SIST EN 10213:2008+A1:2016

(Main)Steel castings for pressure purposes

Steel castings for pressure purposes

This European Standard applies to steel castings for pressure containing parts. It includes materials which are used for the manufacture of components, for pressure equipment.

This European Standard relates to castings characterised by their chemical composition (see Table 2) and mechanical properties (see Tables 3 to 6).

In cases where castings are joined by welding by the founder, this European Standard applies.

In cases where castings are welded:

- to wrought products (plates, tubes, forgings), or

- by non founders,

this European Standard does not apply.

NOTE For this harmonised supporting standard for materials, presumption of conformity to the Essential Requirements of the Directive is limited to technical data of the material in the standard and does not presume adequacy of the material to specific equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of the specific equipment to verify that the Essential Requirements of the Pressure Equipment Directive (PED) are satisfied.

Stahlguss für Druckbehälter

Diese Europäische Norm gilt für Stahlguss für drucktragende Teile. Sie schließt Werkstoffe ein, die für die Herstellung von Druckbehältercodes unterliegenden Teilen verwendet werden.

Diese Europäische Norm gilt für Gussstücke, die durch ihre chemische Zusammensetzung (siehe Tabelle 2) und ihre mechanischen Eigenschaften (siehe Tabellen 3 bis 6) gekennzeichnet sind.

In Fällen, in denen Gussstücke vom Gießer zusammengeschweißt werden, gilt diese Europäische Norm.

In Fällen, in denen Gussstücke geschweißt werden

zusammen mit umformbaren Erzeugnissen (Bleche, Rohre, Schmiedestücke) oder

von anderen als Gießern

gilt diese Europäische Norm nicht.

ANMERKUNG Für diese unterstützende, harmonisierte Norm für Werkstoffe ist die Annahme ihrer Konformität mit den grundlegenden Anforderungen (ESR) der Richtlinie auf die technischen Daten von Werkstoffen in dieser Europäischen Norm beschränkt, und es darf nicht angenommen werden, dass damit die Eignung des Werkstoffs für ein bestimmtes Ausrüstungsteil festgestellt ist. Folglich sollten die in dieser Werkstoffnorm angegebenen technischen Parameter im Hinblick auf die konstruktiven Anforderungen dieses bestimmten Ausrüstungsteils bewertet werden, um damit zu verifizieren, dass den ESR der Druckgeräterichtlinie (PED) entsprochen wird.

Pièces moulées en acier pour service sous pression

La présente Norme européenne concerne les pièces moulées en acier utilisées dans des appareils soumis à la pression. Elle comprend des matériaux qui sont utilisés pour la fabrication de composants pour équipements sous pression.

La présente norme est relative à des pièces moulées caractérisées par leur composition chimique (voir Tableau 2) et leurs caractéristiques mécaniques (voir Tableaux 3 à 6).

Dans les cas où des pièces moulées sont assemblées par soudage par le fondeur, la présente Norme européenne s’applique.

Dans les cas où des pièces moulées sont soudées :

— à des produits corroyés (plaques, tubes, pièces forgées) ; ou

— par des non-fondeurs ;

— la présente Norme européenne ne s’applique pas.

NOTE Pour la présente norme harmonisée support pour les matériaux, la présomption de conformité aux exigences essentielles de la Directive est limitée aux données techniques du matériau dans la norme et ne préjuge pas de l’adéquation du matériau à un équipement spécifique. En conséquence, il convient d’évaluer les données techniques mentionnées dans la norme par rapport aux exigences de conception de l’équipement spécifique pour vérifier que les exigences essentielles de la Directive Equipements Sous Pression sont satisfaites.

Jekleni ulitki za tlačne posode

Ta evropski standard se uporablja za jeklene odlitke za tlačne elemente. Vključuje materiale, ki se uporabljajo za izdelavo komponent tlačnih posod.

Ta evropski standard se nanaša na odlitke z določeno kemijsko sestavo (glej preglednico 2) in mehanskimi lastnostmi (glej preglednice od 3 do 6).

Ta evropski standard se uporablja tudi za ulitke, ki jih zavari livar.

