SIST EN 13656:2020

(Main)Soil, treated biowaste, sludge and waste - Digestion with a hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrofluoric (HF) acid mixture for subsequent determination of elements

Soil, treated biowaste, sludge and waste - Digestion with a hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrofluoric (HF) acid mixture for subsequent determination of elements

This document specifies three methods for the digestion of soil, treated biowaste, sludge and waste by the use of an acid mixture composed of hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrochloric (HCl), nitric (HNO3) and hydrofluoric (HF) acid as the digestion solution.

Digestion with these acids is effectively considered as a total decomposition of the sample. For a broad range of samples the extracted analyte concentrations will reflect the total content in the sample.

This document is applicable for the following elements:

Aluminium (Al), antimony (Sb), arsenic (As), barium (Ba), beryllium (Be), cadmium (Cd), calcium (Ca), chromium (Cr), cobalt (Co), copper (Cu), iron (Fe), lead (Pb), magnesium (Mg), manganese (Mn), mercury (Hg), molybdenum (Mo), nickel (Ni), phosphorus (P), potassium (K), selenium (Se), silver (Ag), sodium (Na), strontium (Sr), sulfur (S), tellurium (Te), thallium (Tl), tin (Sn), titanium (Ti), vanadium (V), and zinc (Zn).

This document can also be applied for the digestion of other elements, provided the user has verified the applicability.

Boden, behandelter Bioabfall, Schlamm und Abfall - Aufschluss mit einem Gemisch aus Salzsäure (HCl), Salpetersäure (HNO3) und Tetrafluorborsäure (HBF4) oder Fluorwasserstoffsäure (HF) für die anschließende Bestimmung der Elemente

Dieses Dokument legt drei Verfahren für den Aufschluss von Boden, behandeltem Bioabfall, Schlamm und Abfall unter Verwendung eines Gemisches aus Salzsäure (HCl), Salpetersäure (HNO3) und Tetrafluor-borsäure (HBF4) oder eines Gemisches aus Salzsäure (HCl), Salpetersäure (HNO3) und Fluorwasserstoff-säure (HF) als Aufschlusslösung fest.

Der Aufschluss mit diesen Säuren wird im Grunde als vollständige Zersetzung der Probe angesehen. Elemente, die durch dieses Verfahren extrahierbar sind, können in vielen Fällen als „vollständig“ beschrieben werden, obwohl dies von der Probe abhängig ist.

Dieses Dokument gilt für die nachstehend aufgeführten Elemente:

Aluminium (Al), Antimon (Sb), Arsen (As), Barium (Ba), Beryllium (Be), Cadmium (Cd), Calcium (Ca), Chrom (Cr), Kobalt (Co), Kupfer (Cu), Eisen (Fe), Blei (Pb), Magnesium (Mg), Mangan (Mn), Quecksilber (Hg), Molybdän (Mo), Nickel (Ni), Phosphor (P), Kalium (K), Selen (Se), Silber (Ag), Natrium (Na), Strontium (Sr), Schwefel (S), Tellur (Te), Thallium (Tl), Zinn (Sn), Titan (Ti), Vanadium (V) und Zink (Zn).

Dieses Dokument kann auch für den Aufschluss anderer Elemente angewandt werden, sofern die Eignung durch den Anwender nachgewiesen wurde.

Sols, bio-déchets traités, boues et déchets - Digestion par un mélange d’acides chlorhydrique (HCl), nitrique (HNO3) et tétrafluoroborique (HBF4) ou fluorhydrique (HF) pour la détermination ultérieure des éléments

Le présent document décrit trois méthodes pour la digestion des sols, des bio-déchets traités, des boues et des déchets en utilisant un mélange acide composé d’acide chlorhydrique (HCl), nitrique (HNO3) et tétrafluoroborique (HBF4) ou d’acide chlorhydrique (HCl), nitrique (HNO3) et fluorhydrique (HF) comme solution de digestion.

La digestion par ces acides est effectivement considérée comme une décomposition totale de l’échantillon. Les éléments extractibles par ce mode opératoire peuvent, dans de nombreux cas, être décrits comme « totaux », bien que cela dépende de l’échantillon.

Le présent document est applicable aux éléments suivants :

Aluminium (Al), antimoine (Sb), arsenic (As), baryum (Ba), béryllium (Be), cadmium (Cd), calcium (Ca), chrome (Cr), cobalt (Co), cuivre (Cu), fer (Fe), plomb (Pb), magnésium (Mg), manganèse (Mn), mercure (Hg), molybdène (Mo), nickel (Ni), phosphore (P), potassium (K), sélénium (Se), argent (Ag), sodium (Na), strontium (Sr), soufre (S), tellure (Te), thallium (Tl), étain (Sn), titane (Ti), vanadium (V) et zinc (Zn).

Le présent document peut également être appliqué à la digestion d’autres éléments, à condition que l’applicabilité soit vérifiée par l’utilisateur.

Tla, obdelani biološki odpadki, blato in odpadki - Razklop z zmesjo klorovodikove kisline (HCl), dušikove(V) kisline (HNO3) in tetrafluoroborove kisline (HBF4) ali fluorovodikove kisline (HF) za določevanje elementov

General Information

- Status

- Published

- Public Enquiry End Date

- 03-Nov-2019

- Publication Date

- 12-Nov-2020

- Technical Committee

- KAT - Soil quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Nov-2020

- Due Date

- 11-Jan-2021

- Completion Date

- 13-Nov-2020

- Directive

- 99/31/EC - Landfill of waste

Relations

- Effective Date

- 01-Dec-2020

Overview

EN 13656:2020 (CEN) specifies validated acid-digestion procedures for the mineralization of soil, treated biowaste, sludge and waste prior to multi‑element analysis. The standard describes three digestion routes using an acid mixture of hydrochloric (HCl), nitric (HNO3) and either tetrafluoroboric (HBF4) or hydrofluoric (HF) acid. Digestion by these mixtures is considered an effective total decomposition for a broad range of matrices and is intended for subsequent determination of many metals and metalloids.

Key topics and requirements

- Three validated methods

- Method A (heating block): HCl + HNO3 + HBF4 at (105 ± 5) °C for 2 h, followed by filtration/centrifugation.

