ASTM D6556-21

(Test Method)Standard Test Method for Carbon Black-Total and External Surface Area by Nitrogen Adsorption

Standard Test Method for Carbon Black-Total and External Surface Area by Nitrogen Adsorption

SIGNIFICANCE AND USE

4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores, pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as the specific surface area that is accessible to rubber.

4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards.

SCOPE

1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical thickness surface area method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye and face protection).

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D6556-21 is a standard published by ASTM International. Its full title is "Standard Test Method for Carbon Black-Total and External Surface Area by Nitrogen Adsorption". This standard covers: SIGNIFICANCE AND USE 4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores, pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as the specific surface area that is accessible to rubber. 4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards. SCOPE 1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical thickness surface area method. 1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye and face protection). 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores, pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as the specific surface area that is accessible to rubber. 4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards. SCOPE 1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical thickness surface area method. 1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye and face protection). 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D6556-21 is classified under the following ICS (International Classification for Standards) categories: 71.060.10 - Chemical elements. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D6556-21 has the following relationships with other standards: It is inter standard links to ASTM D1900-06(2015), ASTM D1799-03a(2014), ASTM D1900-06(2011), ASTM D1799-03a(2008), ASTM D1900-06, ASTM D3765-04, ASTM D1799-03a, ASTM D3765-03a, ASTM D3765-03, ASTM D1799-03, ASTM D3765-02, ASTM D1799-02, ASTM D3765-99, ASTM D1799-93(1997), ASTM D1900-94(2002). Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D6556-21 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6556 − 21

Standard Test Method for

Carbon Black—Total and External Surface Area by Nitrogen

Adsorption

This standard is issued under the fixed designation D6556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3765Test Method for Carbon Black—CTAB (Cetyltrim-

ethylammonium Bromide) Surface Area (Withdrawn

1.1 This test method covers the determination of the total

2007)

surfaceareabytheBrunauer,Emmett,andTeller(B.E.T.NSA)

D4483Practice for Evaluating Precision for Test Method

theory of multilayer gas adsorption behavior using multipoint

StandardsintheRubberandCarbonBlackManufacturing

determinations and the external surface area based on the

Industries

statistical thickness surface area method.

3. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

3.1 The total and external surface areas are measured by

standard. The values given in parentheses are for information

evaluating the amount of nitrogen adsorbed, at liquid nitrogen

only.

temperature, by a carbon black at several partial pressures of

1.3 This standard does not purport to address all of the

nitrogen. The adsorption data is used to calculate the NSAand

safety concerns, if any, associated with its use. It is the

STSA values.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 This test method is used to measure the total and

(The minimum safety equipment should include protective

external surface area of carbon blacks based on multipoint

gloves, sturdy eye and face protection).

nitrogen adsorption. The NSA measurement is based on the

B.E.T.theoryanditincludesthetotalsurfacearea,inclusiveof

1.4 This international standard was developed in accor-

micropores,porediameterslessthan2nm(20Å).Theexternal

dance with internationally recognized principles on standard-

surfacearea,basedonthestatisticalthicknessmethod(STSA),

ization established in the Decision on Principles for the

is defined as the specific surface area that is accessible to

Development of International Standards, Guides and Recom-

rubber.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 4.2 CTAB SurfaceArea (formerly Test Method D3765) has

been withdrawn. The CTAB value may be estimated from the

STSA value using Eq 1. The equation is based on a linear

2. Referenced Documents

regressionoftheSTSAandCTABmeasuredvaluesoftheSRB

2.1 ASTM Standards:

5 standards.

D1799 Practice for Carbon Black—Sampling Packaged

CTAB 5STSA*1.017012.6434 (1)

Shipments

D1900Practice for Carbon Black—Sampling Bulk Ship-

5. Apparatus

ments

5.1 MultipointStatic-VolumetricGasAdsorptionApparatus,

with Dewar flasks and all other accessories required for

operation.

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

5.2 Sample Cells, that when attached to the adsorption

Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black

Surface Area and Related Properties. apparatus, will maintain isolation of the sample from the

–5 3

CurrenteditionapprovedMay1,2021.PublishedJuly2021.Originallyapproved

atmosphere equivalent to a helium leak rate of <10 cm /min,

in 2000. Last previous edition approved in 2019 as D6556–19a. DOI: 10.1520/

per atmosphere of pressure difference.