Kadar se ulitke vari:

– na gnetene zlitine (plošče, cevi, kovane predmete) ali

– ko to izvajajo druge osebe, ki niso livarji,

se ta mednarodni standard ne uporablja.

OPOMBA: za ta harmonizirani dodatni standard za materiale so zagotovila o skladnosti z osnovnimi varnostnimi zahtevami (ESR) Direktive omejena na tehnične podatke o materialih, navedene v tem standardu, standard pa ne zagotavlja ustreznosti materiala za določen element opreme. Zato naj bi tehnične podatke, podane v tem standardu za materiale, ocenili glede na zahteve zasnove določenega elementa opreme, da se zagotovi, da so osnovne varnostne zahteve Direktive o tlačni opremi (PED) spoštovane.

General Information

- Status

- Published

- Publication Date

- 03-Jul-2016

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 24-Jun-2016

- Due Date

- 29-Aug-2016

- Completion Date

- 04-Jul-2016

Relations

- Effective Date

- 24-Feb-2016

- Effective Date

- 24-Feb-2016

- Effective Date

- 24-Feb-2016

Overview

EN 10213:2007+A1:2016 - Steel castings for pressure purposes is a CEN European standard that specifies technical delivery conditions for steel castings used in pressure-containing parts and pressure equipment. It defines cast grades by chemical composition (Table 2) and mechanical properties (Tables 3–6), covers manufacturing, heat treatment, welding by the founder, inspection, marking and packaging, and provides harmonised material data relevant to the EU Pressure Equipment Directive (PED).

Key points:

- Applies to castings intended for pressure equipment and components.

- Applies when the founder performs welding; it does not apply to castings welded to wrought products or welded by non-founders.

- Material data in the standard support PED conformity but must be assessed against specific equipment design.

Key topics and requirements

- Material designation and composition: Cast steels are designated per EN 10027 and EN 10027-2 and must meet cast-analysis limits given in the standard (see Table 2). Unspecified elements must not be intentionally added without purchaser agreement.

- Mechanical properties: Room-temperature and low/high-temperature mechanical properties are specified (Tables 3–6). Impact and proof-strength requirements are verified on test blocks; a maximum test thickness of 150 mm is noted for verification unless otherwise agreed.

- Manufacture and heat treatment: Heat treatment symbols are used to indicate required conditions; specific heat-treatment requirements and allowable manufacturing processes are included.

- Welding: Welding by the founder is permitted under the standard; welding procedure qualification (EN ISO 11970) and welder qualification (EN 287-1) are required. Annex A provides welding-related heat-treatment conditions (normative for austenitic and duplex grades).

- Inspection and non‑destructive testing (NDT): Requirements for NDT methods, extent of testing and acceptance criteria are to be agreed between purchaser and manufacturer. The standard references established NDT standards (ultrasonic, radiography, magnetic particle, penetrant testing).

- Documentation, marking and packaging: Types of inspection documents, marking, surface protection and packaging requirements are covered to support traceability and delivery.

Applications and users

Who uses EN 10213:

- Foundries and manufacturers of steel castings for pressure vessels, boilers, valves, flanges and pressure-containing components.

- Design engineers and equipment manufacturers specifying materials for pressure equipment under the PED.

- Quality inspectors, welding engineers and NDT technicians responsible for acceptance testing, welding procedure qualification and inspection.

- Procurement and regulatory compliance teams verifying material data and conformity to PED essential requirements.

Practical uses:

- Specifying cast-steel grades and heat treatment for pressure-service parts.

- Defining inspection and testing plans for delivery of cast components.

- Ensuring welding and fabrication meet material and NDT acceptance criteria.

Related standards

- EN 1559-2 (technical delivery conditions for castings)

- EN 10027 series (steel designation)

- EN ISO 11970 (welding procedure qualification for steel castings)

- EN 12680 (ultrasonic examination of castings)

- EN 10204 (types of inspection documents)

- NDT standards: EN ISO 3452‑1, EN ISO 5579, EN ISO 16810, EN ISO 9934‑1

For purchasers and suppliers of pressure equipment components, EN 10213 is a primary reference for specifying steel castings, matching material properties to design requirements and supporting PED compliance.