- Method B1 (microwave, temperature‑controlled): HCl + HNO3 + HBF4 to (175 ± 5) °C in closed vessels, then filtration/centrifugation.

- Method B2 (microwave, power‑controlled): HCl + HNO3 + HF in closed vessels, followed by filtration/centrifugation.

- Target analytes: validated for Al, Sb, As, Ba, Be, Cd, Ca, Cr, Co, Cu, Fe, Pb, Mg, Mn, Hg, Mo, Ni, P, K, Se, Ag, Na, Sr, S, Te, Tl, Sn, Ti, V and Zn. Applicability to additional elements may be verified by users.

- Validation and matrices: Includes validated matrices such as incineration ash, sewage and industrial sludges, sediments, coal fly ash, steel/copper slags and organic sludges.

- Quality control: Use analytical‑grade reagents, procedure blanks, and appropriate cleaning to minimise contamination and blanks.

- Safety & equipment: Strong warning about corrosive/toxic reagents (especially HF), pressure and high temperature in closed microwave vessels, and need for fume hoods, dedicated laboratory microwave equipment and trained personnel. HBF4 is preferred over HF for safety when applicable.

- Interferences: Notes on contamination sources (containers, milling), potential losses of volatile elements and precipitation of low‑solubility compounds (chlorides/fluorides/sulphates).

Applications

- Routine sample preparation for environmental laboratories, waste characterization, regulatory compliance testing, remediation assessment and research.

- Used when a near‑total elemental content is required for risk assessment, material recycling studies, or emission/ash characterization in waste management.

- Supports downstream techniques such as ICP‑MS, ICP‑OES and AAS for multi‑element determination.

Who should use this standard

- Environmental and contract testing laboratories

- Waste treatment and resource recovery facilities

- Regulatory agencies and environmental consultants

- Research groups working on soil and waste characterization

- Manufacturers of microwave digestion and sample preparation equipment

Related standards

- EN 15002 - Preparation of test portions from the laboratory sample

- EN 15934 - Calculation of dry matter fraction

- EN 16179 - Guidance for sample pretreatment

Keywords: EN 13656, soil digestion standard, acid digestion, microwave digestion, sample preparation, elemental analysis, sludge, biowaste, waste characterization.

Frequently Asked Questions

SIST EN 13656:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Soil, treated biowaste, sludge and waste - Digestion with a hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrofluoric (HF) acid mixture for subsequent determination of elements". This standard covers: This document specifies three methods for the digestion of soil, treated biowaste, sludge and waste by the use of an acid mixture composed of hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrochloric (HCl), nitric (HNO3) and hydrofluoric (HF) acid as the digestion solution. Digestion with these acids is effectively considered as a total decomposition of the sample. For a broad range of samples the extracted analyte concentrations will reflect the total content in the sample. This document is applicable for the following elements: Aluminium (Al), antimony (Sb), arsenic (As), barium (Ba), beryllium (Be), cadmium (Cd), calcium (Ca), chromium (Cr), cobalt (Co), copper (Cu), iron (Fe), lead (Pb), magnesium (Mg), manganese (Mn), mercury (Hg), molybdenum (Mo), nickel (Ni), phosphorus (P), potassium (K), selenium (Se), silver (Ag), sodium (Na), strontium (Sr), sulfur (S), tellurium (Te), thallium (Tl), tin (Sn), titanium (Ti), vanadium (V), and zinc (Zn). This document can also be applied for the digestion of other elements, provided the user has verified the applicability.

This document specifies three methods for the digestion of soil, treated biowaste, sludge and waste by the use of an acid mixture composed of hydrochloric (HCl), nitric (HNO3) and tetrafluoroboric (HBF4) or hydrochloric (HCl), nitric (HNO3) and hydrofluoric (HF) acid as the digestion solution. Digestion with these acids is effectively considered as a total decomposition of the sample. For a broad range of samples the extracted analyte concentrations will reflect the total content in the sample. This document is applicable for the following elements: Aluminium (Al), antimony (Sb), arsenic (As), barium (Ba), beryllium (Be), cadmium (Cd), calcium (Ca), chromium (Cr), cobalt (Co), copper (Cu), iron (Fe), lead (Pb), magnesium (Mg), manganese (Mn), mercury (Hg), molybdenum (Mo), nickel (Ni), phosphorus (P), potassium (K), selenium (Se), silver (Ag), sodium (Na), strontium (Sr), sulfur (S), tellurium (Te), thallium (Tl), tin (Sn), titanium (Ti), vanadium (V), and zinc (Zn). This document can also be applied for the digestion of other elements, provided the user has verified the applicability.

SIST EN 13656:2020 is classified under the following ICS (International Classification for Standards) categories: 13.030.40 - Installations and equipment for waste disposal and treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13656:2020 has the following relationships with other standards: It is inter standard links to SIST EN 13656:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13656:2020 is associated with the following European legislation: EU Directives/Regulations: 99/31/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13656:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2020

Nadomešča:

SIST EN 13656:2004

Tla, obdelani biološki odpadki, blato in odpadki - Razklop z zmesjo klorovodikove

kisline (HCl), dušikove(V) kisline (HNO3) in tetrafluoroborove kisline (HBF4) ali

fluorovodikove kisline (HF) za določevanje elementov

Soil, treated biowaste, sludge and waste - Digestion with a hydrochloric (HCl), nitric

(HNO3) and tetrafluoroboric (HBF4) or hydrofluoric (HF) acid mixture for subsequent

determination of elements

Boden, behandelter Bioabfall, Schlamm und Abfall - Aufschluss mit einem Gemisch aus

Salzsäure (HCl), Salpetersäure (HNO3) und Tetrafluorborsäure (HBF4) oder

Fluorwasserstoffsäure (HF) für die anschließende Bestimmung der Elemente

Sols, bio-déchets traités, boues et déchets - Digestion par un mélange d’acides

chlorhydrique (HCl), nitrique (HNO3) et tétrafluoroborique (HBF4) ou fluorhydrique (HF)

pour la détermination ultérieure des éléments

Ta slovenski standard je istoveten z: EN 13656:2020

ICS:

13.030.40 Naprave in oprema za Installations and equipment

odstranjevanje in obdelavo for waste disposal and

odpadkov treatment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13656

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2020

EUROPÄISCHE NORM

ICS 13.030.40 Supersedes EN 13656:2002

English Version

Soil, treated biowaste, sludge and waste - Digestion with a

hydrochloric (HCl), nitric (HNO ) and tetrafluoroboric

(HBF ) or hydrofluoric (HF) acid mixture for subsequent

determination of elements

Sols, bio-déchets traités, boues et déchets - Digestion Boden, behandelter Bioabfall, Schlamm und Abfall -

par un mélange d'acides chlorhydrique (HCl), nitrique Aufschluss mit einem Gemisch aus Salzsäure (HCl),

(HNO ) et tétrafluoroborique (HBF ) ou fluorhydrique Salpetersäure (HNO ) und Tetrafluorborsäure (HBF )

3 4 3 4

(HF) pour la détermination ultérieure des éléments oder Fluorwasserstoffsäure (HF) für die anschließende

Bestimmung der Elemente

This European Standard was approved by CEN on 21 September 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13656:2020 E

worldwide for CEN national Members.

