SIST EN 1755:2024

(Main)Industrial trucks - Safety requirements and verification - Supplementary requirements for operation in potentially explosive atmospheres

Industrial trucks - Safety requirements and verification - Supplementary requirements for operation in potentially explosive atmospheres

This document is applicable to self-propelled and pedestrian propelled manual and semi-manual industrial trucks as defined in ISO 5053-1:2020 including their load handling devices and attachments (hereafter referred to as trucks) intended for use in potentially explosive atmospheres.

NOTE 1 Attachments mounted on the load carrier or on fork arms which are removable by the user are not considered to be a part of the truck.

This document specifies supplementary technical requirements for the prevention of the ignition of an explosive atmosphere of flammable gases, vapours, mists or dusts by industrial trucks of equipment group II and equipment category 2G, 3G, 2D or 3D.

NOTE 2 The relationship between an equipment category (hereafter referred to as category) and the corresponding zone (area classification) is shown in informative Annex B.

This document does not apply to:

- trucks of equipment group I;

- trucks of equipment group II, equipment category 1;

- trucks intended for use in potentially explosive atmospheres with hybrid mixtures;

- protective systems.

This document does not apply to trucks intended for use in potentially explosive atmospheres of carbon disulfide (CS2), carbon monoxide (CO) and/or ethylene oxide (C2H4O) due to the special properties of these gases.

Technical requirements relating to lithium-ion batteries and fuel cells as energy sources are not given in this document due to their specific hazards.

Flurförderzeuge - Sicherheitsanforderungen und Verifizierung - Zusätzliche Anforderungen für den Einsatz in explosionsgefährdeten Bereichen

Dieses Dokument ist anwendbar für motorkraftbetriebene und mitgängerbetriebene, manuelle und halbmanuelle Flurförderzeuge, wie in ISO 5053 1:2020 festgelegt, einschließlich deren Lastaufnahmemittel und Anbaugeräte (im Folgenden als Flurförderzeuge bezeichnet) für die bestimmungsgemäße Anwendung in explosionsgefährdeten Bereichen.

ANMERKUNG 1 Auf dem Lastenträger oder an den Gabelzinken angebrachte Anbaugeräte, die durch den Benutzer abnehmbar sind, gelten nicht als Teil des Flurförderzeugs.

Dieses Dokument legt ergänzende technische Anforderungen zur Verhinderung der Zündung einer explosionsfähigen Atmosphäre aus brennbaren Gasen, Dämpfen, Nebeln oder Stäuben durch Flurförderzeuge der Gerätegruppe II und Gerätekategorie 2G, 3G, 2D oder 3D fest.

ANMERKUNG 2 Der Zusammenhang zwischen einer Gerätekategorie (im Folgenden als Kategorie bezeichnet) und der zugehörigen Zone (Einteilung von Bereichen) ist im informativen Anhang B dargestellt.

Dieses Dokument ist nicht anwendbar für:

Flurförderzeuge der Gerätegruppe I;

Flurförderzeuge der Gerätegruppe II, Gerätekategorie 1;

Flurförderzeuge, die zur Anwendung in explosionsgefährdeten Bereichen mit hybriden Gemischen vorgesehen sind;

Schutzsysteme.

Dieses Dokument ist wegen der besonderen Eigenschaften dieser Gase nicht anwendbar für Flurförderzeuge, die für den Einsatz in explosionsgefährdeten Bereichen mit Schwefelkohlenstoff (CS2), Kohlenstoffmonoxid (CO) und/oder Ethylenoxid (C2H4O) vorgesehen sind.

Die technischen Anforderungen im Zusammenhang mit Lithium-Ionen-Batterien und Brennstoffzellen als Energiequellen sind aufgrund ihrer spezifischen Gefährdungen nicht in diesem Dokument angegeben.

Chariots de manutention - Prescriptions de sécurité et vérification - Prescriptions supplémentaires pour le fonctionnement en atmosphères explosibles

Le présent document est applicable aux chariots automoteurs et aux chariots à conducteur à propulsion manuelle et semi-manuelle, tels que définis dans l’ISO 5053-1:2020, y compris leurs dispositifs de manutention des charges et accessoires (désignés ci-après par « chariots ») destinés à être utilisés en atmosphères explosibles.

NOTE 1 Les accessoires démontables par l’utilisateur qui sont installés sur le porteur de charge ou sur les bras de fourche ne sont pas considérés comme faisant partie intégrante du chariot.

Le présent document spécifie les prescriptions techniques supplémentaires relatives à la prévention de l’inflammation d’une atmosphère explosive de gaz, vapeurs, brouillards ou poussières inflammables, dus aux chariots de manutention du groupe d’appareil II et de la catégorie d’appareil 2G, 3G, 2D ou 3D.

NOTE 2 La relation entre une catégorie d’appareil (désignée ci-après par « catégorie ») et la zone correspondante (classification de zone) est illustrée à l’Annexe B (informative).

Le présent document ne s'applique pas :

- aux chariots du groupe d’appareils I ;

- aux chariots du groupe d’appareils II, catégorie d’appareils 1 ;

- aux chariots destinés à être utilisés en atmosphères explosibles constituées de mélanges hybrides ;

- aux systèmes de protection.

Le présent document ne s’applique pas aux chariots destinés à être utilisés en atmosphères explosibles contenant du sulfure de carbone (CS2), du monoxyde de carbone (CO) et/ou de l’oxyde d’éthylène (C2H4O), en raison des propriétés spécifiques de ces gaz.

