SIST EN 16028:2012

(Main)Railway appllications - Wheel/rail friction management - Lubricants for trainborne and trackside applications

Railway appllications - Wheel/rail friction management - Lubricants for trainborne and trackside applications

This European Standard specifies the requirements of lubricants intended for lubrication of the wheel-rail interface between the wheel flange and the rail gauge corner (active interface) applied either directly or indirectly to the wheel flange or to the rail to achieve an acceptable level of friction and wear.

It covers the approval procedure, the method of testing and routine control/monitoring of the lubricant.

Bahnanwendungen - Spurkranzschmierung - Prüfung der Schmiermittel

Diese Europäische Norm legt die Anforderungen an Schmierstoffe fest, die für die Schmierung der Kontakt-fläche zwischen Spurkranz und der Schienenkopfflanke (aktive Kontaktfläche) vorgesehen sind und die entweder direkt oder indirekt auf den Spurkranz oder die Schiene aufgetragen werden, um einen akzeptablen Grad von Reibung und Verschleiß zu erreichen.

Sie deckt das Freigabeverfahren, die Art der Prüfung sowie die Betriebskontrolle/Überwachung des Schmierstoffes ab.

Applications ferroviaires - Gestion des frottements roue/rail - Lubrifiants pour les applications embarquées et fixes de voie

La présente Norme européenne spécifie les exigences des lubrifiants destinés à la lubrification de l’interface roue-rail entre le boudin de roue et le rayon de guidage de rail (interface active) appliqué directement ou indirectement au boudin de roue ou au rail pour permettre un niveau acceptable de frottement et d’usure.

Elle couvre la procédure d’approbation, la méthode d’essai et le contrôle ou la surveillance en production de série du lubrifiant.

Železniške naprave - Trenje na stiku kolo/tirnica - Maziva za mazalke na vozilih in za tirne mazalke

Ta evropski standard določa zahteve glede maziv za mazanje vmesnika kolo/tirnica med kolesno prirobnico in kotom tirne širine (aktivni vmesnik), ki se nanese neposredno ali posredno na kolesno prirobnico ali na tirnico, da bi se dosegla sprejemljiva raven trenja in obrabe. Vključuje postopek odobritve, preskusno metodo in nadzor kakovosti/spremljanje maziva.

General Information

- Status

- Withdrawn

- Public Enquiry End Date

- 25-Mar-2010

- Publication Date

- 09-Sep-2012

- Withdrawal Date

- 25-May-2022

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 26-May-2022

- Due Date

- 18-Jun-2022

- Completion Date

- 26-May-2022

Relations

- Effective Date

- 25-May-2022

- Effective Date

- 25-Apr-2018

Frequently Asked Questions

SIST EN 16028:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway appllications - Wheel/rail friction management - Lubricants for trainborne and trackside applications". This standard covers: This European Standard specifies the requirements of lubricants intended for lubrication of the wheel-rail interface between the wheel flange and the rail gauge corner (active interface) applied either directly or indirectly to the wheel flange or to the rail to achieve an acceptable level of friction and wear. It covers the approval procedure, the method of testing and routine control/monitoring of the lubricant.

This European Standard specifies the requirements of lubricants intended for lubrication of the wheel-rail interface between the wheel flange and the rail gauge corner (active interface) applied either directly or indirectly to the wheel flange or to the rail to achieve an acceptable level of friction and wear. It covers the approval procedure, the method of testing and routine control/monitoring of the lubricant.

SIST EN 16028:2012 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering; 75.100 - Lubricants, industrial oils and related products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16028:2012 has the following relationships with other standards: It is inter standard links to SIST EN 15427-2-1:2022, SIST EN 15427-2-1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16028:2012 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC, 93/38/EEC, 96/48/EC; Standardization Mandates: M/275, M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 16028:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Trenje na stiku kolo/tirnica - Maziva za mazalke na vozilih in za tirne mazalkeBahnanwendungen - Spurkranzschmierung - Prüfung der SchmiermittelApplications ferroviaires - Gestion des frottements roue/rail - Lubrifiants pour les applications embarquées et fixes de voieRailway appllications - Wheel/rail friction management - Lubricants for trainborne and trackside applications75.100MazivaLubricants, industrial oils and related products45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 16028:2012SIST EN 16028:2012en,fr01-oktober-2012SIST EN 16028:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16028

July 2012 ICS 45.040; 75.100 English Version

Railway applications - Wheel/rail friction management - Lubricants for trainborne and trackside applications

