ASTM G76-18

(Test Method)Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets

Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets

SIGNIFICANCE AND USE

5.1 The significance of this test method in any overall measurements program to assess the erosion behavior of materials will depend on many factors concerning the conditions of service applications. The users of this test method should determine the degree of correlation of the results obtained with those from field performance or results using other test systems and methods. This test method may be used to rank the erosion resistance of materials under the specified conditions of testing.

SCOPE

1.1 This test method covers the determination of material loss by gas-entrained solid particle impingement erosion with jetnozzle type erosion equipment. This test method may be used in the laboratory to measure the solid particle erosion of different materials and has been used as a screening test for ranking solid particle erosion rates of materials in simulated service environments (1, 2).2 Actual erosion service involves particle sizes, velocities, attack angles, environments, and so forth, that will vary over a wide range (3-5). Hence, any single laboratory test may not be sufficient to evaluate expected service performance. This test method describes one well characterized procedure for solid particle impingement erosion measurement for which interlaboratory test results are available.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard (exceptions below).

1.2.1 Exceptions: Table 1 uses HRB hardness. Footnote 7 and 11.2 use abrasive grit designations.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G76 − 18

Standard Test Method for

Conducting Erosion Tests by Solid Particle Impingement

1

Using Gas Jets

ThisstandardisissuedunderthefixeddesignationG76;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This test method covers the determination of material

E122PracticeforCalculatingSampleSizetoEstimate,With

loss by gas-entrained solid particle impingement erosion with

Specified Precision, the Average for a Characteristic of a

jetnozzle type erosion equipment. This test method may be

Lot or Process

used in the laboratory to measure the solid particle erosion of

G40Terminology Relating to Wear and Erosion

different materials and has been used as a screening test for

2.2 American National Standard:

ranking solid particle erosion rates of materials in simulated

4

2

ANSI B74.10Grading of Abrasive Microgrits

service environments (1, 2). Actual erosion service involves

particle sizes, velocities, attack angles, environments, and so

3. Terminology

forth, that will vary over a wide range (3-5). Hence, any single

3.1 Definitions:

laboratory test may not be sufficient to evaluate expected

3.1.1 erosion—progressive loss of original material from a

service performance. This test method describes one well

solid surface due to mechanical interaction between that

characterizedprocedureforsolidparticleimpingementerosion

surfaceandafluid,amulticomponentfluid,orimpingingliquid

measurement for which interlaboratory test results are avail-

or solid particles.

able.

3.1.2 impingement—a process resulting in a continuing

1.2 Units—The values stated in SI units are to be regarded

succession of impacts between (liquid or solid) particles and a

asstandard.Nootherunitsofmeasurementareincludedinthis

solid surface.

standard (exceptions below).

3.2 Definitions of Terms Specific to This Standard:

1.2.1 Exceptions: Table 1 uses HRB hardness. Footnote 7

3.2.1 erosion value—the volume loss of specimen material

and 11.2 use abrasive grit designations.

dividedbythetotalmassofabrasiveparticlesthatimpactedthe

3 −1

1.3 This standard does not purport to address all of the specimen (mm ·g ).

3 −1

safety concerns, if any, associated with its use. It is the

3.2.2 Normalized Erosion Rate—erosionvalue(mm ·g )of

3 −1

responsibility of the user of this standard to establish appro-

specimen material divided by erosion value (mm ·g )of

priate safety, health, and environmental practices and deter-

reference material.

mine the applicability of regulatory limitations prior to use.

4. Summary of Test Method

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.1 This test method utilizes a repeated impact erosion

ization established in the Decision on Principles for the approach involving a small nozzle delivering a stream of gas

containing abrasive particles which impacts the surface of a

Development of International Standards, Guides and Recom-

test specimen. A standard set of test conditions is described.

mendations issued by the World Trade Organization Technical

However, deviations from some of the standard conditions are

Barriers to Trade (TBT) Committee.

permitted if described thoroughly. This allows for laboratory

scale erosion measurements under a range of conditions. Test

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of Subcommittee G02.10 on Erosion by

3

Solids and Liquids. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2018. Published November 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1983. Last previous edition approved in 2013 as G76–13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0076-18. the ASTM website.

