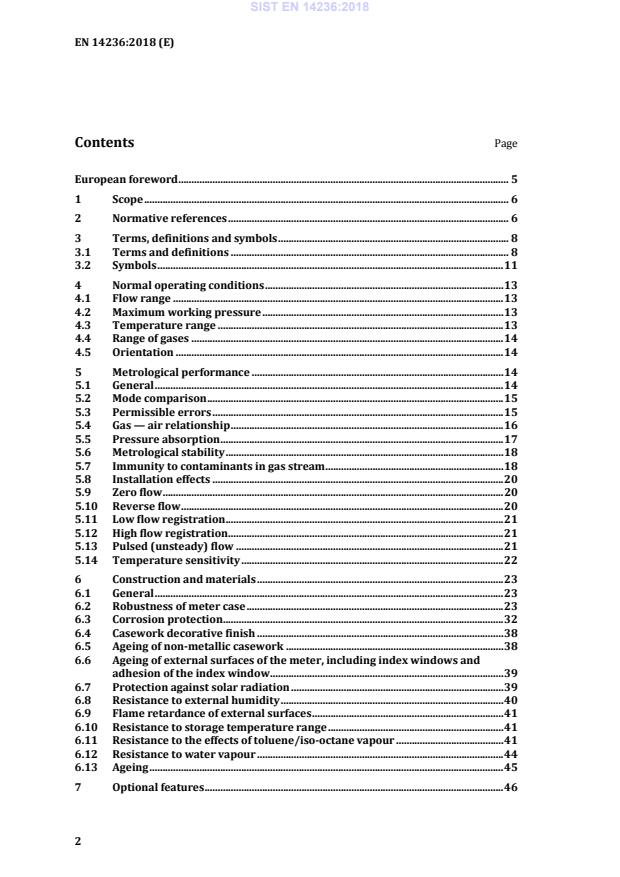

SIST EN 14236:2018

(Main)Ultrasonic domestic gas meters

Ultrasonic domestic gas meters

This European Standard specifies requirements and tests for the construction, performance and safety of class 1,0 and class 1,5 battery powered ultrasonic gas meters (hereinafter referred to as meters), having co-axial single pipe, or two pipe connections, used to measure volumes of distributed fuel gases of the second and/or third family, as given in EN 437, at maximum working pressures not exceeding 0,5 bar ) and maximum actual flow rates of up to 10 m3/h over a minimum ambient temperature range of -10 °C to +40 °C, and minimum gas temperature span of 40 K, for domestic applications. This European Standard applies to meters where the measuring element and the register(s) are enclosed in the same case.

This European Standard applies to meters with and without built-in temperature conversion, that are installed in locations with vibration and shocks of low significance and in

- closed locations (indoor or outdoor with protection as specified by the manufacturer) with condensing or with non-condensing humidity

or, if specified by the manufacturer,

- open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity

and in locations with electromagnetic disturbances.

Unless otherwise stated, all pressures given in this European Standard are gauge pressures.

When more than one meter type is submitted for testing, then each meter type is required to be tested against this European Standard.

Clauses 1 to 15 and Annex C are for design and type testing only.

NOTE See Annex A for production requirements.

Ultraschall-Haushaltsgaszähler

Diese Europäische Norm beschreibt die Anforderungen und Prüfungen hinsichtlich der Konstruktion, Funktion und Sicherheit von Klasse 1,0 und Klasse 1,5 batteriebetriebenen Ultraschallgaszählern (im Folgenden Zähler genannt), die einen gleichachsigen Einstutzen- oder Zweistutzenanschluss aufweisen und zur Volumenmessung von verteilten Brenngasen der zweiten und/oder dritten Gasfamilie, wie in EN 437 angegeben, bei maximalen Betriebsdrücken bis zu 0,5 bar ) und maximalen tatsächlichen Durchflüssen bis zu 10 m3/h bei einem Mindestumgebungstemperaturbereich von −10 °C bis +40 °C und einer Mindestgastemperaturspanne von 40 K für Haushaltsanwendungen eingesetzt werden. Diese Europäische Norm gilt für Zähler, bei denen das Messelement und das/die Zählwerke im selben Gehäuse untergebracht sind.

