SIST-TS CEN/TS 17405:2020

(Main)Stationary source emissions - Determination of the mass concentration of carbon dioxide - Reference method: infrared spectrometry

Stationary source emissions - Determination of the mass concentration of carbon dioxide - Reference method: infrared spectrometry

This document specifies the reference method (RM) for the measurement of carbon dioxide (CO2) based on the infrared (IR) absorption principle. It includes the sampling and the gas conditioning system, and allows the determination of the CO2 in flue gases emitted to the atmosphere from ducts and stacks. This document specifies the measurement of the total CO2 concentration and does not differentiate between biogenic and fossil derived CO2.

This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the IR measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

Emissionen aus stationären Quellen - Ermittlung der Massenkonzentration von Kohlenstoffdioxid - Referenzverfahren: Infrarot-Spektrometrie

Dieses Dokument legt das Referenzverfahren (RM) zur Messung von Kohlenstoffdioxid (CO2) auf Basis des Infrarot-Absorptionsverfahrens fest. Es beinhaltet die Einrichtungen zur Probenahme und zur Probengasaufbereitung und erlaubt die Bestimmung von CO2 in Abgasen, die aus Abgaskanälen und Kaminen in die Atmosphäre emittiert werden. Dieses Dokument legt die Messung der gesamten CO2-Konzentration fest und unterscheidet nicht zwischen biogenem und fossilem CO2.

Dieses Dokument legt zu bestimmende Verfahrenskenngrößen und Mindestanforderungen fest, die von portablen automatischen Messeinrichtungen (P AMS) auf Basis des Infrarot-Messverfahrens eingehalten werden müssen. Es gilt für wiederkehrende Messungen und für die Kalibrierung oder Überprüfung von automatischen Messeinrichtungen (AMS), die aus gesetzgeberischen oder anderen Gründen stationär an einem Abgaskanal installiert sind.

Émissions de sources fixes - Détermination de la concentration massique en dioxyde de carbone - Méthode de référence spectrométrie infrarouge

Le présent document spécifie la méthode de référence (RM) permettant de mesurer le dioxyde de carbone (CO2) en utilisant le principe de l’absorption infrarouge (IR). Elle inclut le système de prélèvement et de conditionnement des gaz et permet de doser le CO2 dans les effluents gazeux rejetés dans l’atmosphère par les conduits et les cheminées. Le présent document spécifie le mesurage de la concentration totale en CO2 et ne fait pas de distinction entre le CO2 d’origine biogénique et d’origine fossile.

Le présent document spécifie les caractéristiques devant être déterminées et les critères de performance devant être remplis par les systèmes de mesurage automatisés portables (P AMS) en utilisant la méthode de mesurage IR. Il s’applique à la surveillance périodique ainsi qu’à l’étalonnage ou au contrôle des systèmes de mesurage automatisés (AMS) installés à demeure sur une cheminée, à des fins réglementaires ou autres.

Emisije nepremičnih virov - Določevanje masne koncentracije ogljikovega dioksida - Referenčna metoda: infrardeča spektroskopija

General Information

- Status

- Published

- Public Enquiry End Date

- 01-Aug-2019

- Publication Date

- 04-Oct-2020

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 30-Sep-2020

- Due Date

- 05-Dec-2020

- Completion Date

- 05-Oct-2020

Overview

CEN/TS 17405:2020 - "Stationary source emissions - Determination of the volume concentration of carbon dioxide - Reference method: infrared spectrometry" - is a CEN Technical Specification that defines the reference method (RM) for measuring CO2 in flue gases using infrared (IR) spectrometry. The document covers sampling, gas conditioning and analyser requirements to determine the total CO2 concentration (volume concentration) emitted from ducts and stacks. It explicitly does not distinguish between biogenic and fossil-derived CO2. CEN/TS 17405:2020 also specifies the characteristics and performance criteria for portable automated measuring systems (P-AMS) applying the IR method, for periodic monitoring and for calibration/control of permanently installed automated measuring systems (AMS/CEMS).

Key topics and technical requirements

- Measurement principle: non‑dispersive infrared (NDIR) / IR absorption for CO2 volume concentration.

- Sampling and gas conditioning: requirements for probe, sample lines, filters and conditioners to deliver representative, conditioned gas to the analyser.

- Measuring system description: scope of an AMS/P‑AMS including probe, pump, conditioner, analyser and data acquisition.

- Performance characteristics: defined quantities such as response time, short‑term zero/span drift, lack of fit (linearity), repeatability and reproducibility under field conditions.

- Suitability and uncertainty: procedures to evaluate whether an IR measurement system meets the measurement task and uncertainty requirements (references include ISO/IEC Guide 98-3 and EN ISO 14956).

- Field operation and quality control: requirements for setup, operation, span/zero checks, calibration and ongoing QC for periodic campaigns and AMS calibration.