Applications ferroviaires - Gestion des frottements roue/rail - Lubrifiants pour les applications embarquées et fixes de voie

Bahnanwendungen - Spurkranzschmierung - Prüfung der Schmierstoffe This European Standard was approved by CEN on 9 June 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16028:2012: ESIST EN 16028:2012

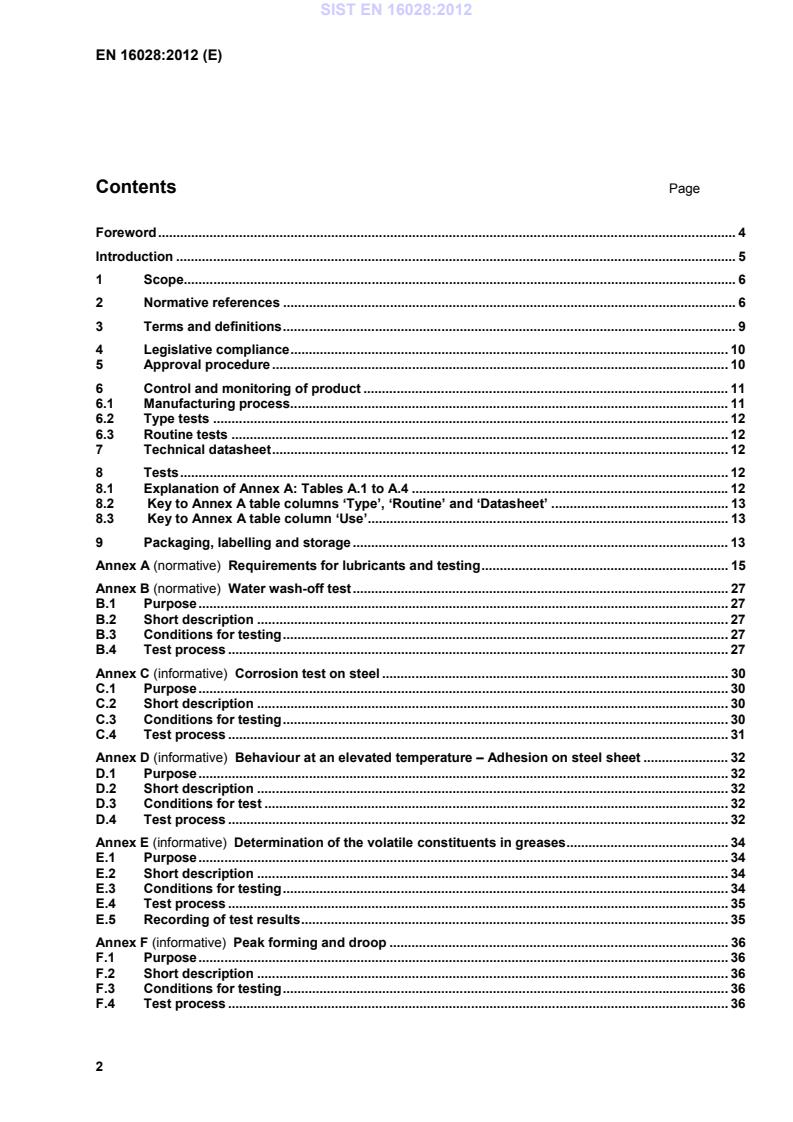

Requirements for lubricants and testing . 15Annex B (normative)

Water wash-off test . 27B.1Purpose . 27B.2Short description . 27B.3Conditions for testing . 27B.4Test process . 27Annex C (informative)

Corrosion test on steel . 30C.1Purpose . 30C.2Short description . 30C.3Conditions for testing . 30C.4Test process . 31Annex D (informative)

Behaviour at an elevated temperature – Adhesion on steel sheet . 32D.1Purpose . 32D.2Short description . 32D.3Conditions for test . 32D.4Test process . 32Annex E (informative)

Determination of the volatile constituents in greases . 34E.1Purpose . 34E.2Short description . 34E.3Conditions for testing . 34E.4Test process . 35E.5Recording of test results . 35Annex F (informative)

Peak forming and droop . 36F.1Purpose . 36F.2Short description . 36F.3Conditions for testing . 36F.4Test process . 36SIST EN 16028:2012

Low-temperature torque (rheometer measurement at -20 °C and -30 °C) . 39G.1Purpose . 39G.2Short description . 39G.3Conditions for test . 39G.4Test process . 40Annex H (informative)

