SIST EN 15895:2025

(Main)Powder actuated hand-held fixing and hard marking tools - Safety requirements

Powder actuated hand-held fixing and hard marking tools - Safety requirements

This document covers safety requirements for powder actuated fixing and hard marking tools which operate with an intermediate member (piston) and are handled manually.

This document deals with all significant hazards (see Annex I), hazardous situations and events relevant to powder actuated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in EN ISO 12100:2010, 5.4, 5.5, 5.6.

Although the safe use of powder actuated tools depends to an important extent on the use of appropriate cartridges and fasteners, this document is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 6).

This document applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer mix with a composition different from that of the main propellant.

This document applies to tools designed for use with single cartridges or with cartridges collated in disks or in strips.

The fixing tools in the scope are those intended for use with fasteners made from metal.

NOTE Information about cartridges can be found either in EN 16264:2014 or the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.).

This document is not applicable to powder actuated fixing and hard marking tools which are manufactured before this document’s date of publication.

Pulverkraftbetriebene handgeführte Befestigungs- und Markierungswerkzeuge - Sicherheitsanforderungen

Dieses Dokument behandelt Sicherheitsanforderungen für pulverbetriebene handgeführte Befestigungs- und Hartmarkierwerkzeuge, die mit einem Zwischenglied (Kolben) funktionieren und manuell bedient werden.

Dieses Dokument befasst sich mit allen signifikanten Gefährdungen (siehe Anhang I), Gefährdungssituationen und Ereignissen, die auftreten können, wenn pulverbetriebene Befestigungs- und Hartmarkierwerkzeuge wie vorgesehen verwendet werden oder unter Bedingungen einer vernünftigerweise vorhersehbaren Fehlanwendung (siehe Abschnitt 4). Es behandelt die signifikanten Gefährdungen in den verschiedenen Betriebsarten sowie Eingriffsmöglichkeiten nach EN ISO 12100:2010, 5.4, 5.5, 5.6.

Obwohl die Gebrauchssicherheit pulverbetriebener Werkzeuge in erheblichem Maß von der Verwendung geeigneter Kartuschen und Befestigungselemente abhängig ist, formuliert dieses Dokument keine Anforderungen an die mit den Werkzeugen zu verwendenden Kartuschen und Befestigungselemente (siehe Abschnitt 6).

Dieses Dokument ist anwendbar für Werkzeuge, die für die Verwendung von Kartuschen mit Hülsen aus Metall oder Kunststoff sowie festem Treibmittel vorgesehen sind, welche eine geringe Menge Zündmittel mit einer von der des Haupttreibmittels abweichenden Zusammensetzung enthalten.

Dieses Dokument ist anwendbar für Werkzeuge, die für die Verwendung mit einzelnen Kartuschen oder mit Kartuschen, die in Scheiben oder Streifen zusammengefasst sind, ausgelegt sind.

Die in den Anwendungsbereich fallenden Befestigungswerkzeuge sind jene, die für den Gebrauch mit Befestigungselementen aus Metall vorgesehen sind.

ANMERKUNG Angaben zu Kartuschen sind entweder in EN 16264:2014 oder den Veröffentlichungen der Ständigen Internationalen Kommission zur Prüfung von Handfeuerwaffen (C.I.P, en: Commission for the Proof of Small Arms) zu entnehmen.

Dieses Dokument ist nicht anwendbar für kartuschenbetriebene Befestigungs- und Hartmarkierwerkzeuge, die vor dem Datum der Veröffentlichung dieses Dokuments hergestellt werden.

Outils portatifs de scellement et de marquage actionnés par poudre - Prescriptions de sécurité

Le présent document couvre les exigences de sécurité relatives aux outils de scellement et de marquage actionnés par poudre qui fonctionnent avec un élément intermédiaire (piston) et sont manipulés manuellement.

Le présent document traite tous les phénomènes dangereux, situations dangereuses ou événements dangereux significatifs (voir Annexe I) pertinents pour les outils de scellement et de marquage actionnés par poudre, lorsque ces outils sont utilisés normalement et dans les conditions de mauvais usage raisonnablement prévisible (voir Article 4). Il traite tous les phénomènes dangereux significatifs dans les différents modes de fonctionnement et modes opératoires d’intervention tels que mentionnés dans l’EN ISO 12100:2010, 5.4, 5.5, 5.6.

Bien que l’usage sûr d’outils actionnés par poudre dépend, dans une importante mesure, de l’emploi de cartouches et d’éléments de fixation appropriés, le présent document ne formule pas d’exigences relatives aux cartouches et aux éléments de fixation à utiliser avec les outils (voir Article 6).

Le présent document s’applique aux outils conçus pour être utilisés avec des cartouches munies d’étuis en métal ou en plastique et avec une charge propulsive pyrotechnique solide et contenant une faible quantité de mélange d’amorçage dont la composition diffère de celle de la cartouche pyrotechnique principale.

Le présent document s’applique aux outils conçus pour être utilisés avec des cartouches individuelles ou avec des cartouches groupées en disques ou en bandes.

Les outils de scellement du domaine d’application sont ceux destinés à être utilisés avec des éléments de fixation en métal.

NOTE Les informations relatives aux cartouches sont données dans l’EN 16264:2014 ou dans la publication de la Commission internationale permanente pour l’épreuve des armes à feu portatives (C.I.P.).