Diese Europäische Norm gilt für Zähler mit und ohne eingebaute Temperaturumwertung, die an Aufstellungsorten, die in geringem Ausmaß Schwingungen und Erschütterungen ausgesetzt sind, und

- an geschlossenen Aufstellungsorten (in Gebäuden oder im Freien mit vom Hersteller vorgeschriebenem Schutz) mit Betauung oder mit betauungsfreier Feuchte

oder, falls vom Hersteller angegeben,

- an offenen Aufstellungsorten (im Freien ohne Abdeckung) mit Betauung oder mit betauungsfreier Feuchte

und an Aufstellungsorten mit elektromagnetischen Störungen aufgestellt sind.

Soweit nicht anders angegeben, handelt es sich bei allen in dieser Europäischen Norm verwendeten Drücken um Überdrücke.

Wenn mehr als ein Zählertyp zur Prüfung eingereicht wird, ist es notwendig, jeden Zählertyp gegen diese Europäische Norm zu prüfen.

Die Abschnitte 1 bis 15 und Anhang C gelten nur für Bauart und Typprüfung.

ANMERKUNG Siehe Anhang A für Produktionsanforderungen.

Compteurs à gaz domestiques à ultrasons

La présente Norme européenne spécifie les exigences et essais de construction, de fonctionnement et de sécurité des compteurs de gaz à ultrasons alimentés par pile de classes 1,0 et 1,5 (ci-après appelés compteurs), ayant des connexions coaxiales à un seul tuyau ou à deux tuyaux, utilisés pour mesurer les volumes de combustibles gazeux distribués de la deuxième et/ou troisième familles, tels qu'indiquées dans l’EN 437, à des pressions maximales de service pouvant atteindre 0,5 bar ) et à des débits réels maximaux pouvant atteindre 10 m3/h sur une plage minimale de température ambiante de 10 °C à +40 °C et une plage minimale de température de gaz de 40 K, pour des applications domestiques. La présente Norme européenne s'applique à des compteurs dont l'élément de mesure et le ou les enregistreurs sont enfermés dans le même boîtier.

La présente Norme européenne s’applique aux compteurs avec ou sans dispositif intégré de compensation de température installés dans des endroits où les vibrations et les chocs sont peu importants et :

- dans des endroits fermés (à l’intérieur ou à l’extérieur avec la protection spécifiée par le fabricant) avec ou sans condensation d’humidité ;

ou, si le fabricant le spécifie ;

- dans des endroits ouverts (à l’extérieur sans protection) avec ou sans condensation d’humidité ;

ainsi que dans des endroits avec interférences électromagnétiques.

Sauf indication contraire, toutes les pressions fournies dans la présente Norme européenne sont des pressions relatives.

Lorsque plusieurs types de compteur sont soumis à essai, chaque type de compteur doit être soumis aux essais spécifiés dans la présente Norme européenne.

Les Articles 1 à 15 et l'Annexe C sont fournis uniquement pour la conception et les essais de type.

NOTE Se reporter à l'Annexe A pour les exigences liées à la production.

Ultrazvočni plinomeri za gospodinjstva

Samo za revizijo dodatka ZA in povezanega telesa besedila standarda EN 14236, da se zagotovi usklajenost z direktivo 2014/32/EU.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Aug-2017

- Publication Date

- 06-Nov-2018

- Technical Committee

- DPL - Gas supply

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Apr-2018

- Due Date

- 28-Jun-2018

- Completion Date

- 07-Nov-2018

Relations

- Effective Date

- 01-Dec-2018

Overview

SIST EN 14236:2018 is the European standard that specifies requirements and type tests for battery‑powered ultrasonic domestic gas meters. It covers class 1.0 and 1.5 ultrasonic meters with co‑axial single‑pipe or two‑pipe connections used to measure distributed fuel gases of the 2nd and/or 3rd family (per EN 437). The standard applies to meters with the measuring element and register enclosed in the same case, with maximum working pressures ≤ 0.5 bar and maximum actual flow rates up to 10 m3/h, designed for domestic applications over a minimum ambient range of -10 °C to +40 °C and a minimum gas temperature span of 40 K.