Miscibility with flange/rail lubricants in use – greases . 43H.1Purpose . 43H.2Short description . 43H.3Conditions for testing . 43H.4Test process . 44Annex I (informative)

Miscibility with flange/rail lubricants in use – oils . 45I.1Purpose . 45I.2Short description . 45I.3Conditions for testing . 45I.4Test process . 46Annex J (informative)

Determination of low temperature cone penetration of greases . 47J.1Purpose . 47J.2Short description . 47J.3Conditions for test . 47J.4Test process . 47Annex K (informative)

Functional test on specific equipment . 49K.1General . 49K.2Flowing behaviour of wheel-flange greases . 49K.3Test of spraying of oils at various temperatures . 51Annex L (informative)

Solid stick testing on twin-disc machine . 55L.1Purpose . 55L.2Short description . 55L.3Conditions for test . 55L.4Test process . 58L.5Test results . 58Annex M (informative)

Lubricant product performance - Field assessment . 60M.1General . 60M.2Product performance assessment . 60Bibliography . 61 SIST EN 16028:2012

(ISO 5659-1) EN ISO 5659-2, Plastics — Smoke generation — Determination of optical density by a single-chamber test (ISO 5659-2) ISO/TR 5659-3, Plastics — Smoke generation — Part 3: Determination of optical density by a dynamic-flow method EN ISO 12185, Crude petroleum and petroleum products — Determination of density — Oscillating U-tube method (ISO 12185) SIST EN 16028:2012

ISO 2049, Petroleum products — Determination of colour (ASTM scale) ISO 2137, Petroleum products and lubricants — Determination of cone penetration of lubricating greases and petrolatum ISO 2176, Petroleum products — Lubricating grease — Determination of dropping point ISO 3016, Petroleum products — Determination of pour point ISO 3733, Petroleum products and bituminous materials — Determination of water — Distillation method ISO 6072,Rubber — Compatibility between hydraulic fluids and standard elastomeric materials ISO 6743-99, Lubricants, industrial oils and related products (class L) — Classification — Part 99: General ISO 7120, Petroleum products and lubricants — Petroleum oils and other fluids — Determination of rust-preventing characteristics in the presence of water ISO 9772, Cellular plastics — Determination of horizontal burning characteristics of small specimens subjected to a small flame ISO 11007, Petroleum products and lubricants — Determination of rust-prevention characteristics of lubricating greases DIN 51350-4, Testing of lubricants — Testing by the Shell four-ball tester — Determination of welding load of consistent lubricants DIN 51350-5, Testing of lubricants — Testing by the Shell four-ball tester — Determination of wear data for consistent lubricants DIN 51398, Testing of lubricants — Procedure for measurement of low temperature apparent viscosity by means of the Brookfield viscometer (liquid bath method) DIN 51418-1, X-ray spectrometry — X-ray emissions and X-ray fluorescence analysis (XRF) —

Part 1: Definitions and principles DIN 51418-2, X-ray spectrometry — X-ray emissions and X-ray fluorescence analysis (XRF) —

Part 2: Definitions and basic principles for measurements, calibration and evaluation of results DIN 51451, Testing of petroleum products and related products — Analysis by infrared spectrometry — General working principles DIN 51631, Mineral spirits — Special boiling point spirits — Requirements DIN 51777-2, Testing of mineral oil-hydrocarbons and solvents — Determination of the water content according to Karl Fischer (indirect method) DIN 51805, Testing of lubricants — Determination of flow pressure of lubricating greases — Kesternich method DIN 51807-1, Testing of lubricants — Test of the behaviour of lubricating greases in the presence of water — Static test SIST EN 16028:2012

temperatures, route information etc.; NOTE The typical operating temperature range to take into account is from -25 °C to +80 °C. SIST EN 16028:2012

It is suggested that the mass of any piece of debris should be no greater than 5 g. 8 Tests 8.1 Explanation of Annex A: Tables A.1 to A.4 For each required property of the lubricants, Tables A.1, A.2 and A.3 list the mandatory and optional tests for grease, oil and sticks respectively, and parameters for trainborne and trackside applications. SIST EN 16028:2012

Key to Annex A table columns ‘Type’, ‘Routine’ and ‘Datasheet’ The key to the columns ‘Type’, ‘Routine’ and ‘Datasheet’ in Tables A.1 to A.4 is as follows:

‘Type’

