operator should avoid contacting the

of the force range defined in 1.2 may be used to evaluate bulk

machine, or the support table, in any manner during the entire

hardness. In general, the Vickers indenter is better suited for

test cycle.

determining bulk (average) properties as Vickers hardness is

not altered by the choice of the test force, from 25gf to 1000 6.2 Vickers Indenter—The Vickers indenter normally pro-

gf, because the indent geometry is constant as a function of duces geometrically-similar indentation shapes at all test

indent depth. The Knoop indentation, however, is not geo- forces. Except for tests at very low forces that produce

E384 − 22

indentations with diagonals smaller than about 20 µm, the separated from the mounting material. Never touch the in-

Vickers hardness number will be the same, within statistical denter tip with your finger.

precision limits, as produced using test forces that produce

6.4 Measuring Equipment—The test machine’s measuring

diagonal lengths ≥20 µm, using either a microindentation test

deviceshouldreportthediagonallengthsin0.1µmincrements

machineupto1000gforamacroindentationtestmachinewith

for indentations with diagonals from 1 to 200 µm.

test forces ≥ 1 kgf, as long as the material being tested is

NOTE3—Thisisthereportedlengthandnottheresolutionofthesystem

reasonably homogeneous and the magnification and image

used for performing the measurements.As an example, if a length of 200

qualityareoptimal(seeAppendixX4).Forisotropicmaterials,

µm corresponds to 300 filar units or pixels, the corresponding calibration

the two diagonals of a Vickers indentation are equal in size.

constant would be 200/300 = 0.66666667. This value would be used to

Metals/alloys with preferred crystallographic textures may

compute diagonal lengths, but the reported length would only be reported

produce distorted indents and invalid or questionable test to the nearest 0.1 µm.

results. The Vickers indenter must meet the verification re-

6.4.1 The optical portion of the measuring device should

quirements defined in Test Method E92.

utilizeKöhlerillumination.Consultthemanufacturer’sinstruc-

6.2.1 The ideal Vickers indenter is a highly polished,

tion manual for the adjustments that can be made on your

pointed, square-based pyramidal diamond with face angles of

tester.

136° 0'. The effect that geometrical variations of these angles

6.4.2 To obtain maximum resolution, the measuring micro-

have on the measured values of Vickers hardness is discussed

scope should have high quality objectives with adequate

in Section 10.

numerical apertures, a suitable eyepiece, adjustable illumina-

6.2.2 ThefourfacesoftheVickersindentershallbeequally

tion intensity, adjustable alignment and aperture and field

inclined to the axis of the indenter (within 6 30') and shall

diaphragms. These are adjusted in the same manner as on a

meet at a sharp point. The line of junction between opposite

reflected light microscope or metallograph. Some systems are

faces (offset) shall be not more than 0.5 µm in length as shown

now designed using computer monitors and indent length

in Fig. 2.

detection by image analysis and may not utilize a traditional

eyepiece, but have a projection lens connected to a CCD

6.3 Knoop Indenter—The Knoop indenter does not produce

camera. While a traditional eyepiece has a circular field of

geometrically-similar indentation shapes as a function of test

view, the computer monitor is rectangular and its height-to-

forceandindentdepth.Consequently,theKnoophardnesswill

width ratio can vary.

vary with test force (see Appendix X4). Due to its rhombic

6.4.3 Magnifications should be provided so that the diago-

shape, the indentation depth is shallower for a Knoop inden-

nal can be enlarged to greater than 25 % but less than 75 % of

tation compared to a Vickers indentation under identical test

the field width. If the computer screen hasa4to3 ratio of

conditions. But, for the same test force, the Knoop long

width to height, or a greater difference between the screen

diagonal will be substantially longer than the mean of the two

width and height, the maximum field height must be <75% of

Vickers diagonals. The two diagonals of a Knoop indentation

the width to measure both Vickers diagonals. A 40× or 50×

aremarkedlydifferent.Ideally,thelongdiagonalis7.114times

objective may not be adequate for precise measurement of

longer than the short diagonal, but this ratio is influenced by

indents <30 µm in length. Measurements of diagonal lengths

elastic recovery. Because of its shape, the Knoop indenter is

<20 µm in length with the light microscope may be imprecise,

very useful for evaluating hardness gradients or thin coatings.

regardless of the objective magnification used, with the prob-

The Knoop test is not recommended for use above a 1 kgf test

lem becoming more acute as the diagonal length decreases

load. The Knoop indenter must meet the verification require-

below 20 µm.

ments defined in Test Method E92.

