ASTM D5846-07(2012)

(Test Method)Standard Test Method for Universal Oxidation Test for Hydraulic and Turbine Oils Using the Universal Oxidation Test Apparatus

Standard Test Method for Universal Oxidation Test for Hydraulic and Turbine Oils Using the Universal Oxidation Test Apparatus

SIGNIFICANCE AND USE

5.1 Degradation of hydraulic fluids and turbine oils, because of oxidation or thermal breakdown, can result in the formation of acids or insoluble solids and render the oil unfit for further use.

5.2 This test method can be used to estimate the relative oxidation stability of petroleum-base oils. It should be recognized that correlation between results of this test and the oxidation stability in use can vary markedly with service conditions and with various oils.

SCOPE

1.1 This test method covers a procedure for evaluating the oxidation stability of petroleum base hydraulic oils and oils for steam and gas turbines.

1.2 This test method was developed to evaluate the oxidation stability of petroleum base hydraulic oils and oils for steam and gas turbines.

1.2.1 Rust and oxidation inhibited hydraulic, anti-wear hydraulic and turbine oils of ISO 32–68 viscosity were used to develop the precision statement. This test method has been used to evaluate the oxidation stability of fluids made with synthetic basestock and in-service oils; however, these fluids have not been used in cooperative testing to develop precision data.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Identified hazardous chemicals are listed in 7.3, 7.6, and 7.8. Before using this test method, refer to suppliers' safety labels, Material Safety Data Sheets, and other technical literature.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5846 − 07 (Reapproved 2012)

Standard Test Method for

Universal Oxidation Test for Hydraulic and Turbine Oils

Using the Universal Oxidation Test Apparatus

This standard is issued under the fixed designation D5846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D664Test Method for Acid Number of Petroleum Products

by Potentiometric Titration

1.1 This test method covers a procedure for evaluating the

D943TestMethodforOxidationCharacteristicsofInhibited

oxidationstabilityofpetroleumbasehydraulicoilsandoilsfor

Mineral Oils

steam and gas turbines.

D974Test Method for Acid and Base Number by Color-

1.2 This test method was developed to evaluate the oxida-

Indicator Titration

tion stability of petroleum base hydraulic oils and oils for

D3339TestMethodforAcidNumberofPetroleumProducts

steam and gas turbines.

by Semi-Micro Color Indicator Titration

1.2.1 Rust and oxidation inhibited hydraulic, anti-wear hy-

D4057Practice for Manual Sampling of Petroleum and

draulic and turbine oils of ISO 32–68 viscosity were used to

Petroleum Products

develop the precision statement. This test method has been

D4740Test Method for Cleanliness and Compatibility of

used to evaluate the oxidation stability of fluids made with

Residual Fuels by Spot Test

synthetic basestock and in-service oils; however, these fluids

D4871Guide for Universal Oxidation/Thermal Stability

have not been used in cooperative testing to develop precision

Test Apparatus

data.

D5770Test Method for Semiquantitative Micro Determina-

tion of Acid Number of Lubricating Oils During Oxida-

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information tion Testing

only.

2.2 Energy Institute Standard:

1.4 This standard does not purport to address all of the IP 2546 Practice for Sampling of Petroleum Products;

alternate to Practice D4057

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2.3 British Standard:

priate safety and health practices and determine the applica-

BS 1829Specification for Carbon Steel Wire; alternate to

bility of regulatory limitations prior to use. Identified hazard-

Specification A510

ous chemicals are listed in 7.3, 7.6, and 7.8. Before using this

2.4 ASTM Adjuncts:

test method, refer to suppliers’ safety labels, Material Safety

Reference Spot Sheet

Data Sheets, and other technical literature.

3. Terminology

2. Referenced Documents

2 3.1 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.1.1 inhibited mineral oil, n—a petroleum oil containing

A510SpecificationforGeneralRequirementsforWireRods

additives to retard oxidation.

and Coarse Round Wire, Carbon Steel

3.1.2 oxidation life, n—of an oil, the time in hours required

B1Specification for Hard-Drawn Copper Wire

for degradation of the oil under test.

3.1.3 universal oxidation test, n—the apparatus and proce-

dures described in Guide D4871.

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

D02.09.0D on Oxidation of Lubricants.