D6556-21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6556 − 21

5.3 Balance, Analytical, with 0.1 mg sensitivity. especially if moisture exposure has been minimal. In these

cases, the minimum time that gives a stable surface area shall

5.4 Heating Mantle or Equivalent, capable of maintaining a

be the minimum time used for degassing. It will be necessary

temperature of 300 6 10°C.

to determine these minimum times for each grade of carbon

5.5 Oven, Gravity Convection, capable of maintaining a

black.

temperature of 125 6 10°C.

8.4.4 After degassing, the sample tube may be moved

directly to the analyzer. Otherwise, remove the sample tube

6. Reagents

fromtheheatsourceandcontinuetheflowofpurginggasuntil

it is ready for analysis.

6.1 Liquid Nitrogen, 98% or higher purity.

8.4.5 Go directly to Section 9 and continue the remaining

6.2 Ultra-High Purity Nitrogen Gas, cylinder or other

steps of the procedure.

source of prepurified nitrogen gas.

8.5 Vacuum Degassing:

6.3 Ultra-High Purity Helium Gas, cylinder or other source

8.5.1 With the apparatus at atmospheric pressure, place the

of prepurified helium gas.

sample cell containing the carbon black onto the degassing

apparatus.

7. Sampling

8.5.2 Begin the degassing procedure as appropriate for the

7.1 Samples may be taken in accordance with Practices

apparatus.

D1799 and D1900.

8.5.3 Place a heating mantle or other source of heat around

the sample cell and degas the sample at 300 6 10°C for ⁄2 h

8. Sample Preparation Procedure

orlongerasrequiredtoobtainandholdapressurelessthan1.4

8.1 Dry a portion of carbon black at 125°C for 1 h. If the Pa (10 µm Hg).

carbon black is known to be substantially free of moisture, or

NOTE 3—Attention! One-half hour vacuum degassing may be inad-

subsequent preparation steps are known to be adequate for

equate for some grades and may result in statistically different results to

moisture removal, then this step may be omitted.

flow degassing.

8.2 Condition an empty sample cell for a minimum of 10

8.5.4 Once the typical degassing times have been

min at the same conditions intended for degassing the sample.

determined, future samples can be degassed on the basis of

Weigh the empty sample cell to the nearest 0.1 mg and record

time alone, if desired, allowing a reasonable margin of excess

the mass.

time. Some samples will be found to require less than ⁄2 h,

especially if moisture exposure has been minimal. In these

8.3 Weigh approximately 0.4 g of the carbon black into the

cases, the minimum time that gives a stable surface area shall

sample cell.

be the minimum time used for degassing (see Note 2). It will

NOTE 1—For carbon black powder samples, add enough carbon black

benecessarytodeterminetheseminimumtimesforeachgrade

to give a depth of approximately 2 in. in straight wall sample tubes, or

of carbon black.

approximately 0.4 g for bulb-type sample cells.

8.5.5 Go directly to Section 9 and continue the remaining

8.4 Flow Degassing:

steps of the procedure.

8.4.1 Openthegascontrolvalveandinsertthedeliverytube

into the sample tube, through the sample bed, and allow

9. Measurement Procedure

purging with nitrogen for a minimum of 1 min.

9.1 Refertotheuser’smanualorspecificinstructionsforthe

8.4.2 Place a heating mantle or other source of heat around

multipoint gas adsorption analyzer to be used, and become

the sample cell and degas the sample at 300 6 10°C for ⁄2 h

thoroughly familiar with the procedures. There are numerous

orlongertoensurethatalltracesofmoisturecondensinginthe

instruments available that offer a variety of saturation vapor

top of the tube are absent. The minimum degassing time that

pressure(P )measurementoptionsandDewarsizes.Followall

gives a stable surface area (that is, a surface area that does not

o

manufacturer’sspecificrecommendationsforfreespaceandP

increase with additional degassing) shall be the minimum time

o

measurement options to obtain reliable NSAand STSAvalues.

usedfordegassing.Failuretodosowillleadtounderreporting

of the NSA and STSA values for the sample under test.