Frequently Asked Questions

SIST EN 10213:2008+A1:2016 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Steel castings for pressure purposes". This standard covers: This European Standard applies to steel castings for pressure containing parts. It includes materials which are used for the manufacture of components, for pressure equipment. This European Standard relates to castings characterised by their chemical composition (see Table 2) and mechanical properties (see Tables 3 to 6). In cases where castings are joined by welding by the founder, this European Standard applies. In cases where castings are welded: - to wrought products (plates, tubes, forgings), or - by non founders, this European Standard does not apply. NOTE For this harmonised supporting standard for materials, presumption of conformity to the Essential Requirements of the Directive is limited to technical data of the material in the standard and does not presume adequacy of the material to specific equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of the specific equipment to verify that the Essential Requirements of the Pressure Equipment Directive (PED) are satisfied.

This European Standard applies to steel castings for pressure containing parts. It includes materials which are used for the manufacture of components, for pressure equipment. This European Standard relates to castings characterised by their chemical composition (see Table 2) and mechanical properties (see Tables 3 to 6). In cases where castings are joined by welding by the founder, this European Standard applies. In cases where castings are welded: - to wrought products (plates, tubes, forgings), or - by non founders, this European Standard does not apply. NOTE For this harmonised supporting standard for materials, presumption of conformity to the Essential Requirements of the Directive is limited to technical data of the material in the standard and does not presume adequacy of the material to specific equipment. Consequently the technical data stated in the material standard should be assessed against the design requirements of the specific equipment to verify that the Essential Requirements of the Pressure Equipment Directive (PED) are satisfied.

SIST EN 10213:2008+A1:2016 is classified under the following ICS (International Classification for Standards) categories: 77.140.30 - Steels for pressure purposes; 77.140.80 - Iron and steel castings. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10213:2008+A1:2016 has the following relationships with other standards: It is inter standard links to SIST EN 10213:2008/AC:2008, SIST EN 10213:2008/kprA1:2015, SIST EN 10213:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 10213:2008+A1:2016 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 10213:2008+A1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stahlguss für DruckbehälterPièces moulées en acier pour service sous pressionSteel castings for pressure purposes77.140.80Železni in jekleni ulitkiIron and steel castings77.140.30Jekla za uporabo pod tlakomSteels for pressure purposesICS:Ta slovenski standard je istoveten z:EN 10213:2007+A1:2016SIST EN 10213:2008+A1:2016en,fr,de01-september-2016SIST EN 10213:2008+A1:2016SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 10213:2007+A1

June 2016 ICS 77.140.30 Supersedes EN 10213:2007

English Version

Steel castings for pressure purposes

Pièces moulées en acier pour service sous pression

Stahlguss für Druckbehälter This European Standard was approved by CEN on 11 March 2016.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2016 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 10213:2007+A1:2016 E SIST EN 10213:2008+A1:2016

