SIST EN 13480-3:2018/A2:2020

(Amendment)Metallic industrial piping - Part 3: Design and calculation

Metallic industrial piping - Part 3: Design and calculation

Specifies the design and calculation of industrial metallic piping systems, including supports, covered by EN 13480. Revision of Clause 12 and Annex H related to Stress Intensification Factors SIF

Metallische industrielle Rohrleitungen - Teil 3: Konstruktion und Berechnung

Tuyauteries industrielles métalliques - Partie 3 : Conception et calcul

No scope available

Kovinski industrijski cevovodi - 3. del: Konstruiranje in izračun - Dopolnilo A2

General Information

- Status

- Withdrawn

- Public Enquiry End Date

- 04-May-2019

- Publication Date

- 14-Sep-2020

- Withdrawal Date

- 07-Nov-2024

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 03-Oct-2024

- Due Date

- 26-Oct-2024

- Completion Date

- 08-Nov-2024

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 01-Dec-2024

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 01-Oct-2020

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

SIST EN 13480-3:2018/A2:2020 is a amendment published by the Slovenian Institute for Standardization (SIST). Its full title is "Metallic industrial piping - Part 3: Design and calculation". This standard covers: Specifies the design and calculation of industrial metallic piping systems, including supports, covered by EN 13480. Revision of Clause 12 and Annex H related to Stress Intensification Factors SIF

Specifies the design and calculation of industrial metallic piping systems, including supports, covered by EN 13480. Revision of Clause 12 and Annex H related to Stress Intensification Factors SIF

SIST EN 13480-3:2018/A2:2020 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13480-3:2018/A2:2020 has the following relationships with other standards: It is inter standard links to SIST EN 13480-3:2024, SIST EN ISO 6506-1:2014, SIST EN 15001-1:2023, SIST EN 12952-3:2023, SIST EN ISO 15156-2:2021, SIST EN 14071:2025, SIST EN 13480-3:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13480-3:2018/A2:2020 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC, EUR-PUB; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13480-3:2018/A2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2020

Kovinski industrijski cevovodi - 3. del: Konstruiranje in izračun - Dopolnilo A2

Metallic industrial piping - Part 3: Design and calculation

Metallische industrielle Rohrleitungen - Teil 3: Konstruktion und Berechnung

Tuyauteries industrielles métalliques - Partie 3 : Conception et calcul

Ta slovenski standard je istoveten z: EN 13480-3:2017/A2:2020

ICS:

23.040.10 Železne in jeklene cevi Iron and steel pipes

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13480-3:2017/A2

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2020

EUROPÄISCHE NORM

ICS 23.040.01

English Version

Metallic industrial piping - Part 3: Design and calculation

Tuyauteries industrielles métalliques - Partie 3 : Metallische industrielle Rohrleitungen - Teil 3:

Conception et calcul Konstruktion und Berechnung

This amendment A2 modifies the European Standard EN 13480-3:2017; it was approved by CEN on 12 July 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for inclusion of

this amendment into the relevant national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This amendment exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13480-3:2017/A2:2020 E

worldwide for CEN national Members.