Key topics and technical requirements

- Metrological performance: Permissible errors, mode comparison, gas–air relationship, zero‑flow, low/high flow registration, pressure absorption and metrological stability.

- Construction and materials: Meter case robustness, corrosion protection, ageing of non‑metallic surfaces, resistance to humidity and solar radiation.

- Environmental and installation conditions: Ambient temperature, gas temperature span, vibration/shock (low significance), indoor/outdoor locations (manufacturer‑specified protection), condensing or non‑condensing humidity, and gauge pressure convention.

- Optional features: Built‑in gas temperature conversion, pressure measuring points, ancillary devices, and use in hazardous zones (where specified).

- Electromagnetic and acoustic immunity: Immunity to electromagnetic disturbances and ultrasonic (acoustic) noise interference.

- Indexing, marking and software: Display, recording, non‑volatile memory, marking durability, software requirements and testing.

- Communications & battery: Data ports (optical/galvanic), communications protocol, diagnostics, battery life and minimum operating voltage.

- Testing scope: Clauses 1–15 and Annex C cover type/design testing; Annex B addresses production requirements; Annex A provides guidance on test gases.

Practical applications and who uses it

SIST EN 14236:2018 is essential for:

- Gas meter manufacturers designing and certifying battery‑powered ultrasonic domestic meters.

- Test laboratories performing type testing and conformity assessment against European metrological and safety requirements.

- Gas utilities and metering service providers selecting compliant meters for residential billing and network deployment.

- Regulators, conformity bodies and procurement teams enforcing legal metrology and product safety.

- Product engineers integrating temperature conversion, communications or smart‑meter features while ensuring compliance.

Benefits include clear compliance criteria for accuracy, environmental robustness, electromagnetic compatibility and interoperability for modern domestic gas metering.

Related standards (select)

- EN 437 (classification of test gases)

- EU Measuring Instruments Directive (MID) 2014/32/EU (legal metrology)

- EN 60068 series (environmental testing)

- EN 60079 series (explosive atmospheres)

- EN 60086‑1 (primary batteries)

Keywords: SIST EN 14236:2018, ultrasonic domestic gas meters, ultrasonic gas meter standard, battery powered gas meters, gas meter metrology, EN 437, MID compliance.

Frequently Asked Questions

SIST EN 14236:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Ultrasonic domestic gas meters". This standard covers: This European Standard specifies requirements and tests for the construction, performance and safety of class 1,0 and class 1,5 battery powered ultrasonic gas meters (hereinafter referred to as meters), having co-axial single pipe, or two pipe connections, used to measure volumes of distributed fuel gases of the second and/or third family, as given in EN 437, at maximum working pressures not exceeding 0,5 bar ) and maximum actual flow rates of up to 10 m3/h over a minimum ambient temperature range of -10 °C to +40 °C, and minimum gas temperature span of 40 K, for domestic applications. This European Standard applies to meters where the measuring element and the register(s) are enclosed in the same case. This European Standard applies to meters with and without built-in temperature conversion, that are installed in locations with vibration and shocks of low significance and in - closed locations (indoor or outdoor with protection as specified by the manufacturer) with condensing or with non-condensing humidity or, if specified by the manufacturer, - open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity and in locations with electromagnetic disturbances. Unless otherwise stated, all pressures given in this European Standard are gauge pressures. When more than one meter type is submitted for testing, then each meter type is required to be tested against this European Standard. Clauses 1 to 15 and Annex C are for design and type testing only. NOTE See Annex A for production requirements.

