SIST EN 12480:2026

(Main)Gas meters - Rotary displacement gas meters

Gas meters - Rotary displacement gas meters

This document specifies ranges, construction, performances, output characteristics and testing of rotary displacement gas meters (hereinafter referred to as RD meters or simply meters) for gas volume measurement.

This document applies to rotary displacement gas meters used to measure the volume of fuel gases of at least the 1st, 2nd and 3rd gas families, the composition of which is specified in EN 437:2021, at a maximum working pressure up to and including 20 bar over an ambient and gas temperature range of at least −10 °C to +40 °C.

This document applies to meters that are installed in locations with vibration and shocks of low significance (class M1) and in

- closed locations (indoor or outdoor with protection) with condensing or with non-condensing humidity

or,

- open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity,

and in locations with electromagnetic disturbances (class E1 and E2). The standard applies to mechanical meters with mechanical index, electronic devices are not covered by this standard.

Unless otherwise specified in this standard:

- all pressures used are gauge;

- all influence quantities, except the one under test, are kept relatively constant at their reference value.

This document applies to meters with a maximum allowable pressure PS and the volume V of less than 6 000 bar · L or with a product of PS and DN of less than 3 000 bar.

This document is to be used for both pattern approval and individual meter testing. Cross-reference tables are given in:

- Annex A for the tests that need to be undertaken for pattern approval;

- Annex B for individual meter testing.

Some parts of this standard cover meters with mechanical index only.

The risk philosophy adopted in this standard is based on the analysis of hazards including pressure. The standard applies principles to eliminate or reduce hazards. Where these hazards cannot be eliminated appropriate protection measures are specified.

Gaszähler - Drehkolbengaszähler

Dieses Dokument legt den Einsatzbereich, die Bauart, den Betrieb, die Ausgabecharakteristiken und die Prüfung von Drehkolbengaszählern (nachfolgend RD Zähler oder einfach nur Zähler genannt) für die Gasvolumenmessung fest.

Dieses Dokument gilt für Drehkolbengaszähler, die bei einem maximalen Betriebsdruck bis einschließlich 20 bar in einem Umgebungs- und Gastemperaturbereich von mindestens −10 °C bis +40 °C für die Volumenmessung von Brenngasen von mindestens der 1., 2. und 3. Gasfamilie eingesetzt werden, deren Zusammensetzung in EN 437:2021 beschrieben ist.

Dieses Dokument gilt für Zähler, die an Standorten eingebaut sind, an denen unbedeutende Schwingungen und Erschütterungen (Klasse M1) auftreten können und die an

- geschlossenen Standorten (innen oder außen mit Schutz) mit oder ohne Betauung

oder an

- offenen Standorten (außen ohne Abdeckung) mit oder ohne Betauung

und an Standorten mit elektromagnetischen Störungen (Klasse E1 und E2) eingesetzt werden. Die Normen gelten für mechanische Zähler mit mechanischem Zählwerk. Elektronische Zähler fallen nicht unter dieses Dokument.

Soweit in diesem Dokument nicht anders angegeben:

- sind alle dargestellten Drücke als Überdrücke zu verstehen;

- werden alle Einflussgrößen außer der geprüften Einflussgröße relativ konstant bei ihrem Referenzwert gehalten.

Dieses Dokument gilt auch für Zähler mit einem maximal zulässigen Druck PS und Volumen V von weniger als 6 000 bar·l oder mit einem Produkt aus PS und DN von weniger als 3 000 bar.

Dieses Dokument kann für die Musterzulassungsprüfung und die Einzelzählerprüfung angewendet werden. Verweistabellen sind in den folgenden Abschnitten aufgeführt:

- Anhang A für die Prüfungen, die zur Musterzulassung vorgenommen werden müssen;

- Anhang B für die Einzelzählerprüfung.

Einige Abschnitte dieses Dokuments behandeln ausschließlich Zähler mit einem mechanischen Zählwerk.

Die in diesem Dokument angewendete Risikophilosophie beruht auf einer Gefahrenanalyse, die Druck einschließt. In diesem Dokument werden Grundsätze angewendet, mit denen Gefahren beseitigt oder verringert werden. Dort, wo diese Gefahren nicht beseitigt werden können, werden angemessene Schutzmaßnahmen festgelegt.

Compteurs de gaz - Compteurs de gaz à déplacement rotatif

Le présent document spécifie les plages, construction, performances, caractéristiques de sortie et essais des compteurs de mesure de volume de gaz à pistons rotatifs (appelés ci après simplement compteurs).

Le présent document s’applique aux compteurs de gaz à pistons rotatifs utilisés pour mesurer le volume de gaz au moins des 1re, 2e et 3e familles, dont la composition est spécifiée dans l’EN 437:2021, à une pression de service maximale jusqu’à 20 bar pour une gamme de température ambiante et de température du gaz d’au moins -10 °C à +40 °C.