Les prescription techniques relatives aux batteries lithium-ion et aux piles à combustibles en tant que sources d’énergie ne sont pas données dans le présent document en raison de leurs phénomènes dangereux spécifiques.

Vozila za talni transport - Varnostne zahteve in preverjanje - Dodatne zahteve za delovanje v potencialno eksplozivnih atmosferah

Ta dokument se uporablja za vozila za talni transport z lastnim pogonom ter ročno in napol ročno gnana vozila, opredeljena v standardu ISO 5053-1:2020, vključno z njihovimi napravami za delo z bremenom in priključki (v nadaljevanju: vozila), ki so namenjena za uporabo v potencialno eksplozivnih atmosferah.

OPOMBA 1: Priključki, nameščeni na nosilec bremena ali na vilice, ki jih lahko odstrani uporabnik, se ne obravnavajo kot del vozila.

Ta dokument določa dodatne tehnične zahteve za preprečevanje vžiga eksplozivne atmosfere vnetljivih plinov, hlapov, meglic ali prahu s strani vozil za talni transport skupine opreme II in kategorije opreme 2G, 3G, 2D ali 3D.

OPOMBA 2: Razmerje med kategorijo opreme (v nadaljevanju: kategorija) in ustreznim območjem (klasifikacija območja) je prikazano v informativnem dodatku B.

Ta dokument se ne uporablja za:

– vozila skupine opreme I;

– vozila skupine opreme II in kategorije opreme 1;

– vozila, namenjena uporabi v potencialno eksplozivnih atmosferah s hibridnimi mešanicami;

– varnostne naprave.

Ta dokument se ne uporablja za vozila, namenjena za uporabo v potencialno eksplozivnih atmosferah ogljikovega disulfida (CS2), ogljikovega monoksida (CO) in/ali etilenoksida (C2H4O) zaradi posebnih lastnosti teh plinov.

Tehnične zahteve v zvezi z litij-ionskimi baterijami in gorivnimi celicami kot viri energije niso podane v tem dokumentu zaradi posebnih tveganj, ki jih predstavljajo.

General Information

- Status

- Published

- Publication Date

- 22-May-2024

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 17-Jan-2024

- Due Date

- 23-Mar-2024

- Completion Date

- 23-May-2024

Relations

- Effective Date

- 28-Jan-2023

Overview

EN 1755:2024 - issued by CEN - defines supplementary safety requirements and verification for industrial trucks intended to operate in potentially explosive atmospheres. It applies to self‑propelled and pedestrian propelled manual and semi‑manual trucks as defined in ISO 5053‑1:2020, including load handling devices and attachments (except user‑removable attachments). The standard covers trucks of equipment group II in categories 2G, 3G, 2D, and 3D and focuses on preventing ignition of explosive atmospheres caused by gases, vapours, mists or dusts.

Key exclusions: equipment group I, equipment category 1, hybrid mixtures, protective systems, certain gases with special properties (CS2, CO, ethylene oxide), and detailed requirements for lithium‑ion batteries and fuel cells.

Key Topics

EN 1755:2024 addresses technical and verification requirements relevant to hazardous area operation, including:

- Hot surfaces and temperature classification - procedures for temperature monitoring and maximum surface temperature measurement.

- Safety shutdown and systems to prevent ignition in fault conditions.

- Mechanically generated sparks - requirements for load handling devices, fans and rotating parts.

- Electrical systems - safe electrical design, insulation monitoring, bipolarity and battery connector requirements.

- Category 3G provisions - restricted breathing enclosures (“nR”) and gas detection systems (sensor requirements and integration).

- Internal combustion engines - measures to reduce ignition risks from IC engines and radiator/fan components.

- Electrostatic risk controls - bonding, circuit resistance, non‑conductive parts, transmission belts, hydraulic systems, castors and wheels.

- Brakes, clutches and pneumatic systems - special rules for service and parking brakes in explosive atmospheres.

- Flammability of non‑metallic materials and verification testing (surface temperature, circuit resistance, capacitance).

- Documentation and marking - instruction handbook, charging guidance, Ex‑marking, and warning labels (including annexed label examples).

The standard also contains informative annexes (zone/category relationship, cladding examples, non‑conductive surface examples) and normative test requirements.

Applications and Users

EN 1755:2024 is used by:

- Industrial truck manufacturers (design and certification for hazardous areas)

- System integrators and suppliers of gas detection or restricted enclosures

- Health & safety bodies, regulators and conformity assessors

- Maintenance/service providers and end‑users operating trucks in petrochemical, pharmaceutical, grain handling, mining and other classified hazardous areas

- Design engineers implementing electrostatic and electrical safety controls

Applying this standard helps ensure trucks meet safety and verification requirements for safe operation in potentially explosive atmospheres and supports compliance with relevant EU legislation (see Annex ZA).

Related Standards

- ISO 5053‑1:2020 (truck definitions)

- EN ISO 3691 series (industrial truck general safety)

- EN 1459 series; ISO 24134

- EN 1175 (control systems) - cross‑referenced and assessed in the standard

Keywords: EN 1755:2024, industrial trucks, explosive atmospheres, equipment category 2G 3G 2D 3D, safety requirements, CEN, hazardous area.