Current edition approved Dec. 1, 2012. Published December 2012. Originally

approved in 1995. Last previous edition approved in 2007 as D5846–07. DOI: Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

10.1520/D5846-07R12. U.K., http://www.energyinst.org.uk.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM London W4 4AL, U.K., http://www.bsi-global.com.

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD4740. Original adjunct produced in 2000.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5846 − 07 (2012)

FIG. 1 Apparatus, Showing Gas Flow Control System, Temperature Control System, and Heating Block

4. Summary of Test Method oxidation stability in use can vary markedly with service

conditions and with various oils.

4.1 An oil sample is contacted with air at 135°C in the

presence of copper and iron metals. The acid number and spot

6. Apparatus

forming tendency of the oil are measured daily. The test is

6.1 Heating Block, as shown on the right in Fig. 1, and as

terminated when the oxidation life of the oil has been reached.

further described in Guide D4871, to provide a controlled

4.2 Theoilisconsideredtobedegradedwheneitheritsacid

constant temperature for conducting the test.

number (measured by Test Methods D974 or D664) has

6.1.1 Test cells are maintained at a constant elevated tem-

increased by 0.5 mg KOH/g over that of new oil; or when the

perature by means of a heated aluminum block which sur-

oil begins to form insoluble solids so that when a drop of oil is

rounds each test cell.

placed onto a filter paper it shows a clearly defined dark spot

6.1.2 The test cells shall fit into the block to a depth of 225

surrounded by a ring of clear oil.

6 5 mm. When centered, the side clearance of the 38 mm

outside diameter glass tube to the holes in the aluminum block

5. Significance and Use

shall not exceed 1 mm in any direction.

5.1 Degradationofhydraulicfluidsandturbineoils,because

6.2 Temperature Control System, as shown at lower left in

of oxidation or thermal breakdown, can result in the formation

Fig. 1, and as further described in Guide D4871, to maintain

of acids or insoluble solids and render the oil unfit for further

thetestoilsintheheatingblockat135 60.5°Cfortheduration

use.

of the test.

5.2 This test method can be used to estimate the relative 6.3 Gas Flow Control System, as shown in the upper left in

oxidation stability of petroleum-base oils. It should be recog- Fig.1,andasfurtherdescribedinGuideD4871,toprovidedry

nized that correlation between results of this test and the air at a flow rate of 3.0 6 0.5 L/h to each test cell.

D5846 − 07 (2012)

taper, ground-glass inner joint, opening for gas inlet tube,

septum port for sample withdrawal, and exit tube to conduct

off-gases and entrained vapors. Overall length shall be 125 6

5 mm.

6.7 Test precision was developed using the universal

oxidation/thermal stability test apparatus described in Guide

6,7

D4871. Alternate apparatus designs for sample heating and

for temperature and flow control shall be acceptable provided

theyareshowntomaintaintemperatureandgasflowwithinthe

specified limits.

7. Reagents and Materials

7.1 Reagent grade chemicals shall be used in all tests.

Unless otherwise indicated, it is intended that all reagents

conform to the specifications of the Committee on Analytical

Reagents of the American Chemical Society, where such

specifications are available. Other grades may be used, pro-

vided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

the determination.

7.2 Abrasive Cloth, silicon carbide, 100-grit with cloth

backing.

7.3 Acetone, reagent grade. (Warning—Acetone is flam-

mable and a health hazard.)

7.4 Air, dry with dew point−60°.

7.5 Electrolytic Copper Wire, 1.63 mm in diameter (No. 14

AmericanWireGageorNo.16ImperialStandardWireGage),

99.9% purity, conforming to Specification B1, is preferred.

7.6 Heptane, knock-test grade, conforming to the following

requirements: (Warning—n—Heptane is flammable and a

health hazard.)