9.2 FilltheDewarwithliquidnitrogen(LN2)andallowitto

reach temperature equilibrium. The Dewar shall be refilled

NOTE 2—For carbon blacks at their moisture pickup equilibrium, like

standard reference blacks that have been exposed to atmospheric approximately once per hour or between each analysis. The

conditions, longer degassing times likely will be required in order to

time required to reach equilibrium is dependent upon Dewar

achieve stable results. It has been found that for SRB-8B, SRB-8C, and

size and quality. Consult the manufacturer’s recommendations

SRB-9C, it is necessary to extend the degassing time to at least 60 min in

for Dewar equilibration times and conditions.

ordertoreliablyobtainthetargetNSAandSTSAvalues.Thismaybetrue

9.2.1 Small Dewar (<1 L)—Fill and cover the Dewar for a

for other high structure and high porosity carbon blacks.Again, failure to

fully degas the carbon black will result in underreporting of NSA and minimumof2hpriortouse.TheDewarshouldbecleanedand

STSA values.

dried at the end of each day.

8.4.3 Once the typical degassing times have been 9.2.2 Large Dewar (>1 L)—Fill and cover the Dewar for a

determined, future samples can be degassed on the basis of minimum of 16 h prior to use, unless continuous P measure-

o

time alone, if desired, allowing a reasonable margin of excess ments are employed. For continuous P , use a 2-h Dewar

o

time. Some samples will be found to require less than ⁄2 h, equilibration. Once equilibration is reached, a large Dewar can

D6556 − 21

maintain this equilibration for several days if kept filled and ingNSA/STSAanalyses.AP valueof1.3to2.6kPa(10to20

o

covered. The cleaning frequency is left to the discretion of the mm Hg) above atmospheric pressure and two consecutive P

o

operator, but is not to exceed once per week. Consult the values that differ by no more that 0.13 kPa (1 mm Hg) over a

manufacturer’s recommendations for Dewar cleaning. 10-min time period are indications of a stable Dewar. Experi-

ence will teach the operator about expected differences in P

o

9.3 Following is a list of P measurement options, listed in

o

and atmospheric pressure in their laboratory.

decreasing order of reliability of P values. Follow all manu-

o

facturer’srecommendationsfordeterminationofP valuesthat

o

NOTE 4—Aminimum wait time of 10 min is recommended between P

o

are to be used for NSA and STSA calculations. measurements, as immersing the P cell into the LN2 disrupts the

o

temperature equilibration. P measurements taken at short intervals will

9.3.1 Continuous P (measurement at each relative pressure

o

o

result in erroneously high and unstable values.

point)—This method is considered the best practice. When

available with the instrument and software package, it is

9.5 Determinethefreespaceofthesamplecellbymeasure-

recommended to use this option.

ment with helium or by calculation using an assumed carbon

9.3.2 Single P Per Analysis—Although this value can be

black density of 1.9 g/cm . For calculated sample free space,

o

measured before, during, or after the analysis, a P value

the free space of the empty sample cells must be known,

o

measured at the end of the analysis is preferred, since STSAis

generally from an analysis with empty sample cells. The free

calculatedfromthelastdatapointsacquiredandissignificantly

space for each cell must be determined for some cell designs.

influenced by P values. This method requires that a P value

Follow all manufacturer’s recommendations for obtaining

o o

be determined prior to initiating any measurements to ensure

optimumfreespacevalues,whethermeasureddirectlyoverthe

equilibrium of the Dewar as described in 9.4. Subsequently, a

sample, or calculated using the free space volume of the

new P value is measured for each analysis, which is used for

sample cells, along with the sample mass and density. Follow

o

calculating NSA/STSA values.

all manufacturer’s recommendations for maintaining stable,

9.3.3 Daily P —This method is used when evidence of a

and perhaps minimized, free space values, for example, by

o

stableDewarispresentandnochangesinatmosphericpressure

using filler rods.

greater than 0.13 kPa (1 mm Hg) occur.

9.6 Obtain a minimum of five data points evenly spaced in

9.3.4 Calculated P —This method calculates a P value by

o o

the 0.1 to 0.5 relative pressure (P/P ) range. For some tread

o

measuring atmospheric pressure and adding a value between

carbon blacks, particularly N100 and N200 series, it is neces-

1.3 and 2.6 kPa (10 and 20 mm Hg). The operator is

sary to measure two additional data points, 0.05 and 0.075, in

responsible for determining the constant used in their labora-

ordertoincreasetheaccuracyoftheNSAmeasurement.Adata

tory; however, 2.0 kPa (15 mm Hg) is most commonly used.

point consists of the relative pressure of equilibrium and the

9.4 WiththeexceptionofcontinuousP measurements,itis

o

total amount of nitrogen gas adsorbed by the sample at that

recommended that the P value be determined prior to initiat-

o relative pressure.