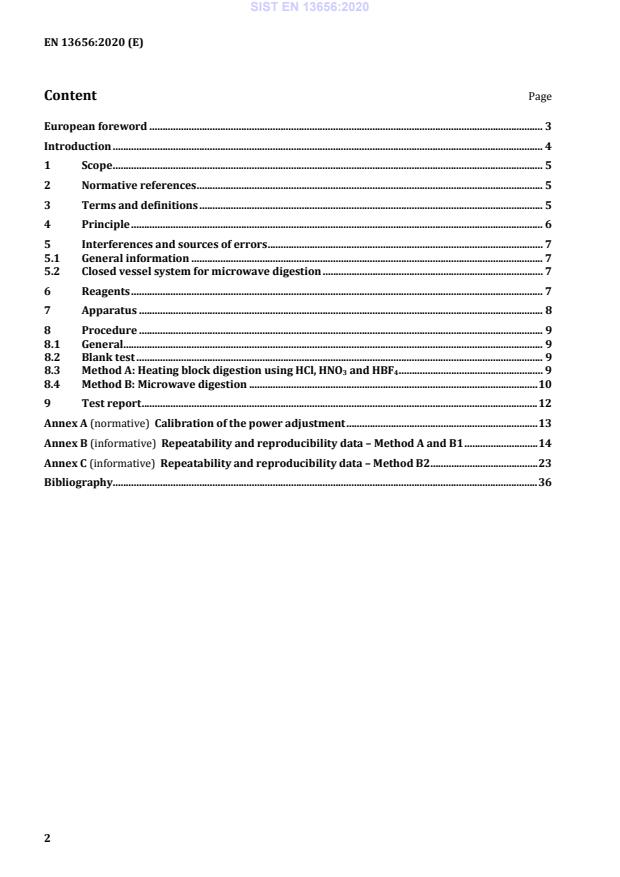

Content Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Principle . 6

5 Interferences and sources of errors . 7

5.1 General information . 7

5.2 Closed vessel system for microwave digestion . 7

6 Reagents . 7

7 Apparatus . 8

8 Procedure . 9

8.1 General . 9

8.2 Blank test . 9

8.3 Method A: Heating block digestion using HCl, HNO and HBF . 9

3 4

8.4 Method B: Microwave digestion . 10

9 Test report . 12

Annex A (normative) Calibration of the power adjustment . 13

Annex B (informative) Repeatability and reproducibility data – Method A and B1 . 14

Annex C (informative) Repeatability and reproducibility data – Method B2 . 23

Bibliography. 36

European foreword

This document (EN 13656:2020) has been prepared by Technical Committee CEN/TC 444 “Environmental

characterization of solid matrices”, of which the secretariat is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by May 2021 and conflicting national standards shall be withdrawn at

the latest by May 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13656:2002.

In comparison with EN 13656:2002, the following modifications have been made:

— addition of HBF4 as acid. For safety reasons the use of HBF4 is preferred over HF;

— addition of a heating block digestion procedure;

— addition of a microwave digestion procedure temperature-controlled;

— removal of the microwave digestion with semi-open vessel system.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus,

Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The methods specified in this document are providing a multi-element digestion of soil, treated biowaste,

sludge and waste prior to analysis. Elements extractable by this procedure can in many instances be

described as “total”, although this will be sample dependent. On the other hand, they cannot be regarded

as available for leaching, as the extraction procedure is too vigorous to represent natural processes.

This document is validated for several types of matrices as indicated in Table 1.

Table 1 — Matrices for which EN 13656 is validated

Materials used in the validation test Validated for digestion Validated for digestion

with HCl:HNO :HBF with HCl:HNO :HF

3 4 3

(see Annex B) (see Annex C)

City waste incineration ash X X

(BCR176/BCR176R)

Ink waste sludge (organic matrix) X X

Electronic industry sludge (“metallic” X X

matrix)

Sediment X

Coal fly ash X

Steel slag X

Copper slag X

City waste incineration fly ash X

(“oxidised” matrix)

City waste incineration bottom ash X

(“silicate” matrix)

Sewage sludge (BCR 146R) X

WARNING — Persons using this document should be familiar with usual laboratory practice. Most

of the reagents used in this document are extremely corrosive and very toxic. Safety precautions

are absolutely necessary, not only due to the strong corrosive reagents employed, but also to the

high temperature and pressures employed.

The use of laboratory-grade microwave equipment with isolated and corrosion resistant safety

devices is essential. Domestic (kitchen) type microwave ovens should not be used, as corrosion by

acid vapours may compromise the function of the safety devices and prevent the microwave

magnetron from shutting off when the door is open, which could result in operator significant

hazardous exposure to microwave energy.

All procedures should be performed in a fume hood or in closed force-ventilated equipment. By the

use of strong oxidising reagents, the formation of explosive organic intermediates is possible,

especially when dealing with samples with a high organic content. Do not open pressurized vessels

before they have cooled down. Avoid contact with the chemicals and the gaseous reaction products.

IMPORTANT — It is absolutely essential that tests conducted according to this document be carried

out by suitably trained staff. People performing the test should be informed on the specific risks

associated with the use of HBF and HF.

1 Scope

This document specifies three methods for the digestion of soil, treated biowaste, sludge and waste by the

use of an acid mixture composed of hydrochloric (HCl), nitric (HNO ) and tetrafluoroboric (HBF ) or

3 4

hydrochloric (HCl), nitric (HNO ) and hydrofluoric (HF) acid as the digestion solution.