2 4

The boldface numbers in parentheses refer to a list of references at the end of Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

this standard. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G76−18

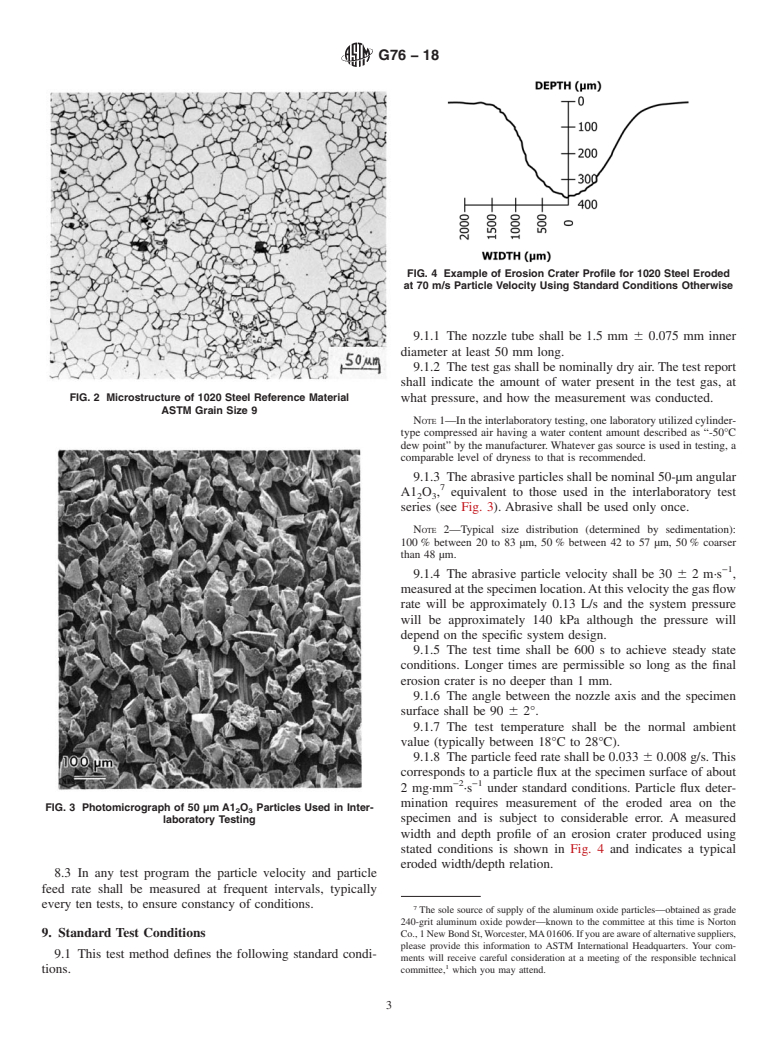

TABLE 1 Characteristics of Type 1020 Steel Reference Material

Annealed 900 s at 760°C, air cooled.

Hardness: HRB = 70 ± 2.

Chemical Composition:

C=0.20±0.01wt%

Mn

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G76 − 13 G76 − 18

Standard Test Method for

Conducting Erosion Tests by Solid Particle Impingement

1

Using Gas Jets

This standard is issued under the fixed designation G76; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of material loss by gas-entrained solid particle impingement erosion with

jetnozzle type erosion equipment. This test method may be used in the laboratory to measure the solid particle erosion of different

materials and has been used as a screening test for ranking solid particle erosion rates of materials in simulated service

2

environments (1, 2). Actual erosion service involves particle sizes, velocities, attack angles, environments, and so forth, that will

vary over a wide range (3-5). Hence, any single laboratory test may not be sufficient to evaluate expected service performance.