Le présent document ne s’applique pas aux outils de scellement et de marquage actionnés par poudre qui sont fabriqués avant la date de publication du présent document.

Ročna orodja za pritrjevanje in trdo označevanje s prašnim pogonom - Varnostne zahteve

Ta dokument zajema varnostne zahteve za orodja za pritrjevanje in trdo označevanje s prašnim pogonom, ki za delovanje uporabljajo vmesni element (bat) in se upravljajo ročno. Ta dokument obravnava vsa večja tveganja (glej dodatek I), nevarne situacije in dogodke v zvezi z orodji za pritrjevanje in trdo označevanje s prašnim pogonom, kadar se uporabljajo v skladu s predvidenim namenom in pod pogoji razumno predvidene nepravilne uporabe (glej točko 4). Obravnava večja tveganja pri različnih načinih delovanja in intervencijske postopke, opisane v točkah 5.4, 5.5 in 5.6 standarda EN ISO 12100:2010. Čeprav je varna uporaba orodij s prašnim pogonom v veliki meri odvisna od uporabe ustreznih kartuš in pritrdilnih elementov, ta dokument ne določa zahtev za kartuše in pritrdilne elemente, ki so namenjeni za uporabo z orodji (glej točko 6). Ta dokument se uporablja za orodja, namenjena za uporabo s kartušami s kovinskim ali plastičnim ohišjem in trdno pogonsko snovjo, ki vsebuje manjšo količino mešanice vžigalnega sredstva, katere sestava se razlikuje od glavne pogonske snovi. Ta dokument se uporablja za orodja, zasnovana za uporabo z enojnimi kartušami ali kartušami, zloženimi v plošče ali trakove. Orodja za pritrjevanje, ki spadajo na to področje uporabe, so namenjena za uporabo s kovinskimi pritrdilnimi elementi. OPOMBA: Informacije o kartušah je mogoče najti v standardu EN 16264:2014 ali publikaciji Stalne mednarodne komisije za preskušanje osebnega orožja (C.I.P.). Ta dokument se ne uporablja za orodja za pritrjevanje in trdo označevanje s prašnim pogonom, ki so bila izdelana pred datumom njegove objave.

General Information

- Status

- Published

- Public Enquiry End Date

- 24-Oct-2023

- Publication Date

- 23-Jul-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Jul-2025

- Due Date

- 27-Sep-2025

- Completion Date

- 24-Jul-2025

Relations

- Effective Date

- 18-Jan-2023

Overview

EN 15895:2025 is the CEN European standard that specifies safety requirements for powder actuated hand‑held fixing and hard‑marking tools that operate with an intermediate member (piston). It covers significant hazards, hazardous situations and events relevant to these tools during intended use and reasonably foreseeable misuse. The standard applies to tools designed for use with single cartridges or cartridges collated in disks or strips, and with cartridge casings of metal or plastic (solid propellant with a small primer mix). It supersedes EN 15895:2011+A1:2018 and aligns tool safety with updated design, testing and verification methods.

Key topics and technical requirements

- Scope and definitions: Clear terms and applicability for fixing and hard‑marking hand‑tools that use a piston.

- Design and construction: Enhanced safety‑related part requirements, pressure and temperature resistance, and compatibility with collated cartridges.

- Prevention of unintentional firing: Requirements and tests for operating safety, impact safety, drop safety and free‑firing safety.

- Internal ballistics and muzzle velocity: Limits and verification methods for piston and fastener velocities (fixing tools).

- Safe retention of the piston: Mechanical retention and verification tests to prevent piston ejection.

- Noise, recoil and exhaust: Requirements and test procedures to reduce noise emission, recoil (shock) and to control exhaust gas direction and hazardous emissions (e.g., CO, lead).

- Ergonomics and human factors: Handle design, trigger actuation and ergonomic guidance to reduce operator risk.

- Verification and testing: Detailed test methods (overpressure, drop, impact, velocity, noise, recoil) and system tests in normative annexes.

- Information for use and marking: Required user instructions, maintenance info, warnings and marking details; residual risk reporting.

- Annexes: Normative and informative annexes include test codes, safety dimensions, internal ballistics data and a list of significant hazards.

Practical applications

- Use EN 15895:2025 to design and manufacture safer powder‑actuated fixing and marking tools.

- Employ the verification and test procedures during product development, conformity assessment and quality control.

- Apply the ergonomic and information requirements to improve operator training, instructions and on‑site safety procedures.

- Reference the standard in procurement, risk assessments and compliance with EU machinery directives.

Who should use this standard

- Tool manufacturers and design engineers

- Safety and compliance engineers

- Test laboratories and conformity assessment bodies

- Health & safety authorities, trainers and site safety managers

- Purchasing/specification teams for construction and industrial operations

Related standards and guidance

- EN ISO 12100:2010 (risk assessment and machinery safety principles)

- EN 16264:2014 (cartridges for powder actuated tools) - compatibility guidance

- Directive 2006/42/EC (machinery directive) - see Annex ZA

- Publications of the Permanent International Commission for the Proof of Small Arms (C.I.P.) for cartridge information

Keywords: EN 15895:2025, powder actuated tools, safety requirements, hand‑held fixing, hard marking, cartridges, piston, CEN.