- Reporting and documentation: standardized expression of results and measurement report content.

- Informative annexes: schematics of NDIR systems, measuring-system layouts, examples for uncertainty assessment and drift correction.

Applications and users

CEN/TS 17405:2020 is intended for:

- Environmental regulators and compliance authorities conducting or validating stack emission measurements.

- Emissions monitoring laboratories and field teams performing periodic CO2 monitoring or site surveys.

- Plant operators and maintenance teams using P‑AMS to calibrate or verify permanent AMS/CEMS.

- Manufacturers and integrators of IR CO2 analysers, AMS/CEMS and portable measuring systems.

- Environmental consultants preparing measurement plans and reports.

Practical benefits include consistent, traceable CO2 measurements from stationary sources, harmonized QA/QC for regulatory compliance, and clearer guidance for AMS/P‑AMS performance evaluation.

Related standards

- EN 15259 (measurement sections and sites)

- EN 15267‑4 (AMS performance criteria)

- EN ISO 14956 / ISO/IEC Guide 98‑3 (uncertainty evaluation)

Keywords: CEN/TS 17405:2020, carbon dioxide measurement, infrared spectrometry, CO2 monitoring, stationary source emissions, P‑AMS, AMS, CEMS, stack emissions, flue gas sampling.

Frequently Asked Questions

SIST-TS CEN/TS 17405:2020 is a technical specification published by the Slovenian Institute for Standardization (SIST). Its full title is "Stationary source emissions - Determination of the mass concentration of carbon dioxide - Reference method: infrared spectrometry". This standard covers: This document specifies the reference method (RM) for the measurement of carbon dioxide (CO2) based on the infrared (IR) absorption principle. It includes the sampling and the gas conditioning system, and allows the determination of the CO2 in flue gases emitted to the atmosphere from ducts and stacks. This document specifies the measurement of the total CO2 concentration and does not differentiate between biogenic and fossil derived CO2. This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the IR measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

This document specifies the reference method (RM) for the measurement of carbon dioxide (CO2) based on the infrared (IR) absorption principle. It includes the sampling and the gas conditioning system, and allows the determination of the CO2 in flue gases emitted to the atmosphere from ducts and stacks. This document specifies the measurement of the total CO2 concentration and does not differentiate between biogenic and fossil derived CO2. This document specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) using the IR measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

SIST-TS CEN/TS 17405:2020 is classified under the following ICS (International Classification for Standards) categories: 13.040.40 - Stationary source emissions. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TS CEN/TS 17405:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2020

Emisije nepremičnih virov - Določevanje masne koncentracije ogljikovega

dioksida - Referenčna metoda: infrardeča spektroskopija

Stationary source emissions - Determination of the mass concentration of carbon dioxide

- Reference method: infrared spectrometry

Emissionen aus stationären Quellen - Ermittlung der Massenkonzentration von

Kohlenstoffdioxid - Referenzverfahren: Infrarot-Spektrometrie

Émissions de sources fixes - Détermination de la concentration massique en dioxyde de

carbone - Méthode de référence spectrométrie infrarouge

Ta slovenski standard je istoveten z: CEN/TS 17405:2020

ICS:

13.040.40 Emisije nepremičnih virov Stationary source emissions

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 17405

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

September 2020

TECHNISCHE SPEZIFIKATION

ICS 13.040.40

English Version

Stationary source emissions - Determination of the volume

concentration of carbon dioxide - Reference method:

infrared spectrometry

Émissions de sources fixes - Détermination de la Emissionen aus stationären Quellen - Ermittlung der

concentration volumique en dioxyde de carbone - Volumenkonzentration von Kohlenstoffdioxid -

Méthode de référence spectrométrie infrarouge Referenzverfahren: Infrarot-Spektrometrie

This Technical Specification (CEN/TS) was approved by CEN on 16 September 2019 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 17405:2020 E

worldwide for CEN national Members.