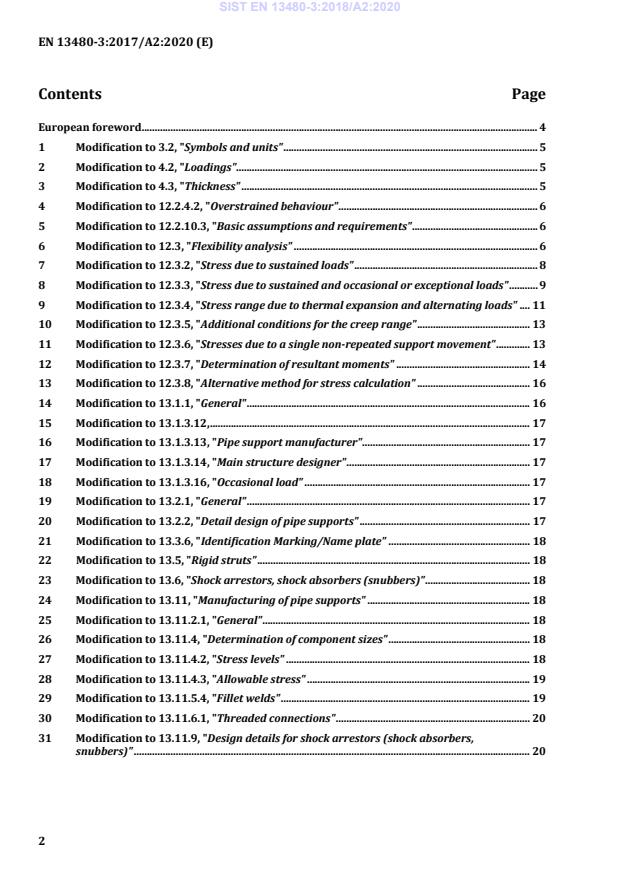

Contents Page

European foreword . 4

1 Modification to 3.2, "Symbols and units" . 5

2 Modification to 4.2, "Loadings". 5

3 Modification to 4.3, "Thickness" . 5

4 Modification to 12.2.4.2, "Overstrained behaviour" . 6

5 Modification to 12.2.10.3, "Basic assumptions and requirements" . 6

6 Modification to 12.3, "Flexibility analysis" . 6

7 Modification to 12.3.2, "Stress due to sustained loads" . 8

8 Modification to 12.3.3, "Stress due to sustained and occasional or exceptional loads" . 9

9 Modification to 12.3.4, "Stress range due to thermal expansion and alternating loads" . 11

10 Modification to 12.3.5, "Additional conditions for the creep range" . 13

11 Modification to 12.3.6, "Stresses due to a single non-repeated support movement" . 13

12 Modification to 12.3.7, "Determination of resultant moments" . 14

13 Modification to 12.3.8, "Alternative method for stress calculation" . 16

14 Modification to 13.1.1, "General" . 16

15 Modification to 13.1.3.12, . 17

16 Modification to 13.1.3.13, "Pipe support manufacturer" . 17

17 Modification to 13.1.3.14, "Main structure designer" . 17

18 Modification to 13.1.3.16, "Occasional load" . 17

19 Modification to 13.2.1, "General" . 17

20 Modification to 13.2.2, "Detail design of pipe supports" . 17

21 Modification to 13.3.6, "Identification Marking/Name plate" . 18

22 Modification to 13.5, "Rigid struts" . 18

23 Modification to 13.6, "Shock arrestors, shock absorbers (snubbers)" . 18

24 Modification to 13.11, "Manufacturing of pipe supports" . 18

25 Modification to 13.11.2.1, "General" . 18

26 Modification to 13.11.4, "Determination of component sizes" . 18

27 Modification to 13.11.4.2, "Stress levels" . 18

28 Modification to 13.11.4.3, "Allowable stress" . 19

29 Modification to 13.11.5.4, "Fillet welds" . 19

30 Modification to 13.11.6.1, "Threaded connections" . 20

31 Modification to 13.11.9, "Design details for shock arrestors (shock absorbers,

snubbers)" . 20

32 Modification to Annex H, “Flexibility characteristics, flexibility and stress

intensification factors and section moduli of piping components and geometrical

discontinuities" . 20

33 Modification to Annex J, "Type testing of support components" . 32

European foreword

This document (EN 13480-3:2017/A2:2020) has been prepared by Technical Committee CEN/TC 267

“Industrial piping and pipelines”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2021, and conflicting national standards

shall be withdrawn at the latest by February 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of

EN 13480-3:2017.

This document includes the text of the amendment itself. The amended/corrected pages of

EN 13480-3:2017 will be published as Issue 4 of the European Standard.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Modification to 3.2, "Symbols and units"

Table 3.2-1 shall be completed with the line e to be placed after e :

c n

e corroded thickness (see Figure 4.3–1 and Figure 4.3–2) mm

c

2 Modification to 4.2, "Loadings"

The second sentence of subclause 4.2.4.6 shall read as follows:

“The specification shall give details relating to the characteristics of the seismic conditions (design basis

earthquake and/or safe shut-down earthquake) to be taken into account.”

The last indent of 4.2.5.2.1 shall read as follows:

“— seismic conditions (Design Basis Earthquake).”

3 Modification to 4.3, "Thickness"

The new Figure 4.3-1 shall read as follows:

The key of Figure 4.3-1 shall be updated with the following correction and addition:

c is the thinning allowance for possible thinning during manufacturing process;

e is the wall thickness after corrosion or erosion used for flexibility analysis in Clause 12;

c

The new Figure 4.3-2 shall read as follows:

The key of Figure 4.3-2 shall be updated with the following correction and addition:

c is the thinning allowance for possible thinning during manufacturing process;

e is the wall thickness after corrosion or erosion used for flexibility analysis in chapter 12;

c

4 Modification to 12.2.4.2, "Overstrained behaviour"

The first indent shall read as follows:

— Where there is large deflection at the connecting point between two pipes with significantly

different cross section;

5 Modification to 12.2.10.3, "Basic assumptions and requirements"

The last paragraph of subclause 12.2.10.3.1 shall read as follows:

When friction forces are significant, they shall be considered in the piping design.