Frequently Asked Questions

SIST EN 15895:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Powder actuated hand-held fixing and hard marking tools - Safety requirements". This standard covers: This document covers safety requirements for powder actuated fixing and hard marking tools which operate with an intermediate member (piston) and are handled manually. This document deals with all significant hazards (see Annex I), hazardous situations and events relevant to powder actuated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in EN ISO 12100:2010, 5.4, 5.5, 5.6. Although the safe use of powder actuated tools depends to an important extent on the use of appropriate cartridges and fasteners, this document is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 6). This document applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer mix with a composition different from that of the main propellant. This document applies to tools designed for use with single cartridges or with cartridges collated in disks or in strips. The fixing tools in the scope are those intended for use with fasteners made from metal. NOTE Information about cartridges can be found either in EN 16264:2014 or the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.). This document is not applicable to powder actuated fixing and hard marking tools which are manufactured before this document’s date of publication.

This document covers safety requirements for powder actuated fixing and hard marking tools which operate with an intermediate member (piston) and are handled manually. This document deals with all significant hazards (see Annex I), hazardous situations and events relevant to powder actuated fixing and hard marking tools, when they are used as intended and under conditions of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the different operating modes and intervention procedures as referred to in EN ISO 12100:2010, 5.4, 5.5, 5.6. Although the safe use of powder actuated tools depends to an important extent on the use of appropriate cartridges and fasteners, this document is not formulating requirements for the cartridges and fasteners to be used with the tools (see Clause 6). This document applies to tools designed for use with cartridges with casings made of metal or plastic and with solid propellant and containing a minor quantity of primer mix with a composition different from that of the main propellant. This document applies to tools designed for use with single cartridges or with cartridges collated in disks or in strips. The fixing tools in the scope are those intended for use with fasteners made from metal. NOTE Information about cartridges can be found either in EN 16264:2014 or the publication of the Permanent International Commission for the Proof of Small Arms (C.I.P.). This document is not applicable to powder actuated fixing and hard marking tools which are manufactured before this document’s date of publication.

SIST EN 15895:2025 is classified under the following ICS (International Classification for Standards) categories: 25.140.99 - Other hand-held tools. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15895:2025 has the following relationships with other standards: It is inter standard links to SIST EN 15895:2011+A1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15895:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15895:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Ročna orodja za pritrjevanje in trdo označevanje s prašnim pogonom - Varnostne

zahteve

Powder actuated hand-held fixing and hard marking tools - Safety requirements

Pulverkraftbetriebene handgeführte Befestigungs- und Markierungswerkzeuge -

Sicherheitsanforderungen

Outils portatifs de scellement et de marquage actionnés par poudre - Prescriptions de

sécurité

Ta slovenski standard je istoveten z: EN 15895:2025

ICS:

25.140.99 Druga ročna orodja Other hand-held tools

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15895

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2025

EUROPÄISCHE NORM

ICS 25.140.99 Supersedes EN 15895:2011+A1:2018

English Version

Powder actuated hand-held fixing and hard marking tools -

Safety requirements

Outils portatifs de scellement et de marquage Pulverbetriebene handgeführte Befestigungs- und

actionnés par poudre - Exigences de sécurité Hartmarkierungswerkzeuge -

Sicherheitsanforderungen

This European Standard was approved by CEN on 4 May 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15895:2025 E

worldwide for CEN national Members.