Frequently Asked Questions

SIST EN 1755:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Industrial trucks - Safety requirements and verification - Supplementary requirements for operation in potentially explosive atmospheres". This standard covers: This document is applicable to self-propelled and pedestrian propelled manual and semi-manual industrial trucks as defined in ISO 5053-1:2020 including their load handling devices and attachments (hereafter referred to as trucks) intended for use in potentially explosive atmospheres. NOTE 1 Attachments mounted on the load carrier or on fork arms which are removable by the user are not considered to be a part of the truck. This document specifies supplementary technical requirements for the prevention of the ignition of an explosive atmosphere of flammable gases, vapours, mists or dusts by industrial trucks of equipment group II and equipment category 2G, 3G, 2D or 3D. NOTE 2 The relationship between an equipment category (hereafter referred to as category) and the corresponding zone (area classification) is shown in informative Annex B. This document does not apply to: - trucks of equipment group I; - trucks of equipment group II, equipment category 1; - trucks intended for use in potentially explosive atmospheres with hybrid mixtures; - protective systems. This document does not apply to trucks intended for use in potentially explosive atmospheres of carbon disulfide (CS2), carbon monoxide (CO) and/or ethylene oxide (C2H4O) due to the special properties of these gases. Technical requirements relating to lithium-ion batteries and fuel cells as energy sources are not given in this document due to their specific hazards.

This document is applicable to self-propelled and pedestrian propelled manual and semi-manual industrial trucks as defined in ISO 5053-1:2020 including their load handling devices and attachments (hereafter referred to as trucks) intended for use in potentially explosive atmospheres. NOTE 1 Attachments mounted on the load carrier or on fork arms which are removable by the user are not considered to be a part of the truck. This document specifies supplementary technical requirements for the prevention of the ignition of an explosive atmosphere of flammable gases, vapours, mists or dusts by industrial trucks of equipment group II and equipment category 2G, 3G, 2D or 3D. NOTE 2 The relationship between an equipment category (hereafter referred to as category) and the corresponding zone (area classification) is shown in informative Annex B. This document does not apply to: - trucks of equipment group I; - trucks of equipment group II, equipment category 1; - trucks intended for use in potentially explosive atmospheres with hybrid mixtures; - protective systems. This document does not apply to trucks intended for use in potentially explosive atmospheres of carbon disulfide (CS2), carbon monoxide (CO) and/or ethylene oxide (C2H4O) due to the special properties of these gases. Technical requirements relating to lithium-ion batteries and fuel cells as energy sources are not given in this document due to their specific hazards.

SIST EN 1755:2024 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection; 53.060 - Industrial trucks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1755:2024 has the following relationships with other standards: It is inter standard links to SIST EN 1755:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1755:2024 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1755:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2024

Vozila za talni transport - Varnostne zahteve in preverjanje - Dodatne zahteve za

delovanje v potencialno eksplozivnih atmosferah

Industrial trucks - Safety requirements and verification - Supplementary requirements for

operation in potentially explosive atmospheres

Flurförderzeuge - Sicherheitsanforderungen und Verifizierung - Zusätzliche

Anforderungen für den Einsatz in explosionsgefährdeten Bereichen

Chariots de manutention - Prescriptions de sécurité et vérification - Prescriptions

supplémentaires pour le fonctionnement en atmosphères explosibles

Ta slovenski standard je istoveten z: EN 1755:2024

ICS:

13.230 Varstvo pred eksplozijo Explosion protection

53.060 Industrijski tovornjaki Industrial trucks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1755

EUROPEAN STANDARD

NORME EUROPÉENNE

January 2024

EUROPÄISCHE NORM

ICS 53.060 Supersedes EN 1755:2015

English Version

Industrial trucks - Safety requirements and verification -

Supplementary requirements for operation in potentially

explosive atmospheres

Chariots de manutention - Prescriptions de sécurité et Flurförderzeuge - Sicherheitsanforderungen und

vérification - Prescriptions supplémentaires pour le Verifizierung - Zusätzliche Anforderungen für den

fonctionnement en atmosphères explosibles Einsatz in explosionsgefährdeten Bereichen

This European Standard was approved by CEN on 27 November 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1755:2024 E

worldwide for CEN national Members.