6 Modification to 12.3, "Flexibility analysis"

The revised Clause 12.3.1 shall read as follows:

“12.3.1 General

The following determination and limitation of stresses shall be used to ensure the safe operation of the

piping.

The Formulae (12.3.2-1) and (12.3.3-1) deal with the longitudinal stresses due to design and operating

loadings, and the Formulae (12.3.4-1) and (12.3.4-2) with the stress range due to such loadings that

gives rise to deformation of the total system.

In Formula (12.3.5-1), one-third of the stress resulting from thermal expansion and alternating loadings

are taken into consideration with respect to the material behaviour in the creep rupture stress range,

assuming that two-thirds will be relieved by relaxation.

Formula (12.3.6-1) ensures that in the event of a single non-repeated load, no strain occurs which can

adversely affect the material.

The forces and moments shall be determined for nominal thickness of the pipe e .

n

The longitudinal stresses for primary loads shall be determined based on the corroded thickness e .

c

The longitudinal stresses for thermal expansion and alternating loads shall be determined based on

nominal thickness e .

n

NOTE Wall thickness reductions, allowed by the technical conditions of delivery for seamless and welded

pipes are covered by the stress limits.

The stress intensification factors, i, i , i , are given in Tables H-1 to H-3 and are calculated based on

i o

nominal wall e .

n

4 4

π()dd−

oi

The sectional modulus of the nominal pipe is: Z=

32d

o

Unless specified otherwise, it is assumed that corrosion happens on the inside of the pipe so that the

inner diameter after corrosion is dd− 2e

io c

π(d −−(d 2e ))

o oc

and the sectional modulus of the corroded pipe is: Z =

c

32d

o

Using the alternative equations given in 12.3.2 to 12.3.6 with the corresponding stress intensification

factors in Table H-3, allow a more detailed determination of the stresses by considering independently

in-plane and out-of-plane moments .

For the general and the alternative route, the stress intensity factors, i, including the reduction factor

0,75, if defined, shall be greater than or equal to 1,0 (0,75 i ≥ 1,0). If a value less than 1 is obtained then

the value 1,0 shall be used.

If considerable corrosion/erosion is expected, it is taken into account in the flexibility analysis as

follows. In the Formulae (12.3.2-1), (12.3.2-2), (12.3.3-1), (12.3.3-2) and (12.3.4-2), using the sectional

modulus based on the corroded pipe.

Optionally the corrosion may be disregarded during flexibility design, if provisions are taken in order

that corrosion is detected during inspection. In this case Z and e shall be used instead of Z and e in

n c c

these equations.”

For most piping systems, the axial forces in the pipe are dominated by the internal pressure reaction

force. In special cases, such as buried pipes or pipes which are otherwise restrained in axial direction,

the axial stresses from external loads may be significant. In these cases, the axial force Q in

Formulae 12.3.2 to 12.3.6 allows taking into account these effects.

=

7 Modification to 12.3.2, "Stress due to sustained loads"

The revised Clause 12.3.2 shall read as follows:

“12.3.2 Stress due to sustained loads

The sum of primary stresses σ , due to calculation pressure, p , and the resultant moment, M , from

1 c A

weight and other sustained mechanical loads shall satisfy the following equation:

iQ 0,75 iM

QA xA

A

σ=+≤ f (12.3.2-1)

1 f

AZ

cc

where

M is the resultant moment from the sustained mechanical loads which shall be determined by using

A

the most unfavourable combination of the following loads:

— piping dead weight including insulation, internals and attachments;

— weight of fluid;

— internal pressure forces due to unrelieved axial expansion joints etc.

2

pdπ

ci

Q max Q ,+ Q

xA xS xS

Q is the axial force from the sustained mechanical loads

xS

d is the inner diameter of the corroded pipe

i

π

2 2

A ()dd− is the cross section of the pipe (reduced by the corrosion allowances)

c o i

i is the stress intensification factor for axial forces for sustained loads. Unless more precise

QA

information is available i = 1,0

QA

i is the stress intensification factor from Table H.1

is the design stress for flexibility analysis in N/mm (MPa) with .

f f = min f; f

( )

f f cr

or alternatively using the stress intensification factors from Table H.3:

(,0 75 iM ) +(,0 75 i M )

iQ

iM

ioiA oA

QA xA

t tA

σ= + +≤ f (12.3.2-2)