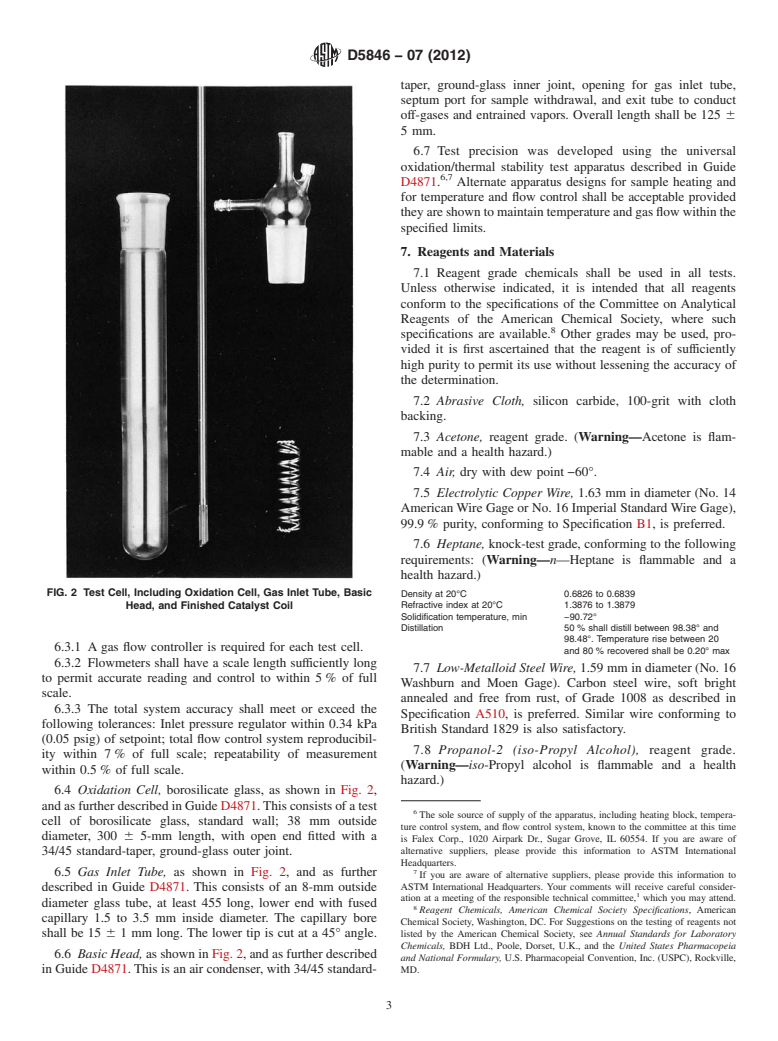

FIG. 2 Test Cell, Including Oxidation Cell, Gas Inlet Tube, Basic

Density at 20°C 0.6826 to 0.6839

Refractive index at 20°C 1.3876 to 1.3879

Head, and Finished Catalyst Coil

Solidification temperature, min −90.72°

Distillation 50 % shall distill between 98.38° and

98.48°. Temperature rise between 20

6.3.1 A gas flow controller is required for each test cell.

and 80 % recovered shall be 0.20° max

6.3.2 Flowmeters shall have a scale length sufficiently long

7.7 Low-Metalloid Steel Wire, 1.59 mm in diameter (No. 16

to permit accurate reading and control to within 5% of full

Washburn and Moen Gage). Carbon steel wire, soft bright

scale.

annealed and free from rust, of Grade 1008 as described in

6.3.3 The total system accuracy shall meet or exceed the

Specification A510, is preferred. Similar wire conforming to

following tolerances: Inlet pressure regulator within 0.34 kPa

British Standard1829 is also satisfactory.

(0.05 psig) of setpoint; total flow control system reproducibil-

7.8 Propanol-2 (iso-Propyl Alcohol), reagent grade.

ity within 7% of full scale; repeatability of measurement

(Warning—iso-Propyl alcohol is flammable and a health

within 0.5% of full scale.

hazard.)

6.4 Oxidation Cell, borosilicate glass, as shown in Fig. 2,

andasfurtherdescribedinGuideD4871.Thisconsistsofatest

The sole source of supply of the apparatus, including heating block, tempera-

cell of borosilicate glass, standard wall; 38 mm outside

ture control system, and flow control system, known to the committee at this time

diameter, 300 6 5-mm length, with open end fitted with a

is Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554. If you are aware of

alternative suppliers, please provide this information to ASTM International

34/45 standard-taper, ground-glass outer joint.

Headquarters.

6.5 Gas Inlet Tube, as shown in Fig. 2, and as further

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

described in Guide D4871. This consists of an 8-mm outside

ation at a meeting of the responsible technical committee, which you may attend.

diameter glass tube, at least 455 long, lower end with fused

Reagent Chemicals, American Chemical Society Specifications, American

capillary 1.5 to 3.5 mm inside diameter. The capillary bore

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

shall be 15 6 1 mm long. The lower tip is cut at a 45° angle. listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

6.6 Basic Head,asshowninFig.2,andasfurtherdescribed

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

inGuideD4871.Thisisanaircondenser,with34/45standard- MD.