Le présent document s’applique aux compteurs installés dans des endroits où les vibrations et les chocs sont peu importants (classe M1) et :

— dans des endroits fermés (à l’intérieur ou à l’extérieur avec la protection spécifiée par le fabricant) avec ou sans condensation d’humidité ;

ou, si le constructeur le spécifie,

— dans des endroits ouverts (à l’extérieur sans protection) avec ou sans condensation d’humidité ;

et dans des endroits avec des perturbations électromagnétiques (classe E1 et E2). La norme s’applique aux compteurs mécaniques avec index mécanique ; les dispositifs électroniques ne sont pas couverts par le présent document.

Sauf spécification contraire dans le présent document :

— toutes les pressions sont des pressions relatives ;

— toutes les grandeurs d’influence, sauf celle qui est soumise à l’essai, sont maintenues constantes à leur valeur de référence.

Le présent document s’applique également aux compteurs avec une pression maximale admissible, PS, et un volume, V, de moins de 6 000 bar · L ou avec un produit de PS et DN inférieur à 3 000 bar.

Le présent document peut être utilisé aussi bien pour l’approbation de modèle que pour des essais individuels de compteurs. Des tableaux de correspondance sont donnés à :

— l’Annexe A pour les essais qu’il est nécessaire d’effectuer pour l’approbation de modèle ;

— l’Annexe B pour les essais individuels de compteurs.

Certaines parties du présent document couvrent les compteurs disposant uniquement d’un index mécanique.

L’approche du risque adoptée dans le présent document repose sur l’analyse des dangers, notamment la pression. Les principes appliqués par le document visent à éliminer ou réduire les dangers. Lorsque ces dangers ne peuvent pas être éliminés, des mesures de protection appropriées sont spécifiées.

Plinomeri - Rotacijski plinomeri

General Information

- Status

- Published

- Public Enquiry End Date

- 14-May-2024

- Publication Date

- 08-Dec-2025

- Technical Committee

- DPL - Gas supply

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Nov-2025

- Due Date

- 18-Jan-2026

- Completion Date

- 09-Dec-2025

Relations

- Effective Date

- 01-Jan-2026

Overview

EN 12480:2025 - Gas meters: Rotary displacement gas meters (CEN) defines requirements for the design, construction, performance and testing of rotary displacement (RD) gas meters used to measure the volume of fuel gases. This updated European Standard (superseding EN 12480:2018) applies to mechanical RD meters for gases of the 1st, 2nd and 3rd families (per EN 437:2021) at maximum working pressures up to 20 bar and ambient/gas temperatures of at least −10 °C to +40 °C. The standard is intended for both pattern approval and individual meter testing and adopts a risk-based approach addressing hazards including pressure.

Key topics and technical requirements

- Scope and limits

- Applies to mechanical rotary displacement gas meters (RD meters) only - electronic devices are not covered.

- Gas families per EN 437:2021; vibration class M1 and electromagnetic disturbance classes E1/E2.

- Maximum allowable pressure PS and volume product limits: PS · V < 6 000 bar·L or PS · DN < 3 000 bar.

- Operating range

- Specified flow rate, pressure and temperature ranges; environmental conditions include condensing and non‑condensing humidity for indoor/outdoor installations.

- Metrological performance

- Requirements and tests for error of indication, pressure loss, repeatability, and bidirectional operation where applicable.

- Design, materials and strength

- Construction, corrosion resistance, penetration resistance, strength against internal pressure, fire resistance, external leak tightness and overload conditions.

- Meter output and interfacing

- Mechanical index, index window, magnetic coupling, output shafts and pulse generator specifications (low/high frequency).

- Durability, marking and documentation

- Durability tests, marking legibility, packaging and required product documentation and instruction manuals.

- Conformity and testing

- Annex A: tests for pattern approval; Annex B: individual meter testing; Annex D: conformity evaluation and quality management expectations.

- Risk philosophy

- Hazard analysis-driven requirements and protective measures where hazards cannot be eliminated.

Applications and who uses this standard

EN 12480:2025 is used by:

- Meter manufacturers for design validation, material selection and production testing.

- Type approval and certification bodies for pattern approval and compliance assessment.

- Testing laboratories performing metrological and durability tests.

- Gas utilities, system designers and procurement teams specifying compliant RD meters for fuel gas measurement.

- Regulatory authorities and conformity assessors ensuring safety and measurement traceability.

Practical applications include selection, testing and approval of rotary displacement gas meters for commercial and industrial fuel gas measurement under the environmental and pressure limits defined by the standard.

Related standards

- EN 437:2021 - Reference for gas family composition and fuel gas classification.

- CEN internal regulations - application and national adoption procedures for EN standards.