Digestion with these acids is effectively considered as a total decomposition of the sample. Elements

extractable by this procedure can in many instances be described as “total”, although this will be sample

dependent.

This document is applicable for the following elements:

Aluminium (Al), antimony (Sb), arsenic (As), barium (Ba), beryllium (Be), cadmium (Cd), calcium (Ca),

chromium (Cr), cobalt (Co), copper (Cu), iron (Fe), lead (Pb), magnesium (Mg), manganese (Mn), mercury

(Hg), molybdenum (Mo), nickel (Ni), phosphorus (P), potassium (K), selenium (Se), silver (Ag), sodium

(Na), strontium (Sr), sulfur (S), tellurium (Te), thallium (Tl), tin (Sn), titanium (Ti), vanadium (V), and

zinc (Zn).

This document can also be applied for the digestion of other elements, provided the user has verified the

applicability.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 15002, Characterization of waste - Preparation of test portions from the laboratory sample

EN 15934, Sludge, treated biowaste, soil and waste - Calculation of dry matter fraction after determination of

dry residue or water content

EN 16179, Sludge, treated biowaste and soil - Guidance for sample pretreatment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

digestion

mineralization of the organic matter of a sample and dissolution of its mineral part, more or less completely,

when reacting with a reagent mixture

3.2

dry residue

remaining mass fraction of a sample after a drying process at 105 °C under specified conditions

[SOURCE: EN 15934:2012, 3.1]

3.3

dry matter fraction

(dm)

mass fraction of a sample excluding water expressed as mass fraction calculated by determination of dry

residue or water content

[SOURCE: EN 15934:2012, 3.3]

3.4

laboratory sample

sample intended for laboratory inspection of testing

[SOURCE: EN ISO 11074:2015, 4.3.7]

3.5

sample

portion of material selected from a larger quantity of material

3.6

test portion

quantity of material, of proper size for measurement of the concentration or other property of interest,

removed from the test sample

Note 1 to entry: The test portion may be taken from the laboratory sample directly if no preparation of sample is

required (e.g. with liquids), but usually it is taken from the prepared test sample.

Note 2 to entry: A unit or increment of proper homogeneity, size and fineness, needing no further preparation, may

be a test portion.

[SOURCE: EN ISO 11074:2015, 4.3.15]

3.7

test sample

portion of material resulting from the laboratory sample by means of an appropriate method of sample

pretreatment and having the size (volume/mass) necessary for the desired testing or analysis

[SOURCE: EN ISO 11074:2015, 4.3.16]

4 Principle

A test portion is digested according to one of the following heating procedures:

— Method A: Heating block digestion

— A: Digestion with HCl, HNO and HBF using a heating block at (105 ± 5) °C for 2 h, followed by

3 4

filtration/centrifugation.

— Method B: Microwave digestion

— B1: Digestion with HCl, HNO and HBF using a microwave oven with temperature-controlled

3 4

procedure to an end temperature at (175 ± 5) °C in a closed vessel followed by

filtration/centrifugation.

— B2: Digestion with HCl, HNO and HF using a microwave oven with power-controlled procedure in

a closed vessel followed by filtration/centrifugation.

NOTE Alternatively, microwave digestion with temperature-controlled procedure in a closed vessel can be used,

provided the user has verified the applicability.

Due to safety considerations, the digestion with HCl, HNO and HBF is strongly recommended over the

3 4

much more hazardous digestion using HCl, HNO and HF.

5 Interferences and sources of errors

5.1 General information

The container in which the sample is delivered and stored can be a source of errors. Its material shall be

chosen according to the elements to be determined (e.g. elemental Hg can penetrate polyethylene walls

very rapidly in both directions. Glass can contaminate samples with elements that it contains: - e.g. Na, K,

Al).

Grinding or milling samples includes a risk of contamination of the sample by the environment (air, dust,

wear of milling equipment). Due to elevated temperature, losses of volatile elements/compounds are

possible.

For the determination of elements forming volatile elements/compounds (e.g. Hg, As, Pb), special care has

to be taken at sample pre-treatment.

In the case of filtration of the digested solution, it is necessary to take care that the filtration procedure

does not introduce contaminants.

Ensure that all of the test portion is brought into contact with the acid mixture in the digestion vessel.

Some elements of interest can be lost due to precipitation with ions present in the digest solution, e.g. low

soluble chlorides, fluorides and sulphates.

5.2 Closed vessel system for microwave digestion

The upper limits of mass of the test portion according to the manufacturer's specifications have to be taken

into account.

Very reactive or volatile materials that may create high pressures when heated may cause a venting of the

vessels with potential loss of sample and analytes. The complete decomposition of either carbonates, or

carbon based samples, may cause sufficient pressure to vent the vessel.

After digestion, the vessel shall be cooled to room temperature before opening.

6 Reagents

Use only acids and reagents of recognized analytical grade or verify the content of the elements to be

analysed to avoid high blank values for subsequent analytical measurements. Use a test blank solution

throughout the procedure applying all steps with the same amount of acids, but without a sample.

6.1 Water, e.g. deionized.

6.2 Tetrafluoroboric acid (HBF ), c(HBF ) approximately 6 mol/l, w(HBF ) = 38 % (m/m) to

4 4 4

48 % (m/m).

6.3 Hydrofluoric acid (HF), c(HF) approximately 23 mol/l, w(HF) = 40 % (m/m) to 45 % (m/m).

6.4 Boric acid (B(OH) ), solid.

6.5 Boric acid (B(OH) ) solution, e.g. 4 % (m/m) solution.

Dissolve 40 g of boric acid (6.4) in water and dilute to 1 l of water (6.1).

6.6 Hydrochloric acid, c(HCl) approximately 12 mol/l, w(HCl) = 35 % (m/m) to 37 % (m/m).

6.7 Nitric acid, c(HNO ) approximately 15 mol/l, w(HNO ) = 65 % (m/m) to 70 % (m/m).

3 3

7 Apparatus

Usual laboratory apparatus. All glassware and plastics ware shall be adequately cleaned and stored in order

to avoid any contamination.

Depending on the concentration of the element of interest, particular caution shall be taken with respect to

the cleaning of the vessels.