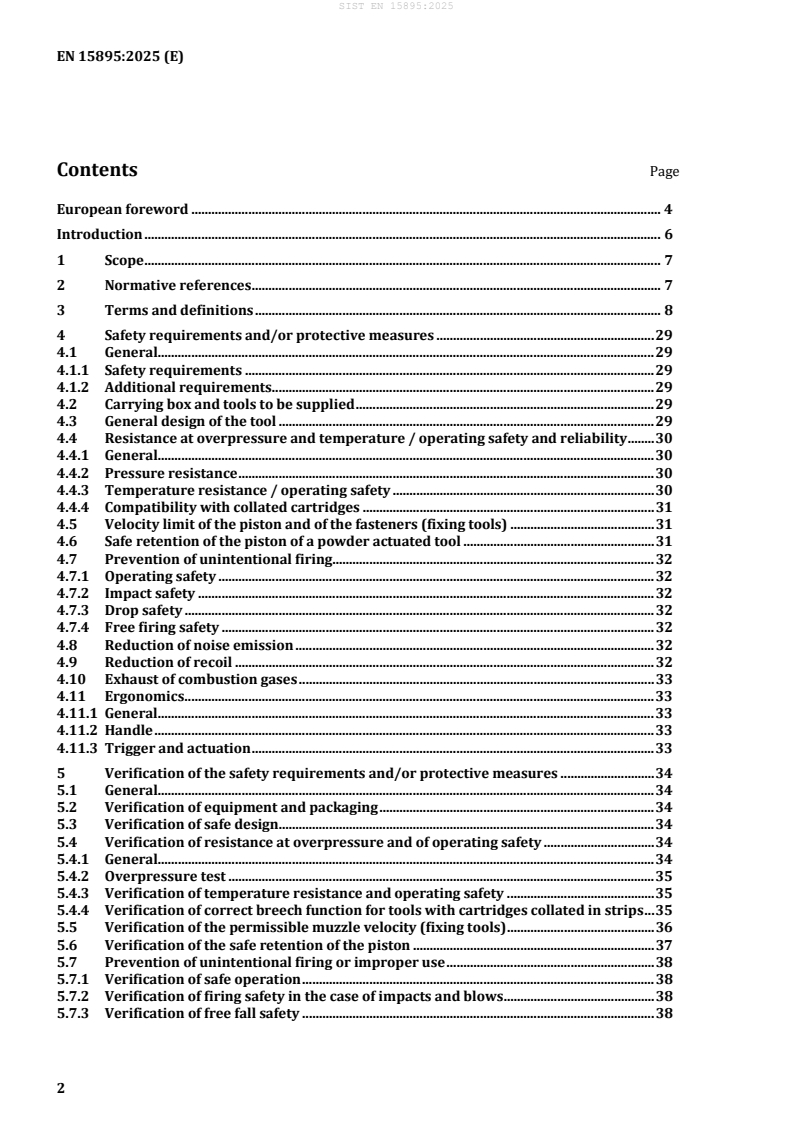

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Safety requirements and/or protective measures . 29

4.1 General. 29

4.1.1 Safety requirements . 29

4.1.2 Additional requirements. 29

4.2 Carrying box and tools to be supplied . 29

4.3 General design of the tool . 29

4.4 Resistance at overpressure and temperature / operating safety and reliability . 30

4.4.1 General. 30

4.4.2 Pressure resistance . 30

4.4.3 Temperature resistance / operating safety . 30

4.4.4 Compatibility with collated cartridges . 31

4.5 Velocity limit of the piston and of the fasteners (fixing tools) . 31

4.6 Safe retention of the piston of a powder actuated tool . 31

4.7 Prevention of unintentional firing. 32

4.7.1 Operating safety . 32

4.7.2 Impact safety . 32

4.7.3 Drop safety . 32

4.7.4 Free firing safety . 32

4.8 Reduction of noise emission . 32

4.9 Reduction of recoil . 32

4.10 Exhaust of combustion gases . 33

4.11 Ergonomics . 33

4.11.1 General. 33

4.11.2 Handle . 33

4.11.3 Trigger and actuation . 33

5 Verification of the safety requirements and/or protective measures . 34

5.1 General. 34

5.2 Verification of equipment and packaging . 34

5.3 Verification of safe design. 34

5.4 Verification of resistance at overpressure and of operating safety . 34

5.4.1 General. 34

5.4.2 Overpressure test . 35

5.4.3 Verification of temperature resistance and operating safety . 35

5.4.4 Verification of correct breech function for tools with cartridges collated in strips . 35

5.5 Verification of the permissible muzzle velocity (fixing tools) . 36

5.6 Verification of the safe retention of the piston . 37

5.7 Prevention of unintentional firing or improper use . 38

5.7.1 Verification of safe operation . 38

5.7.2 Verification of firing safety in the case of impacts and blows . 38

5.7.3 Verification of free fall safety . 38

5.7.4 Verification of free firing safety . 39

5.8 Verification of the noise emission . 39

5.9 Verification of the recoil (shock) levels . 39

5.10 Verification of exhaust direction . 39

5.11 Verification of ergonomic design . 39

6 Information for use . 40

6.1 General . 40

6.2 Signals and warning device . 40

6.3 Accompanying documents . 40

6.3.1 General . 40

6.3.2 Information for the safe use . 41

6.3.3 Information for maintenance and servicing . 42

6.3.4 Information on noise emission . 42

6.3.5 Information on vibration . 43

6.4 Residual risks . 43

6.4.1 Emission of hazardous substances: Carbon monoxide . 43

6.4.2 Emission of hazardous substances: Lead . 43

6.5 Marking . 44

Annex A (normative) Values of combustion equation for the calculation of maximum gas

pressure p in the cartridge chamber according to 3.21 . 45

max

Annex B (informative) Volumes in cartridge and cartridge chamber relevant for the internal

ballistics of a powder actuated tool . 48

Annex C (informative) Example of testing procedures for determination of muzzle velocity

................................................................................................................................................................... 49

Annex D (normative) Testing for the verification of safe operation . 50

Annex E (normative) Noise test code . 52

Annex F (informative) Information on the ergonomic design of the handle . 62

Annex G (normative) Essential safety dimensions . 63

Annex H (normative) Testing for the verification of safe operation (system test) . 64

Annex I (informative) List of significant hazards . 65

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 68

Bibliography . 70

European foreword

This document (EN 15895:2025) has been prepared by Technical Committee CEN/TC 213 “Powder

actuated hand-held tools - Safety”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2025, and conflicting national standards shall

be withdrawn at the latest by December 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15895:2011+A1:2018.

EN 15895:2011+A1:2018:

— applicability for single cartridge, collated cartridges in disks as well as collated cartridges in strips;

— enhanced design requirements for safety-related parts;

— improved compatibility with EN 16264:2014 to enable conformity assessments of new

tool/cartridge systems;

— updated requirements for drop tests;

— new and updated terms and definitions and enhanced drawings;

— new and updated standard references;

— updated informative Annex ZA.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

This document has been drawn up in co-operation with representatives of manufacturers of cartridge-

operated hand-held tools and health and safety authorities (Schweizerische Unfallversicherung (SUVA)).

The “Permanent International Commission for the Proof of Small Arms, C.I.P.” has given substantial

contributions to this document. The C.I.P. regulations pertinent to powder actuated hand-held tools have

been largely integrated in this document.