This European Standard specifies requirements and tests for the construction, performance and safety of class 1,0 and class 1,5 battery powered ultrasonic gas meters (hereinafter referred to as meters), having co-axial single pipe, or two pipe connections, used to measure volumes of distributed fuel gases of the second and/or third family, as given in EN 437, at maximum working pressures not exceeding 0,5 bar ) and maximum actual flow rates of up to 10 m3/h over a minimum ambient temperature range of -10 °C to +40 °C, and minimum gas temperature span of 40 K, for domestic applications. This European Standard applies to meters where the measuring element and the register(s) are enclosed in the same case. This European Standard applies to meters with and without built-in temperature conversion, that are installed in locations with vibration and shocks of low significance and in - closed locations (indoor or outdoor with protection as specified by the manufacturer) with condensing or with non-condensing humidity or, if specified by the manufacturer, - open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity and in locations with electromagnetic disturbances. Unless otherwise stated, all pressures given in this European Standard are gauge pressures. When more than one meter type is submitted for testing, then each meter type is required to be tested against this European Standard. Clauses 1 to 15 and Annex C are for design and type testing only. NOTE See Annex A for production requirements.

SIST EN 14236:2018 is classified under the following ICS (International Classification for Standards) categories: 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14236:2018 has the following relationships with other standards: It is inter standard links to SIST EN 14236:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14236:2018 is associated with the following European legislation: EU Directives/Regulations: 2014/32/EU; Standardization Mandates: M/541. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14236:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ultraschall-HaushaltsgaszählerCompteurs à gaz domestiques à ultrasonsUltrasonic domestic gas meters91.140.40Sistemi za oskrbo s plinomGas supply systemsICS:Ta slovenski standard je istoveten z:EN 14236:2018SIST EN 14236:2018en,fr,de01-december-2018SIST EN 14236:2018SLOVENSKI

STANDARDSIST EN 14236:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14236

October

t r s z ICS

{ sä s v rä v r Supersedes EN

s v t u xã t r r yEnglish Version

Ultrasonic domestic gas meters Compteurs de gaz domestiques à ultrasons

UltraschallæHaushaltsgaszähler This European Standard was approved by CEN on

t r November

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v t u xã t r s z ESIST EN 14236:2018

Test gases . 66 A.1 General . 66 A.2 Test gas properties . 66 SIST EN 14236:2018

Production requirements for gas meters . 67 B.1 Specification . 67 B.2 Technical requirements . 67 B.3 Certificates of conformity . 67 Annex C (normative)

Meters with gas temperature conversion devices . 69 C.1 Scope . 69 C.2 Metrological performance . 69 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2014/32/EU Measuring Instruments Directive aimed to be covered . 73 Bibliography . 79

1) 1 bar = 1 000 mbar = 105 Pa. SIST EN 14236:2018

is the indicated volume in cubic metres (m3); Vc

is the volume in cubic metres (m3) that has actually flowed through the meter 3.1.8 external leak tightness leak tightness of the gas carrying components of the gas meter with respect to the atmosphere 3.1.9 flag single alphabetic character on the index giving a visual signal of significant events and/or change(s) in the operation of the meter 3.1.10 galvanic connection/interface hard wired serial connection or pulse output from the meter 3.1.11 index all that which is viewed through the index window, including the display 3.1.12 index window(s) area(s) of transparent material through which the index can be read 3.1.13 maximum error shift maximum mean error shift at any of the tested flow rates 3.1.14 maximum working pressure upper limit of the working pressure for which the meter has been designed, as declared by the manufacturer and marked on the index or the data plate 3.1.15 mean error arithmetic mean of consecutive errors of indication at a flow rate SIST EN 14236:2018

·

s w r

·

s r

·

sá t 1,0

·

s w r

·

w

·

sá t 4.2 Maximum working pressure The manufacturer shall declare the maximum working pressure of the meter and this pressure shall be marked on the index or data plate of the meter. This pressure shall not exceed 0,5 bar. 4.3 Temperature range Unless otherwise stated, all temperatures given in this document shall be measured to within ± 1 °C. All meters shall be capable of meeting the requirements for a minimum ambient temperature range of -10 °C to +40 °C (see 5.14), a minimum gas temperature span of 40 K and a storage SIST EN 14236:2018

