SIST EN 17023:2019

(Main)Railway applications - Rolling stock maintenance - Creation and modification of maintenance plan

Railway applications - Rolling stock maintenance - Creation and modification of maintenance plan

This document describes the methodology and the elements to be considered for the creation and modification of a vehicle maintenance plan, up to the validation. This document describes general requirements (list of input data, structure and content) of a maintenance plan.

For the creation and modification of a maintenance plan, this document lists:

- preparation and selection of documents and input data;

- analysis of input data and development of the maintenance plan up to its validation;

- process to be followed to create a maintenance plan

- reasons to check a current maintenance plan;

- risk assessment and process to be followed to modify the maintenance plan;

- monitoring conditions (e.g. justification methods, verification, validation, documentation, roles, skills and knowledge).

This document applies only to preventive maintenance.

Bahnanwendungen - Schienenfahrzeuginstandhaltung - Erstellung und Änderung von Instandhaltungsplänen

Dieses Dokument beschreibt die Methodik und die Elemente, die bei der Erstellung und Änderung eines Instandhaltungsplans für Eisenbahnfahrzeuge bis zur Validierung berücksichtigt werden. Dieses Dokument beschreibt die allgemeinen Anforderungen (Liste der Eingangsgrößen, Struktur und Inhalt) eines Instandhaltungsplans.

Dieses Dokument zur Erstellung und Änderung eines Instandhaltungsplans für Eisenbahnfahrzeuge, umfasst folgende Punkte:

Vorbereitung und Auswahl der Dokumente und Eingangsgrößen (Felddaten);

Analyse der Eingangsgrößen und Entwicklung des Instandhaltungsplans bis zu seiner Validierung;

einzuhaltende Verfahren für die Erstellung eines Instandhaltungsplanes;

Gründe für die Überprüfung eines aktuellen Instandhaltungsplans;

Risikobewertung und einzuhaltende Verfahren für die Änderung von Instandhaltungsplänen;

Monitoring (z. B. Verfahren zur Begründung, Verifizierung, Validierung, Dokumentation, Rollen, Fähigkeiten und Wissen).

Dieses Dokument ist nur für die präventive Instandhaltung anwendbar.

Applications ferroviaires - Maintenance du matériel roulant - Création et modification du plan de maintenance

Le présent document décrit la méthodologie et les éléments à prendre en considération pour la création et la modification d'un plan de maintenance de véhicule, jusqu'à la validation. Le présent document décrit les exigences générales (liste des données d'entrée, structure et contenu) d'un plan de maintenance.

Pour la création et la modification d'un plan de maintenance, le présent document fournit les éléments suivants :

- préparation et sélection des documents et des données d'entrée ;

- analyse des données d'entrée et élaboration du plan de maintenance jusqu'à sa validation ;

- processus à suivre pour la création d'un plan de maintenance ;

- raisons qui motivent la vérification d'un plan de maintenance existant ;

- évaluation des impacts et processus à suivre pour modifier le plan de maintenance ;

- conditions de suivi (par exemple : méthodes de justification, vérification, validation, documentation, rôles, compétences et connaissances).

Le présent document s'applique uniquement à la maintenance préventive.

Železniške naprave - Vzdrževanje voznega parka - Oblikovanje in sprememba načrta vzdrževanja

Ta evropski standard opisuje metodologijo in elemente, ki jih je treba upoštevati pri oblikovanju in spremembi načrta vzdrževanja železniškega voznega parka do potrditve.

Ta dokument opisuje splošne zahteve (seznam vhodnih podatkov, strukturo in vsebino) načrta vzdrževanja.

Za oblikovanje in spremembo načrta vzdrževanja železniškega voznega parka ta evropski standard navaja naslednje:

– priprava in izbira dokumentov in vhodnih podatkov;

– analiza vhodnih podatkov in razvoj načrta vzdrževanja do njegove potrditve;

– razlogi za preverjanje trenutnega načrta vzdrževanja;

– ocena učinka in postopek, ki ga je treba upoštevati;

– pogoji spremljanja (npr. metode utemeljitve, preverjanje, potrjevanje, dokumentacija, vloge, spretnosti in znanje).