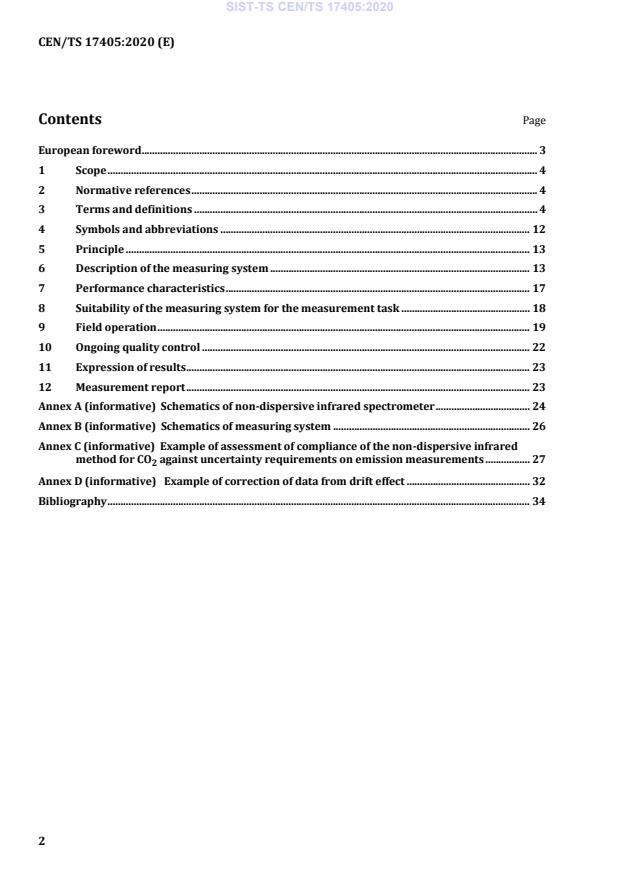

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Symbols and abbreviations . 12

5 Principle . 13

6 Description of the measuring system . 13

7 Performance characteristics . 17

8 Suitability of the measuring system for the measurement task . 18

9 Field operation . 19

10 Ongoing quality control . 22

11 Expression of results . 23

12 Measurement report . 23

Annex A (informative) Schematics of non-dispersive infrared spectrometer . 24

Annex B (informative) Schematics of measuring system . 26

Annex C (informative) Example of assessment of compliance of the non-dispersive infrared

method for CO against uncertainty requirements on emission measurements . 27

Annex D (informative) Example of correction of data from drift effect . 32

Bibliography . 34

European foreword

This document (CEN/TS 17405:2020) has been prepared by Technical Committee CEN/TC 264 “Air

quality”, the secretariat of which is held by DIN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies the reference method (RM) for the measurement of carbon dioxide (CO ) based

on the infrared (IR) absorption principle. It includes the sampling and the gas conditioning system, and

allows the determination of the CO in flue gases emitted to the atmosphere from ducts and stacks. This

document specifies the measurement of the total CO concentration and does not differentiate between

biogenic and fossil derived CO .

This document specifies the characteristics to be determined and the performance criteria to be fulfilled

by portable automated measuring systems (P-AMS) using the IR measurement method. It applies for

periodic monitoring and for the calibration or control of automated measuring systems (AMS)

permanently installed on a stack, for regulatory or other purposes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 15259:2007, Air quality - Measurement of stationary source emissions - Requirements for measurement

sections and sites and for the measurement objective, plan and report

EN 15267-4:2017, Air quality - Certification of automated measuring systems - Part 4: Performance criteria

and test procedures for automated measuring systems for periodic measurements of emissions from

stationary sources

EN ISO 14956, Air quality - Evaluation of the suitability of a measurement procedure by comparison with a

required measurement uncertainty (ISO 14956)

ISO/IEC Guide 98-3, Uncertainty of measurement - Part 3: Guide to the expression of uncertainty in

measurement (GUM:1995)

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

standard reference method

SRM

reference method prescribed by European or national legislation

[SOURCE: EN 15259:2007]

3.2

reference method

RM

measurement method taken as a reference by convention, which gives the accepted reference value of

the measurand

Note 1 to entry: A reference method is fully described.

Note 2 to entry: A reference method can be a manual or an automated method.

Note 3 to entry: Alternative methods can be used if equivalence to the reference method has been

demonstrated.

[SOURCE: EN 15259:2007]

3.3

measurement method

method described in a written procedure containing all the means and procedures required to sample

and analyse, namely field of application, principle and/or reactions, definitions, equipment, procedures,

presentation of results, other requirements and measurement report

[SOURCE: EN 14793:2017]

3.4

alternative method

AM

measurement method which complies with the criteria given by this document with respect to the

reference method

Note 1 to entry: An alternative method can consist of a simplification of the reference method.

[SOURCE: EN 14793:2017]

3.5

measuring system

set of one or more measuring instruments and often other devices, including any reagent and supply,

assembled and adapted to give information used to generate measured quantity values within specified

intervals for quantities of specified kinds

[SOURCE: JCGM 200:2012]

3.6

automated measuring system

AMS

entirety of all measuring instruments and additional devices for obtaining a result of measurement

Note 1 to entry: Apart from the actual measuring device (the analyser), an AMS includes facilities for taking

samples (e.g. probe, sample gas lines, flow meters and regulator, delivery pump) and for sample conditioning (e.g.

dust filter, pre-separator for interferents, cooler, converter). This definition also includes testing and adjusting

devices that are required for functional checks and, if applicable, for commissioning.

Note 2 to entry: The term “automated measuring system” (AMS) is typically used in Europe. The term

“continuous emission monitoring system” (CEMS) is also typically used in the UK and USA.