Frequently Asked Questions

SIST EN 12480:2026 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Gas meters - Rotary displacement gas meters". This standard covers: This document specifies ranges, construction, performances, output characteristics and testing of rotary displacement gas meters (hereinafter referred to as RD meters or simply meters) for gas volume measurement. This document applies to rotary displacement gas meters used to measure the volume of fuel gases of at least the 1st, 2nd and 3rd gas families, the composition of which is specified in EN 437:2021, at a maximum working pressure up to and including 20 bar over an ambient and gas temperature range of at least −10 °C to +40 °C. This document applies to meters that are installed in locations with vibration and shocks of low significance (class M1) and in - closed locations (indoor or outdoor with protection) with condensing or with non-condensing humidity or, - open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity, and in locations with electromagnetic disturbances (class E1 and E2). The standard applies to mechanical meters with mechanical index, electronic devices are not covered by this standard. Unless otherwise specified in this standard: - all pressures used are gauge; - all influence quantities, except the one under test, are kept relatively constant at their reference value. This document applies to meters with a maximum allowable pressure PS and the volume V of less than 6 000 bar · L or with a product of PS and DN of less than 3 000 bar. This document is to be used for both pattern approval and individual meter testing. Cross-reference tables are given in: - Annex A for the tests that need to be undertaken for pattern approval; - Annex B for individual meter testing. Some parts of this standard cover meters with mechanical index only. The risk philosophy adopted in this standard is based on the analysis of hazards including pressure. The standard applies principles to eliminate or reduce hazards. Where these hazards cannot be eliminated appropriate protection measures are specified.

This document specifies ranges, construction, performances, output characteristics and testing of rotary displacement gas meters (hereinafter referred to as RD meters or simply meters) for gas volume measurement. This document applies to rotary displacement gas meters used to measure the volume of fuel gases of at least the 1st, 2nd and 3rd gas families, the composition of which is specified in EN 437:2021, at a maximum working pressure up to and including 20 bar over an ambient and gas temperature range of at least −10 °C to +40 °C. This document applies to meters that are installed in locations with vibration and shocks of low significance (class M1) and in - closed locations (indoor or outdoor with protection) with condensing or with non-condensing humidity or, - open locations (outdoor without any covering) with condensing humidity or with non-condensing humidity, and in locations with electromagnetic disturbances (class E1 and E2). The standard applies to mechanical meters with mechanical index, electronic devices are not covered by this standard. Unless otherwise specified in this standard: - all pressures used are gauge; - all influence quantities, except the one under test, are kept relatively constant at their reference value. This document applies to meters with a maximum allowable pressure PS and the volume V of less than 6 000 bar · L or with a product of PS and DN of less than 3 000 bar. This document is to be used for both pattern approval and individual meter testing. Cross-reference tables are given in: - Annex A for the tests that need to be undertaken for pattern approval; - Annex B for individual meter testing. Some parts of this standard cover meters with mechanical index only. The risk philosophy adopted in this standard is based on the analysis of hazards including pressure. The standard applies principles to eliminate or reduce hazards. Where these hazards cannot be eliminated appropriate protection measures are specified.

SIST EN 12480:2026 is classified under the following ICS (International Classification for Standards) categories: 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12480:2026 has the following relationships with other standards: It is inter standard links to SIST EN 12480:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12480:2026 is associated with the following European legislation: EU Directives/Regulations: 2014/32/EU, 2014/68/EU; Standardization Mandates: M/071, M/541, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12480:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Nadomešča:

SIST EN 12480:2018

Plinomeri - Rotacijski plinomeri

Gas meters - Rotary displacement gas meters

Gaszähler - Drehkolbengaszähler

Compteurs de gaz - Compteurs de gaz à déplacement rotatif

Ta slovenski standard je istoveten z: EN 12480:2025

ICS:

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12480

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 91.140.40 Supersedes EN 12480:2018

English Version

Gas meters - Rotary displacement gas meters

Compteurs de gaz - Compteurs de gaz à déplacement Gaszähler - Drehkolbengaszähler

rotatif

This European Standard was approved by CEN on 8 September 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12480:2025 E

worldwide for CEN national Members.