1 f

AZ Z

cc c

where

M is the in-plane moment from the sustained mechanical loads

iA

M is the out-of-plane moment from the sustained mechanical loads

oA

M is the torsional moment from the sustained mechanical loads

tA

=

=

i is the stress intensification factor for torsional moments. Unless more precise

t

information is available i = 1,0

t

For the consideration of pressure test loads in Formula (12.3.2-1), the calculation pressure p shall be

c

replaced by the test pressure p (see EN 13480-5). In addition, the design stress f shall be replaced

test

f

by a value of 95 % R at test temperature.”

eH

8 Modification to 12.3.3, "Stress due to sustained and occasional or exceptional

loads"

The revised Clause 12.3.3 shall read as follows:

“12.3.3 Stress due to sustained and occasional or exceptional loads

The sum of primary stresses, σ , due to internal pressure, p , resultant moment, M , from weight and

2 c A

other sustained mechanical loads and resultant moment, M , from occasional or exceptional loads shall

B

satisfy the following equation:

iQ

0,,75 iM 0 75 iM

QA x AB

σ=+ +≤ kf (12.3.3-1)

2 f

AZ Z

cc c

where

M is the resultant moment from the occasional or exceptional loads which shall be determined by

B

using the most unfavourable combination of the following loads:

— wind loads (T ≤ T /10);

B

— snow loads;

— dynamic loads from switching operations (T ≤ T /100);

B

— seismic loads (T ≤ T /100);

B

Q is the axial force from the sustained and occasional or exceptional loads

x

The axial force shall include the most unfavourable combination of the following loads:

— pressure effect (acting or not);

— sustained loads Q (acting all the time);

xA

— occasional or exceptional loads Q (acting or not, reversing or not).

xB

for reversing loads:

2

pdπ

ci

Q max QQ+ , ++QQ (12.3.3-2)

x xA xB xA xB

=

for non-reversing loads:

p ππd p d

ci ci

Q max Q , QQ+ , + Q , ++QQ (12.3.3-3)

x xA xA xB xA xA xB

f is the design stress for flexibility analysis in N/mm (MPa) with f = min f; f .

( )

f f cr

k = 1 if the occasional load is acting for more than 10 % in any 24 h operating period, e.g. normal

snow, normal wind;

k = 1,15 if the occasional load is acting for less than 10 % in any 24 h operating period;

k = 1,2 if the occasional load is acting for less than 1 % in any 24 h operating period, e.g. dynamic

loadings due to valve closing/opening, operational basis earthquake;

k = 1,3 for exceptional loads with very low probability e.g. very heavy snow/wind

(i.e. 1,75 times normal);

k = 1,8 for safe shut-down earthquake;

p is the maximum calculation pressure occurring at the considered loading condition, the calculation

c

pressure shall be taken as a minimum.

or alternatively using the stress intensification factors from Table H.3:

0,(75 iM ++M ) 0,75 i (M + M )

iQ

ioiA iB oA oB iM + iM

QA x

t tA t tB

σ + +≤ kf⋅

2 f

AZ Z

cc c

(12.3.3-4)

where

M is the moment from occasional or exceptional loads with the components:

B

M is the in-plane moment from occasional or exceptional loads

iB

M is the out-of-plane moment from occasional or exceptional loads

oB

M is the torsional moment from occasional or exceptional loads

tB

For reversing loads both signs of M shall be considered.

B

The effects of anchor displacements due to earthquake may be excluded if they are included in

Formula (12.3.4–1).

Unless specified otherwise, the following agreements apply:

a) the action time T corresponds to the bracketed values referring to the total operating time T ;

B

b) snow and wind loads are not applied simultaneously;

c) loadings with T ≤ T /100 are not applied simultaneously”;.

B

=

=

9 Modification to 12.3.4, "Stress range due to thermal expansion and alternating

loads"

The revised Clause 12.3.4 shall read as follows:

“12.3.4 Stress range due to thermal expansion and alternating loads

The stress range, σ , due to the resultant moment, M , from thermal expansion and alternating loads,

3 C

e.g. seismic loads, shall either satisfy the following equation:

iQ iM

QC xC

C

σ= +≤ f (12.3.4-1)

3 a

AZ

where

A is the nominal cross section of the pipe

π

2 2

()dd−

o i

i is the stress intensification factor for axial forces for alternating loads. Unless

QC

more precise information is available i = 1,0

QC

iM is the weighted range of resultant moment due to thermal expansion and

C

alternating loads which shall be determined from the greatest difference

between moments of any two load cases (j and k) using the moduli of elasticity

and stress intensification factors i from Table H.1 at the relevant temperatures

and pressures:

2 2 2

iM max (iM− i M )(+ iM− i M )(+−iM i M )

C j xCj k xCk j yCj k yCk jkzCj zCk

j 11.N; k .N

The stress free initial state shall be included in the range calculation if relevant.