Normative and informative annexes to this document are indicated in the contents list.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document specifies up-to-date requirements for powder actuated hand-held fixing and hard

marking tools. Requirements are mainly based on safety functions. This approach significantly increases

the design details of the safety aspects.

This document is a type C standard as stated in EN ISO 12100:2010.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document. When provisions of this type C standard are

different from those which are stated in type A or B standards, the provisions of this type C standard take

precedence over the provisions of the other standards, for machines that have been designed and built

according to the provisions of this type C standard.

1 Scope

This document covers safety requirements for powder actuated fixing and hard marking tools which

operate with an intermediate member (piston) and are handled manually.

This document deals with all significant hazards (see Annex I), hazardous situations and events relevant

to powder actuated fixing and hard marking tools, when they are used as intended and under conditions

of misuse which are reasonably foreseeable (see Clause 4). It deals with the significant hazards in the

different operating modes and intervention procedures as referred to in EN ISO 12100:2010, 5.4, 5.5, 5.6.

Although the safe use of powder actuated tools depends to an important extent on the use of appropriate

cartridges and fasteners, this document is not formulating requirements for the cartridges and fasteners

to be used with the tools (see Clause 6).

This document applies to tools designed for use with cartridges with casings made of metal or plastic and

with solid propellant and containing a minor quantity of primer mix with a composition different from

that of the main propellant.

This document applies to tools designed for use with single cartridges or with cartridges collated in disks

or in strips.

The fixing tools in the scope are those intended for use with fasteners made from metal.

NOTE Information about cartridges can be found either in EN 16264:2014 or the publication of the Permanent

International Commission for the Proof of Small Arms (C.I.P.).

This document is not applicable to powder actuated fixing and hard marking tools which are

manufactured before this document’s date of publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 16264:2014, Pyrotechnic articles — Other pyrotechnic articles — Cartridges for powder actuated tools

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals (IEC 61310-1:2007)

EN 61672-1:2013, Electroacoustics — Sound level meters - Part 1: Specifications (IEC 61672-1:2013)

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

ISO 2768-1:1989, General tolerances — Part 1: Tolerances for linear and angular dimensions without

individual tolerance indications

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

powder actuated tool

PAT

tool with a piston powered by the hot combustion gases from a cartridge and comprising powder

actuated fixing and hard marking tools

Note 1 to entry: Referred to as cartridge-operated fixing and other impact machinery in Directive 2006/42/EU,

Annex IV, Clause 18.

Note 2 to entry: Referred to as portable cartridge-operated fixing and other impact machinery in Regulation

(EU) 2023/1230, Annex I, Part A, Number 4.

3.1.1

tool for single cartridges

tool designed for the use of single cartridges

Note 1 to entry: Also called single-shot tools.

3.1.2

tool for collated cartridges

tool designed for the use of cartridges collated in disks or strips

Note 1 to entry: Also called tools for collated cartridges.

Note 2 to entry: Conventionally cartridges are collated in disks or strips.

3.2

fixing tool

tool to drive fasteners into base materials

3.3

hard marking tool

tool for embossing characters, symbols or letters on the surface of workpieces by means of punches, e.g.

made of hardened steel

3.4

universal tool

tool which is intended for use in any possible operating direction and which can be held with one or two

hands

3.5

stand-up tool

tool which is intended for the operating direction vertically downward and which is operated with both

hands and with the operator in a standing position

Note 1 to entry: A universal tool which is operated in the vertically downward operating direction with a long

auxiliary handle or in a fixture is not considered a stand-up tool.

3.6

pole tool

tool which is affixed to the end of a pole and which is intended exclusively for the operating direction

vertically upward and which is operated with both hands and with the operator in a standing position

Note 1 to entry: A universal tool affixed to a pole which is an accessory is not considered a pole tool.

3.7

cartridge

device which contains a primer mix and a propellant creating hot high-pressure combustion gas used to

drive the piston

Note 1 to entry: See Figure 1.

Figure 1 — Cartridge (example: calibre 6,8/11; external view and section)

3.7.1

single cartridge

cartridge intended to be inserted by hand in the cartridge chamber one at a time

3.7.2

collated cartridge

cartridge that is contained with a number of others in a means of collation, either a disk or a strip

3.7.3

proof cartridge

cartridge used exclusively for strength testing of tools and loaded with a stronger than usual propellant

charge

Note 1 to entry: See 5.4.2 and Annex A.

3.8

cartridge chamber

essentially cylindrical or conical bore in a powder actuated fixing or hard marking tool which contains

and supports the cartridge; located in the rear end of the piston guide

Note 1 to entry: The safety-relevant minimum allowable dimensions of the cartridge chamber correspond to the

cartridge calibre and are listed in Table G.1 (see also 3.8.1 and 3.8.2).

Note 2 to entry: In order to ensure correct chambering, the minimum dimensions of the cartridge chamber are

larger than or equal to the corresponding maximum allowable dimensions of the cartridge of the respective calibre.

EN 16264:2014 provides information on maximum cartridge dimensions.

3.8.1

cartridge chamber

tool for single cartridges

cartridge chamber designed to receive a single cartridge

Note 1 to entry: See Figure 2.