Ta evropski standard se uporablja samo za preventivno vzdrževanje.

General Information

- Status

- Published

- Public Enquiry End Date

- 26-Oct-2016

- Publication Date

- 08-Jan-2019

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Jan-2019

- Due Date

- 10-Mar-2019

- Completion Date

- 09-Jan-2019

Overview

EN 17023:2018 (CEN) - "Railway applications - Railway vehicle maintenance - Creation and modification of maintenance plan" defines a structured methodology for creating, assessing, modifying and validating preventive maintenance plans for rolling stock. The standard sets out the input data, structure and content required for a maintenance plan and describes processes for justification, verification, validation, documentation, roles and required skills up to final approval.

Key topics and requirements

- Scope: Applies only to preventive maintenance for railway vehicles (rolling stock).

- Input data: Lists preparation and selection of documents and technical input required to build a maintenance plan.

- Structure & content: Defines the recommended structure of a maintenance plan and what content must be included (periodicity tables, step frequency tables, supporting technical documentation).

- Creation process: Describes project workflow and step-by-step process to develop a maintenance plan from analysis of inputs through to validation.

- Modification process: Specifies when and how to assess and implement changes to an existing maintenance plan, including reasons to review a plan.

- Risk & safety assessment: Requires safety relevance assessment, significance analysis and risk assessment methods to justify changes.

- Verification & validation: Sets expectations for verification activities, validation trials and evidence required to approve a new or modified plan.

- Documentation & justification: Emphasises documentation of decisions, justification files and change control.

- Roles, skills & knowledge: Defines role categories and the competencies needed for personnel involved in creation, assessment and validation.

Practical applications and users

Who uses EN 17023:2018:

- Rolling stock manufacturers developing initial maintenance plans for new vehicles.

- Maintenance providers and workshops implementing or updating preventive maintenance programmes.

- Railway undertakings and fleet managers responsible for lifecycle maintenance and compliance.

- Safety assessors and certifiers validating maintenance arrangements against EU regulations.

Practical benefits:

- Creates a consistent, auditable process for maintenance plan creation and change management.

- Supports compliance with EU Directive 2008/57/EC and RAMS processes by linking maintenance decisions to safety and risk assessments.

- Improves asset reliability by defining periodicities, verification and validation steps for preventive maintenance.

Related standards

- EN 17018 - Rolling stock maintenance terms and definitions

- EN 50126 (RAMS) - Reliability, Availability, Maintainability and Safety specification

- EN 50128 - Software for railway control and protection systems

- EN 31010 / ISO 31010 - Risk assessment techniques

EN 17023:2018 is essential reading for professionals shaping preventive maintenance strategies for railway vehicles and for organisations aiming to implement controlled, safety-driven maintenance plans for rolling stock.

Frequently Asked Questions

SIST EN 17023:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Rolling stock maintenance - Creation and modification of maintenance plan". This standard covers: This document describes the methodology and the elements to be considered for the creation and modification of a vehicle maintenance plan, up to the validation. This document describes general requirements (list of input data, structure and content) of a maintenance plan. For the creation and modification of a maintenance plan, this document lists: - preparation and selection of documents and input data; - analysis of input data and development of the maintenance plan up to its validation; - process to be followed to create a maintenance plan - reasons to check a current maintenance plan; - risk assessment and process to be followed to modify the maintenance plan; - monitoring conditions (e.g. justification methods, verification, validation, documentation, roles, skills and knowledge). This document applies only to preventive maintenance.

This document describes the methodology and the elements to be considered for the creation and modification of a vehicle maintenance plan, up to the validation. This document describes general requirements (list of input data, structure and content) of a maintenance plan. For the creation and modification of a maintenance plan, this document lists: - preparation and selection of documents and input data; - analysis of input data and development of the maintenance plan up to its validation; - process to be followed to create a maintenance plan - reasons to check a current maintenance plan; - risk assessment and process to be followed to modify the maintenance plan; - monitoring conditions (e.g. justification methods, verification, validation, documentation, roles, skills and knowledge). This document applies only to preventive maintenance.