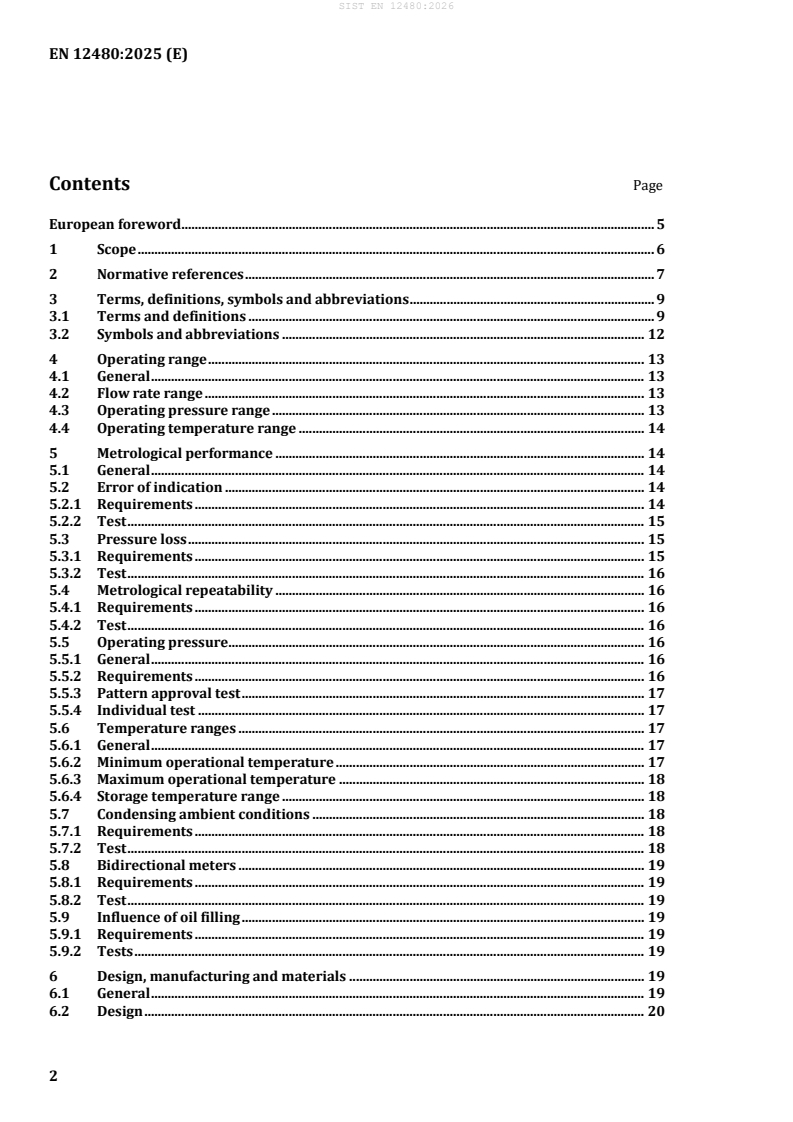

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 7

3 Terms, definitions, symbols and abbreviations . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviations . 12

4 Operating range . 13

4.1 General . 13

4.2 Flow rate range . 13

4.3 Operating pressure range . 13

4.4 Operating temperature range . 14

5 Metrological performance . 14

5.1 General . 14

5.2 Error of indication . 14

5.2.1 Requirements . 14

5.2.2 Test . 15

5.3 Pressure loss . 15

5.3.1 Requirements . 15

5.3.2 Test . 16

5.4 Metrological repeatability . 16

5.4.1 Requirements . 16

5.4.2 Test . 16

5.5 Operating pressure . 16

5.5.1 General . 16

5.5.2 Requirements . 16

5.5.3 Pattern approval test . 17

5.5.4 Individual test . 17

5.6 Temperature ranges . 17

5.6.1 General . 17

5.6.2 Minimum operational temperature . 17

5.6.3 Maximum operational temperature . 18

5.6.4 Storage temperature range . 18

5.7 Condensing ambient conditions . 18

5.7.1 Requirements . 18

5.7.2 Test . 18

5.8 Bidirectional meters . 19

5.8.1 Requirements . 19

5.8.2 Test . 19

5.9 Influence of oil filling . 19

5.9.1 Requirements . 19

5.9.2 Tests . 19

6 Design, manufacturing and materials . 19

6.1 General . 19

6.2 Design . 20

6.2.1 General . 20

6.2.2 Design method . 20

6.3 Material . 21

6.3.1 General . 21

6.3.2 Resistance to external corrosion . 21

6.3.3 Penetration resistance. 21

6.3.4 Adhesion of the protective coating . 22

6.3.5 Materials for pressurized parts . 23

6.4 Adequate strength . 23

6.4.1 Resistance to internal pressure . 23

6.4.2 Fire resistance . 24

6.4.3 External leak tightness . 24

6.4.4 Overload . 25

6.4.5 Bending and torsional moment . 25

6.5 Transportation and storage . 27

6.5.1 Protection against foreign matter . 27

6.5.2 Protection against damage . 27

6.6 Connections . 28

6.7 Pressure and temperature tappings . 28

6.7.1 Pressure tappings . 28

6.7.2 Temperature tappings . 29

6.8 Manufacturing. 29

7 Meter output . 30

7.1 Index . 30

7.1.1 General . 30

7.1.2 Magnetic coupling. 30

7.1.3 Mechanical indicating device . 30

7.1.4 Test element . 31

7.2 Index window . 31

7.2.1 Requirements . 31

7.2.2 Tests . 32

7.3 Output drive shafts. 33

7.3.1 Requirements . 33

7.3.2 Tests . 34

7.4 Pulse generators . 35

7.4.1 General . 35

7.4.2 Specification for low frequency pulse generator . 35

7.4.3 Specification for high frequency pulse generator . 36

7.4.4 Electrical connection . 36

8 Durability . 36

8.1 Requirements . 36

8.2 Tests . 36

9 Marking, labelling and packaging . 36

9.1 General . 36

9.2 Direction of flow . 37

9.3 Pressure tappings . 37

9.4 Durability and legibility of marking . 37

9.4.1 Requirements . 37

9.4.2 Test . 37

10 Documentation . 38

10.1 Documentation related to the product tests . 38

10.2 Instruction manual . 38

Annex A (normative) Pattern approval . 39

Annex B (normative) Individual meter testing . 41

Annex C (normative) Resistance to high temperature . 42

C.1 General . 42

C.2 Requirements . 42

C.3 Test . 42

C.3.1 Apparatus . 42

C.3.2 Test conditions . 43

C.3.3 Test procedure . 43

C.4 Marking . 44

Annex D (normative) Compliance evaluation for gas meters . 45

D.1 General . 45

D.2 Quality Management System . 45

D.2.1 General . 45

D.2.2 Compliance evaluation . 45

D.2.3 Issue of the certificate of compliance with EN 12480 . 45

Annex E (normative) Non-destructive testing (NDT) . 46

Annex F (informative) Materials for pressurized parts . 48

Annex G (normative) Additional tests for meters to be used in open locations . 60

G.1 General . 60

G.2 Weathering . 60

G.2.1 Requirements . 60

G.2.2 Test . 60

Annex H (normative) Meter family . 61

H.1 Definition of meter family . 61

H.2 Criteria for grouping meters together in order to form a family . 61

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2014/32/EU aimed to be covered . 62

Annex ZB (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2014/68/EU aimed to be covered . 67

Bibliography . 69

European foreword

This document (EN 12480:2025) has been prepared by Technical Committee CEN/TC 237 “Gas meters”,