Key

P minimum diameter of cartridge chamber

L minimum length of cartridge chamber

R minimum axial depth of recess in cartridge chamber receiving rim of cartridge

R minimum diameter of recess in cartridge chamber receiving rim of cartridge

NOTE Adequate chambering in a tool for single cartridges is assured by observing the calibre-specific

dimensions of P1, L3, R, and R1 in the design of the tool.

Figure 2 — Cartridge chamber (tool for single cartridges)

3.8.2

cartridge chamber

tool for cartridges collated in disks

cartridge chamber designed to receive a cartridge collated in a disk

Note 1 to entry: See Figure 3.

Key

1 cartridge chamber

2 breech block with breech face (left)

P1 minimum diameter of cartridge chamber

L3 minimum length of cartridge chamber

R minimum axial depth of recess in cartridge chamber receiving rim of cartridge

R minimum diameter of recess in cartridge chamber receiving rim of cartridge

NOTE 1 Adequate chambering in a tool for disk collated cartridges is assured by observing the calibre-specific

dimensions of P1 and L3 in the design of the tool.

NOTE 2 R and R requirements as in a single-shot tool are less relevant in a disk collated tool as any deviation

from suitable R and R1 will lead to incomplete breech block closing and/or no actuation or inefficient percussion of

the cartridge.

Figure 3 — Cartridge collated in a disk (chambered)

3.8.3

cartridge chamber

tool for cartridges collated in strips

cartridge chamber designed to receive a cartridge collated in a strip

Note 1 to entry: See Figure 4.

Key

1 cartridge chamber

2 breech block with breech face (left)

NOTE 1 Adequate chambering in a tool for cartridges collated in strips is proven by the testing procedure in

Annex H and 5.4.4.

NOTE 2 In a tool for cartridges collated in strips, the dimensions of the cartridge chamber cannot be measured

on the tool. The collar of the collation strip surrounding the cartridge acts as a gasket between the cylindrical

cartridge and the conical cartridge chamber.

NOTE 3 The dimensions of the bore of the strip roughly correspond to the cartridge chamber dimensions in a

tool for single cartridges. However, to prevent loss of the cartridge and maintain its tight fit, the bore diameter is

designed and manufactured slightly tighter than the outer diameter (calibre) of the cartridge. The strip deforms and

retains the cartridge by the friction created by the undersize.

NOTE 4 Similarly, the conical outer surface of the collar corresponds approximately to the shape and dimensions

of the conical chamber bore of the tool.

NOTE 5 During chambering, the advancing breech face pushes the cartridge forward together with the strip and

compresses the strip against the cartridge chamber. The strip is slightly deformed and seals the chamber against

the breech face against the gas pressure which will build up after firing.

NOTE 6 Therefore, before firing and unlike in a tool for single cartridges, the cartridge does not necessarily make

contact with the cartridge chamber of the tool to create a gas-tight seal.

Figure 4 — Cartridge collated in a strip (chambered)

3.9

chambering

act of loading a cartridge into the chamber prior to firing the tool

Note 1 to entry: Correct chambering requires adequate and near-complete enclosure of the cartridge by

components of the tool so as to adequately support the cartridge walls and prevent the cartridge from rupturing

under the gas pressure.

3.10

calibre

designation of a cartridge, derived from the main dimensions and normally expressed in the form “body

diameter/length”

Note 1 to entry: Annex A lists calibres for PAT cartridges.

3.11

fastener

fixing device intended for use in a fixing tool

Note 1 to entry: The fixing device can be a nail, a threaded stud, an eyelet or a similar object intended to be

driven into a base material.

3.12

base material

material into which the fastener is driven

3.13

average muzzle velocity

v

mean arithmetic value of test element/piston velocity evaluated out of 10 single test values

Note 1 to entry: See 5.5.

3.14

maximum muzzle velocity

v

e

maximum test element/piston velocity to be expected calculated on the basis of the average

muzzle velocity and the standard deviation for the 10 tests

Note 1 to entry: See 5.5.

3.15

volumes

V

x

empty spaces inside the tool and / or the cartridge relevant for internal ballistics, i.e. determining the

maximum gas pressure p developed by the combustion of the propellant

max

Note 1 to entry: In single shot tools, the volumes can be directly calculated based on dimensional measurements in

*

combination with the volumes V and V tabulated in Annex A.

ET

h

Note 2 to entry: In case of tools for collated cartridges, volumes shall be calculated based on CAD analysis because

not all the relevant dimensions (or none of them) are represented in the tool, but in the collation system (compare

3.8.2, 3.8.3 and the informative Annex B for relations between the volumes defined in 3.16 to 3.24).

3.16

total volume

V

tot

sum of the volumes of the combustion chamber and the empty cartridge chamber as determined from

the design drawings or CAD models

Note 1 to entry: See Figure 5.

a) total volume V

tot

(tool for single cartridges)

b) total volume V

tot

(tool for cartridges collated in disks)

c) total volume V

tot

(tool for cartridges collated in strips)

Key

1 total volume Vtot

NOTE Vtot is a design-specific value.

