SIST EN 15895:2011+A1:2018

(Main)Cartridge operated hand-held tools - Safety requirements - Fixing and hard marking tools

Cartridge operated hand-held tools - Safety requirements - Fixing and hard marking tools

This European standard covers safety requirements for cartridge operated fixing and hard marking tools which operate with an intermediate member (piston).

This European standard deals with all significant hazards, hazardous situations and events relevant to cartridge operated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in !EN ISO 12100:2010, 5.4, 5.5, 5.6".

Although the safe use of cartridge operated tools depends to an important extent on the use of appropriate cartridges and fasteners, this standard is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 7).

This European Standard applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer with a composition different from that of the main propellant.

The fixing tools in the scope are those intended for use with fasteners made from metal.

NOTE Information about cartridges can be found in the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.).

This European standard is not applicable to cartridge operated fixing and hard marking tools which are manufactured before the date of its publication as EN.

Kartuschenbetriebene handgehaltene Werkzeuge - Sicherheit - Befestigungs- und Markierwerkzeuge

Diese Europäische Norm behandelt Sicherheitsanforderungen für kartuschenbetriebene Befestigungs- und Markierwerkzeuge, die mit einem Zwischenglied (Kolben) funktionieren.

Diese Europäische Norm befasst sich mit allen signifikanten Gefährdungen, Gefährdungssituationen und Ereignissen, die auftreten können, wenn kartuschenbetriebene Befestigungs- und Markierwerkzeuge wie vorgesehen verwendet werden oder unter Bedingungen einer vernünftigerweise vorhersehbaren Fehlanwendung (siehe Abschnitt 4). Sie behandelt die signifikanten Gefährdungen in den verschiedenen Betriebsarten sowie Eingriffsmöglichkeiten nach !EN ISO 12100:2010, 5.4, 5.5, 5.6".

Obwohl die Gebrauchssicherheit kartuschenbetriebener Werkzeuge in erheblichem Maß von der Verwendung geeigneter Kartuschen und Befestigungselemente abhängig ist, formuliert diese Norm keine Anforderungen an die mit den Werkzeugen zu verwendenden Kartuschen und Befestigungselemente (siehe Abschnitt 7).

Diese Europäische Norm gilt für Werkzeuge, die für die Verwendung von Kartuschen mit Hülsen aus Metall oder Kunststoff sowie festem Treibmittel vorgesehen sind, welche eine geringe Menge Zündmittel mit einer von der des Haupttreibmittels abweichenden Zusammensetzung enthalten.

Die in den Anwendungsbereich fallenden Befestigungswerkzeuge sind jene, die für den Gebrauch mit Befestigungselementen aus Metall vorgesehen sind.

ANMERKUNG Angaben zu Kartuschen sind den Veröffentlichungen der Ständigen Internationalen Kommission zur Prüfung von Handfeuerwaffen (C.I.P, en: Commission for the Proof of Small Arms) zu entnehmen.

Diese Europäische Norm gilt nicht für kartuschenbetriebene Befestigungs- und Markierwerkzeuge, die vor dem Datum ihrer Veröffentlichung als EN hergestellt werden.

Outils portatifs à charge propulsive - Exigences de sécurité - Outils de scellement et de marquage

La présente Norme européenne couvre les exigences de sécurité relatives aux outils portatifs de scellement et de marquage à charge propulsive, qui fonctionnent avec un élément intermédiaire (piston).

La présente Norme européenne traite de l’ensemble des phénomènes dangereux, des situations dangereuses et des événements dangereux significatifs qui sont liés aux outils de scellement et de marquage à charge propulsive lorsque ces outils sont utilisés conformément à l’usage prévu et dans des conditions de mauvais usage raisonnablement prévisibles (voir l’Article 4). Elle traite des phénomènes dangereux significatifs dans les différents modes de fonctionnement et procédures d’intervention tels que mentionnés dans l’EN ISO 12100:2010, 5.4, 5.5, 5.6.

Bien que l’usage sûr des outils à charge propulsive dépende, dans une large mesure, de l’emploi de cartouches et d’éléments de fixation appropriés, la présente norme ne formule pas d’exigences relatives aux cartouches et aux éléments de fixation devant être utilisés avec les outils (voir l’Article 7).

La présente Norme européenne est applicable aux outils conçus pour être utilisés avec des cartouches munies d’étuis en métal ou en matière plastique et avec une charge propulsive pyrotechnique solide et qui contiennent une faible quantité de matière d’amorçage dont la composition diffère de celle de la cartouche pyrotechnique principale.

Les outils de scellement du domaine d’application sont ceux destinés à être utilisés avec des éléments de fixation en métal.