6.3.1 The Knoop indenter is a highly polished, pointed,

7. Test Specimen

rhombic-based, pyramidal diamond (1). The ideal included

longitudinal edge angles are 172° 30' and 130° 0'. The ideal

7.1 For optimum accuracy of measurement, the test should

indenter constant, c , is 0.07028. The effect that geometrical

p beperformedonaflatspecimenwithapolishedsurfacefreeof

variations of these angles have on the measured values of

preparation-induced damage. The surface must be free of any

Knoop hardness is discussed in Section 10.

problems that could affect the indentation or the subsequent

6.3.2 The four faces of the Knoop indenter shall be equally

measurement of the diagonals. Conducting tests on non-planar

inclined to the axis of the indenter (within 6 30') and shall

surfaces is not recommended. Results will be affected even in

meet at a sharp point. The line of junction between opposite

the case of the Knoop test where the radius of curvature is in

faces (offset) shall be not more than 1.0 µm in length for

the direction of the short diagonal.

indentations greater than 20 µm in length, as shown in Fig. 1.

7.1.1 In all tests, the indentation perimeter, and the inden-

For shorter indentations, the offset should be proportionately

tation tips in particular, must be clearly defined in the micro-

less.

scope field of view.

6.3.3 Indenters should be examined periodically and re-

7.1.2 For best results, the specimen surface should not be

placed if they become worn, dulled, chipped, cracked or

etched before making an indentation (2), although etching is

often necessary to aid indent location. Deeply etched surfaces

will obscure the edge of the indentation, making an accurate

measurement of the size of the indentation difficult or impos-

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this standard. sible. When determining the microindentation hardness of an

E384 − 22

isolated phase or constituent, or when evaluating segregated 8.7 Adjust the tester so that the indenter is in the proper

comparedtonon-segregatedareas,andothersimilarsituations, place for force application. Select the desired force.

alightetchisrequiredtodelineatetheobjectorareaofinterest

8.8 Activate the tester so that the indenter is automatically

so that the indentations can be placed in the desired locations.

loweredandmakescontactwiththespecimenforthenormally

The necessary quality of the required surface preparation does

required time period. Then, remove the force either manually

vary with the forces and magnifications used in microindenta-

or automatically.

tion hardness testing. The lighter the force and the smaller the

8.9 After the force is removed, switch to the measuring

indentation size, the more critical is the surface preparation.

Some materials are more sensitive to preparation-induced mode, and select the proper objective lens. Focus the image,

adjust the light intensity if necessary, and adjust the apertures

damagethanothers.Ingeneral,face-centeredcubicmetals(for

example, austenitic stainless steels, copper and its alloys, for maximum resolution and contrast.

nickel and its alloys, gold and silver) exhibit a larger deforma-

8.10 Examine the indentation for its position relative to the

tionfieldaroundtheindentthananindentofthesametestforce

desired location and for its symmetry.

made in a body-centered cubic metal (for example, ferritic and

8.10.1 If the indentation did not occur at the desired spot,

martensitic steels).

the tester is out of alignment. Consult the manufacturer’s

7.1.3 Due to the small size of the indentations, special

instruction manual for the proper procedure to produce align-

precautions must be taken during specimen preparation. It is

ment. Make another indentation and recheck the indentation

well known that improper preparation can alter test results.

location. Readjust and repeat as necessary.

Specimen preparation must remove any damage introduced

8.10.2 For a Knoop indentation, if one half of the long

during these steps, either due to excessive heating or cold

diagonalismorethan10%longerthantheotherdiagonalhalf,

work, for example.

orifbothendsoftheindentationarenotinsharpfocus,thetest

7.1.4 Specimen preparation should be performed in accor-

specimen surface may not be perpendicular to the indenter

dance with Guide E3.

axis.Suchanindentmayyieldincorrectdataandthecalculated

7.2 Inmanyinstances,itisnecessarytomountthespecimen

HK based upon it should be reported outside these limits.

for convenience in preparation and for best edge retention.

Checkthespecimenalignmentandmakeanothertesttobesure

When mounting is required, the specimen must be adequately

that the test data is correct.

supported by the mounting medium so that the specimen does

8.10.3 For a Vickers indentation, if one half of either

not move during force application, such as might happen in an

diagonal is more than 5 % longer than the other half of that

improperly cured polymer mount.

diagonal, or if the four corners of the indentation are not in

sharp focus, the test surface may not be perpendicular to the

8. Procedure

indenter axis. Such an indent may yield incorrect data and the

calculated HV based upon it should be reported outside these

8.1 Turnontheilluminationsystemandpowerforthetester.

limits. Check the specimen alignment and make another test to

8.2 Select the desired indenter. If it is necessary to physi-

be sure that the test data is correct.

callychangeindenters,refertothemanufacturer’sinstructions.

8.10.4 Ifthediagonallegsareunequalasdescribedin8.10.2

With some machines, both indenters can be mounted on the

or 8.10.3, rotate the specimen 90° and make another indenta-

turret and changed by a simple switch or computer command.

tion in an untested region. If the nonsymmetrical aspect of the

Occasionally clean the indenter with a cotton swab and

indentations has rotated 90°, then the specimen surface is not

alcohol. Avoid creating static charges during cleaning. Never

perpendicular to the indenter axis. If the nonsymmetrical

touch the indenter tip with your fingers as this will alter the

natureoftheindentationremainsinthesameorientation,check

measurements.

the indenter for misalignment or damage.