the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12480:2018.

The main goal of this revision was to be harmonized with 2014/32/EU (Measuring Instruments

Directive) and 2014/68/EU Pressure Equipment Directive.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, and Annex ZB, which are integral

parts of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies ranges, construction, performances, output characteristics and testing of rotary

displacement gas meters (hereinafter referred to as RD meters or simply meters) for gas volume

measurement.

This document applies to rotary displacement gas meters used to measure the volume of fuel gases of at

least the 1st, 2nd and 3rd gas families, the composition of which is specified in EN 437:2021, at a

maximum working pressure up to and including 20 bar over an ambient and gas temperature range of at

least −10 °C to +40 °C.

This document applies to meters that are installed in locations with vibration and shocks of low

significance (class M1) and in

— closed locations (indoor or outdoor with protection) with condensing or with non-condensing

humidity

or,

— open locations (outdoor without any covering) with condensing humidity or with non-condensing

humidity,

and in locations with electromagnetic disturbances (class E1 and E2). The standard applies to mechanical

meters with mechanical index, electronic devices are not covered by this standard.

Unless otherwise specified in this standard:

— all pressures used are gauge;

— all influence quantities, except the one under test, are kept relatively constant at their reference

value.

This document applies to meters with a maximum allowable pressure PS and the volume V of less than

6 000 bar · L or with a product of PS and DN of less than 3 000 bar.

This document is to be used for both pattern approval and individual meter testing. Cross-reference

tables are given in:

— Annex A for the tests that need to be undertaken for pattern approval;

— Annex B for individual meter testing.

Some parts of this standard cover meters with mechanical index only.

The risk philosophy adopted in this standard is based on the analysis of hazards including pressure. The

standard applies principles to eliminate or reduce hazards. Where these hazards cannot be eliminated

appropriate protection measures are specified.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

EN 1092-1:2018, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 1: Steel flanges

EN 1092-2:2023, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 3: Copper alloy flanges

EN 1092-4:2002, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 4: Aluminium alloy flanges

EN 1759-1:2004, Flanges and their joint — Circular flanges for pipes, valves, fittings and accessories, Class

designated — Part 1: Steel flanges, NPS 1/2 to 24

EN 1759-3:2003, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, Class

designated — Part 3: Copper alloy flanges

EN 1759-4:2003, Flanges and their joint — Circular flanges for pipes, valves, fittings and accessories, class

designated — Part 4: Aluminium alloy flanges

EN 10204:2004, Metallic products — Types of inspection documents

EN 12516-2:2014+A1:2021, Industrial valves — Shell design strength — Part 2: Calculation method for

steel valve shells

EN 12516-3:2002, Valves — Shell design strength — Part 3: Experimental method

EN 12516-4:2014+A1:2018, Industrial valves — Shell design strength — Part 4: Calculation method for

valve shells manufactured in metallic materials other than steel

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60079-11:2012, Explosive atmospheres — Part 11: Equipment protection by intrinsic safety "i"

(IEC 60079-11:2011 + Cor.:2012)

EN IEC 60730-1:2024, Automatic electrical controls — Part 1: General requirements (IEC 60730-1:2022)

EN IEC 60079-0:2018, Explosive atmospheres — Part 0: Equipment — General requirements (IEC 60079-

0:2017)

As impacted by EN 60529:1991/A1:2000, EN 60529:1991/A2:2013, EN 60529:1991/AC:2016-12 and

EN 60529:1991/A2:2013/AC:2019-02.