Figure 5 — Total volume V

tot

3.17

minimum volume of the cartridge chamber

V

ET

volume of the smallest technically possible cartridge chamber for a given calibre and the maximum length

of the open cartridge, L

Note 1 to entry: See Figure 6.

a) minimum volume of the cartridge chamber V

ET

(tool for single cartridges)

(comp. Table G.1 for L )

b) minimum volume of the cartridge chamber V

ET

(tool for cartridges collated in disks)

(comp. Table G.1 for L )

c) minimum volume of the cartridge chamber V

ET

(tool for cartridges collated in strips)

(comp. Table G.1 for L )

Key

1 minimum volume of the cartridge chamber VET

L3 maximum length of the open cartridge

NOTE V and L are constant values for each calibre and are laid down in Table A.1 of Annex A.

ET 3

Figure 6 — Minimum volume of the cartridge chamber V

ET

3.18

minimum operational volume of the combustion chamber

V

a

volume consisting of the volume of the combustion chamber with the piston in its extreme top position

and the open volume in the piston head, if any

Note 1 to entry: See Figure 7.

a) minimum operational volume of the combustion chamber V

a

(tool for single cartridges)

(comp. Table G.1 for L )

b) minimum operational volume of the combustion chamber V

a

(tool for cartridges collated in disks)

(comp. Table G.1 for L )

c) minimum operational volume of the combustion chamber V

a

(tool for cartridges collated in strips)

(comp. Table G.1 for L )

Key

1 minimum operational volume of the combustion chamber Va

L3 maximum length of the open cartridge

NOTE V is a design-specific value and is calculated as the difference between the design-specific volume V

a tot

and the calibre-specific volume VET:

VV− V

a tot ET

Figure 7 — Minimum operational volume of the combustion chamber V

a

3.19

reduced volume of the cartridge chamber

*

V

h

volume of the minimum size cartridge chamber V minus the volumes of the cartridge casing and the

ET

propellant

Note 1 to entry: See Figure 8.

=

*

a) reduced volume of the cartridge chamber V

h

(tool for single cartridges)

(comp. Table G.1 for L )

*

b) reduced volume of the cartridge chamber V

h

(tool for cartridges collated in disks)

(comp. Table G.1 for L )

*

c) reduced volume of the cartridge chamber V

h

(tool for cartridges collated in strips)

(comp. Table G.1 for L )

Key

*

reduced volume of the cartridge chamber V

h

(L3) maximum length of the open cartridge

NOTE 1 Hatched area inside the cartridge denotes empty space between grains of propellant.

*

NOTE 2 V is a constant value for a given calibre laid down in Table A.1 of Annex A.

h

*

Figure 8 — Reduced volume of the cartridge chamber V

h

3.20

effective combustion volume

V

eff

effective (total) volume of all connecting voids between the cartridge and the piston before the firing of

the cartridge

Note 1 to entry: See Figure 9.

**

Note 2 to entry: The effective combustion volume is calculated by V = VV+= VV+ − V

eff h a h tot ET

a) effective combustion volume V

eff

(tool for single cartridges)

b) effective combustion volume V

eff

(tool for cartridges collated in disks)

c) effective combustion volume V

eff

(tool for cartridges collated in strips)

Key

1 effective combustion volume Veff

(L3) maximum length of the open cartridge

NOTE 1 Hatched area inside the cartridge denotes empty space between grains of propellant.

NOTE 2 V is the volume which in combination with the selected cartridge energy effectively determines the gas

eff

pressure generated in a tool.

NOTE 3 Veff is a design specific value.

Figure 9 — Effective combustion volume V

eff

3.21

maximum gas pressure

p

max

maximum value of combustion pressure in the cartridge chamber depending on the calibre and the

effective volume of the combustion chamber

Note 1 to entry: pmax is calculated according to the combustion equation

b

p aV⋅

max eff

*

with V VV+ as the effective combustion volume, thus

eff h a

b

*

p =aV⋅+ V

( )

max h a

Note 2 to entry: Table A.1 of Annex A contains all the necessary values of a, b, etc. per calibre.

Note 3 to entry: The maximum gas pressure p is a constant value per tool with its individual minimum

max

operational volume of the combustion chamber Va and thus its individual effective combustion volume Veff. It refers

to the strongest possible cartridge of the respective calibre.

=

=

3.22

reduced proof volume of the combustion chamber

V

E

reduced proof volume of the combustion chamber for resistance testing with an overpressure of 1,3 times

of the maximum gas pressure p

max

Note 1 to entry See Figure 10.

Note 2 to entry VE is calculated using the equation

*

bb

VV1,3 ⋅+ 1,3−⋅1 V

Eha

a) reduced proof volume of the combustion chamber V

E

(tool for single cartridges)

=

b) reduced proof volume of the combustion chamber V

E

(tool for cartridges collated in disks)

c) reduced proof volume of the combustion chamber V

E

(tool for cartridges collated in strips)

Key

1 reduced proof volume of the combustion chamber VE

L maximum length of the open cartridge

NOTE VV<

Ea

Figure 10 — Reduced proof volume of the combustion chamber V

E

3.23

system test

procedure for testing a tool for its suitability of operation with collated cartridges

Note 1 to entry: As described in the normative Annex H.

3.24

reduced system testing volume of the combustion chamber

V

S

reduced volume of the combustion chamber for system testing with an overpressure of 1,15 times of the

maximum gas pressure p of each tested cartridge energy

max

Note 1 to entry: See Figure 11.