NOTE Les informations relatives aux cartouches sont données dans la publication de la Commission Internationale Permanente pour l’épreuve des armes à feu portatives (C.I.P).

La présente Norme européenne n’est pas applicable aux outils de scellement et de marquage à charge propulsive qui sont fabriqués avant la date de publication de cette Norme européenne.

Ročna orodja z nabojnim delovanjem - Varnostne zahteve - Pritrjevalniki in označevalniki (vključno z dopolnilom A1)

Ta evropski standard zajema varnostne zahteve za pritrjevalnike in označevalnike z nabojnim delovanjem, ki za delovanje uporabljajo vmesni element (bat).

Ta evropski standard obravnava vsa večja tveganja, nevarne situacije in nevarne dogodke v zvezi s pritrjevalniki in označevalniki z nabojnim delovanjem, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji razumno predvidene nepravilne uporabe (glejte točko 4). Obravnava večja tveganja pri različnih načinih delovanja in intervencijske postopke, opisane v standardu EN ISO 12100:2010, 5.4, 5.5, 5.6.

Čeprav je varna uporaba orodij z nabojnim delovanjem v veliki meri odvisna od uporabe ustreznih kartuš in pritrdilnih elementov, ta standard ne določa zahtev za kartuše in pritrdilne elemente, ki so namenjeni za uporabo na orodjih (glejte točko 7).

Ta evropski standard se uporablja za orodja, ki so namenjena za uporabo s kartušami s kovinskim ali plastičnim ohišjem in trdo pogonsko snovjo, ki vsebujejo manjšo količino vžigalnega sredstva, katerega sestava se razlikuje od glavne pogonske snovi.

Pritrjevalniki, ki sodijo na to področje, so namenjeni za uporabo s kovinskimi pritrdilnimi elementi.

OPOMBA: Informacije o kartušah je mogoče najti v publikaciji Stalne mednarodne komisije za preskušanje osebnega orožja (C. I. P.).

Ta evropski standard se ne uporablja za pritrjevalnike in označevalnike z nabojnim delovanjem, ki so bili proizvedeni pred objavo te publikacije kot standarda EN.

General Information

- Status

- Withdrawn

- Publication Date

- 05-Jun-2018

- Withdrawal Date

- 22-Jul-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 23-Jul-2025

- Due Date

- 15-Aug-2025

- Completion Date

- 23-Jul-2025

Relations

- Effective Date

- 10-May-2017

- Effective Date

- 10-May-2017

- Revises

SIST EN 15895:2025 - Powder actuated hand-held fixing and hard marking tools - Safety requirements - Effective Date

- 18-Jan-2023

Frequently Asked Questions

SIST EN 15895:2011+A1:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cartridge operated hand-held tools - Safety requirements - Fixing and hard marking tools". This standard covers: This European standard covers safety requirements for cartridge operated fixing and hard marking tools which operate with an intermediate member (piston). This European standard deals with all significant hazards, hazardous situations and events relevant to cartridge operated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in !EN ISO 12100:2010, 5.4, 5.5, 5.6". Although the safe use of cartridge operated tools depends to an important extent on the use of appropriate cartridges and fasteners, this standard is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 7). This European Standard applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer with a composition different from that of the main propellant. The fixing tools in the scope are those intended for use with fasteners made from metal. NOTE Information about cartridges can be found in the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.). This European standard is not applicable to cartridge operated fixing and hard marking tools which are manufactured before the date of its publication as EN.

This European standard covers safety requirements for cartridge operated fixing and hard marking tools which operate with an intermediate member (piston). This European standard deals with all significant hazards, hazardous situations and events relevant to cartridge operated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in !EN ISO 12100:2010, 5.4, 5.5, 5.6". Although the safe use of cartridge operated tools depends to an important extent on the use of appropriate cartridges and fasteners, this standard is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 7). This European Standard applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer with a composition different from that of the main propellant. The fixing tools in the scope are those intended for use with fasteners made from metal. NOTE Information about cartridges can be found in the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.). This European standard is not applicable to cartridge operated fixing and hard marking tools which are manufactured before the date of its publication as EN.