= This indicates the type tests required for the purpose of approval testing (see 5.4 and 6.2). ‘Routine’ = This indicates the routine tests required for testing from approved mass produced batches (see 6.3). ‘Datasheet’ = This indicates the characteristics to be listed in the product documentation. In each column, a symbol is used to indicate the required test or information: ‘p’ indicates a mandatory test or piece of information is required; ‘’ indicates an optional test or piece of information is required; where it is blank there is no requirement. 8.3

Key to Annex A table column ‘Use’ Tables A.1 to A.4 include a column headed ‘Use’ and the letters used mean the following: A – Trainborne

B – Trackside

C – Trainborne using a solid lubricant This column identifies the most common systems in current use. Most trainborne equipment sprays the lubricant in the form of a free-flowing grease or thin oil and most trackside equipment pumps it in the form of a thicker grease. However, where alternatives exist, careful consideration to the tests required is needed. 9 Packaging, labelling and storage The packaging shall protect the contents from contamination and damage. The labelling shall include at least the following: supplier’s name; brand name and/or code of the lubricant; batch number and date of manufacture, uncoded or coded; net mass/quantity/volume; NOTE Local regulatory requirements might also apply. SIST EN 16028:2012

Requirements for lubricants and testing Table A.1 — Requirements for greases (1 of 6) Item Property Use Unit Test method Values Type Routine Datasheet Comments A.1.1 Appearance A & B - Visual Homogenous

p p ∏ Appearance is a general assessment of the product.

A.1.2 Colour A & B - ISO 2049 Homogenous

p ∏ ∏

A.1.3 Consistency A - ISO 6743-99 Typically 00-000 p p p

B - ISO 6743-99 Typically 1 p p p

A.1.4.1 Un-worked grease penetration at:

A

a) 25 °C

0,1 mm ISO 2137 Typically 400 to 475 p ∏

b) 0 °C

0,1 mm Annex J ≥ 350 p ∏

c) -25 °C

0,1 mm Annex J ≥ 300 p ∏

A.1.4.2 Un-worked grease penetration at:

B

a) 25 °C

0,1 mm ISO 2137 Informative – no criteria p ∏

b) 0 °C

0,1 mm Annex J Informative – no criteria p ∏

c) -25 °C

0,1 mm Annex J Informative – no criteria p ∏

A.1.6 Drop point A & B °C ISO 2176 or IP 396 Higher than operating range upper limit p p p

A.1.7 Flash point

A & B °C EN ISO 2592 ≥ 200 p

p

A.1.8 Water content A & B % mass ISO 760 or DIN 51777-2 or ISO 3733

≤ 1,0 p p

A.1.9 Water resistance at 40 °C A & B Level DIN 51807-1 1 p ∏ p

A.1.10 Adhesion to sheet steel

A Stage Annex D 1 ∏ ∏ ∏

(0,05 mm, 24 h at 60 °C) B Stage Annex D 1 ∏ ∏ ∏

A.1.11 Volatile components (24 h at 60 °C) A & B % mass Annex E ≤ 10 ∏ ∏ ∏

A.1.12.1 (18 h at 40 °C) A % mass DIN 51817 ≤ 5 p ∏

Without 100 g weight A.1.12.2 (168 h [7 days] at

40 °C) B % mass DIN 51817 5 % maximum by weight for NLGI No.2 grease & 7 % maximum by weight for a NLGI No.1 grease p ∏

With 100 g weight

A.1.13 Corrosion test

a) Steel A Level Annex C 1 ∏ ∏ ∏

B Rating ISO 11007 using water 0; 0 ∏ ∏ ∏

b) Copper 24 h at 50 °C A & B Grade DIN 51811

∏ ∏ ∏

A.1.14 Compatibility with elastomers (60 °C for 168 h) A & B

Where applicable a) Change in volume for NBR1

% ISO 6072 +15/-0 p

Other elastomer types may be tested as necessary b) Change in hardness for NBR1

IRHD ISO 6072 + 8 p

Other elastomer types may be tested as necessary

Standard laboratory method. (See comments for applicable standards) For routine tests compare with approved batch using same process p p