¶ -20

¹C to

·

ª x r °C. The gas temperature range shall be within the ambient temperature range. The manufacturer shall declare the gas temperature range and the ambient temperature range. The manufacturer can declare a wider ambient temperature range using a minimum temperature of -10 °C, -25 °C or -40 °C and a maximum temperature of 40 °C, 55 °C or 70 °C and/or a wider storage temperature range. The meter shall be capable of meeting the requirements over this declared wider range. If the manufacturer declares that the meter is resistant to high ambient temperatures, the meter shall also be capable of meeting the requirements of the heat resistance test and shall be marked accordingly (see 7.2.1 and 9.1). 4.4 Range of gases 4.4.1 Test gases The manufacturer shall specify the range of gases for which the meter is suitable, from Table 3. Table 3 — Gas groups from EN 437 Second family Groups H L E Third family Groups P/B P B Additional Air

Meters suitable for: — second family gases shall be tested with air and 99,5 % CH4. — third family gases shall be tested with air and 99,5 % Propane and/or 99,5 % Butane, as appropriate. By agreement with the Test House any other test gas can be included. The additional gases shall be marked on the meter as defined in 9.1. NOTE For further information on test gases see Annex A. 4.5 Orientation Where meters can be installed in orientations other than with the connection ports vertical, meters shall be tested in those other orientations, for durability and as agreed with the Test House. 5 Metrological performance 5.1 General Provision shall be made for synchronizing the start and finish of test periods with test equipment, either via a galvanic connection or optical port. The test equipment shall generate an event that starts the test. The measured response (volume reading) from the meter shall be synchronous with its sampling instant. To achieve this, the meter shall delay its measured response until the next sample period after it has received a start command. SIST EN 14236:2018

¶ Q

¶ Qmax and 0,6 % for Qmin

¶ Q < Qt. If this requirement is not satisfied, subsequent tests shall be undertaken in the normal operating mode. 5.2.3 Test Test the meter in the standard mode and in the test-mode in accordance with 5.3.2 a). Calculate the difference in mean error at each flow rate. 5.3 Permissible errors 5.3.1 Requirements The meter, including any additional functionality devices intended by the manufacturer, shall have the error adjusted as close to zero as the adjustments allow, without systematically favouring any party. When tested in accordance with 5.3.2 a) the mean error shall be within the maximum permissible errors specified in Table 4 and the range of mean errors shall be within the limits specified in Table 5. When the errors between Qt and Qmax all have the same sign, they shall not exceed 1 % for class 1,5 and 0,5 % for class 1,0. When tested in accordance with 5.3.2 b) the mean error shall be within the maximum permissible errors specified in Table 4 and the range of mean errors shall be within the limits specified in Table 5 for each individual test gas at each test temperature. If the manufacturer has declared a wider ambient and gas temperature range, then the extreme temperatures declared shall be substituted for -10 °C and +40 °C, as appropriate. After the meter has been subjected to other influences, given by the individual clauses of this European Standard, the mean errors shall be within the error limits specified within those clauses when tested by the methods given in 5.3.2 a) or 5.3.2 b). SIST EN 14236:2018

¶ Q < Qt ± 3 % ± 2 % Qt

¶ Q

¶ Qmax ± 1,5 % ± 1 % Table 5 — Maximum difference between errors Flow rate range Maximum range of mean errors m3/h Class 1,5 Class 1,0 Qmin < Q < Qt 4 % 11/3 % Qt < Q < Qmax 2 % 2/3 % 5.4 Gas — air relationship 5.4.1 General Where meters satisfy the requirements in 5.4.2, air shall be used for subsequent tests as the test medium. 5.4.2 Requirements When tested in accordance with 5.4.3 the range of mean errors on all test gases combined (including air) shall be within the limits specified in Table 5 (see X in Figure 1). The difference between the mean error on the test gases and that on air at each flow rate shall satisfy the limits specified in Table 6 (see Y in Figure 1). SIST EN 14236:2018

¶ Q < Qt ± 3 % 2 % Qt

¶ Q

¶ Qmax ± 1,5 % 1 % NOTE Figure 1 represents a graphical explanation of the requirements given in 5.3 and 5.4.