Q is the range of axial force due to thermal expansion and alternating loads

xC

f

is the design stress for flexibility analysis in N/mm (MPa) from Formula (12.1.3–1)

a

or where the conditions of Formula 12.3.4-1 are not met, the sum of stresses, σ , due to calculation

pressure p , resultant moment, M , from sustained mechanical loads and the resultant moment, M ,

c

A C

from thermal expansion and alternating loads shall satisfy the following equation:

σ=σσ+ ≤ f+ f (12.3.4-2)

4 1 3 f a

or alternatively using the stress intensification factors from Table H.3:

22 2

(iM )(+ i M )

iQ

iM

QC xC ioiC oC

t tC

σ= + +≤ f (12.3.4-3)

3 a

AZ Z

where

M is the in-plane moment range due to thermal expansion and alternating loads

iC

==

=

=

M is the out-of-plane moment range due to thermal expansion and alternating loads

oC

M is the torsional moment range due to thermal expansion and alternating loads

tC

The above equation assumes that the moment range can be calculated as the difference between one

thermal expansion load case and the stress free initial condition.

In the case of multiple load situations with different temperature and pressure situations the stress

range (Formula 12.3.4-4) is the maximum difference between all pairs (j,k) of thermal expansion or

alternating load cases calculated in the following way:

2 2

i Q −−i Q (iM − i M )(+ i M − i M ) iM i M

ij iCj ik iCk oj oCj ok oCk

Qj xCj Qk xCk tj tCj tk tCk

σ=max + +≤ f

3 a

AZ Z

j 11.N; k .N

(12.3.4-4)

where

N is the number of load cases which contribute to thermal expansion or alternating

loads

i is the stress intensification factor for axial forces in the load case L. Unless more

QL

precise information is available i = 1,0

QL

i is the stress intensification factor for in-plane moments in the load case L taken

iL

from Table H.3 using the relevant operation conditions

i is the stress intensification factor for out-of-plane moments in the load case L

oL

taken from Table H.3 using the relevant operation conditions

i is the stress intensification factor for torsional moments in the load case L. Unless

tL

more precise information is available i = 1,0

tL

M is the in-plane moment in load case L

iCL

M is the out-of-plane moment in load case L

oCL

M is the torsional moment in load case L

tCL

or where the conditions of Formula 12.3.4-4 are not met, the sum of stresses, σ , due to calculation

pressure p , resultant moment, M , from sustained mechanical loads and the resultant moment, M ,

c A C

from thermal expansion and alternating loads shall satisfy the Formula (12.3.4-2).

Particular attention shall be given to:

— longitudinal expansion, including terminal point movements, due to thermal expansion and

internal pressure;

— anchor point movements due to earthquake if anchor displacement effects were omitted from

Formula (12.3.3-1) or (12.3.3-2);

— anchor point movements due to wind;

— frictional forces.

==

The condition of the piping during shut-down shall be also considered. Cold pull, if any, applied during

installation shall not be taken into account, i.e. the operating case pertinent to M shall be so designed

C

as if no cold pulling was applied unless the cold state including cold pull is also considered in the

calculation of the stress range.”

10 Modification to 12.3.5, "Additional conditions for the creep range"

The revised Clause 12.3.5 shall read as follows:

“12.3.5 Additional conditions for the creep range

For piping operating within the creep range, the stresses, σ , due to calculation pressure, p , resultant

5 c

moment, M , from weight and other sustained mechanical loadings, and to resultant moment, M , from

A C

thermal expansion and alternating loadings, shall satisfy the following equation:

iQ 0,75 iM

QC xC C

σ=σ++ ≤ f (12.3.5-1)

5 1 CR

33AZ

or alternatively using the stress intensification factors from Table H.3:

iQ

M M iM

QC xC

iC2 oC 2 t tC

σ=σ++ (,0 75 ii)+(,0 75 ) + ≤ f

5 1 io CR

3A 3Z 33ZZ

(12.3.5-2)

In Formula (12.3.5-1), one-third of the moment M is considered with respect to the material behaviour

C

in the creep rupture stress range, unless confirmed otherwise by detailed inelastic analysis.”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...