9.7 Determine the mass of the cell with dry sample to the

TABLE 1 Example of NSA Data Analysis

A nearest 0.1 mg. This may be done before or after measuring

N121

Raw Data Calculation nitrogen adsorption.Avoid inconsistent use of helium, particu-

Vol. Ads., Rel. Press. Correlation NSA,

larlywhenbackfillingattheendofdegassingorananalysis,as

3 2

P/Po cm /g Range Coefficient m /g

a buoyancy error of 1 mg/cm of cell volume can occur.As an

0.0500 26.716 . . . . . . . . .

0.1000 29.753 . . . . . . . . .

alternative, the carbon black mass may be determined directly

0.1500 32.313 0.05–0.15 0.999981 123.9

by pouring it from the sample cell into a tared weighing pan,

0.2000 34.692 0.05–0.20 0.999992 124.0

taking care to remove all of the carbon black.

0.2500 37.110 0.05–0.25 0.999990 123.6

0.3000 39.641 0.05–0.30 0.999935 122.8

B

N326

10. Calculation

Raw Data Calculation

Vol. Ads., Rel. Press. Correlation NSA,

10.1 Most automated instruments will per

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6556 − 19a D6556 − 21

Standard Test Method for

Carbon Black—Total and External Surface Area by Nitrogen

Adsorption

This standard is issued under the fixed designation D6556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory

of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical

thickness surface area method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye and face

protection).

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D3765 Test Method for Carbon Black—CTAB (Cetyltrimethylammonium Bromide) Surface Area (Withdrawn 2007)

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Summary of Test Method

3.1 The total and external surface areas are measured by evaluating the amount of nitrogen adsorbed, at liquid nitrogen

temperature, by a carbon black at several partial pressures of nitrogen. The adsorption data is used to calculate the NSA and STSA

values.

4. Significance and Use

4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black Surface

Area and Related Properties.

Current edition approved Dec. 15, 2019May 1, 2021. Published January 2020July 2021. Originally approved in 2000. Last previous edition approved in 2019 as

D6556 – 19.D6556 – 19a. DOI: 10.1520/D6556-19A.10.1520/D6556-21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6556 − 21

adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores,

pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as

the specific surface area that is accessible to rubber.

4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA

value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards.

CTAB 5 STSA*1.017012.6434 (1)

5. Apparatus

5.1 Multipoint Static-Volumetric Gas Adsorption Apparatus, with Dewar flasks and all other accessories required for operation.

5.2 Sample Cells, that when attached to the adsorption apparatus, will maintain isolation of the sample from the atmosphere

–5 3

equivalent to a helium leak rate of <10 cm /min, per atmosphere of pressure difference.

5.3 Balance, Analytical, with 0.1 mg sensitivity.

5.4 Heating Mantle or Equivalent, capable of maintaining a temperature of 300 6 10°C.

5.5 Oven, Gravity Convection, capable of maintaining a temperature of 125 6 10°C.

6. Reagents

6.1 Liquid Nitrogen, 98 % or higher purity.

6.2 Ultra-High Purity Nitrogen Gas, cylinder or other source of prepurified nitrogen gas.

6.3 Ultra-High Purity Helium Gas, cylinder or other source of prepurified helium gas.

7. Sampling

7.1 Samples may be taken in accordance with Practices D1799 and D1900.

8. Sample Preparation Procedure

8.1 Dry a portion of carbon black at 125°C for 1 h. If the carbon black is known to be substantially free of moisture, or subsequent

preparation steps are known to be adequate for moisture removal, then this step may be omitted.

8.2 Condition an empty sample cell for a minimum of 10 min at the same conditions intended for degassing the sample. Weigh

the empty sample cell to the nearest 0.1 mg and record the mass.

8.3 Weigh approximately 0.4 g of the carbon black into the sample cell.

NOTE 1—For carbon black powder samples, add enough carbon black to give a depth of approximately 2 in. in straight wall sample tubes, or

approximately 0.4 g for bulb-type sample cells.

8.4 Flow Degassing:

8.4.1 Open the gas control valve and insert the delivery tube into the sample tube, through the sample bed, and allow purging with

nitrogen for a minimum of 1 min.

8.4.2 Place a heating mantle or other source of heat around the sample cell and degas the sample at 300 6 10°C for ⁄2 h or longer

to ensure that all traces of moisture condensing in the top of the tube are absent. The minimum degassing time that gives a stable

surface area (that is, a surface area that does not increase with additional degassing) shall be the minimum time used for degassing.

Failure to do so will lead to underreporting of the NSA and STSA values for the sample under test.