7.1 Method A: heating block digestion

7.1.1 Digestion tube, 50 ml polypropylene tube with a screw cap from polyethylene.

The material of the tube and screw cap shall be tested in order to be sure that release of elements of interest

does not take place. Other materials and vessels with other volumes than mentioned above are allowed to

be used if suitability has been proven.

7.1.2 Temperature-controlled heating block, heating block able to heat the tube(s) to a temperature

of (105 ± 5) °C.

7.2 Method B: microwave digestion, temperature and/or power-controlled, closed vessels

7.2.1 Digestion vessel, for pressurized microwave digestion, typically of 100 ml volume, reagent-,

temperature- and pressure-resistant and capable of containing the mixture of sample and digest solution.

The vessel shall be suitable for the safe application in the temperature and pressure range applied, capable

of withstanding pressures of at least 3 000 kPa.

Digestion vessels made of modified polytetrafluoroethylene (PTFE) and equipped with a safety pressure

releasing system to avoid explosion of the vessel, shall be used. The inner wall of the vessel shall be inert

and shall not release contaminations to the digest solution.

NOTE It can be necessary to periodically clean the digestion vessels with a suitable surfactant to remove

persistent deposits.

7.2.2 Microwave digestion system, temperature-controlled, corrosion resistant and well ventilated.

All electronics shall be protected against corrosion for safe operation.

Use a laboratory-grade microwave oven with temperature feedback control mechanisms.

The microwave digestion system shall be able to control the temperature with an accuracy of at least ± 5 °C

and automatically adjust the microwave field output power within 2 s of sensing. Temperature sensors

shall be accurate to ± 2 °C, including the final reaction temperature of (175 ± 5) °C. Temperature feedback

control provides the primary performance mechanism for the method. Due to the variability in sample

matrix types and microwave digestion equipment (i.e. different vessel types and microwave designs),

control of the temperature during digestion is important for reproducible microwave heating and

comparable data.

The accuracy of the temperature measurement system shall be periodically tested at an elevated

temperature according to the manufactures instructions. If the temperature deviates by more than 2 °C

from the temperature measured by an external, calibrated temperature measurement system, the

microwave oven temperature measurement system shall be re-calibrated.

7.2.3 Microwave digestion system, power-controlled, corrosion resistant and well ventilated. All

electronics shall be protected against corrosion for safe operation.

The microwave unit shall be able to provide programmable power which can be programmed to

within ± 10 W of the required power. Typical units provide a nominal 600 W to 1 200 W of power. If

necessary (referring to manufactures specifications) calibration of the microwave unit shall be performed

(see Annex A).

The microwave unit shall be designed in a way that guarantees homogeneous heating of the samples.

The microwave unit cavity shall be built in a way that even in case of leakage or explosion of the vessels the

safety of the operators can be guaranteed. Household instruments are not suitable for laboratory use.

The microwave unit shall include a temperature and/or pressure control system.

7.3 Sample containers, plastic and glass containers are both suitable.

7.4 Filter, usually with a pore size of 0,45 µm and resistant to the employed acid mixture.

7.5 Volumetric flasks, usually of nominal capacity of 50 ml or 100 ml.

7.6 Analytical balance, with an accuracy of 1 mg or better.

8 Procedure

8.1 General

Pre-treat, if not otherwise specified, soil, sludge and biowaste samples according to EN 16179 and waste

samples according to EN 15002.

Determine the dry matter content, depending on the matrix of the sample, according to EN 15934.

Pre-treatment should include drying and grain size reduction below a particle size of 250 µm, or

homogenizing by use of a high speed mixer or sonification for liquid samples.

The mass of test portion for a single digestion shall be selected in a way that:

— it is representative for the laboratory sample;

— it complies with the specifications of manufacturer of the digestion unit.

If the required representative test portion exceeds the manufacturers' specifications, the test portion

should be divided into smaller quantities and digested separately. The individual digests should be

combined prior to analysis.

8.2 Blank test

Carry out a reagent blank test digestion in parallel with the determination, using the same procedure and

the same quantities of all the reagents as in the determination, but omitting the test portion. The laboratory

shall define acceptable limits.

NOTE The measurement of a blank is introduced to determine the contribution of the extracting solution,

digestion tube and filter used to the measured value.

8.3 Method A: Heating block digestion using HCl, HNO3 and HBF4

Weigh approximately 0,2 g to 0,5 g of the dried and pre-treated test portion with an accuracy of 0,001 g

and transfer to the digestion tube (7.1.1).

The amount of the test sample depends on the amount of organic matter. The maximum amount of organic

carbon shall not exceed 0,15 g when 8 ml of HCl/HNO mixture is used. Per additional 0,1 g organic carbon

(more than this 0,15 g), 1 ml of additional concentrated HNO (6.7) shall be added before the digestion

process is started.

If necessary, moisten the test portion with a few drops of water (6.1). Add (6,0 ± 0,1) ml hydrochloric acid

(6.6) followed by (2,0 ± 0,1) ml nitric acid (6.7) and (4,0 ± 0,1) ml tetrafluoroboric acid (6.2). Let stand at

room temperature until any effervescence almost ceases to allow for slow oxidation of the organic matter

in the sample.

Turn the screw cap gently (not very tight!) and place the digestion tube on the heating block (7.1.2) and

slowly increase the temperature to (105 ± 5) °C. Keep this temperature during 120 min.

Let the tube cool down to room temperature and add water (6.1) to the volume mark.

If a non-graduated digestion tube is used, transfer quantitatively the solution content into a suitable sized

volumetric flask and add water (6.1) to the volume mark. Alternatively, another procedure can be applied,

such that the adjustment to volume shall be carried out immediately after digestion.

If the measurement solution contains suspended particles which may clog nebulizers or interfere with an

injection of the sample into the instrument, the sample may be centrifuged or filtered (7.4).

If the measurement solution contains suspended particles, the digestion is not complete. This should be

stated in the report.

The measurement solution is now ready for the determination of the elements of interest using appropriate

elemental analysis techniques.

8.4 Method B: Microwave digestion

8.4.1 Method B1: Digestion with HBF , HNO and HCl using microwave heating, temperature-

4 3

controlled, closed vessels

Weigh an amount between 0,2 g to 0,5 g of the dried and pre-treated test portion with an accuracy of

0,001 g and transfer it into the digestion vessel (7.2.1).