As impacted by EN IEC 60079-0:2018/AC:2020-02 and EN IEC 60079-0:2018/A11:2024.

EN IEC 61000-6-1:2019, Electromagnetic compatibility (EMC) — Part 6-1: Generic standards — Immunity

standard for residential, commercial and light-industrial environments (IEC 61000-6-1:2016)

EN IEC 61000-6-2:2019, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity

standard for industrial environments (IEC 61000-6-2:2016)

EN IEC 61000-6-3:2021, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards — Emission

standard for equipment in residential environments (IEC 61000-6-3:2020)

EN IEC 61000-6-4:2019, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards — Emission

standard for industrial environments (IEC 61000-6-4:2018)

EN 61000-6-5:2015, Electromagnetic compatibility (EMC) — Part 6-5: Generic standards — Immunity for

equipment used in power station and substation environment (IEC 61000-6-5:2015)

EN 61000-6-7:2015, Electromagnetic compatibility (EMC) — Part 6-7: Generic standards — Immunity

requirements for equipment intended to perform functions in a safety-related system (functional safety) in

industrial locations (IEC 61000-6-7:2014)

EN IEC 61000-6-8:2020, Electromagnetic compatibility (EMC) — Part 6-8: Generic standards — Emission

standard for professional equipment in commercial and light-industrial locations (IEC 61000-6-8:2020)

EN ISO 6270-2:2025, Paints and varnishes — Determination of resistance to humidity — Part 2:

Condensation (in-cabinet exposure with heated water reservoir) (ISO 6270-2:2025)

EN ISO 9606-1:2017, Qualification testing of welders — Fusion welding — Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012 and Cor 2:2013)

EN ISO 9606-2:2004, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium

alloys (ISO 9606-2:2004)

EN ISO 9712:2022, Non-destructive testing — Qualification and certification of NDT personnel

(ISO 9712:2021)

EN ISO 14732:2025, Welding personnel — Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2025)

EN ISO 15607:2019, Specification and qualification of welding procedures for metallic materials — General

rules (ISO 15607:2019)

EN ISO 15609-1:2019, Specification and qualification of welding procedures for metallic materials —

Welding procedure specification — Part 1: Arc welding (ISO 15609-1:2019)

EN ISO 15614-1:2017, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1:2017, Corrected version 2017-10-01)

EN ISO 15614-2:2025, Specification and qualification of welding procedures for metallic materials —

Welding procedure test — Part 2: Arc welding of aluminium and its alloys (ISO 15614-2:2025)

As impacted by EN 61000-6-5:2015/AC:2018-01.

EN ISO/CIE 11664-4:2019, Colorimetry — Part 4: CIE 1976 L*a*b* colour space (ISO/CIE 11664-4:2019)

ISO 834-1:2025, Fire-resistance tests — Elements of building construction — Part 1: General requirements

ISO 7005-1:2011, Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems

ISO 7005-2:1988, Metallic flanges — Part 2: Cast iron flanges

ISO 14782:2021, Plastics — Determination of haze for transparent materials

ISO 17663:2023, Welding — Quality requirements for heat treatment in connection with welding and allied

processes

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

accuracy class 1,0

Q,

accuracy achieved by a meter, which has an error of indication between −2 % and +2 % for flow rates

Q Q,

where Q ≤ < Q , and an error of indication between −1 % and +1 % for flow rates where

min t

Q ≤ Q ≤ Q

t max

3.1.2

cyclic volume

V

cyc

volume of the gas measured by one complete revolution of the element(s)

3.1.3

density of gas

ρ

mass of gas divided by the volume

3.1.4

allowable design temperature range

TS

range of gas temperatures (minimum to maximum) for which the meter is designed as declared and

marked on the meter

3.1.5

diameter

DN

alphanumeric designation of size for components of a pipework system, which is used for reference

purposes

Note 1 to entry: It comprises the letters DN followed by a dimensionless whole number which is indirectly

related to the physical size, in millimetres, of the bore or outside diameter of the end connections

3.1.6

error of indication

E

value which shows the relationship in percentage terms of the difference between the volume indicated

by the meter and the volume which has actually flowed through the meter, to the latter value:

VV−

ic

E ⋅ 100

V

c

where

V is the indicated volume and V is the volume which has actually flowed through the meter

i c

3.1.7

maximum allowable pressure

PS

maximum pressure for which the meter is designed

3.1.8

minimum flow rate

Q

min

lowest flow rate at which the gas meter provides indications that satisfy the requirements regarding

maximum permissible error (MPE)

3.1.9

maximum flow rate

Q

max

highest flow rate at which the gas meter provides indications that satisfy the requirements regarding

maximum permissible error (MPE)

3.1.10

meter family

group of meters of different sizes but with similar construction (see Annex H)

Note 1 to entry: By specifying a meter family it is possible to reduce the number of tests and documents during

assessment.