SIST EN 17023:2019 is classified under the following ICS (International Classification for Standards) categories: 03.100.10 - Purchasing. Procurement. Logistics; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17023:2019 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17023:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SUHPHPEDBahnanwendungen - Schienenfahrzeuginstandhaltung - Erstellung und Änderung von InstandhaltungsplänenApplications ferroviaires - Maintenance du matériel roulant - Création et modification du plan de maintenanceRailway applications - Rolling stock maintenance - Creation and modification of maintenance plan45.060.01Železniška vozila na splošnoRailway rolling stock in general03.100.10Nabava. Dobava. LogistikaPurchasing. Procurement. LogisticsICS:Ta slovenski standard je istoveten z:EN 17023:2018SIST EN 17023:2019en,fr,de01-marec-2019SIST EN 17023:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 17023

December

t r s z ICS

v wä r x rä r s English Version

Railway applications æ Railway vehicle maintenance æ Creation and modification of maintenance plan Applications ferroviaires æ Maintenance des véhicules ferroviaires æ Création et modification du plan de maintenance

Bahnanwendungen æ Instandhaltung von Eisenbahnfahrzeugen æ Erstellung und Änderung von Instandhaltungsplänen This European Standard was approved by CEN on

s t October

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s y r t uã t r s z ESIST EN 17023:2019

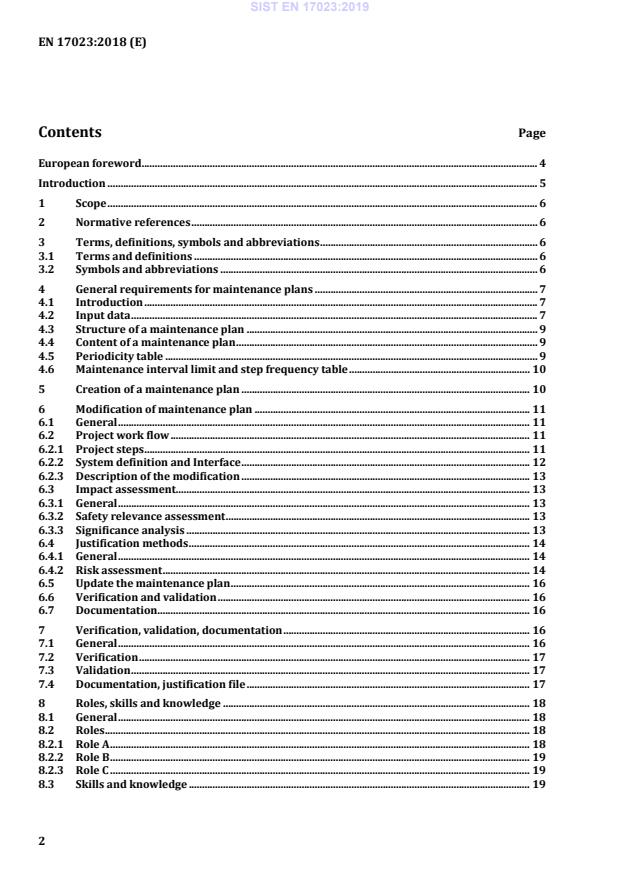

Examples of a process to assess the safety significance of a proposed Maintenance Plan modification . 20 A.1 General . 20 A.2 Example 1 . 20 A.2.1 Foreword . 20 A.2.2 Method used to assess the significance . 20 A.3 Example 2 . 22 A.3.1 General . 22 A.3.2 Steps of the method to assess significance . 23 A.4 Example 3 . 24 A.4.1 Methodology for using the criteria . 24 A.4.2 Choosing an approach . 25 A.5 Example 4 . 28 A.5.1 Foreword . 28 A.5.2 General . 28 A.5.3 Safety relevance . 29 Annex B (informative)