The amount of the test sample depends on the amount of organic matter. The maximum amount of organic

carbon shall not exceed 0,15 g when 8 ml of HCl/HNO mixture is used. Per additional 0,1 g organic carbon

(more than this 0,15 g), 1 ml of additional concentrated HNO (6.7) shall be added before the digestion

process is started.

Referring to the manufacturer’s instructions, the upper limits of mass of the test portion shall be taken into

account.

If necessary, moisten the test portion with a few drops of water (6.1). Add (6,0 ± 0,1) ml hydrochloric acid

(6.6) followed by (2,0 ± 0,1) ml nitric acid (6.7) and (4,0 ± 0,1) ml tetrafluoroboric acid (6.2).

If a vigorous reaction occurs, allow the reaction cease before capping the vessel.

Cap the digestion vessel according to the manufacturer’s instructions. Place in all positions of the

microwave oven carrousel (usually 6, 12, 16 or 40 positions) sample vessels. If a lower number of samples

are available compared to the vessel positions, place vessels filled with same amount of the acid mixture

without sample. This is to ensure the same microwave energy absorption occurs during each digestion

procedure. This method is an operationally defined method, designed to achieve consistent digestion of

samples by specific reaction conditions. The temperature of the digestion mixture in each vessel shall be

raised with a heating rate of approximately 10 °C/min to 15 °C/min to (175 ± 5) °C and remain at

(175 ± 5) °C for (10 ± 1) min. Cool down to room temperature.

WARNING — A too high temperature increase may cause a vigorous, exothermic reaction in the digestion

solution with high pressure increase and blow-off of the security valve. Losses of analytes are then possible.

At the end of the microwave oven programme, allow the vessels to cool according to the manufacturer's

instructions before removing them from the microwave system. Cooling of the vessels may be accelerated

by internal or external cooling devices.

After reaching room temperature, check if the microwave vessels maintained their seal throughout the

digestion. Due to the wide variety of vessel designs, a single procedure is not appropriate.

Carefully uncap and vent each vessel in a well-ventilated fume hood according to the manufacturer's

instructions. Transfer quantitatively the solution content of each vessel into a suitable sized volumetric

flask and add water (6.1) to the volume mark.

Alternatively, another procedure can be applied, such that the adjustment to volume with the solid residue

still present shall be carried out immediately after digestion.

If the measurement solution contains suspended particles which may clog nebulizers or interfere with an

injection of the sample into the instrument, the sample may be centrifuged or filtered (7.4).

If the measurement solution contains suspended particles, the digestion is not complete. This should be

stated in the report.

The measurement solution is now ready for the determination of the elements of interest using appropriate

elemental analysis techniques.

8.4.2 Method B2: Digestion with HF, HNO and HCl using microwave heating, power-controlled,

closed vessels

Weigh an amount between 0,2 g to 0,5 g of the dried and pre-treated test portion with an accuracy of

0,001 g and transfer it into the digestion vessel (7.2.1).

The amount of the test sample depends on the amount of organic matter. The maximum amount of organic

carbon shall not exceed 0,15 g when 8 ml of HCl/HNO mixture is used. Per additional 0,1 g organic carbon

(more than this 0,15 g), 1 ml of additional concentrated HNO (6.7) shall be added before the digestion

process is started.

Referring to the manufacturer’s instructions, the upper limits of mass of the test portion shall be taken into

account.

If necessary, moisten the test portion with a few drops of water (6.1). Add (6,0 ± 0,1) ml hydrochloric acid

(6.6) followed by (2,0 ± 0,1) ml nitric acid (6.7) and (2,0 ± 0,1) ml hydrofluoric acid (6.3).

If a vigorous reaction occurs, allow the reaction cease before capping the vessel.

Cap the digestion vessel according to the manufacturer’s instructions. Place in all positions of the

microwave oven carrousel (usually 6, 12, 16 or 40 positions) sample vessels and start the digestion

procedure. The power programme (see Table 2) is intended to be used for batches of 6 samples.

Commercial available microwave units may contain more or less sample positions. In order to ensure

consistant reaction conditions in these cases the power programme shall be adjusted according to the

manufactures instructions. If a lower number of samples are available compared to the vessel positions,

place vessels filled with same amount of the acid mixture without sample. This is to ensure the same

microwave energy absorption occurs during each digestion procedure.

Table 2 — Power programme

Time Power

Min W

2 250

2 0

5 250

5 400

5 500

WARNING — A too high temperature increase may cause a vigorous, exothermic reaction in the digestion

solution with high pressure increase and blow-off of the security valve. Losses of analytes are then possible.

At the end of the microwave programme, allow the vessels to cool according to the manufacturer's

instructions before removing them from the microwave system. Cooling of the vessels may be accelerated

by internal or external cooling devices.

After reaching room temperature, check if the microwave vessels maintained their seal throughout the

digestion. Due to the wide variety of vessel designs, a single procedure is not appropriate.

Carefully uncap and vent each vessel in a well-ventilated fume hood according to the manufacturer's

instructions, then add a solution containing 650 mg of boric acid (e.g. 22 ml of 4 % m/m (6.5)). Cap the

vessels and put them into the microwave unit cavity and start the following programme: 3 min (time) at

300 W (power).

At the end of the microwave programme, allow the vessels to cool according to the manufacturer's

instructions before removing them from the microwave system. Cooling of the vessels may be accelerated

by internal or external cooling devices.

Carefully uncap and vent each vessel in a well-ventilated fume hood according to the manufacturer's

instructions. Transfer quantitatively the solution content of each vessel into a suitable sized volumetric

flask and add water (6.1) to the volume mark.

Alternatively, another procedure can be applied, such that the adjustment to volume with the solid residue

still present shall be carried out immediately after digestion.

If the measurement solution contains suspended particles which may clog nebulizers or interfere with an

injection of the sample into the instrument, the sample may be centrifuged or filtered (7.4).

If the measurement solution contains suspended particles, the digestion is not complete. This should be

stated in the report.

The measurement solution is now ready for the determination of the elements of interest using appropriate

elemental analysis techniques.

9 Test report

This test report shall contain at least the following information:

a) the digestion method used, together with a reference to this document, i.e. EN 13656;

b) identity of the sample;

c) any deviation from this method and report of circumstances that can have affected the results.