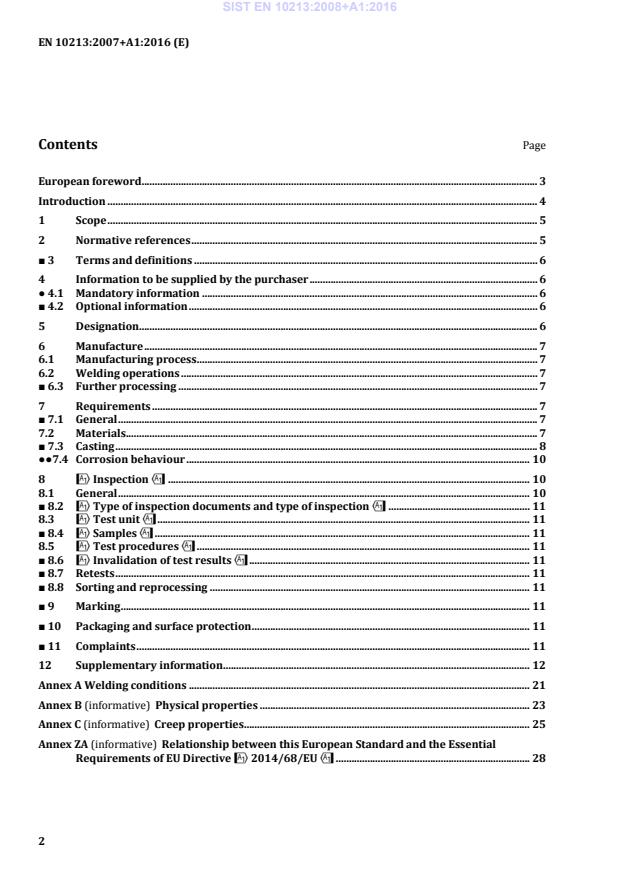

Physical properties . 23 Annex C (informative)

Creep properties . 25 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive !2014/68/EU" . 28

6.2 Welding operations 6.2.1 General Unless otherwise agreed welding is permitted, provided that all welds shall conform to the same criteria for non-destructive testing as the relevant part of the casting. A welding procedure qualification is required (it may include prior agreement for major welds, weld maps…) according to EN ISO 11970. 6.2.2 Production welding Conditions for preheat, interpass and postweld heat-treatment related to welding operations are given in Annex A. These conditions are informative for ferritic and martensitic grades, and are normative for austenitic and austenitic-ferritic grades. The heat treatment procedure established to qualify the weld procedure for the austenitic and austenitic-ferritic steels is mandatory. 6.2.3 Permanent joint welding The welding personnel for permanent joining of components shall be qualified according to EN 287-1. v 6.3 Further processing 7 Requirements v 7.1 General 7.2 Materials 7.2.1 Chemical composition In addition to !EN 1559-2:2014": — chemical composition determined by a cast analysis shall conform with the values given in Table 2; SIST EN 10213:2008+A1:2016

v 7.3.4 Condition of the casting v 7.3.5 Mass of the casting v 7.3.6 Additional requirements regarding the condition of the casting ””7.4 Corrosion behaviour Requirements for resistance to intergranular corrosion may be agreed between the manufacturer and the purchaser for austenitic and austenitic-ferritic grades according to EN ISO 3651-2. 8 !Inspection" 8.1 General 8.1.1 The manufacturer shall take the necessary measures to ensure compliance with the agreed requirements. The testing shall be carried out by competent persons. 8.1.2 ”” The purchaser may agree with the manufacturer suitable measures and levels of quality inspection, whether the inspectors have to be qualified and/or certificated, the requisite level of this certification and the extent of the documentation of test results. When ordering material for pressure equipment applications, the equipment manufacturer has the obligation to request appropriate inspection documentation according to EN 10204:2004 affirming conformity to the specification for the material contained in this European Standard. For all products ordered to the requirements of this European Standard, specific inspection and testing is required. This shall include the following: — amounts of all elements specified (for the cast analysis) for the steel grade required; — results of the mechanical tests as required for the specific steel grade in Tables 3 to 6, as applicable; — statement on the result of agreed dimensional check and non destructive testing; — ”” result of any further mutually agreed testing. SIST EN 10213:2008+A1:2016

In the case of castings under 1 000 kg in mass the delivered quantity shall be subdivided into lots covering castings of the same type from the same melt and having undergone the same heat treatment. The weight of a test lot shall be not greater than 5 000 kg.

In the case of castings with a mass of more than 1 000 kg, each individual casting shall be regarded as the test lot. v 8.4 !Samples" 8.5 !Test procedures" v a) Tensile test at room temperature; v b) ”” tensile test at elevated temperature, verification by agreement at the time of enquiry and order; v c) impact test; v d) ferrite content; e) hardness test (not applicable); v f) homogeneity of test units (hardness test); v g) pressure or leak testing; v h) intergranular corrosion test (according to EN ISO 3651-2); v i) tests for magnetic properties; v j) other tests for any other properties shall be agreed. v 8.6 !Invalidation of test results" v 8.7 Retests v 8.8 Sorting and reprocessing v 9 Marking v 10 Packaging

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...