Safety relevant components, functions and maintenance activities . 30 B.1 Introduction. 30 B.2 Process for addressing safety relevant functions/components and their maintenance activities . 30 B.3 Process to determine safety relevance of a maintenance plan change . 31 Annex C (informative)

Structured list of the content of a Maintenance Plan . 33 C.1 General . 33 C.2 Cover. 33 C.3 Approval record . 33 C.4 Changes control . 33 C.5 Table of contents . 33 C.6 Scope of application for this MP . 34 C.7 Step frequency table . 34 C.8 Periodicity table and supporting technical documentation . 34 C.9 Relevant information . 34 C.10 Definitions and abbreviations . 34 C.11 List of reference documentation . 35 Annex D (informative)

Examples showing the representation of a Maintenance Plan . 36 D.1 Examples of a Step frequency representation. 36 D.2 Maintenance activities . 38 Annex ZA (informative)

Relationship between this European Standard and the essential requirements of Directive 2008/57/EC aimed to be covered . 41 Bibliography . 43

— ISO Online browsing platform: available at http://www.iso.org/obp

3.2 Symbols and abbreviations For the purposes of this document, the abbreviations given in Table 1 apply. SIST EN 17023:2019

Figure 1 — Steps for the modification of a maintenance plan 6.2.2 System definition and Interface In the first stage, the existing documentation relevant to the system being considered, based on the reasons addressing the proposed change and the input data stated in 4.2, shall be gathered. The focus shall be on the following points: — scope of change and system definition: vehicle, system, component; — definition of the interfaces and the system to be considered (vehicle, system, component); SIST EN 17023:2019

Figure 2 — Verification and validation process 7.2 Verification It shall be demonstrated by examination and provision of objective evidence, that the performance targets and safety requirements, are met. In the case this cannot be demonstrated, it is possible to implement the maintenance plan as a trial maintenance plan in order to collect more data. In this case, the vehicles under this regime shall be monitored in a way to avoid introducing additional safety risks. The criteria to abort the trial maintenance plan shall be defined before its implementation. If the demonstration of achievement of expected performance targets and safety requirements is not successful, the maintenance plan needs to be reassessed. The verification shall be ensured by one or several persons, not involved in the creation/modification, in accordance with the 8.2.3 Role C, and finally, the correctness of the maintenance plan shall be declared, before it is applied on the fleet. The maintenance plan shall then be set into force. The results from the verification shall be documented as outlined in 7.4. 7.3 Validation A verified maintenance plan (new or updated) should be monitored in operation in order to confirm that the performance targets and safety requirements, have been met. When the verified version of the maintenance plan is set in force, a period of time should be allocated to confirm its effectiveness. The length of the period is chosen to reflect the complexity of the plan, or the fleet size or the number of maintenance steps covered. This validation can be performed on the entire fleet or a representative sample of the fleet. Validation can be done during a regular monitoring of the fleet. In certain cases it can be necessary to set up specific monitoring measures based on the change (e.g. additional data evaluation, additional inspection evaluation). The validation shall be ensured by one or several persons, in accordance with 8.2.3 Role C, not involved in the creation/modification. If the achievement of expected performance targets and safety requirements is not successful, the maintenance plan needs to be reassessed. The results from the validation shall be documented as outlined in 7.4. 7.4 Documentation, justification file All the steps of the creation or modification process of the maintenance plan carried out and all the associated elements shall be recorded and compiled into a justification file. This file shall be composed of at least the following: — description of the aims and requirements; — description of the scope; SIST EN 17023:2019

Creation

X

Modification

X

Verification

X Set into force X

Validation a

X b X Close the process X

a May involve maintenance workshop. b Role B may assist Role C for validation.

8.2 Roles 8.2.1 Role A This role is responsible for the whole process and shall ensure that all necessary process steps are completed, including justification file documentation. This role determines the need (creation or modification), and launches the process. SIST EN 17023:2019

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...