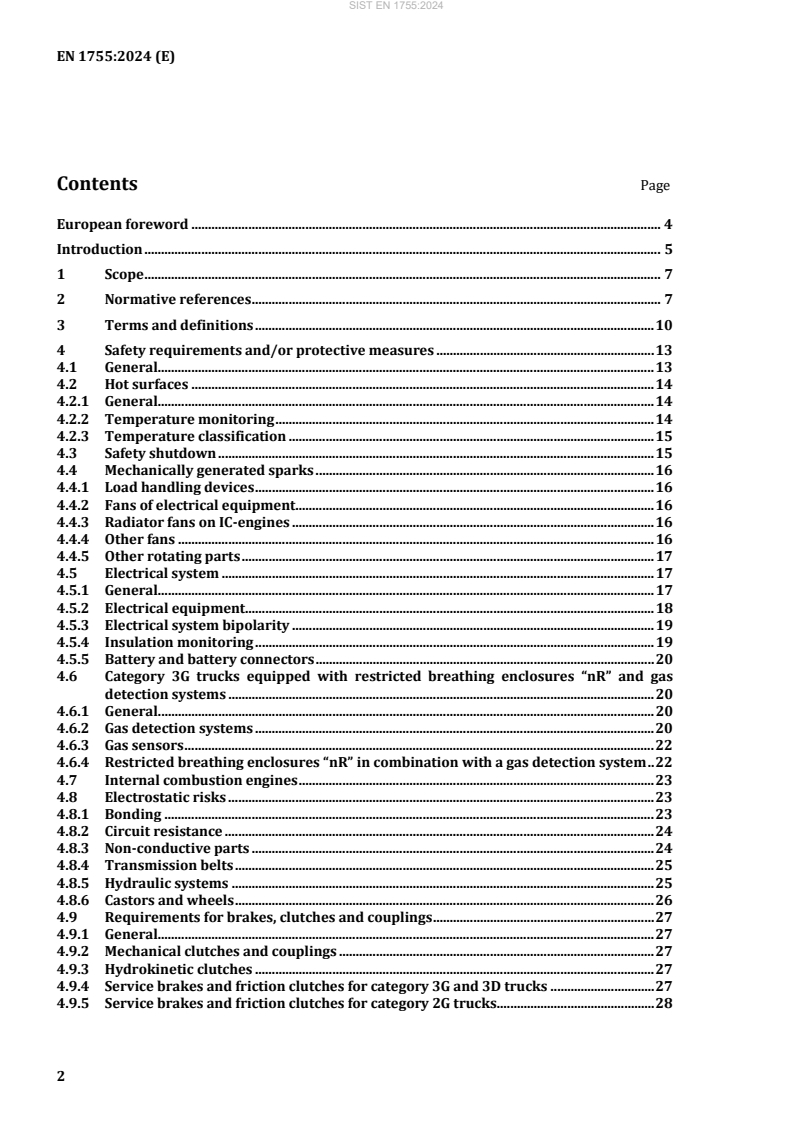

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 10

4 Safety requirements and/or protective measures . 13

4.1 General. 13

4.2 Hot surfaces . 14

4.2.1 General. 14

4.2.2 Temperature monitoring . 14

4.2.3 Temperature classification . 15

4.3 Safety shutdown . 15

4.4 Mechanically generated sparks . 16

4.4.1 Load handling devices . 16

4.4.2 Fans of electrical equipment. 16

4.4.3 Radiator fans on IC-engines . 16

4.4.4 Other fans . 16

4.4.5 Other rotating parts . 17

4.5 Electrical system . 17

4.5.1 General. 17

4.5.2 Electrical equipment. 18

4.5.3 Electrical system bipolarity . 19

4.5.4 Insulation monitoring . 19

4.5.5 Battery and battery connectors . 20

4.6 Category 3G trucks equipped with restricted breathing enclosures “nR” and gas

detection systems . 20

4.6.1 General. 20

4.6.2 Gas detection systems . 20

4.6.3 Gas sensors . 22

4.6.4 Restricted breathing enclosures “nR” in combination with a gas detection system . 22

4.7 Internal combustion engines . 23

4.8 Electrostatic risks . 23

4.8.1 Bonding . 23

4.8.2 Circuit resistance . 24

4.8.3 Non-conductive parts . 24

4.8.4 Transmission belts . 25

4.8.5 Hydraulic systems . 25

4.8.6 Castors and wheels . 26

4.9 Requirements for brakes, clutches and couplings . 27

4.9.1 General. 27

4.9.2 Mechanical clutches and couplings . 27

4.9.3 Hydrokinetic clutches . 27

4.9.4 Service brakes and friction clutches for category 3G and 3D trucks . 27

4.9.5 Service brakes and friction clutches for category 2G trucks . 28

4.9.6 Service brakes and friction clutches for category 2D trucks . 28

4.9.7 Parking brakes . 29

4.9.8 Emergency stop brake . 29

4.10 Requirements for pneumatic systems . 29

4.11 Flammability of non-metallic materials . 29

5 Verification of safety requirements and/or protective measures . 29

5.1 Determination of the maximum surface temperatures . 29

5.1.1 General . 29

5.1.2 Test conditions . 29

5.1.3 Test procedures . 30

5.1.4 Measurements . 32

5.2 Measurement of circuit resistance and capacitance . 33

5.2.1 Verification and tests of circuit resistance and bonding resistance . 33

5.2.2 Measurement of capacitance of insulated metal parts . 34

6 Information for use . 34

6.1 General . 34

6.2 Instruction handbook . 35

6.2.1 Operation of the truck. 35

6.2.2 Service and maintenance of the truck . 35

6.2.3 Additional safety information . 36

6.2.4 Information for charging of the battery and battery handling . 37

6.3 Marking . 37

6.3.1 General . 37

6.3.2 Minimum marking . 37

6.3.3 Additional marking according to this document (Ex - marking). 38

6.4 Warning labels . 39

Annex A (normative) List of significant hazards . 40

Annex B (informative) Relationship between zones (area classification) and truck categories

................................................................................................................................................................... 41

Annex C (informative) Typical example of cladding of load handling devices . 42

Annex D (informative) Typical examples of non-conductive surface areas according to 4.8.3.1

................................................................................................................................................................... 44

Annex E (normative) Requirements for transmission belts in accordance with ISO 9563:2015

or ISO 1813:2014 . 47

Annex F (informative) Significant technical changes between this document and the previous

edition of this European Standard . 48

Annex G (informative) Warning labels for trucks with restricted breathing enclosure(s) in

combination with gas detection system . 49

Annex ZA (informative) Relationship between this European Standard and the essential

Health and Safety Requirements of Directive 2014/34/EU aimed to be covered . 50

Bibliography . 53

European foreword

This document (EN 1755:2024) has been prepared by Technical Committee CEN/TC 150 “Industrial

Trucks - Safety”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by July 2024, and conflicting national standards shall be

withdrawn at the latest by July 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1755:2015.

In comparison with the previous edition, the following technical changes have been made:

— requirements for driverless trucks have been included;

— requirements of EN 1175:2020 have been assessed and clarified where appropriate;

— requirement b) for brake materials has been removed as it does not represent state of the art in brake

material technology;

— normative references have been updated.