This test method describes one well characterized procedure for solid particle impingement erosion measurement for which

interlaboratory test results are available.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard (exceptions below).

1.2.1 Exceptions: Table 1 uses HRB hardness. Footnote 7 and 11.2 use abrasive grit designations.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

G40 Terminology Relating to Wear and Erosion

2.2 American National Standard:

4

ANSI B74.10 Grading of Abrasive Microgrits

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.10 on Erosion by Solids

and Liquids.

Current edition approved July 1, 2013Oct. 1, 2018. Published July 2013November 2018. Originally approved in 1983. Last previous edition approved in 20072013 as

G76G76 – 13.–07. DOI: 10.1520/G0076-13.10.1520/G0076-18.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

TABLE 1 Characteristics of Type 1020 Steel Reference Material

Annealed 900 s at 760°C, air cooled.

Hardness: HRB = 70 ± 2.

Chemical Composition:

C = 0.20 ± 0.01 wt %

Mn = 0.45 ± 0.10

S = 0.03 ± 0.01

Si = 0.1± 0.05

P = 0.01 ± 0.01

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G76 − 18

where:

a = gas jet nozzle,

b = nozzle length,

c = mixing chamber,

d = abrasive hopper,

e = gas source,

f = test specimen,

g = nozzle-to-specimen distance, and

θ = impingement angle.

FIG. 1 Schematic Drawing of Solid Particle Erosion Equipmentof Test Rig

3. Terminology

3.1 Definitions:

3.1.1 erosion—progressive loss of original material from a solid surface due to mechanical interaction between that surface and

a fluid, a multicomponent fluid, or impinging liquid or solid particles.

3.1.2 impingement—a process resulting in a continuing succession of impacts between (liquid or solid) particles and a solid

surface.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 erosion value—the volume loss of specimen material divided by the total mass of abrasive particles that impacted the