8.3 Place the specimen on the stage or in the stage clamps,

8.10.5 Some materials may have nonsymmetrical indenta-

so that the specimen surface is perpendicular to the indenter

tions even if the indenter and the specimen surface are

axis. A top-referenced clamping system for mounts is an

perfectly aligned. Tests on single crystals or on textured

excellentdeviceforaligningthetestplaneperpendiculartothe

materials may produce such results. When this occurs, check

indenter, particularly if the back face of the mount is not

thealignmentusingatestspecimen,suchasastandard,known

parallel to the polished front surface. If clay is used on a slide,

to produce uniformly shaped indentations.

use very stiff clay and use high pressure when seating the

8.10.6 Brittle materials, such as ceramics, may crack as a

specimen against the clay.

result of being indented. Specific details for testing ceramics

8.4 Focus the measuring microscope with a low power

are contained in Test Methods C1326 and C1327.

objective so that the specimen surface can be observed.

8.11 Measure the long diagonal of a Knoop indentation, or

8.5 Adjust the light intensity and adjust the apertures for

bothdiagonalsofaVickersindentation,inaccordancewiththe

optimum resolution and contrast. Zero the measuring device

manufacturer’s instruction manual.

according to the manufacturer’s recommended method.

8.11.1 DeterminethelengthofthelongdiagonalofaKnoop

8.6 Select the area desired for hardness determination. indentationorbothdiagonalsofaVickersindentationtowithin

Before applying the force, make a final focus using the 0.1 µm (see 6.3). For theVickers indentations, average the two

measuring objective. diagonal length measurements.

E384 − 22

8.12 ComputetheKnooporVickershardnessnumberusing part of the SI system, the calculated numbers will be reported

the appropriate equation in Section 3 or using tables supplied without mention of the units.Also, due to the general unfamil-

with the tester, respectively. Modern testers usually give an iarity of the metallurgical community with hardness numbers

automatic readout of the hardness after the diagonal or diago- in GPa, and the rather narrow range of GPa values for metals,

nals have been measured. a “soft” SI system approach is recommended.

9.1.2 Test force, and

8.13 Spacing of Indentations—Generally, more than one

9.1.3 Any unusual conditions encountered during the test.

indentationismadeonatestspecimen.Itisnecessarytoensure

that the spacing between indentations is large enough so that

9.2 The symbols HK for Knoop hardness and HV for

adjacent tests do not interfere with each other. Because

Vickers hardness shall be used with the reported numerical

face-centered cubic (FCC) metals (for example, austenitic

values.

stainless steels, copper, nickel, silver and gold) work harden

9.2.1 For this standard, the microindentation hardness test

more dramatically than body-centered cubic (BCC) metals

results can be reported in several different ways. For example,

(ferritic steels, for example), the indent spacing distance is

if the Knoop hardness was found to be 400, and the test force

more critical for FCC metals as the deformation zone around

was 100 gf, the test results may be reported as follows:

the indent is larger than for a BCC metal, as mentioned in

9.2.1.1 For microindentation hardness tests, where the test

7.1.2.

forceisgenerallyingramforceunits,withtestforces≤1000gf,

8.13.1 For most testing purposes, the minimum recom-

this result can be reported as 400 HK 0.1, for example, when

mended spacing between separate tests and the minimum

a test at 100 gf yields a Knoop hardness of 400. The same

distance between an indentation and the surface of the

approach is used to report the Vickers hardness.

specimen, are illustrated in Fig. 3.

9.2.1.2 In the SI system the hardness would be reported as

8.13.2 Forsomeapplications,closerspacingofindentations

3.92 GPa, but this practice is not preferred for the reasons

than those shown in Fig. 3 may be necessary. If a closer

stated in 9.1.1.

indentation spacing is used, it shall be the responsibility of the

9.2.1.3 Fornonstandarddwelltimes,otherthan10sto15s,

testing laboratory to verify the accuracy of the testing proce-

the hardness would be reported as 400 HK 0.1/22 s. In this

dure. Parallel, staggered bands of indents from the surface

case, 22 s would be the actual time of the full load dwell time.

inward can be utilized to obtain closer overall spacing of

9.2.1.4 For macro-Vickers tests with forces >1 kgf, seeTest

indents with respect to the distance from the surface than can

Method E92 for the recommended notation.

be safely done with a single line of indents from the surface

9.3 Examplesofthecalculationofmeasurementuncertainty

inward, or within the interior of the specimen.

are given in Test Method E92.

9. Report

10. Precision and Bias

9.1 Report the following information:

9.1.1 The number of tests and, where appropriate or 10.1 The precision and bias of microindentation hardness

required, the mean, standard deviation and 95% confidence measurements depend on strict adherence to the stated test

interval for the tests. Due to the long history of hardness procedure and are influenced by instrumental and material

calculations, and because the traditional kg/mm unit is not factors and indentation measurement errors.