An overview of significant changes is also given in Table F.1.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

The machines concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

This document covers specific safety requirements where industrial trucks will operate in potentially

explosive atmospheres that are not covered exhaustively by:

— EN 1459-1:2017+A1:2020 and EN 1459-2:2015+A1:2018;

— ISO 24134:2006;

— EN ISO 3691-1:2015 ;

— EN ISO 3691-2:2023;

— EN ISO 3691-3:2016 ;

— EN ISO 3691-4:2023;

;

— EN ISO 3691-5:2015

— EN ISO 3691-6:2021.

As impacted by EN ISO 3691-1:2015/AC:2016 and EN ISO 3691-1:2015/A1:2020

As impacted by EN ISO 3691-3:2016/A1:2023

As impacted by EN ISO 3691-5:2015/AC:2016 and EN ISO 3691-5:2015/A1:2020

Assessment of hazards

The product needs to be designed in such a way that it is fit for its purpose or function and can be adjusted

and maintained without putting persons at risk when used under the conditions foreseen by the

manufacturer.

In order to properly design a product and to cover all specific safety requirements, the manufacturer

needs to identify the hazards that apply to their product and carry out a risk assessment. The

manufacturer then needs to design and construct the product taking this assessment into account.

The aim of this procedure is to eliminate the risk of accidents throughout the foreseeable lifetime of the

machinery, including the phases of assembling and dismantling where risks of accidents can also arise

from foreseeable abnormal situations.

In selecting the most appropriate methods, the manufacturer needs to apply the following principles, in

the order given here:

a) eliminate or reduce risks as far as possible by design (inherently safe machinery design and

construction);

b) take the necessary protective measures in relation to risks that cannot be eliminated by design;

c) inform users of any shortcoming of the protective measures adopted;

d) indicate whether any particular training is required;

e) specify any need to provide personal protection equipment;

f) refer to the appropriate user's document for proper operating instructions.

Industrial trucks need to be designed to prevent foreseeable misuse wherever possible, if such would

engender risk. In other cases, the manufacturer's instructions need to draw the user's attention to ways

shown by experience in which the machinery ought not to be used.

This document does not repeat all the technical rules which are state-of-the-art, and which are applicable

to the material used to construct the industrial truck. Refer to ISO 12100:2010.

1 Scope

This document is applicable to self-propelled and pedestrian propelled manual and semi-manual

industrial trucks as defined in ISO 5053-1:2020 including their load handling devices and attachments

(hereafter referred to as trucks) intended for use in potentially explosive atmospheres.

NOTE 1 Attachments mounted on the load carrier or on fork arms which are removable by the user are not

considered to be a part of the truck.

This document specifies supplementary technical requirements for the prevention of the ignition of an

explosive atmosphere of flammable gases, vapours, mists or dusts by industrial trucks of equipment

group II and equipment category 2G, 3G, 2D or 3D.

NOTE 2 The relationship between an equipment category (hereafter referred to as category) and the

corresponding zone (area classification) is shown in informative Annex B.

This document does not apply to:

— trucks of equipment group I;

— trucks of equipment group II, equipment category 1;

— trucks intended for use in potentially explosive atmospheres with hybrid mixtures;

— protective systems.

This document does not apply to trucks intended for use in potentially explosive atmospheres of carbon

disulfide (CS ), carbon monoxide (CO) and/or ethylene oxide (C H O) due to the special properties of

2 2 4

these gases.

Technical requirements relating to lithium-ion batteries and fuel cells as energy sources are not given in

this document due to their specific hazards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1127-1:2019, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic concepts

and methodology

EN 1149-5:2018, Protective clothing — Electrostatic properties — Part 5: Material performance and design

requirements

EN 1175:2020, Safety of industrial trucks — Electrical/electronic requirements

EN 1459-1:2017+A1:2020, Rough-terrain trucks — Safety requirements and verification — Part 1:

Variable-reach trucks

EN 1459-2:2015+A1:2018, Rough-terrain trucks — Safety requirements and verification — Part 2: Slewing

variable-reach trucks

EN 1834-1:2000, Reciprocating internal combustion engines — Safety requirements for design and

construction of engines for use in potentially explosive atmospheres — Part 1: Group II engines for use in

flammable gas and vapour atmospheres

EN 1834-3:2000, Reciprocating internal combustion engines — Safety requirements for design and

construction of engines for use in potentially explosive atmospheres — Part 3: Group II engines for use in

flammable dust atmospheres

EN 14986:2017, Design of fans working in potentially explosive atmospheres

EN 50271:2018, Electrical apparatus for the detection and measurement of combustible gases, toxic gases

or oxygen — Requirements and tests for apparatus using software and/or digital technologies

EN 60079-7:2015 , Explosive atmospheres — Part 7: Equipment protection by increased safety “e”

(IEC 60079-7:2015)

EN 60079-14:2014 , Explosive atmospheres — Part 14: Electrical installations design, selection and

erection (IEC 60079-14:2013)

EN 60079-17:2014, Explosive atmospheres — Part 17: Electrical installations inspection and maintenance

(IEC 60079-17:2013)

EN 60079-29-1:2016 , Explosive atmospheres — Part 29-1: Gas detectors — Performance requirements of

detectors for flammable gases (IEC 60079-29-1:2016)

EN 60079-29-2:2015, Explosive atmospheres — Part 29-2: Gas detectors — Selection, installation, use and

maintenance of detectors for flammable gases and oxygen (IEC 60079-29-2:2015)

EN 60079-29-3:2014, Explosive atmospheres — Part 29-3: Gas detectors — Guidance on functional safety

of fixed gas detection systems (IEC 60079-29-3:2014)