SIST EN 15895:2011+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 25.140.99 - Other hand-held tools. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15895:2011+A1:2018 has the following relationships with other standards: It is inter standard links to SIST EN 15895:2011/kFprA1:2017, SIST EN 15895:2011, SIST EN 15895:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15895:2011+A1:2018 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 15895:2011+A1:2018 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kartuschenbetriebene handgehaltene Werkzeuge - Sicherheit - Befestigungs- und MarkierwerkzeugeOutils portatifs à charge propulsive - Exigences de sécurité - Outils de scellement et de marquageCartridge operated hand-held tools - Safety requirements - Fixing and hard marking tools25.140.99Other hand-held toolsICS:Ta slovenski standard je istoveten z:EN 15895:2011+A1:2018SIST EN 15895:2011+A1:2018en,fr,de01-julij-2018SIST EN 15895:2011+A1:2018SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15895:2011+A1

May

t r s z ICS

t wä s v rä { { Supersedes EN

s w z { wã t r s sEnglish Version

Cartridge operated handæheld tools æ Safety requirements æFixing and hard marking tools Outils portatifs à charge propulsive æ Exigences de sécurité æ Outils de scellement et de marquage

Kartuschenbetriebene handgehaltene Werkzeuge æ Sicherheit æ Befestigungsæ und Markierwerkzeuge This European Standard was approved by CEN on

s v April

t r s s and includes Amendment

s approved by CEN on

t s May

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w z { wã t r s s ªA sã t r s z ESIST EN 15895:2011+A1:2018

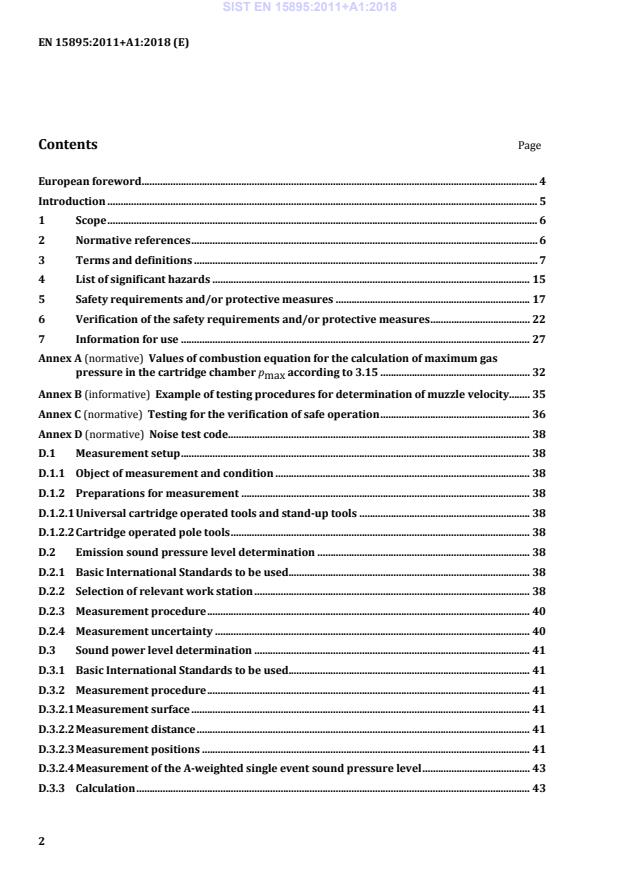

Values of combustion equation for the calculation of maximum gas pressure in the cartridge chamber pmax according to 3.15 . 32 Annex B (informative)

Example of testing procedures for determination of muzzle velocity. 35 Annex C (normative)

Testing for the verification of safe operation . 36 Annex D (normative)

Noise test code . 38 D.1 Measurement setup . 38 D.1.1 Object of measurement and condition . 38 D.1.2 Preparations for measurement . 38 D.1.2.1 Universal cartridge operated tools and stand-up tools . 38 D.1.2.2 Cartridge operated pole tools . 38 D.2 Emission sound pressure level determination . 38 D.2.1 Basic International Standards to be used. 38 D.2.2 Selection of relevant work station . 38 D.2.3 Measurement procedure . 40 D.2.4 Measurement uncertainty . 40 D.3 Sound power level determination . 41 D.3.1 Basic International Standards to be used. 41 D.3.2 Measurement procedure . 41 D.3.2.1 Measurement surface . 41 D.3.2.2 Measurement distance . 41 D.3.2.3 Measurement positions . 41 D.3.2.4 Measurement of the A-weighted single event sound pressure level . 43 D.3.3 Calculation . 43 SIST EN 15895:2011+A1:2018

Information on the ergonomic design of the handle . 47 Annex F (normative)

!Essential safety dimensions" . 48 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 49 Bibliography . 50

Key 1 Total volume Vtot (tool for single cartridges) 3.11 minimum volume of the cartridge chamber VET smallest technically possible cartridge chamber for a given calibre NOTE VET is a constant value for each calibre laid down in Table A.1 of Annex A.