FIG. 3 Minimum Recommended Spacing for Knoop and Vickers Indentations

E384 − 22

10.2 The consistency of agreement for repeated tests on the variables:force,indentergeometryanddiagonalmeasurement.

samematerialisdependentonthehomogeneityofthematerial, For theVickers test, the error in measuring the diagonals has a

reproducibility of the hardness tester, and consistent, careful bigger effect on the precision of the HV value than a larger

measurement of the indents by a competent operator. error in the test force or the face geometry. For the Knoop test,

an error in measuring the long diagonal has a bigger influence

10.3 Instrumental factors that can affect test results include:

on the precision of the HK value than a larger error in the test

accuracy of loading; inertia effects; speed of loading; vibra-

force. But, errors in the two face angles, Fig. 1, have a very

tions; the angle of indentation; lateral movement of the

significant effect on the precision of the HK value.

indenter or specimen; and, indentation and indenter shape

deviations. 10.8 Three separate interlaboratory studies have been con-

10.3.1 Vibrations during indenting will produce larger in- ducted in accordance with Practice E691 to determine the

dentations with the potential influence of vibrations becoming precision,repeatability,andreproducibilityofthistestmethod.

greater as the force decreases (2, 3). Thethreestudiesaredefinedasfollows: (a)KnoopandVickers

10.3.2 Theanglebetweentheindenterandspecimensurface tests, six test forces in the micro range, twelve laboratories,

shouldbewithin2°ofperpendicular.Greateramountsoftilting manual measurements, and seven different hardness level

may produce non-uniform indentations and incorrect test specimens (see 10.8.1 and Appendix X1). Results were pub-

lished in 1989 (7, 8) and in ASTM Research Report RR:E04-

results.

1004. (b)KnoopandVickerstests,twotestforcesinthemicro

10.4 Material factors that can affect test results include:

range, seven laboratories, image analysis and manual

specimenhomogeneity,orientationortextureeffects;improper

measurements, four different hardness level specimens (see

specimen preparation; low specimen surface reflectivity; and,

10.8.2, Appendix X2 and ASTM Research Report RR:E04-

transparency of the specimen.

1006). (c)KnoopandVickerstests,sixtestforcesinthemicro

10.4.1 Residual deformation from mechanical polishing

range, twenty-five laboratories, manual measurements, six

must be removed, particularly for low-force (≤200 gf) testing.

different hardness level specimens (see 10.8.3, Appendix X3

10.4.2 Distortion of the indentation shape, due to either

and ASTM Research Report RR:E04-1007).

crystallographicormicrostructuraltexture,influencesdiagonal

10.8.1 An interlaboratory test program was conducted in

lengths and the validity of the calculated hardness.

accordance with Practice E691 to develop information regard-

10.4.3 Plastic deformation during indentation can produce

ing the precision, repeatability, and reproducibility of the

ridging around the indentation periphery that will affect diago-

measurement of Knoop and Vickers indentations (supporting

nal measurement accuracy.

data have been filed atASTM Headquarters; request RR:E04-

10.4.4 Testing of etched surfaces, depending on the extent

1004). Thetestforceswere25,50,100,200,500,and1000gf

of etching, may produce results that are different from those

on three ferrous and four nonferrous specimens (7, 8). Twelve

obtained on unetched surfaces (2).

laboratories measured the indentations, five of each type at

10.5 Measurement errors that can affect test results include:

each force on each sample.Additional details of this study are

inaccurate calibration of the measuring device; inadequate

given in Appendix X1.

resolving power of the objective; insufficient magnification;

10.8.1.1 Tests of the three ferrous specimens revealed that

operator bias in sizing the indentations; poor image contrast;

nine laboratories produced similar measurements while two

non-uniform illumination; and, improper zeroing of the mea-

laboratories consistently undersized the indentations and one

suring device.

laboratory consistently oversized the indentations; that is,

10.5.1 The accuracy of microindentation hardness testing is

biased results were produced. These latter results were most

strongly influenced by the accuracy to which the indentations

pronounced as the force decreased and specimen hardness

can be measured.

increased (that is, as the diagonal size decreased) and were

10.5.2 Theerrorinmeasuringthediagonalsincreasesasthe

observed for bothVickers and Knoop indentations. Results for

numericalapertureofthemeasuringobjectivedecreases (4, 5).

the lower hardness nonferrous indentations produced better

In general, indents <30 µm in length should be measured with

agreement. However, none of the laboratories that obtained

objectives having greater magnification than 40 or 50×. Image

higher or lower results on the ferrous specimens measured the

contrast between the indent and the specimen is critical for

nonferrous indentations.

precise measurement of diagonal length.

10.8.1.2 Repeatability Interval—The difference due to test

10.5.3 Bias is introduced if the operator consistently under-

error between two test results in the same laboratory on the

sizes or over-sizes the indentations.

samematerialincreaseswithincreasingspecimenhardnessand

with decreasing test force (see X1.4.4).