EN 60079-31:2014, Explosive atmospheres — Part 31: Equipment dust ignition protection by enclosure “t”

(IEC 60079-31:2013)

EN 60384-14:2013 , Fixed capacitors for use in electronic equipment — Part 14: Sectional specification —

Fixed capacitors for electromagnetic interference suppression and connection to the supply mains

(IEC 60384-14:2013)

EN 60529:1991 , Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60695-11-10:2013 , Fire hazard testing — Part 11-10: Test flames — 50 W horizontal and vertical

flame test methods (IEC 60695-11-10:2013)

EN 61508-1:2010, Functional safety of electrical/electronic/programmable electronic safety-related

systems — Part 1: General requirements (IEC 61508-1:2010)

As impacted by EN IEC 60079-7:2015/A1:2018

As impacted by EN 60079-14:2014/AC:2016

As impacted by EN 60079-29-1:2016/A1:2022 and EN 60079-29-1:2016/A11:2022

As impacted by EN 60384-14:2013/A1:2016 and EN 60384-14:2013/AC:2016-04

As impacted by EN 60529:1991/corrigendum May 1993, EN 60529:1991/A1:2000, EN 60529:1991/A2:2013

and EN 60529:1991/AC:2016-12

As impacted by EN 60695-11-10:2013/AC:2014

EN IEC 60079-0:2018 , Explosive atmospheres — Part 0: Equipment — General requirements (IEC 60079-

0:2017)

EN IEC 60079-15:2019, Explosive atmospheres — Part 15: Equipment protection by type of protection “n”

(IEC 60079-15:2017)

EN ISO 284:2012, Conveyor belts — Electrical conductivity — Specification and test method (ISO 284:2012)

EN ISO 3691-1:2015 , Industrial trucks — Safety requirements and verification — Part 1: Self-propelled

industrial trucks, other than driverless trucks, variable-reach trucks and burden-carrier trucks (ISO 3691-

1:2011, modified)

EN ISO 3691-4:2023, Industrial trucks — Safety requirements and verification — Part 4: Driverless

industrial trucks and their systems (ISO 3691-4:2023)

EN ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 20344:2021, Personal protective equipment — Test methods for footwear (ISO 20344:2021)

EN ISO 80079-36:2016 , Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements (ISO 80079-36:2016)

EN ISO 80079-37:2016, Explosive atmospheres — Part 37: Non-electrical equipment for explosive

atmospheres — Non-electrical type of protection constructional safety “c”, control of ignition sources “b”',

liquid immersion “k”' (ISO 80079-37:2016)

CLC/TR 60079-32-1:2018, Explosive atmospheres — Part 32-1: Electrostatic hazards, guidance

IEC TS 60079-46:2017, Explosive atmospheres — Part 46: Equipment assemblies

ISO 1813:2014, Belt drives — V-ribbed belts, joined V-belts and V-belts including wide section belts and

hexagonal belts — Electrical conductivity of antistatic belts: Characteristics and methods of test

ISO 9563:2015, Belt drives — Electrical conductivity of antistatic endless synchronous belts —

Characteristics and test method

ISO 15870:2000, Powered industrial trucks — Safety signs and hazard pictorials — General principles

As impacted by EN IEC 60079-0:2018/AC:2020-02

As impacted by EN ISO 80079-36:2016/AC:2019

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org

3.1

explosive atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours,

mists or dusts in which, after ignition has occurred, combustion spreads to the entire unburned mixture

[SOURCE: EN 13237:2012, 3.28]

3.2

potentially explosive atmosphere

atmosphere which could become explosive due to local and operational conditions

[SOURCE: EN 13237:2012, 3.28.2]

3.3

hybrid mixture

mixture of flammable substances with air in different physical states

[SOURCE: EN 13237:2012, 3.40]

3.4

auto ignition temperature

lowest temperature (of a hot surface) at which under specified test conditions an ignition of a flammable

gas or flammable vapour in mixture with air or air/inert gas occurs

[SOURCE: EN 13237:2012, 3.45]

3.5

minimum ignition temperature of a dust cloud

lowest temperature of a hot surface on which the most ignitable mixture of the dust with air is ignited

under specified test conditions

[SOURCE: EN 13237:2012, 3.45.1]

3.6

minimum ignition temperature of a dust layer

lowest temperature of a hot surface at which ignition occurs in a dust layer under specified test conditions

[SOURCE: EN 13237:2012, 3.45.2]

3.7

service temperature

maximum or minimum temperature reached at specific points of the equipment when the equipment is

operating at rated conditions, including ambient temperature and any external sources of heating or

cooling

Note 1 to entry: Each equipment may reach different service temperatures in different parts.

Note 2 to entry: This definition applies to both electrical and non-electrical equipment and components.

[SOURCE: EN IEC 60079-0:2018, 3.79]

3.8

maximum surface temperature

temperature used for marking of the equipment which is the highest temperature that can be attained in

service under the most adverse operating conditions (but within the recognized tolerance) by any part

or surface of equipment or protective system or component which can produce an ignition of the

surrounding explosive atmosphere with an appropriate safety margin

Note 1 to entry: The manufacturer will prescribe the product standard and also in his particular design he should

take into account the following other conditions:

a) fault conditions specified in the standard for the type of protection concerned;

b) all operating conditions specified in any other standard specified by him including recognized overloads; any

other operating condition specified by him.

Note 2 to entry: The relevant surface temperature can be internal or external depending upon the type of

protection concerned.