Annex A

(normative)

Calibration of the power adjustment

In order to compare the power adjustment of different apparatus among themselves, the actually supplied

(effective) power shall be determined. Also the relationship between the supplied power and the

adjustment scale shall be controlled. Furthermore, the effective power shall be checked periodically.

Calibration is carried out by heating a known amount of water during a fixed time period (e.g. 2 min) at

different microwave power rates. Each raise of temperature has to be measured with a limit deviation

of ± 0,1 °C after each heating cycle. The absorbed power is calculated from the raise of temperature (see

formula at the end of this annex).

Put e.g. 1 kg of water in a plastic beaker (or a beaker made of other material that does not absorb or reflect

microwave energy, glass beaker shall be avoided), stir and measure the temperature. Place the beaker in

the microwave oven. Do always select the same position. Set the microwave during 2 min at full power.

Remove the beaker, stir and measure the final temperature. Repeat this procedure also at lower power

rates.

The power absorbed is calculated with the following formula:

C × m ×∆T

p

P=

t

where

P is the power absorbed by the water in W (J/s);

C is the specific heat for water J/kg °C (= 4184 J/kg °C);

p

m is the mass of the water that is used for the calibration in kg;

ΔT is the difference between initial and final temperature in °C;

t is the time period in s.

If in the described procedure 2 min and 1 kg water are used, the formula can be simplified to:

P = ΔT ×34,87 J/s·°C

where

P is the power absorbed by the water in W (J/s);

ΔT is the difference between initial and final temperature in °C.

Annex B

(informative)

Repeatability and reproducibility data – Method A and B1

B.1 Inter-laboratory study

Between October 2018 and February 2019, a project for validation of method A (Heating block digestion

with HCl, HNO and HBF ) and method B1 (Microwave digestion, temperature-controlled, with HCl, HNO

3 4 3

and HBF ) has been organized and carried out. The validation included an inter-laboratory study for

evaluation of performance characteristics of the method (reproducibility, repeatability, accuracy where

applicable).

B.2 Selection of laboratories

Several CEN/TC444 members were requested to circulate information about the inter-laboratory trial and

collect a list of interested European laboratories. Respectively 9 (for method A) and 8 (for method B1)

laboratories gave their availability to participate to the inter-laboratory trial. All laboratories carried out

the digestion with a heating block and/or microwave at regular basis. The laboratories were informed

about the necessity to carry out digestion and analysis according to this standard. According to the

ISO 5725 series [2] no selection has been made in advance on the basis of the supposed “ability” of

laboratories, their certifications, etc: it's therefore possible to assume that participating laboratories are a

rather good “sample” of “normal” European laboratories.

B.3 Selection of samples

Two samples were taken from the interlaboratory trial for the validation of EN 13656:

— ink waste sludge (organic matrix) (CEN8/99 “INK WASTE CW12 POWDER”);

— electronic industry sludge (“metallic” matrix) (CEN9/99 “SEWAGE SLUDGE SL11 POWDER”).

For accuracy evaluation, two certified reference materials (CRM) have been included:

— ISE 859 (sediment);

— BCR 176R (city waste incineration ash, with identical matrix as BCR 176, used in the inter laboratory

trial for the evaluation of EN 13656).

Additionally, three materials used in robustness validation tests for CEN/TC 351 [14] [15] have been

included:

— CFA Coal fly ash;

— GSS Steel slag;

— CUS Copper slag.

All samples, including the two CRMs, have been delivered to laboratories in anonymous form.

B.4 Experimental

Preparation and homogenization of samples, packaging, delivering, collection and evaluation of results

have been carried out by VITO NV in Mol (Belgium) and Synlab Analytics and Services B.V. in Rotterdam

(The Netherlands) [12] [13].

B.5 Results

All laboratories have actually returned results for the inter-laboratory study. The means and standard

deviations of reproducibility have been evaluated according to ISO 13528:2015, C.1 [9], following these

steps:

— removing of data with a value below the detection limit (“<”-values);

— data have been evaluated if the mean measured concentration is above 1 mg/kg dm (for Hg 0,1 mg/kg

dm);

— data have been evaluated only if more than six results remain;

— for the remaining data sets, means and standard deviations were calculated as Huber-M estimates with

Winsorising at 1.5 standard deviations;

— where a “conventional true value” was available, accuracy (recovery) has been calculated.

The inter-laboratory study involved 9 (method A) and 8 (method B1) laboratories, performing analyses in

two replicates on seven samples, for the determination of a large number of elements (up to 28): this led

to a large data set. For some elements, only few data were available, anyway, even for these elements, useful

information on performance has been obtained.

B.6 Conclusions

The performances of the method should be compared on an element-by-element, matrix-by-matrix basis,

in the tables below. In general, performances are actually well comparable, especially for most

environmentally-sensitive (toxic) elements.

For some elements, e.g. Ba, Sn, Ti, microwave digestion might result in a higher recovery compared to a

heating block digestion.

For the element Ti, a higher recovery might be obtained when using HF instead of HBF (sample

dependent).

Table B.1 — Sample CEN 8/99 “INK WASTE CW12 POWDER”

Method A: Heating block digestion with HCl, HNO and HBF Method B1. Microwave digestion, temperature-controlled, with HCl, HNO and HBF

3 4 3 4

XREF Mean Recovery Reproducibility Repeatability XREF Mean Recovery Reproducibility Repeatability