10.6 Some of the factors that affect test results produce

systematic errors that influence all test results while others

primarily influence low-force (≤25 gf) test results (6). Some of

Supporting data have been filed atASTM International Headquarters and may

beobtainedbyrequestingResearchReportRR:E04-1004.ContactASTMCustomer

these problems occur continually, others may occur in an

Service at service@astm.org.

undefined, sporadic manner. Low-force hardness tests are

Supporting data have been filed atASTM International Headquarters and may

influencedbythesefactorstoagreaterextentthanhigherforce

beobtainedbyrequestingResearchReportRR:E04-1006.ContactASTMCustomer

tests. Service at service@astm.org.

Supporting data have been filed atASTM International Headquarters and may

10.7 For both the Vickers and Knoop hardness tests, the

beobtainedbyrequestingResearchReportRR:E04-1007.ContactASTMCustomer

calculated microindentation hardness is a function of three Service at service@astm.org.

E384 − 22

10.8.1.3 Reproducibility Interval—The difference in test 10.8.2.3 Neither Practice E691, nor any other ASTM

results on the same material tested in different laboratories standard, deals with comparing test results of a single property

increasedwithincreasingspecimenhardnessandwithdecreas- madebytwodifferenttestmethods.Hence,itisnotpossibleto

ing test force (see X1.4.5). statistically and accurately compare the hardness measure-

10.8.1.4 The within-laboratory and between-laboratory pre- ments made by the manual and automated procedures.

cision values improved as specimen hardness decreased and However, this information is graphically represented for com-

test force increased. The repeatability interval and reproduc- parative purposes, X2.6.

ibility interval were generally larger than the precision 10.8.3 Tests of six ferrous alloys with hardness values of

estimate, particularly at low test forces and high specimen <20HRC,30,40,50,60and67HRCweretestedusingKnoop

hardness. andVickerstestsatavarietyoftestforces,usually25,50,100,

10.8.2 An interlaboratory test program was conducted in 300, 500 and 1000 gf (except that the lowest test forces for

accordance with Practice E691 to develop information regard- Vickers tests of the 60 and 67 HRC specimens were not

ing the repeatability and reproducibility of Knoop and Vickers performed). Twenty-five different laboratories tested the steels

measurements made with automated image analysis systems using the Vickers test while thirteen different laboratories

compared to measurements by manual procedures. Four fer- testedthesteelsusingtheKnooptest.Additionaldetailsofthis

study are given in Appendix X3.

rous specimens were used in the round robin. The tests were

conducted at 100 gf and 300 gf. The participants in the test 10.8.3.1 Repeatability and reproducibility statistics were

determinedfortheKnoopandVickersdiagonalmeasurements.

program measured the same indentations on the four speci-

mens. Seven labs measured the specimens using both proce- Results are tabulated in Table X3.1 and Table X3.2 and are

shown graphically in Fig. X3.1 and Fig. X3.2.

dures. The Knoop indentations on specimen C1 were too long

for accurate measurements to be made by one lab; hence, only 10.8.3.2 Repeatability and reproducibility statistics were

determinedfortheKnoopandVickershardnessvalues.Results

sixsetsofmeasurementsweremadeonthisspecimen.Nearthe

endofthetestprogram,specimenB1waslostinshipping;thus are tabulated in Table X3.3 and Table X3.4 and are shown

only six sets of measurements were made on this specimen. graphically in Fig. X3.3 and Fig. X3.4.

Additional details of the study are contained in Appendix X2.

11. Conversion to Other Hardness Scales or Tensile

10.8.2.1 Repeatability concerns the variability between in-

Strength Values

dividual test results obtained within a single laboratory by a

single operator with a specific set of test apparatus. For both 11.1 There is no generally accepted method for precise

the manual and automated measurements, the repeatability conversion of Knoop or Vickers microindentation hardness

interval increased with specimen hardness and decreasing test numbers to other hardness scales or tensile strength values.

force, Appendix X2. For equivalent testing conditions, the Suchconversionsareempiricalandarelimitedinprecisionand

repeatabilityintervalforautomatedmeasurementswasslightly should be used with caution, except for special cases where a

larger than for manual measurements. reliable basis for the conversion has been obtained by com-

10.8.2.2 Reproducibility deals with the variability between parison tests. For loads ≥ 25 gf microindentation Vickers

single test results obtained by different laboratories applying hardness numbers are in statistical agreement with macro-

the same test methods to the same or similar test specimens. Vickers hardness numbers. Refer to Standard Hardness Con-

For both the manual and automated measurements, the repro- version Tables in E140.

ducibility interval increased with specimen hardness and de-

12. Keywords

creasing test force, Appendix X2. For equivalent testing

conditions, the reproducibility interval for automated measure- 12.1 hardness; indentation; Knoop; microindentation; Vick-

ments was slightly larger than for manual measurements. ers

ANNEXES

(Mandatory Information)