Note 3 to entry: For equipment intended for use in explosive dust atmospheres, the surface temperature is

determined without any deposited dust on the equipment. See EN ISO 80079-36:2016, 6.2.7.2.

[SOURCE: EN ISO 80079-36:2016, 3.4]

3.9

wheel

circular structure able to rotate on an axle, either directly or with the use of bearing(s), with the external

part in contact with the ground

[SOURCE: ISO 22877:2004, 1.1.1]

3.10

castor

assembly comprising a housing, one or more wheels, an axle and, if required, accessories

[SOURCE: ISO 22877:2004, 3.1]

3.11

tyre

outer part of a wheel, produced from different material from the wheel centre

[SOURCE: ISO 22877:2004, 1.1.6]

3.12

service brake

brake system allowing the operator or driverless control system to control, directly or indirectly, the

speed of the truck or to bring the truck to a halt

EXAMPLE The brake can be electrical, hydraulic or mechanical or a combination of the three.

[SOURCE: ISO 6292:2020, 3.9, modified- “braking system” replaced with “brake”, addition of an example]

3.13

restricted breathing enclosure “nR”

enclosure that is designed to restrict the entry of gases, vapours and mists

[SOURCE: EN IEC 60079-15:2019, 3.3]

3.14

safety function

function to be implemented by a safety device, which is intended to achieve or maintain a safe state for

the equipment under control (EUC), in respect of ignition hazards

Note 1 to entry: See EN 50495 for the definitions of “safety device”, “safe state” and “equipment under control”.

[SOURCE: EN 50495:2010, 3.7, modified, addition of Note 1 to entry]

3.15

safety shutdown

shutdown of a truck or a piece of equipment activated by a safety function to prevent potential ignition

sources from becoming effective

3.16

normal operation

operation of equipment conforming electrically and mechanically with its design specification and used

within the limits specified by the manufacturer

Note 1 to entry: Failures (such as a breakdown of pump seals, flange gaskets or releases of substances caused by

accidents) which involve repair or shut -down are not considered to be part of normal operation.

[SOURCE: EN ISO 80079-36:2016, 3.2]

3.17

malfunction

equipment, protective systems and components do not perform the intended function

[SOURCE: EN ISO 80079-36:2016, 3.3.1, modified- “with respect to explosion protection” deleted]

3.18

expected malfunction

disturbance or equipment malfunction which normally occur in practice

[SOURCE: EN ISO 80079-36:2016, 3.3.2]

3.19

rare malfunction

type of malfunction which may happen only in rare instances

[SOURCE: EN ISO 80079-36:2016, 3.3.3]

3.20

earthing strap

strap made of conductive or dissipative material strong enough to withstand mechanical and chemical

influences and installed to achieve potential equalization between truck chassis and the floor/ground

3.21

controlled stop

condition in which the truck is in a safe stationary state

3.22

highly efficient electrostatic charge generating mechanism

process that generates a higher rate of electrostatic charge than simple operations

Note 1 to entry: For more information, see EN ISO 80079-36:2016, 6.7.3.

EXAMPLE 1 Rubbing, cleaning with a dry cloth, raising from a seat, walking, wiping of clothes are examples of

simple operations

EXAMPLE 2 The flow of insulating liquids or powders, high voltage spray charging, running of transmission belts

are examples of highly efficient electrostatic charge generating mechanisms

4 Safety requirements and/or protective measures

4.1 General

Trucks for use in potentially explosive atmospheres shall comply with the additional requirements given

in 4.1 up to and including 4.11.

Where the additional hazards specified in normative Annex A could occur, an ignition hazard assessment

in accordance with EN 1127-1:2019 and EN ISO 80079-36:2016 shall be carried out and appropriate

measures implemented.

Trucks of Group II shall be subdivided according to the explosive gas atmosphere for which they are

intended. See EN IEC 60079-0:2018, 4.3.

Group II subdivisions:

a) IIA;

b) IIB;

c) IIB + H ;

d) IIB + C H ;

2 2

e) IIB + H + C H .

2 2 2

NOTE 1 Trucks marked IIB are also suitable for IIA applications.

, IIB+C H or IIB+H +C H are also suitable for IIA or IIB applications.

NOTE 2 Trucks marked IIB+H2 2 2 2 2 2

NOTE 3 Trucks equipped with a gas detection system are specifically marked in accordance with 6.3.3 g).

NOTE 4 H is the chemical formula for hydrogen and C H for acetylene.

2 2 2

Trucks of Group III shall be subdivided according to the explosive dust atmosphere for which they are

intended in accordance with EN IEC 60079-0:2018, 4.3.

Group III subdivisions:

1) IIIA: combustible flyings;

2) IIIB: non-conductive dusts;

3) IIIC: conductive dusts.

The following climatic conditions shall apply:

— maximum ambient temperature, unless otherwise specified and marked: +40 °C;

— lowest ambient temperature, unless otherwise specified and marked: −20 °C;

— altitude: up to 2 000 m.

NOTE 5 According to EN ISO 3691-1:2015, the lowest ambient temperature for trucks intended for use in normal

indoor conditions is +5 °C.

Equipment shall be selected taking into consideration any service temperatures measured during the

temperature tests described in 5.1.

4.2 Hot surfaces

4.2.1 General

For category 3G and 2G trucks the maximum surface temperature of any part of the truck shall not exceed

the temperature class or maximum surface temperature specified on the truck marking plate.

For category 3D and 2D trucks the maximum surface temperature of any part of the truck which can come

into contact with dust clouds or dust layers shall not exceed the maximum surface temperature specified

on the truck marking plate.