3 −1

specimen (mm

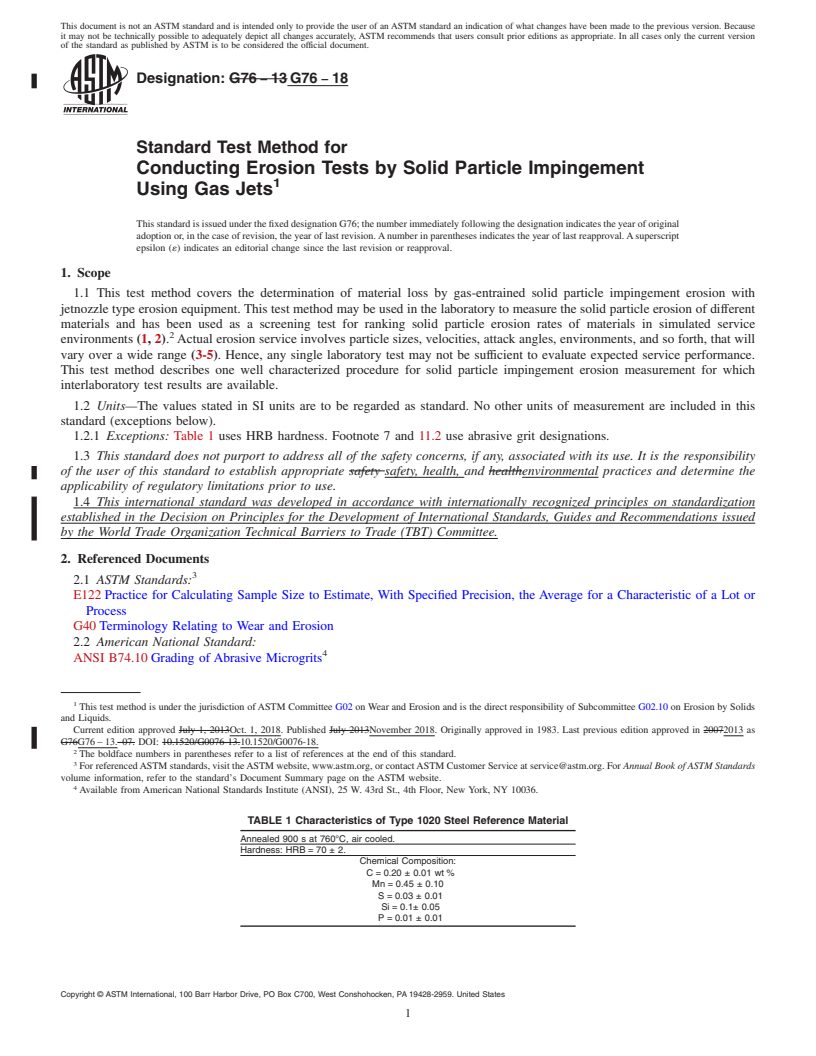

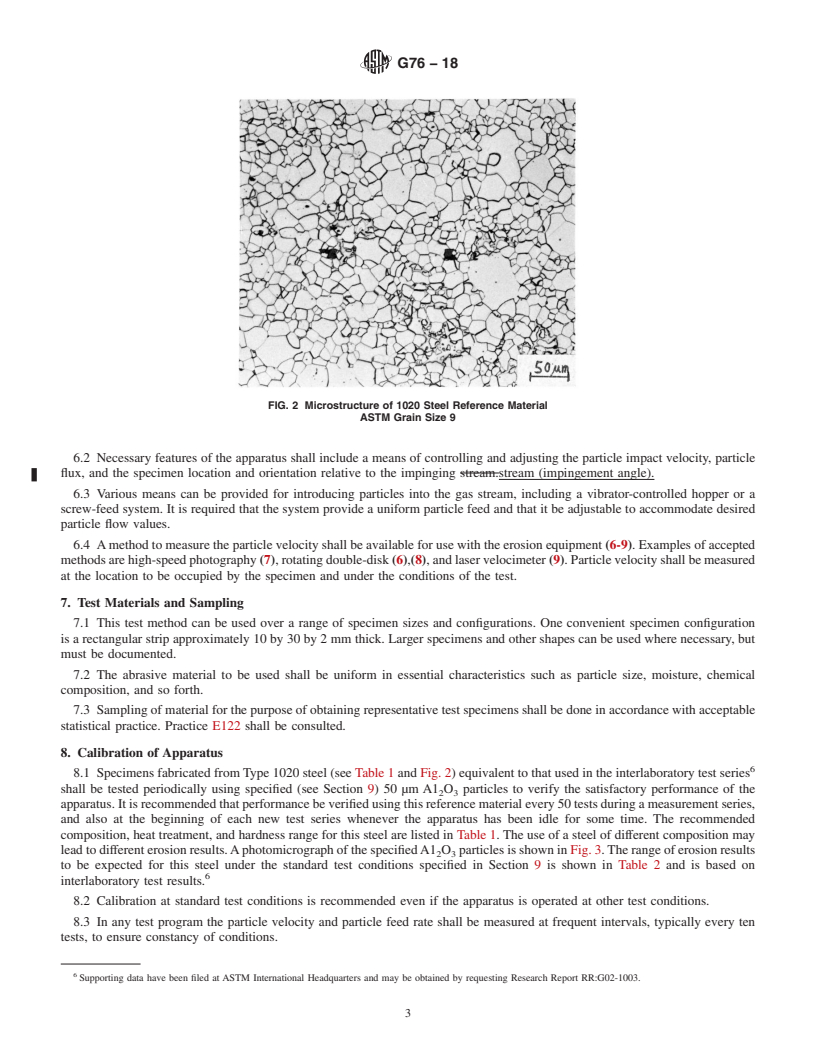

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.