A1. VERIFICATION OF KNOOP AND VICKERS HARDNESS TESTING MACHINES AND INDENTERS

A1.1 Scope ing the consistency of microindentation measurements based

on the periodic verification tests and detecting measurement

A1.1.1 Annex A1 specifies three types of procedures for

deviations is described in Practices E2554 and E2587.

verifying microindentation (Knoop andVickers) hardness test-

ing machines: direct verification, indirect verification, and A1.1.2 Direct verification is a process normally performed

periodicverification.Thisannexalsocontainsgeometricspeci- bythemanufactureforverifyingthatcriticalcomponentsofthe

fications for the indenter. A control chart method for monitor- hardness testing machine are within allowable tolerances by

E384 − 22

direct measurement of the applied test forces, the indentation formedinaccordancewiththeschedulegiveninTableA1.1for

measuring system, and the testing cycle. For additional infor- each microindentation hardness indenter that will be used.

mation about direct verification see Test Method E92.

A1.3.2 It is recommended that the periodic verification

A1.1.3 Indirect verification is a process performed by the procedures be performed whenever the indenter is changed,

user of the machine, or by an outside certification agency, to that is, if one indenter is physically removed from t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E384 − 17 E384 − 22

Standard Test Method for

Microindentation Hardness of Materials

This standard is issued under the fixed designation E384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers determination of the microindentation hardness of materials.

1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from

-3

9.8 × 10 to 9.8 N (1 to 1000 gf).

1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how

these factors affect the precision, bias, repeatability, and reproducibility of test results.

1.4 Information pertaining to the requirements for direct verification and calibration of the testing machine and the requirements

for the manufacture and calibration of Vickers and Knoop reference hardness test blocks are in Test Method E92.

NOTE 1—While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C1326 Test Method for Knoop Indentation Hardness of Advanced Ceramics

C1327 Test Method for Vickers Indentation Hardness of Advanced Ceramics

E3 Guide for Preparation of Metallographic Specimens

This test method is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.05 on Microindentation

Hardness Testing. With this revision the test method was expanded to include the requirements previously defined in E28.92, Standard Test Method for Vickers Hardness

Testing of Metallic Material that was under the jurisdiction of E28.06

Current edition approved June 1, 2017Oct. 1, 2022. Published August 2017November 2022. Originally approved in 1969. Last previous edition approved in 20162017

as E384 – 16.E384 – 17. DOI: 10.1520/E0384-1710.1520/E0384-22

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E384 − 22

E7 Terminology Relating to Metallography

E92 Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E175 Terminology of Microscopy (Withdrawn 2019)

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E766 Practice for Calibrating the Magnification of a Scanning Electron Microscope

E1268 Practice for Assessing the Degree of Banding or Orientation of Microstructures

E2554 Practice for Estimating and Monitoring the Uncertainty of Test Results of a Test Method Using Control Chart Techniques

E2587 Practice for Use of Control Charts in Statistical Process Control

2.2 ISO Standard:

ISO/IEC 17025 General Requirements for the Competence of Testing and Calibration Laboratories

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, see Terminology E7.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibrating, v—determining the values of the significant parameters by comparison with values indicated by a reference

instrument or by a set of reference standards.

3.2.2 Knoop hardness number, HK, n—an expression of hardness obtained by dividing the force applied to the Knoop indenter by

the projected area of the permanent impression made by the indenter.