Maximum surface temperatures shall be determined in accordance with 5.1.

Reduction of surface temperatures by means of thermal insulation is not permitted.

NOTE 1 The relationship between the maximum surface temperature of the equipment and the minimum

ignition temperature of dust layers and dust clouds is given in EN 1127-1:2019, 6.4.2 and EN 60079-14:2014,

5.6.3.3.

NOTE 2 The possible insulation effects of a dust layer on the surface temperatures are taken into account by the

safety margin to the minimum ignition temperature of a dust layer specified in EN 1127-1:2019, 6.4.2 and

EN 60079-14:2014, 5.6.3.3.

4.2.2 Temperature monitoring

Surface temperatures may be limited by the use of a temperature monitoring and control system which

provides a safety shutdown in accordance with 4.3 if limiting values are exceeded.

For both category 3 and category 2 trucks, the electrical temperature monitoring and control system shall

fulfil the performance level PLr = c in accordance with EN ISO 13849-1:2023 or SIL 1 in accordance with

EN 61508-1:2010.

4.2.3 Temperature classification

Trucks shall be classified:

a) with a temperature class in accordance with Table 1 for category 3G or 2G,

or

b) by the maximum surface temperature for category 3G, 2G, 3D or 2D.

Table 1 — Classification of maximum surface temperatures for trucks of category 3G or 2G

Temperature class Maximum surface

temperature

[°C]

T1 450

T2 300

T3 200

T4 135

T5 100

T6 85

4.3 Safety shutdown

The requirements of this subclause apply to the following safety (monitoring) functions:

a) hot surfaces in accordance with 4.2;

b) concentration of the flammable gas in the atmosphere surrounding the truck in accordance with

4.6.2.5;

c) insulation monitoring in accordance with 4.5.4.

For driver operated trucks, a safety shutdown shall be clearly indicated by a visual alarm in the view of

the operator prior to the effective shutdown of the truck to enable the operator to bring the truck safely

to a controlled stop.

For driverless trucks, a safety shutdown shall be clearly indicated by an effective audible and visual alarm

on an external part of the truck prior to the effective shutdown of the truck. The driverless control system

shall bring the truck safely to a controlled stop.

In both driver operated and driverless trucks, it is permitted to have a time delay between the alarm and

shutdown up to a maximum of 30 s. During this time interval the critical operating functions and

functional safety systems of the truck shall be available.

The requirements of 4.2.1, 4.6.2.5 and 4.5.4 shall not be compromised during the time delay and/or after

shutdown.

EXAMPLE Exceeding of the maximum surface temperature after shutdown due to heat soak is an example of

compromising safety.

For driver operated trucks, reset of a safety monitoring function by the operator is not permitted except

for shutdown caused by over temperature. Resetting the system following a temperature shutdown shall

require an additional operator action.

For driverless trucks, reset of a safety monitoring function automatically by the driverless control system

is not permitted including shutdown caused by over temperature.

NOTE 1 Organizational measures including the facility’s safety procedures are an example of additional elements

included in a safety shutdown reset procedure.

NOTE 2 For driverless trucks a shutdown caused by overtemperature resulting from overload conditions is

considered to be low probability.

4.4 Mechanically generated sparks

4.4.1 Load handling devices

All surfaces of load handling devices which have or may have ground or load frictional contact shall be

manufactured from or clad with materials specified below:

— In the case of combustible gas/air-mixtures of Group IIA and IIB and for combustible dust/air-

mixtures, load handling devices made of copper zinc (brass), copper, or stainless steel, or clad with

stainless steel or non-metallic material for example rubber are permitted. Stainless steel shall have

a mass percentage of at least 16,5 % chromium and maximum mass percentage of 0,07 % carbon;

— In the case of combustible gas/air-mixtures of Groups IIB+H2, IIB+C2H2 or IIB+H2+C2H2 load handling

devices made of copper zinc (brass) or copper are permitted, or clad with copper zinc (brass), copper

or non-metallic material for example rubber, are permitted. Such materials shall have a mass

percentage of less than 10 % aluminium.

Information for use shall be provided according to 6.2.3.

Cladded load handling devices shall have provisions to inspect for wear.

Forks shall be cladded in such a way that inspection for hair cracks on critical locations shall always be

possible (see 6.2.2 o)).

An example of how to clad load handling devices is given in Annex C.

NOTE For IIB+H2, IIB+C2H2 or IIB+H2+C2H2 applications travel speeds greater than 1 m/s can have an ignition

risk where the load handling device contacts load storage devices.

4.4.2 Fans of electrical equipment

Fans being an integral part of electrical equipment shall comply with EN IEC 60079-0:2018 and the

applicable standards for the specific type of equipment.

4.4.3 Radiator fans on IC-engines

Taking into account design tolerances, clearances between rotating parts and fixed parts shall be at least

1/100 of the maximum diameter of the rotating part, except that the clearances need not exceed 5 mm

and may be reduced to 1 mm if the opposing parts are manufactured so as to have dimensional accuracy

and stability. In no case shall the clearances be less than 1 mm.

The truck chassis shall provide adequate protection against the ingress of foreign bodies that could give

rise to incendive sparking.

Exposed rotating parts shall be protected at least to a degree of IP 2X in accordance with EN 60529:1991,

5.2.

4.4.4 Other fans

Other fans shall comply with EN 14986:2017.

4.4.5 Other rotating parts

Seals shall fulfil the requirements of EN ISO 80079-37:2016, 5.3.

Bearings shall fulfil the requirements of EN ISO 80079-37:2016, 5.7.

Clearances be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...