Applicable standards: DIN 51418-1 DIN 51418-2 DIN 51451 DIN 51820-1

A.1.16 Apparent viscosity (1° cone, s = 300 s, D = 1 000 s-1) at: A

a) 25 °C

mPa·s

DIN 51810-1 ≥ 150 ∏ ∏ ∏

b) 0 °C

≥ 400 ∏ ∏ ∏

c) -25 °C

≤ 4 000 ∏ ∏ ∏

A.1.17 Four ball test A & B

a) Wear test rating (300 N, 1 h at 1 500 r/min)

mm DIN 51350-5; Method D ≤ 0,8

p

p

b) Extreme pressure

kg DIN 51350-4 Weld load not less than 315 kg p

A.1.18 Effect of water (water wash-off test) B visual Annex B No corrosion after 72 h

∏

% loss ASTM D4049 at

83 kPa Informative – no criteria ∏

A.1.19 Low temperature flow pressure (pumpability) B mbar DIN 51805 Less than 500 mbar at -20 °C ∏ ∏

A.1.21 Biodegradability A & B % Dependent upon test type from OECD 301 suite or its equivalent standard >60 after 28 days ∏

∏ As defined in Product Specification. See normative references in Clause 2.

A.1.22 Fire behaviour a) Smoke b) Spread of flame c) Toxicity A & B

As defined in the Product Specification

∏

∏

A.1.23 Bead size/droop/peaking B

Example test in Annex F Sufficient bead size that peaks and does not droop ∏

A.1.24 Water pollution A & B As required As defined in the Product Specification, see comment. Local conditions may apply ∏

For example, in Germany: Verwaltungsvorschrift wassergefährdender Stoffe [German Administrative Regulation on Substances Hazardous to Water]

A.1.25 Low-temperature torque (rheometer measurement)

A.1.25.1 at -30 °C A mNm Annex G Max. 10 ∏ ∏

A.1.25.2 at -20 °C B mNm Annex G Indicative ∏ ∏

Follow Annex H and then carry out tests A.1.26.1 to A.1.26.3

∏

A.1.26.1 Worked penetration (60 double strokes) at 25 °C A & B 0,1 mm ISO 2137 400 to 475

A.1.26.2 a) Oil separation (18 h at 40 °C) A % mass DIN 51817 ≤ 5

Without 100 g weight A.1.26.2 b) Oil separation (168 h [7 days] at 40 ûC) B % mass DIN 51817 5 % maximum by weight for NLGI No.2 grease & 7 % maximum by weight for a NLGI No.1 grease

With 100 g weight A.1.26.3 Dropping point A & B °C ISO 2176 ≥ 90

A.1.27 Electrical resistance A & B

As defined in the Product Specification

∏

p p ∏ Appearance is a holistic assessment of the product

A.2.2 Colour A - ISO 2049 Homogenous

p ∏ ∏

A.2.3 Flash point

A °C EN ISO 2592 ≥ 200 p

p

A.2.4 Corrosion test

a) Steel A level ISO 7120 1 ∏ ∏ ∏

b) Copper 3 h at 50 °C A grade EN ISO 2160 1b ∏ ∏ ∏

A.2.5 Compatibility with elastomers (60 °C for 168 h) A

Where applicable a) Change in volume for NBR1

% ISO 6072 +15/-0 p

Other elastomer types may be tested as necessary b) Change in hardness for NBR1

IRHD ISO 6072 ± 8 p

Other elastomer types may be tested as necessary

A.2.6 Identity testing: Using Infra-red, or Xray fluorescence, or ICP A

Standard laboratory method. (See comments for applicable standards) For routine tests compare with approved batch using same process p p

Applicable standards: DIN 51418-1 DIN 51418-2 DIN 51451 DIN 51820-1

a) Wear test rating

(400 N, 1 h at 1 500 r/min)

mm EN ISO 20623 0,45

p

p

b) Extreme pressure

kg EN ISO 20623 Weld load not less than 315 kg p

A.2.8 Density at 15 °C A kg/m3 EN ISO 12185 EN ISO 3675 Informative – no criteria ∏ ∏ ∏

A.2.9 Biodegradability A % Dependent upon test type from OECD 301 suite or its equivalent standard > 60 after 28 days ∏

∏ As defined in Product Specification. See normative references in Clause 2.