D6556 − 21

NOTE 2—For carbon blacks at their moisture pickup equilibrium, like standard reference blacks that have been exposed to atmospheric conditions, longer

degassing times likely will be required in order to achieve stable results. It has been found that for SRB-8B, SRB-8C, and SRB-9C, it is necessary to

extend the degassing time to at least 60 min in order to reliably obtain the target NSA and STSA values. This may be true for other high structure and

high porosity carbon blacks. Again, failure to fully degas the carbon black will result in underreporting of NSA and STSA values.

8.4.3 Once the typical degassing times have been determined, future samples can be degassed on the basis of time alone, if desired,

allowing a reasonable margin of excess time. Some samples will be found to require less than ⁄2 h, especially if moisture exposure

has been minimal. In these cases, the minimum time that gives a stable surface area shall be the minimum time used for degassing.

It will be necessary to determine these minimum times for each grade of carbon black.

8.4.4 After degassing, the sample tube may be moved directly to the analyzer. Otherwise, remove the sample tube from the heat

source and continue the flow of purging gas until it is ready for analysis.

8.4.5 Go directly to Section 9 and continue the remaining steps of the procedure.

8.5 Vacuum Degassing:

8.5.1 With the apparatus at atmospheric pressure, place the sample cell containing the carbon black onto the degassing apparatus.

8.5.2 Begin the degassing procedure as appropriate for the apparatus.

8.5.3 Place a heating mantle or other source of heat around the sample cell and degas the sample at 300 6 10°C for ⁄2 h or longer

as required to obtain and hold a pressure less than 1.4 Pa (10 μm Hg).

NOTE 3—Attention! One-half hour vacuum degassing may be inadequate for some grades and may result in statistically different results to flow degassing.

8.5.4 Once the typical degassing times have been determined, future samples can be degassed on the basis of time alone, if desired,

allowing a reasonable margin of excess time. Some samples will be found to require less than ⁄2 h, especially if moisture exposure

has been minimal. In these cases, the minimum time that gives a stable surface area shall be the minimum time used for degassing

(see Note 2). It will be necessary to determine these minimum times for each grade of carbon black.

8.5.5 Go directly to Section 9 and continue the remaining steps of the procedure.

9. Measurement Procedure

9.1 Refer to the user’s manual or specific instructions for the multipoint gas adsorption analyzer to be used, and become

thoroughly familiar with the procedures. There are numerous instruments available that offer a variety of saturation vapor pressure

(P ) measurement options and Dewar sizes. Follow all manufacturer’s specific recommendations for free space and P

o o

measurement options to obtain reliable NSA and STSA values.

9.2 Fill the Dewar with liquid nitrogen (LN2) and allow it to reach temperature equilibrium. The Dewar shall be refilled

approximately once per hour or between each analysis. The time required to reach equilibrium is dependent upon Dewar size and

quality. Consult the manufacturer’s recommendations for Dewar equilibration times and conditions.

9.2.1 Small Dewar (<1 L)—Fill and cover the Dewar for a minimum of 2 h prior to use. The Dewar should be cleaned and dried

at the end of each day.

9.2.2 Large Dewar (>1 L)—Fill and cover the Dewar for a minimum of 16 h prior to use, unless continuous P measurements are

o

employed. For continuous P , use a 2-h Dewar equilibration. Once equilibration is reached, a large Dewar can maintain this

o

equilibration for several days if kept filled and covered. The cleaning frequency is left to the discretion of the operator, but is not

to exceed once per week. Consult the manufacturer’s recommendations for Dewar cleaning.

9.3 Following is a list of P measurement options, listed in decreasing order of reliability of P values. Follow all manufacturer’s

o o

recommendations for determination of P values that are to be used for NSA and STSA calculations.

o

D6556 − 21

9.3.1 Continuous P (measurement at each relative pressure point)—This method is considered the best practice. When available

o

with the instrument and software package, it is recommended to use this option.

9.3.2 Single P Per Analysis—Although this value can be measured before, during, or after the analysis, a P value measured at

o o

the end of the analysis is preferred, since STSA is calculated from the last data points acquired and is significantly influenced by

P values. This method requires that a P value be determined prior to initiating any measurements to ensure equilibrium of the

o o

Dewar as described in 9.4. Subsequently, a new P value is measured for each analysis, which is used for calculating NSA/STSA

o

values.

9.3.3 Daily P —This method is used when evidence of a stable Dewar is present and no changes in atmospheric pressure greater

o

than 0.13 kPa (1 mm Hg) occur.