Note 2 to entry: V is calculated using the equation

S

*

bb

V 1,,15 ⋅ V+ 1 15−⋅1 V

S ah

a) reduced system testing volume of the combustion chamber V

S

(tool for single cartridges)

=

b) reduced system testing volume of the combustion chamber V

S

(tool for cartridges collated in disks)

c) reduced system testing volume of the combustion chamber V

S

(tool for cartridges collated in strips)

Key

1 reduced system testing volume VS

L maximum length of the open cartridge

NOTE V <

Es a

Figure 11 — Reduced system testing volume of the combustion chamber V

S

3.25

A-weighted emission sound pressure level

L

pA

ten times the logarithm to the base 10 of the ratio of the square of the A-weighted emission sound

pressure, p, to the square of a reference value, p

Note 1 to entry: is expressed in decibels and the reference value, p , is 20 µPa.

L 0

pA

3.26

A-weighted single event emission sound pressure level in dB

L

EA

A-weighted and time-integrated emission sound pressure level of an isolated single sound event of

specified duration T (or specified measurement time interval T = t2 – t1 covering the single event),

normalized to reference time interval T = 1 s

Note 1 to entry: L is expressed in decibels and given by the following equation:

EA

p t

T ( )

1

L = 10lg dt dB

EA ∫

0 2

T

p

Note 2 to entry: The reference sound pressure is p = 20 µPa.

3.27

sound energy level in dB

L

J

ten times the logarithm to the base 10 of the ratio of the sound energy, J, radiated by the sound source

under test, to the reference sound energy, J

Note 1 to entry: L is expressed in decibels and given by the following equation

J

J

L = 10lg dB

J

J

where the reference value, J , is 1 pJ.

Note 2 to entry: The A-weighted sound energy level is denoted by LJA.

3.28

C-weighted peak emission sound pressure level in dB

L

pC, peak

ten times the logarithm to the base 10 of the ratio of the square of the peak emission sound pressure,

p , to the square of a reference value, p

peak 0

Note 1 to entry: L is expressed in decibels and the reference value, p0, is 20 µPa.

pC, peak

3.29

piston stopping device

dedicated component for preventing the piston from being ejected from the tool

Note 1 to entry: The piston stopping device is often an exchangeable wear part.

3.30

operation rate

number of driving processes per unit of time, e.g. per hour

3.31

fastener guide

front part of a powder-actuated tool with a bore coaxial with the piston, which serves as a

guide for the fastener

Note 1 to entry: Some tools are equipped with interchangeable fastener guides and associated pistons for

different fastening tasks.

4 Safety requirements and/or protective measures

4.1 General

4.1.1 Safety requirements

Powder actuated hand-held tools shall comply with the safety requirements and/or protective measures

of this clause.

4.1.2 Additional requirements

In addition, the tool shall be designed according to the principles of EN ISO 12100:2010 for relevant but

not significant hazards, which are not dealt with by this document.

4.2 Carrying box and tools to be supplied

Powder actuated fixing and hard marking tools shall be supplied with the following equipment:

a) specific tools required for maintenance and cleaning of the tool in compliance with the instruction

handbook;

b) solid box which can be protected/secured against unauthorized opening and having space for the

powder actuated tool, instructions for use, essential tools for daily maintenance and cleaning (e.g.

brushes), and protective accessories other than personal protective equipment, such as e.g. spall

guards. To protect the box against unauthorized opening, the box shall have a lock or allow the user

to affix a lock of his own choice, e.g. a padlock.

For verification see 5.2.

4.3 General design of the tool

4.3.1 General

Powder actuated fixing and marking tools shall be designed for correct and safe functioning with the

cartridges, collation systems and the fasteners or marking accessories for which they are intended.

4.3.2 Tools that are intended to be used in applications where spalls might occur shall have fixtures

where spall guards can be attached at the front end of the tool, e.g. the fastener guide. Matching spall

guards shall be made available by the manufacturer.

4.3.3 The design of the tool shall prevent errors that could be made when assembling and reassembling

parts of them if such errors can be a hazard.

Relevant errors in assembly are e.g.:

— assembling a tool with a wrong piston stopping device or without inserting a piston stopping device;

— assembling a tool without sufficiently tightening the thread joining the fastener guide and the main

tool body;

— fitting a guard with too much distance from the work surface.

The manufacturer shall indicate all the parts which can be disassembled and reassembled by the user

which could create a hazard if they were mounted incorrectly. These parts shall be designed such that

they cannot be assembled in a way that they create a hazard.

In particular, parts that shall be considered are:

— piston;

— piston stopping device;

— fastener guide;

— magazine (tools for collated fasteners);

— spall guard.

For verification see 5.3.3.

4.3.4 Essential dimensions

For single shot tools (tools for single cartridges), the safety-relevant dimensions of the cartridge chamber

P , L , R, and R shall match the dimensions of the related cartridges.

1 3 1

For tools with cartridges collated in disks, the safety-relevant dimensions P and L of the cartridge

1 3

chamber shall match the dimensions of the related cartridges.

For verification, see 5.3.4.

For tools with cartridges collated in strips, no verification of dimensions is required.

4.4 Resistance at overpressure and temperature / operating safety and reliability

4.4.1 General

The design of the tool shall ensure that the combustion pressure and the temperature do not cause

damage to the tool itself or to the system components which are directly affected by this pressure and

this temperature and are relevant for user safety.

4.4.2 Pressure resistance

The tool shall be able to withstand the highest pressures that can be expected without any deformation,

cracks or other defects.

For verification

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...