Key 1 Minimum volume of the cartridge chamber VET (tool for single cartridges) 3.12 minimum operational volume of the combustion chamber Va volume consisting of the volume of the combustion chamber with the piston in its extreme top position and the open volume in the piston head NOTE Va is a design-specific value and is calculated as the difference between the design-specific volume Vtot and the calibre-specific volume VET: SIST EN 15895:2011+A1:2018

Key 1 Minimum operational volume of the combustion chamber Va (tool for single cartridges) 3.13 reduced volume of the cartridge chamber *hV volume of the minimum size cartridge chamber VET minus the volumes of the cartridge casing and the propellant NOTE *hV is a constant value for a given calibre laid down in Table A.1 of Annex A.

Key 1 Reduced volume of the cartridge chamber *hV (tool for single cartridges) 3.14 effective combustion volume Veff effective (total) volume of all connecting voids between the cartridge and the piston before the firing of the cartridge; calculated by Veff = *hV + Va = *hV + Vtot – VET SIST EN 15895:2011+A1:2018

Key 1 Effective combustion volume Veff (tool for single cartridges)

Key 1 Effective combustion volume Veff (tool for collated cartridges) 2 Va collated cartridges 3 Boundary line of VET 4 Collation strip 5 Separation line between cartridge chamber and collation strip NOTE 1 Veff is the volume which in combination with the selected cartridge strength effectively determines the gas pressure generated in a tool. NOTE 2 Veff is a design-specific value. 3.15 maximum gas pressure pmax maximum value of combustion pressure in the cartridge chamber depending on the calibre and the effective volume of the combustion chamber, calculated according to the combustion equation pmax = a „ bVeff or, with Veff = *hV + Va as the effective combustion volume SIST EN 15895:2011+A1:2018

Key 1 Reduced proof volume of the combustion chamber VE 3.19 adapted reduced proof volume of the combustion chamber VE, adapted volume of the combustion chamber reduced to an even lower value than the theoretical value VE to account for a factually available cartridge weaker than X = 0,85 in overpressure testing. VE, adapted is dependent on the relative cartridge strength X and is calculated using the equation *h1a1adaptedE,185,03,185,03,1VXVXVbb⋅−⋅+⋅⋅==This=equation=is=valid=for=′artridges=with=a=relative=strength=of=X below 0,85 as long as VE, adapted does not drop below 50 % of VE calculated according to 3.18. 3.20 reduced system testing volume of the combustion chamber VS reduced volume of the combustion chamber for system testing with an overpressure of 1,15 times of the maximum gas pressure pmax of each tested cartridge strength calculated using the equation *h1a1S115,115,1VVVbb⋅−+⋅===SIST EN 15895:2011+A1:2018

Key Va Minimum operational volume VS Reduced system testing volume VE Reduced proof volume 3.21 A-weighted emission sound pressure level LpA ten times the logarithm to the base 10 of the ratio of the square of the emission sound pressure, p, to the square of a reference value, p0, expressed in decibels dBlg10202AppLp==where=the=referen′e=value,=p0, is 20 µPa 3.22 A-weighted single event emission sound pressure level in dB LEA A-weighted and time-integrated emission sound pressure level of an isolated single sound event of specified duration T (or specified measurement time interval T = t2 – t1 covering the single event), normalized to reference time interval T0 = 1 s; given by the following equation: dBd)(1lg1002020A=∫TEtptpTL NOTE The reference sound pressure is p0 = 20 µPa. 3.23 A-weighted sound power level LWA ten times the logarithm to the base 10 of the ratio of the sound power of a source, P, to a reference value, P0, expressed in decibels SIST EN 15895:2011+A1:2018

! Tolerances ISO 2768:— mk Rt: surface roughness" Figure 1 — Test element If the test element needs additional guidance in the barrel, this shall be ensured by slipping two washers made of plastic (or of AlMg alloy material of 0,3 mm thickness) onto the front and rear end of the test element. The washers shall have a bore diameter of 5,5 mm and an outside diameter adapted to the barrel bore diameter. The mass of the test element shall be (8 ± 0,3) g. By means of a suitable rod the test element shall be pushed into the fastener guide towards the rear of the cartridge operated fixing tool so as to intimately contact the face of the piston. By this, it is ensured that the test element is accelerated at the same rate as the piston and reaches the same velocity as the piston at the muzzle. The cartridge operated fixing tool loaded with the test element shall then be pressed against a plate of thin sheet metal and fired such as to enforce the exiting of the test element from the muzzle and the penetration of the sheet metal by the test element. By this, the test element is simulating the free flight of a fastener which might occur unintentionally in a similar situation. To determine the muzzle velocity of the cartridge operated fixing tool, one of the following shall be measured: — the velocity of the piston attained close to the muzzle, i.e. immediately before the piston impacts the piston stopping device, — the velocity of the test element immediately after leaving the muzzle in its forced free flight. !For the determination of either velocity, a suitable measuring method and measuring equipment shall be used." Measuring

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...