9.3.4 Calculated P —This method calculates a P value by measuring atmospheric pressure and adding a value between 1.3 and

o o

2.6 kPa (10 and 20 mm Hg). The operator is responsible for determining the constant used in their laboratory; however, 2.0 kPa

(15 mm Hg) is most commonly used.

9.4 With the exception of continuous P measurements, it is recommended that the P value be determined prior to initiating

o o

NSA/STSA analyses. A P value of 1.3 to 2.6 kPa (10 to 20 mm Hg) above atmospheric pressure and two consecutive P values

o o

that differ by no more that 0.13 kPa (1 mm Hg) over a 10-min time period are indications of a stable Dewar. Experience will teach

the operator about expected differences in P and atmospheric pressure in their laboratory.

o

NOTE 4—A minimum wait time of 10 min is recommended between P measurements, as immersing the P cell into the LN2 disrupts the temperature

o o

equilibration. P measurements taken at short intervals will result in erroneously high and unstable values.

o

9.5 Determine the free space of the sample cell by measurement with helium or by calculation using an assumed carbon black

density of 1.9 g/cm . For calculated sample free space, the free space of the empty sample cells must be known, generally from

an analysis with empty sample cells. The free space for each cell must be determined for some cell designs. Follow all

manufacturer’s recommendations for obtaining optimum free space values, whether measured directly over the sample, or

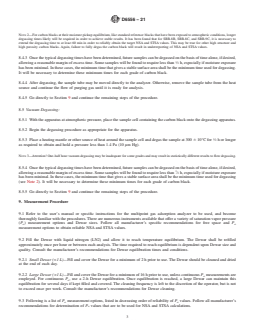

TABLE 1 Example of NSA Data Analysis

A

N121

Raw Data Calculation

Vol. Ads., Rel. Press. Correlation NSA,

3 2

P/Po cm /g Range Coefficient m /g

0.0500 26.716 . . . . . . . . .

0.1000 29.753 . . . . . . . . .

0.1500 32.313 0.05–0.15 0.999981 123.9

0.2000 34.692 0.05–0.20 0.999992 124.0

0.2500 37.110 0.05–0.25 0.999990 123.6

0.3000 39.641 0.05–0.30 0.999935 122.8

B

N326

Raw Data Calculation

Vol. Ads., Rel. Press. Correlation NSA,

3 2

P/Po cm /g Range Coefficient m /g

0.0500 16.675 . . . . . . . . .

0.1000 18.318 . . . . . . . . .

0.1500 19.859 0.05–0.15 0.999960 75.6

0.2000 21.426 0.05–0.20 0.999948 76.3

0.2500 23.035 0.05–0.25 0.999964 76.6

0.3000 24.751 0.05–0.30 0.999979 76.6

B

N683

Raw Data Calculation

Vol. Ads., Rel. Press. Correlation NSA,

3 2

P/Po cm /g Range Coefficient m /g

0.0500 8.194 . . . . . . . . .

0.1000 9.113 . . . . . . . . .

0.1500 9.945 0.05–0.15 0.999939 38.2

0.2000 10.739 0.05–0.20 0.999950 38.5

0.2500 11.543 0.05–0.25 0.999972 38.6

0.3000 12.364 0.05–0.30 0.999973 38.4

A

The most accurate NSA is measured between 0.05 and 0.20 relative pressure.

B

The most accurate NSA is measured between 0.05 and 0.30 relative pressure.

D6556 − 21

calculated using the free space volume of the sample cells, along with the sample mass and density. Follow all manufacturer’s

recommendations for maintaining stable, and perhaps minimized, free space values, for example, by using filler rods.

9.6 Obtain a minimum of five data points evenly spaced in the 0.1 to 0.5 relative pressure (P/P ) range. For some tread carbon

o

blacks, particularly N100 and N200 series, it is necessary to measure two additional data points, 0.05 and 0.075, in order to increase

the accuracy of the NSA measurement. A data point consists of the relative pressure of equilibrium and the total amount of nitrogen

gas adsorbed by the sample at that relative pressure.

9.7 Determine the mass of the cell with dry sample to the nearest 0.1 mg. This may be done before or after measuring nitrogen

adsorption. Avoid inconsistent use of helium, particularly when backfilling at the end of degassing or an analysis, as a buoyancy

error of 1 mg/cm of cell volume can occur. As an alternative, the carbon black mass may be determined direct

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...