Key 1 error % 2 flow rate Q

error on gas

error on air NOTE All points are the mean of at least 3 measurements. Figure 1 — Relationship between defined errors 5.4.3 Test Apply the requirements of 5.4.2 to the results from testing the meter in accordance with 5.3.2 a) and 5.3.2 b). 5.5 Pressure absorption 5.5.1 Requirements The pressure absorption of the meter with a flow of air of density 1,2 kg/m3, at a flow rate equal to Qmax, shall not exceed 2,0 mbar. SIST EN 14236:2018

Key 1 meter connection 2 dust inlet (screwed plug) 3 air supply (fan) 4 fast acting full bore valve Figure 2 — Example of a typical test rig for the addition of dust Referring to Figure 2, the apparatus consists of the following components: a) 10 D of vertical parallel bore pipe, to connect to the meter inlet; b) a removable screwed plug, for the addition of dust; c) a ball valve, to release the dust; d) a length of straight pipe 30 D to 45 D in length, to ensure that all dust is airborne before entering the meter; e) copper pipework with soldered or compression fittings is preferred. Steel pipe fittings are not recommended as the dust will adhere to the screw threads. Other designs of test rig can be used, at the discretion of the Test House. Check the effectiveness of a test rig design on a regular basis, using a test box. This is to ensure that when 20 g of dust is added using the procedure mentioned above at least 18 g is deposited inside the test box fitted to the rig outlet. Ensure that the test box has a similar volume and shape to the meter to be tested and fitted with a filter on the outlet to minimize the dust passing through the outlet. 5.7.3 Specification of contamination dust Four separate batches of dust shall be used with 95 % of the particles in each batch in the appropriate size range given below: a)

to

Average size (50 ±

b)

to

Average size (150 ±

c)

to

Average size (250 ±

d)

to

Average size (350 ±

8 %; Paint residual flake

1 %. 5.8 Installation effects 5.8.1 Requirements When tested in accordance with 5.8.2, the mean errors at all flow rates shall remain within the MPE and the mean error difference at each flow rate shall not exceed one third of the MPE specified in Table 4. The meter shall recover from the flow disturbance to be within the MPE, specified in Table 4. 5.8.2 Test Test the meter in accordance with 5.3.2 a) with a straight pipe of length no less than 10 D connected to the meter inlet. Repeat the test, with a pipe of the same diameter as the nominal connection diameter of the meter, but with two 90° elbows with their planes at right angles and not more than 2 D apart. Connect this to the meter inlet with the first bend not more than 2 D from the inlet. Repeat the test in accordance with 5.3.2 a) with a straight pipe of length not less than 10 D connected to the meter inlet. 5.9 Zero flow 5.9.1 Requirements Neither the meter display nor the internal register shall change in value (increase or decrease) when the meter is tested by the method given in 5.9.2. 5.9.2 Test This test is carried out at -10 °C, +20 °C and +40 °C. If the manufacturer has declared a wider ambient and gas temperature range, then the extreme temperatures declared are substituted for -10 °C and +40 °C above as appropriate. Record the meter display and the internal register of the meter. Fill the meter with dry pure methane at atmospheric pressure and seal the inlet and outlet ports of the meter with gas tight fittings. Allow the meter to stabilize at the test temperature and then store for 24 h at the test temperature. Record the meter display and internal register and subtract the respective first readings from the second readings to indicate any registration change. Repeat the test at each test temperature. 5.10 Reverse flow 5.10.1 Requirements If the meter has been designed to only be used in one direction, then when tested in accordance with 5.10.2 the register shall neither increase nor decrease. Where an additional reverse flow register is fitted, this shall indicate the passage of the test volume during the test described in 5.10.2. SIST EN 14236:2018

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...