N L NR N L NR

mg/kg dm mg/kg dm % % % mg/kg dm mg/kg dm % % %

Al 14 7 0 – 2195 – 25,3 5,0 12 6 0 – 2344 – 25,5 15,4

Sb – – – – – – – – – – – – – – – –

As 8 9 10 – 10,3 – 51,3 12,1 9 8 7 – 7,3 – 40,0 6,1

Ba 16 8 0 – 70 – 26,0 7,7 14 7 0 – 92 – 17,3 4,0

Cd – – – – – – – – – – – – – – – –

Ca 14 7 0 – 114971 – 10,3 6,6 14 7 0 – 112376 – 8,4 5,1

Cr 18 9 0 – 3865 – 5,5 3,5 16 8 0 – 3814 – 9,9 5,0

Co 16 8 0 – 16,0 – 6,6 3,5 14 7 0 – 16,3 – 5,1 1,5

Cu 18 9 0 – 13109 – 5,7 4,4 16 8 0 – 12808 – 6,7 4,4

Fe 16 8 0 – 76864 – 4,7 4,3 14 7 0 – 77318 – 8,9 5,0

Pb 18 9 0 – 5805 – 8,2 5,6 16 8 0 – 5791 – 11,1 6,1

Mg 14 7 0 – 1013 – 9,8 1,9 14 7 0 – 938 – 12,6 8,2

Mn 16 8 0 – 581 – 5,0 2,5 14 7 0 – 553 – 15,3 2,8

Hg 18 9 0 – 1,82 – 16,6 3,1 16 8 0 – 1,89 – 29,6 5,9

Mo 10 7 4 – 4,6 – 11,2 3,5 12 6 0 – 4,2 – 27,8 5,2

Ni 18 9 0 – 22 – 6,9 1,9 16 8 0 – 22 – 13,6 3,0

P 16 8 0 – 14017 – 4,9 2,3 14 7 0 – 13632 – 17,3 5,7

K 14 7 0 – 1113 – 14,3 3,1 14 7 0 – 1042 – 25,8 5,4

Ag – – – – – – – – – – – – – – – –

S 16 8 0 – 28508 – 6,7 2,8 14 7 0 – 30209 – 20,8 4,8

Se 8 8 8 – 3,8 – 40,3 14,1 8 7 6 – 3,8 – 10,3 14,5

Na 14 7 0 – 5435 – 6,3 2,1 14 7 0 – 4797 – 32,4 4,2

Sr 16 8 0 – 125 – 12,2 2,8 14 7 0 – 122 – 12,0 1,8

Sn 6 8 10 – 3 – 22,3 10,7 8 7 6 – 4 – 32,1 37,6

Tl – – – – – – – – – – – – – – – –

Ti 16 8 0 – 175 – 4,1 2,2 14 7 0 – 188 – 15,1 5,0

V 16 8 0 – 18 – 8,6 4,3 14 7 0 – 15,9 – 14,6 6,8

Zn 18 9 0 – 1269 – 7,5 2,3 16 8 0 – 1260 – 13,8 3,3

N = Number of results, L = Number of laboratories, NR = Number of results rejected for statistical evaluation, XREF = Conventional true value (where applicable)

Table B.2 — Sample CEN9/99 “SEWAGE SLUDGE SL11 POWDER”

Method A: Heating block digestion with HCl, HNO and HBF Method B1. Microwave digestion, temperature-controlled, with HCl, HNO and HBF

3 4 3 4

XREF Mean Recovery Reproducibility Repeatability XREF Mean Recovery Reproducibility Repeatability

N L NR N L NR

mg/kg dm mg/kg dm % % % mg/kg dm mg/kg dm % % %

Al 14 7 0 – 87073 – 27,6 11,8 12 6 0 – 66795 – 52,7 22,3

Sb 8 8 8 – 5 – 10,1 2,6 8 7 6 – 5 – 6,9 12,4

As 10 9 8 – 5,6 – 34,5 8,8 10 8 6 – 5,5 – 24,9 8,9

Ba 16 8 0 – 74 – 26,8 22,4 14 7 0 – 78 – 21,3 4,5

Cd – – – – – – – – – – – – – – – –

Ca 12 6 0 – 63779 – 11,7 4,8 12 6 0 – 55399 – 23,1 10,1

Cr 18 9 0 – 92 – 5,3 3,2 16 8 0 – 91 – 8,9 3,1

Co 10 9 8 – 6,7 – 19,5 15,8 12 7 2 – 5,8 – 15,0 13,0

Cu 18 9 0 – 104858 – 6,4 3,0 16 8 0 – 103694 – 4,8 3,7

Fe 16 8 0 – 5861 – 11,6 3,2 14 7 0 – 6433 – 12,6 13,2

Pb 18 9 0 – 10126 – 3,4 23,5 16 8 0 – 10245 – 6,4 8,2

Mg 12 6 0 – 2493 – 12,7 9,2 12 6 0 – 1974 – 26,8 17,6

Mn 16 8 0 – 712 – 4,0 1,9 14 7 0 – 713 – 6,2 1,2

Hg 14 9 4 – 0,19 – 22,3 4,7 10 8 6 – 0,21 – 31,0 10,7

Mo 10 7 4 – 5,3 – 6,0 3,1 12 6 0 – 5,3 – 7,9 3,8

NI 18 9 0 – 1967 – 5,4 1,8 16 8 0 – 1993 – 6,6 6,4

P 14 7 0 – 604,9 – 15,2 5,9 12 6 0 – 5823 – 11,3 3,6

K 14 7 0 – 4216 – 29,0 12,4 14 7 0 – 4046 – 37,6 10,5

Ag 14 8 2 – 11,3 – 14,3 25,6 14 7 0 – 10,6 – 15,2 11,7

S 16 8 0 – 70119 – 7,0 3,0 14 7 0 – 70207 – 9,6 4,0

Se – – – – – – – – – – – – – – – –

Na 14 7 0 – 14101 – 16,4 2,8 14 7 0 – 12862 – 19,2 7,2

Sr 16 8 0 – 196 – 20,7 4,6 14 7 0 – 199 – 18,2 3,1

Sn 16 8 0 – 13413 – 10,2 3,7 14 7 0 – 19459 – 14,5 5,5

Tl – – – – – – – – – – – – – – – –

Ti 14 8 2 – 74 – 10,2 2,5 14 7 0 – 87 – 32,9 6,2

V 14 8 2 – 7 – 14,7 5,3 14 7 0 – 6,9 – 13,3 5,8

Zn 18 9 0 – 233 – 6,8 1,3 16 8 0 – 265 – 19,7 1,9

N = Number of results, L = Number of laboratories, NR = Number of results rejected for statistical evaluation, XREF = Conventional true value (where applicable)

Table B.3 — Sample ISE 859 “sediment”

Method A: Heating block digestion with HCl, HNO and HBF Method B1. Microwave digestion, temperature-controlled, with HCl, HNO and HBF

3 4 3 4

XREF Mean Recovery Reproducibility Repeatability XREF Mean Recovery Reproducibility Repeatability

N L NR mg/kg dm mg/kg dm % % % N L NR mg/kg dm m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...