3.1.11

metering condition

condition of the gas prevailing at the point of measurement

=

3.1.12

metering pressure

p

m

absolute pressure at which the volume of the gas is measured

3.1.13

normal conditions of use

conditions referring to the meter operating:

— within the range of working pressure;

— within the operational temperature and gas temperature range;

— with the distributed gas

3.1.14

operating pressure range

p

limits of working pressure for which the meter will continue to operate within its metrological

characteristics

3.1.15

operating temperature range

t

range of gas and ambient temperatures for which the meter satisfies the metrological requirements of

this standard

3.1.16

overload flow rate

Q

r

highest flow rate at which the meter operates for a short period of time without deteriorating

3.1.17

pressure loss

non-recoverable pressure drop caused by the presence of the meter in the pipeline

3.1.18

rotary displacement meter

gas volume meter in which a rigid measuring compartment is formed between the walls of a stationary

chamber and rotating element or elements

Note 1 to entry: Each rotation of the element(s) displaces a fixed volume of gas which is cumulatively registered

and indicated by an indicating device. It is designed to measure, memorize and display the volume of a fuel gas that

has passed through it.

3.1.19

storage temperature range

ts

range of temperatures at which the meter is stored without being adversely affected

3.1.20

transitional flow rate

Q

t

flow rate occurring between the maximum and minimum flow rates at which the flow rate range is

divided into two zones, the upper zone and the lower zone, each zone having a characteristic MPE

3.1.21

volume of meter

V

internal volume of meter excluding the volume of internal parts

3.1.22

working pressure

pressure of the gas at the inlet of the meter

3.1.23

limit pressure

pl

pressure at which yielding becomes apparent in any component of the meter or its fixtures

3.1.24

safety factor body

Sb

ratio of the limit pressure pl to the maximum allowable pressure PS applied to the meter body

3.1.25

safety factor others

S

ratio of the limit pressure pl to the maximum allowable pressure PS applied to other pressure containing

parts of the meter

3.2 Symbols and abbreviations

Table 1 — Symbols

Symbol Represented quantity Unit

V cyclic volume

dm

cyc

-3

ρ Density of gas

kg⋅m

TS Allowable design temperature range °C

DN Diameter Dimensionless

E Error of indication %

MPE Maximum permissible error %

WME Weighted mean error %

PS Maximum allowable pressure bar

Q flow rate

m /h

p Metering pressure bar

m

p Operating pressure range bar

Symbol Represented quantity Unit

t Operating temperature range °C

Q Overload flow rate

r m /h

ts Storage temperature range °C

Q Transitional flow rate

m /h

t

V Volume of meter in litres

dm

pl Limit pressure bar

S Safety factor body Dimensionless

b

S Safety factor others Dimensionless

tr Revolution Dimensionless

Subscripts

m Metering conditions of the gas

min Minimum

max Maximum

i Indicated

t Transitional

4 Operating range

4.1 General

Gas meters shall be classified according to accuracy class 1,0. The values of maximum flow rates and the

corresponding values of the upper limits of the minimum flow rates shall be one of those given in 4.2,

when the meter is tested with air of density approximately 1,2 kg/m .

4.2 Flow rate range

Unless covered in the E.U. type examination certificate, the values of the maximum and minimum flow

rates of rotary displacement gas meters shall be decimal multiples and sub-multiples of these values, with

≥ 20 Q . For example, for one decade:

Q

max min

Q (m /h): 100, 160, 250, 400, 650

max

(m /h): 10, 13, 16, 20, 25, 32, 40, 50, 65, 80

Q

min

4.3 Operating pressure range

The upper limit of the operating pressure range shall not exceed the maximum allowable pressure PS.

The operating pressure range shall be marked on the meter.

4.4 Operating temperature range

All meters shall be capable of meeting the requirements in 5.6 for the following: gas; ambient; storage;

design temperature ranges:

— a minimum ambient temperature range of –10 °C to 40 °C;

If a wider ambient temperature range is required, then these values shall be chosen using a maximum

temperature of 40 °C, 55 °C, or 70 °C and a lower temperature limit of –10 °C, –25 °C, or –40 °C.

— a minimum gas temperature range of 40 K (the gas temperature range shall be within the ambient

temperature range);

— a minimum storage temperature range of –20 °C to 60 °C (see 5.6) (the storage temperature range

shall be wider than or equal to the ambient temperature range).

The operating temperature range shall be inside the limits of the allowable design temperature range.

The operating temperature range shall be marked on the meter.