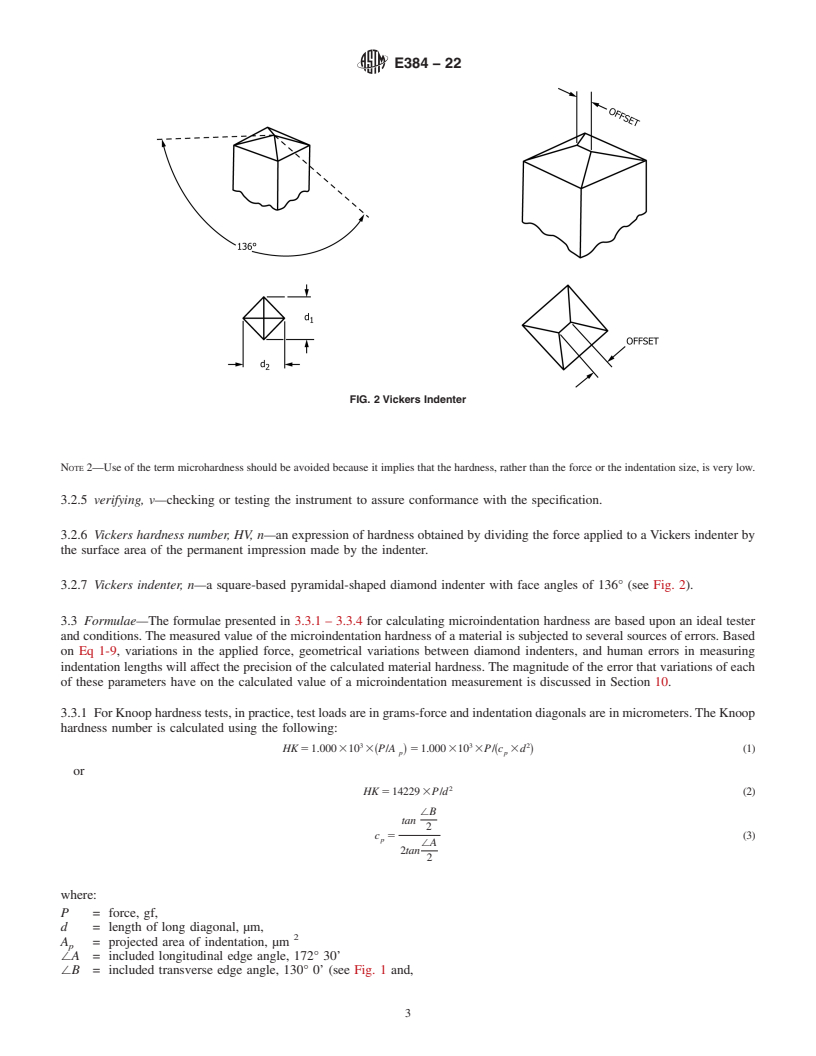

3.2.3 Knoop indenter, n—a rhombic-based pyramidal-shaped diamond indenter with edge angles of / A = 172° 30' and / B =

130° 0' (see Fig. 1).

3.2.4 microindentation hardness test, n—a hardness test using a calibrated machine to force a diamond indenter of specific

-3

geometry into the surface of the material being evaluated, in which the test forces range from 1 to 1000 gf (9.8 × 10 to 9.8 N),

and the indentation diagonal, or diagonals, are measured with a light microscope after load removal; for any microindentation

hardness test, it is assumed that the indentation does not undergo elastic recovery after force removal.

FIG. 1 Knoop Indenter

The last approved version of this historical standard is referenced on www.astm.org.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.org.

E384 − 22

FIG. 2 Vickers Indenter

NOTE 2—Use of the term microhardness should be avoided because it implies that the hardness, rather than the force or the indentation size, is very low.

3.2.5 verifying, v—checking or testing the instrument to assure conformance with the specification.

3.2.6 Vickers hardness number, HV, n—an expression of hardness obtained by dividing the force applied to a Vickers indenter by

the surface area of the permanent impression made by the indenter.

3.2.7 Vickers indenter, n—a square-based pyramidal-shaped diamond indenter with face angles of 136° (see Fig. 2).

3.3 Formulae—The formulae presented in 3.3.1 – 3.3.4 for calculating microindentation hardness are based upon an ideal tester

and conditions. The measured value of the microindentation hardness of a material is subjected to several sources of errors. Based

on Eq 1-9, variations in the applied force, geometrical variations between diamond indenters, and human errors in measuring

indentation lengths will affect the precision of the calculated material hardness. The magnitude of the error that variations of each

of these parameters have on the calculated value of a microindentation measurement is discussed in Section 10.

3.3.1 For Knoop hardness tests, in practice, test loads are in grams-force and indentation diagonals are in micrometers. The Knoop

hardness number is calculated using the following:

3 3 2

HK 5 1.000 310 3~P/A ! 5 1.000 310 3P/~c 3d ! (1)

p p

or

HK 5 14229 3P/d (2)

/B

tan

c 5 (3)

p

/A

2tan

where:

P = force, gf,

d = length of long diagonal, μm,

A = projected area of indentation, μm

p

/A = included longitudinal edge angle, 172° 30’

/B = included transverse edge angle, 130° 0’ (see Fig. 1 and,

E384 − 22

c = indenter constant relating projected area of the indentation to the square of the length of the long diagonal, ideally

p

0.07028.

3.3.2 The Knoop hardness, kgf/mm is determined as follows:

HK 5 14.229 3P /d (4)

1 1

where:

P = force, kgf, and

d = length of long diagonal, mm.

3.3.3 The Knoop hardness reported with units of GPa is determined as follows:

HK 5 0.014229 3P /d (5)

2 2

where:

P = force, N, and

d = length of the long diagonal of the indentation, mm.

3.3.4 For the Vickers hardness test, in practice, test loads are in grams-force and indentation diagonals are in micrometers. The

Vickers hardness number is calculated as follows:

3 3 2

HV 5 1.000 310 3P/A 5 2.000 310 3Psin~α/2!/d (6)

s

or

HV 5 1854.4 3P/d (7)

where:

P = force, gf,

A = surface area of the indentation, μm ,

s

d = mean diagonal length of the indentation, μm, and

α = face angle of the indenter, 136° 0’ (see Fig. 2).

3.3.5 The Vickers hardness, kgf/mm is determined as follows:

HV 5 1.8544 3P /d (8)

1 1

where:

P = force, kgf, and

d = mean diagonal length of the indentations, mm.