A.2.10 Fire behaviour a) Smoke b) Spread of flame c) Toxicity A

As defined in the Product Specification

∏

∏

A.2.11 Pour point A °C ISO 3016 Lower than operating range lower limit ∏

A.2.12 Dynamic viscosity at 40 °C A mPa⋅s EN ISO 3104 Informative – no criteria ∏ ∏ ∏

A.2.13 Brookfield viscosity at 40 °C A mPa⋅s DIN 51398 Informative – no criteria ∏ ∏ ∏

For example, in Germany: Verwaltungsvorschrift wassergefährdender Stoffe [German Administrative Regulation on Substances Hazardous to Water]

A.2.15 Miscibility with other flange/rail lubricants used A

Follow Annex I and then carry out tests 2.15.1 to 2.15.6 below

∏

A.2.15.1 Dynamic viscosity at 40 °C

mPa⋅s EN ISO 3104 Between the limits of two oils tested

A.2.15.2 Flash point

°C EN ISO 2592 ≥ 200

A.2.15.3 Pour point

°C ISO 3016 Lower than operating range lower limit

A.2.15.4 Corrosiveness to steel

level ISO 7120 1

A.2.15.5 Corrosiveness to copper 3 h at 50 °C

grade EN ISO 2160 1b

A.2.15.6 Compatibility with elastomers (60 °C for 168 h)

a) Change in volume for NBR1

% ISO 6072 +15/-0

b) Change in hardness for NBR1

IRHD ISO 6072 ±8

A.3.2 Colour C - ISO 2049 For routine tests compare with approved batch p p p Batch to batch comparison

A.3.3 Melting point C °C EN ISO 3146 Higher than operating range p

A.3.4 Friction value C Coefficient of Friction Twin disc test in Annex L ≤ 0,15 p p p

A.3.5 Stick dimensions C mm Measurement As specified p p p Batch to batch comparison. See Note 1

A.3.6 Behaviour in fire C

The following standards may be used: a) Smoke density

- See comments

∏

∏ EN ISO 5659-1 EN ISO 5659-2 ISO/TR 5659-3 b) Spread of flame

- See comments

∏

∏ EN ISO 4589-1 EN ISO 4589-2 ISO 9772 NOTE 1

Consistent stick dimensions are critical to ensure that the solid sticks fit and do not jam in the applicator. SIST EN 16028:2012

X-ray fluorescence C

Standard laboratory method

For routine tests compare with approved batch using same process ∏

A.3.9 Density at 23 °C C kg/m3 EN ISO 1183-1 Method A For routine tests compare with approved batch p p

See Note 2

A.3.10 Hardness

C Shore EN ISO 868 For routine tests compare with approved batch p p

See Note 3

A.3.11 Water pollution C As required As defined in the Product Specification, see comment Local conditions might also apply ∏

For example, in Germany: Verwaltungsvorschrift wassergefährdender Stoffe [German Administrative Regulation on Substances Hazardous to Water] NOTE 2

Significant differences in density could indicate a change in composition or level of solid lubricants, or presence of voids in product. NOTE 3

Different hardness value could lead to differing stick consumption values under

...

The article discusses a European Standard called SIST EN 16028:2012, which focuses on the use of lubricants in managing the friction between train wheels and railway tracks. The standard outlines the requirements for these lubricants, which are used to reduce friction and wear between the wheel and the rail. It also covers the approval process, testing methods, and quality control procedures for these lubricants.

記事のタイトル:SIST EN 16028:2012 - 鉄道の応用 - 車輪/レールの摩擦管理 - 列車および線路側の応用のための潤滑剤 記事の内容:このヨーロッパ標準では、車輪フランジとレールのゲージコーナー(アクティブなインターフェース)の間の車輪とレールの摩擦インターフェースの潤滑に使用される潤滑剤の要件を指定しています。車輪フランジやレールに直接的または間接的に適用され、摩擦と摩耗のレベルを受け入れるための潤滑剤に関してカバーしています。また、この標準は、潤滑剤の承認手続き、試験方法、品質管理/監視についても取り扱っています。

기사 제목: SIST EN 16028:2012 - 철도 응용 - 바퀴/레일 마찰 관리 - 기차 및 트랙 사이드 응용을 위한 윤활제 기사 내용: 이 유럽 표준은 바퀴 플랜지와 레일 가우지 코너(활성 인터페이스) 사이의 바퀴-레일 인터페이스를 윤활하기 위해 직접 또는 간접적으로 적용되는 윤활제의 요구 사항을 규정합니다. 이는 마찰과 마모의 수준을 수용할 수 있도록 바퀴 플랜지나 레일에 직접 적용되는 윤활제, 또는 레일에 적용되는 윤활제를 포함합니다. 이 표준은 윤활제의 승인 절차, 시험 방법 및 품질 관리/모니터링을 다룹니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...