5 Metrological performance

5.1 General

The uncertainty of the test rig (best measurement capability) shall be at a maximum of 1/5 of the MPE

for the initial pattern approval test and at a maximum of 1/3 of the MPE for the individual meter testing.

Meters family shall be applied according to Annex H.

5.2 Error of indication

5.2.1 Requirements

When tested in accordance with 5.2.2, the meter error of indication shall be within the limits specified in

Table 2.

Table 2 — Limits of maximum permissible errors

Flow rate Q Maximum permissible errors

m /h

Q ±2 %

Q ≤ < Q

min t

±1 %

Q

Q ≤ ≤ Q

t max

Transitional flow rate values, Q , shall be taken from Table 3.

t

Table 3 — Transitional flow rate values

Q / Q Q

max min t

20 ≤ Q / Q ≤ 30 0,20 Q

max min max

Q / Q > 30 ≤ 0,10 Q

max min max

Each meter shall be adjusted so that the weighted mean error (WME) is as close to zero as the adjustment

and the maximum permissible errors allow, without systematically favouring any party.

The WME shall have a value between −0,4 % and +0,4 %.

The WME is calculated as follows:

Σ (/Q Q )⋅ E

i max i

WME=

Σ (/Q Q )

i max

where

Q / Q is a weighting factor;

i max

E is the error of indication at the flow rate QI given as a percentage.

i

When Q = Q , a weighting factor of 0,4 instead of 1 shall be used.

i max

5.2.2 Test

-3

The test is carried out using air (density 1,2 kg⋅m ), or gas specified in the scope, at normal ambient

conditions. The meter is tested at the following flow rates (±10 %):

a) pattern approval:

1) For meters with flow rate range between 1:20 to 1:30:

Q ; 0,05 Q (when this value is larger than Q ) ; 0,1 Q ; 0,2 Q ; 0,4 Q ; 0,7 Q ;

min max min max max max max

Q .

max

2) for meters with a flow rate range ≥ 1:50:

Q ; 0,05 Q ; 0,10 Q ; 0,25 Q ; 0,40 Q ; 0,70 Q ; Q .

min max max max max max max

b) individual factory testing for error of indication (every meter shall be tested) at the flow rates

indicated in Table 4.

If the test point is equal to Q , the tighter limit of the error of indication has to be applied.

t

Table 4 — Test points for individual meter testing

Q / Q Q 0,015 Q 0,1 Q 0,2 Q Q

max min min max max max max

20 ≤ Q / Q ≤ 30 X X X

max min

30 < Q / Q < 160 X X X X

max min

Q / Q ≥ 160 X X X X X

max min

5.3 Pressure loss

5.3.1 Requirements

When tested in accordance with 5.3.2, the maximum pressure loss at Q , when using air with density

max

-3

1,2 kg⋅m , shall be declared.

5.3.2 Test

The pressure loss shall be measured between a point 1 DN upstream and a point 1 DN downstream of the

meter, on piping of the same DN as the meter.

Care shall be taken on selection and manufacturing of the pressure tappings to ensure that flow pattern

distortions do not affect the pressure readings.

5.4 Metrological repeatability

5.4.1 Requirements

When tested in accordance with 5.4.2, in the flow range Q – Q the variation of error of indication

min max

at each flow rate shall stay within the range:

Q

Q ≤ < Q : 1/3 MPE;

min t

Q

Q ≤ ≤ Q : 1/5 MPE.

t max

5.4.2 Test

The error of indication of the meter shall be determined at Q , the flow shall then be increased to at

min

least Q , and then returned to Q and the error of indication determined.

t min

This process shall be repeated and the error of indication at Q determined again.

min

Check that the three successive errors of indication at Q are within the MPE given in 5.4.1.

min

It is possible to combine this test with the test described below for determining the repeatability from Q

t

to Q .

max

The error of indication of the meter is determined at two flow rates in the following order: Q , Q , where

t max

the change from Q to Q is done via 1,10 Q , in order to approach Q from a higher flow rate.

t max max max

The cycle is repeated six times. The test shall be carried out with air, or gas, at atmospheric conditions

(±100 mbar).

Check that the six resulting errors of indication at each flow rate are within a span of 0,2 %, excluding

any interaction between the meter and the test bench.

5.5 Operating pressure

5.5.1 General

The maximum operating pressure for which the meter is useable without additional high-pressure

calibration shall be declared. Above this declared pressure, additional high pressure calibration shall be

undertaken.

5.5.2 Requirements

a) For pattern approval, when tested in accordance with 5.5.3 a), the meter shall comply with 5.2.1.

b) Using the same meter as in a) above, when tested in accordance with 5.5.3 b), at the declared

maximum operating pressure it shall be confirmed that the meter complies with 5.2.1.

c) For individual test, when tested in accordance with 5.5.4, the declared maximum operating pressure

shall be confirmed.

5.5.3 Pattern approval test

a) One meter of each meter family is tested f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...