3.3.6 The Vickers hardness reported with units of GPa is determined as follows:

HV 5 0.0018544 3P /d (9)

2 2

where:

P = force, N, and

d = mean diagonal length of the indentations, mm.

3.4 Equations for calculating % Error and Repeatability for periodic verification is determined as follows:

¯

d 2 d

ref

E 5 100S D (10)

d

ref

¯

d 2 d

? ref?

E 5 100S D (10)

d

ref

E384 − 22

where:

E = % error in performance of the periodic verification,

d¯ = the measured mean diagonal length in μm, and

d = the reported certified mean diagonal length, μm.

ref

d 2 d

max min

R 5 100 (11)

S D

¯

d

where:

R = repeatability in performance of the periodic verification,

d = the longest diagonal length measurement on the standardized test block, μm,

max

d = the shortest diagonal length measurement on the standardized test block, μm, and

min

d¯ = the measured mean diagonal length in μm.

4. Summary of Test Method

4.1 In this test method, a hardness number is determined based on the formation of a very small indentation by application of a

relatively low force, in comparison to traditional bulk indentation hardness tests.

4.2 A Knoop or Vickers indenter, made from diamond of specific geometry, is pressed into the test specimen surface under an

applied force in the range of 1 to 1000 gf using a test machine specifically designed for such work.

4.3 The size of the indentation is measured using a light microscope equipped with a filar type eyepiece, or other type of measuring

device (see Terminology E175).

4.4 The Knoop hardness number is based upon the force divided by the projected area of the indentation. The Vickers hardness

number is based upon the force divided by the surface area of the indentation.

4.5 It is assumed that elastic recovery does not occur when the indenter is removed after the loading cycle, that is, it is assumed

that the indentation retains the shape of the indenter after the force is removed, but this is not always true. In Knoop testing, it is

assumed that the ratio of the long diagonal to the short diagonal of the impression is the same as for the indenter, 7.114, but this

is not always true due to elastic recovery.

5. Significance and Use

5.1 Hardness tests have been found to be very useful for materials evaluation, quality control of manufacturing processes and

research and development efforts. Hardness, although empirical in nature, can be correlated to tensile strength for many metals and

alloys, and is also an indicator of machinability, wear resistance, toughness and ductility.

5.2 Microindentation tests are utilized to evaluate and quantify hardness variations that occur over a small distance. These

variations may be intentional, such as produced by localized surface hardening, for example, from shot blasting, cold drawing,

flame hardening, induction hardening, etc., or from processes such as carburization, nitriding, carbonitriding, etc.; or, they may be

unintentional variations due to problems, such as decarburization, localized softening in service, or from compositional/

microstructural segregation problems. Low test forces also extend hardness testing to materials too thin or too small for

macroindentation tests. Microindentation tests permit hardness testing of specific phases or constituents and regions or gradients

too small for evaluation by macroindentation tests.

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single

test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk

hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average and standard deviation

are calculated, as needed or as required.

5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances.

To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must

be carefully constructed to accurately apply the test forces exactly at the desired location and must have a high-quality optical

system to precisely measure the diagonal (or diagonals) of the small indents. Test forces in the upper range of the force range

E384 − 22

defined in 1.2 may be used to evaluate bulk hardness. In general, the Vickers indenter is better suited for determining bulk (average)

properties as Vickers hardness is not altered by the choice of the test force, from 2525 gf to 1000 gf, because the indent geometry

is constant as a function of indent depth. The Knoop indentation, however, is not geometrically identical as a function of depth

and there will be variations in Knoop hardness, particularly at test forces <200 gf, over the force range defined in 1.2 (and above

this range); consequently, Knoop hardness is not normally used to define bulk hardness, except at 500 gf where E140 gives

conversions to other test scales, and Knoop tests should not be performed at test forces above 1000 gf. The majority of Knoop tests

of case hardness variations are conducted at forces from 100100 gf to 500 gf. If the test is being conducted to meet a specified bulk

hardness value, such as HRC, then most such tests will be conducted with Knoop at a 500 gf load. Because of the large difference

between the long and short Knoop diagonals, the Knoop indenter is often better suited for determining variations of hardness over

very small distances compared to the Vickers indenter. Vickers and Knoop tests at forces ≤25 gf are susceptible to imprecision due

to the difficulty in measuring extremely small indents (<20 μm) by light microscopy with high precision and reproducibility. Tests

made at forces ≤25 gf should be considered to be qualitative in nature. Likewise, test forces that create indents <20 μm in length

should be avoided whenever possible and should be considered to be qualitative in nature. The success of the specimen preparation

procedure in removing preparation-induced damage can, and will, influence test results; this problem becomes more critical as the

test force decreases.

6. Apparatus

6.1 Test Machine—The test machine must support the test specimen and control the movement of the indenter into the specimen

under a preselected test force, and should have a light optical microscope to select the desired test locations and to measure the

size of the indentations produced by the test. The plane of the surface of the test specimen must be perpendicular to the axis of