D5846 − 07 (2012)

7.9 Test Paper, chromatographic or filter paper, cellulose, 9.3 Preparation of Catalyst Coil:

medium porosity, qualitative or quantitative grade. Cut the 9.3.1 Twisttheironandcopperwirestightlytogetheratone

paper into 50 mm squares or use as larger sheets, ruled with endforthreetwists.Withthetwowiresparallel,windthewires

7,9

hard pencil into 50 mm squares without cutting. around a cylindrical mandrel to produce a single coil 15.9 to

16.5 mm in inside diameter. The mandrel described in Test

NOTE 1—Paper sheets should be stored without folding, rolling, or

Method D943 is satisfactory, but other cylindrical metal or

bending, in a tightly closed container.

woodstockcanbeused.Removethecoilfromthemandreland

8. Sampling securethefreeendswiththreetwists.Bendthetwistedendsto

conform to the shape of the spiral coil. Stretch the coil to

8.1 Samplesforthistestcancomefromtanks,drums,small

produceafinishedcoilwithanoveralllengthof80 68mmas

containers, or operating equipment. Therefore, use the appli-

7,11

shown in Fig. 2.

cable apparatus and techniques described in Practice D4057 or

9.3.2 Store the catalyst coil in a dry, inert atmosphere until

IP 2546 to obtain suitable samples.

use. For storage up to 24 h, the coil can be stored in heptane.

8.2 Specialprecautionstopreservetheintegrityofasample

Before use, inspect stored coils to ensure that no corrosion

willnotnormallyberequired.Followgoodlaboratorypractice.

products or contaminating materials are present.

Avoid undue exposure of samples to sunlight or strong direct

9.4 Useafreshcatalystcoilforeachtest.Donotreusecoils.

light. Use only samples that are homogeneous on visual

inspection.

10. Procedure

10.1 Adjust the heating block to maintain the oil in the

9. Preparation of Apparatus

oxidation test cell at 135 6 0.5°C.

9.1 Cleaning Glassware:

10.1.1 Other test temperatures can be used but should be

9.1.1 Clean new glassware by washing with a hot detergent

specified.

solution, using a bristle brush; rinse thoroughly with tap water.

10.2 Weigh 100 6 1 g of test fluid into the oxidation test

When any visible deposits remain, soak with hot detergent

cell.

solution and repeat rinses.After final cleaning by soaking with

7,10

a suitable cleaning solution (Warning—Due to extreme

10.3 Place a cleaned catalyst coil in the oil and fit the basic

hazards, chromic acid cleaning solution is not recommended.),

headandgasdeliverytubeintothetestcellsothatthetipofthe

rinse thoroughly with tap water then distilled water and dry at

gas delivery tube rests on the bottom of the test cell inside the

room temperature or in an oven. A final rinse with iso-propyl

catalyst coil, as shown in Fig. 3.

alcohol or acetone will hasten drying at room temperature.

10.4 Insert the test cell into the preheated constant tempera-

9.1.2 Clean used glassware immediately following the end

tureblock.Wait0.5to1.0hfortheoiltowarmto135 60.5°C.

of a test. Drain the used oil completely. Rinse all glassware

10.5 Connect an air delivery tube from the flow control

with heptane to remove traces of oil.Then clean the glassware

systemtothegasinlettubeandadjusttheflowmetercontrolto

by the procedure described in 9.1.1 before re-use.

deliver dry air at 3 6 0.5 L/h. Record this time as the start of

9.2 Cleaning Catalyst:

the test.

9.2.1 Cleanequallengthsofironandcopperwirewithwads

10.6 Recheck the air flow and temperature after the test is

of absorbent cotton wet with heptane or other saturated

underway and at least once daily during the test. Adjust to

paraffinic solvent of comparable boiling point. Follow by

maintain the air flow and temperature as needed.

abrasionwith100-gritsiliconcarbideabrasiveclothuntilfresh

metal surfaces are exposed. Wipe with dry absorbent cotton to

NOTE 2—Exhaust gases need not be collected. Vent exhaust gases

remove loose particles of metal and abrasives. Repeat with properly.

fresh cotton until no particles are visible. In the following

10.7 Withdrawa2.0 60.2goilsamplefordeterminationof

operations, handle the catalyst with clean glov

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.