[SOURCE: EN 15267-4:2017]

3.7

portable automated measuring system

P-AMS

automated measuring system which is in a condition or application to be moved from one to another

measurement site to obtain measurement results for a short measurement period

Note 1 to entry: The measurement period is typically 8 h for a day.

Note 2 to entry: The P-AMS can be configured at the measurement site for the special application but can be also

set-up in a van or mobile container. The probe and the sample gas lines are installed often just before the

measurement task is started.

[SOURCE: EN 15267-4:2017]

3.8

calibration

set of operations that establish, under specified conditions, the relationship between values of quantities

indicated by a measuring method or measuring system, and the corresponding values given by the

applicable reference

Note 1 to entry: In case of automated measuring system (AMS) permanently installed on a stack the applicable

reference is the standard reference method (SRM) used to establish the calibration function of the AMS.

Note 2 to entry: Calibration should not be confused with adjustment of a measuring system.

[SOURCE: EN 15058:2017]

3.9

adjustment

set of operations carried out on a measuring system so that it provides prescribed indications

corresponding to given values of a quantity to be measured

Note 1 to entry: The adjustment can be made directly on the instrument or using a suitable calculation

procedure.

[SOURCE: EN 15058:2017]

3.10

span gas

test gas used to adjust and check a specific point on the response line of the measuring system

[SOURCE: EN 15058:2017]

3.11

measurand

particular quantity subject to measurement

[SOURCE: EN 15259:2007]

Note 1 to entry: The measurand is a quantifiable property of the stack gas under test, for example volume

concentration of a measured component, temperature, velocity, mass flow, oxygen content and water vapour

content.

3.12

interference

negative or positive effect upon the response of the measuring system, due to a component of the sample

that is not the measurand

[SOURCE: EN 15058:2017]

3.13

influence quantity

quantity that is not the measurand but that affects the result of the measurement

Note 1 to entry: Influence quantities are e.g. presence of interfering gases; ambient temperature, pressure of the

gas sample.

[SOURCE: EN 15058:2017]

3.14

ambient temperature

temperature of the air around the measuring system

[SOURCE: EN 15058:2017]

3.15

measurement campaign

single measurement or series of measurements intended to achieve a measurement objective

3.16

measurement period

designated period of time during which emission data set(s) are collected

3.17

measurement site

place on the waste gas duct in the area of the measurement plane(s) consisting of structures and technical

equipment, for example working platforms, measurement ports, energy supply

Note 1 to entry: Measurement site is also known as sampling site.

[SOURCE: EN 15259:2007]

3.18

measurement plane

plane normal to the centreline of the duct at the sampling position

Note 1 to entry: Measurement plane is also known as sampling plane.

[SOURCE: EN 15259:2007]

3.19

measurement port

opening in the waste gas duct along the measurement line, through which access to the waste gas is

gained

Note 1 to entry: Measurement port is also known as sampling port or access port.

[SOURCE: EN 15259:2007]

3.20

measurement line

line in the measurement plane along which the measurement points are located, bounded by the inner

duct wall

Note 1 to entry: Measurement line is also known as sampling line.

[SOURCE: EN 15259:2007]

3.21

measurement point

position in the measurement plane at which the sample stream is extracted or the measurement data are

obtained directly

Note 1 to entry: Measurement point is also known as sampling point.

[SOURCE: EN 15259:2007]

3.22

performance characteristic

one of the quantities (described by values, tolerances, range) assigned to equipment in order to define its

performance

[SOURCE: EN 15058:2017]

3.23

response time

duration between the instant when an input quantity value of a measuring instrument or measuring

system is subjected to an abrupt change between two specified constant quantity values and the instant

when a corresponding indication settles within specified limits around its final steady value

Note 1 to entry: By convention time taken for the output signal to pass from 0 % to 90 % of the final variation

of indication.

[SOURCE: EN 15058:2017]

3.24

short-term zero drift

difference between two zero readings at the beginning and at the end of the measurement period

[SOURCE: EN 15058:2017]

3.25

short-term span drift

difference between two span readings at the beginning and at the end of the measurement period

[SOURCE: EN 15058:2017]

3.26

lack of fit

systematic deviation, within the measurement range, between the measurement result obtained by

applying the calibration function to the observed response of the measuring system measuring test gases

and the corresponding accepted value of such test gases

Note 1 to entry: Lack of fit can be a function of the measurement result.

Note 2 to entry: The expression “lack of fit” is often replaced in everyday language by “linearity” or “deviation

from linearity”.

[SOURCE: EN 15058:2017]

3.27

repeatability in the laboratory

closeness of the agreement between the results of successive measurements of the same measurand

carried out under the same conditions of measurement

[SOURCE: EN 15058:2017]

Note 1 to entry: Repeatability conditions include:

— same measurement method;

— same laboratory;

— same measuring system, used under the same conditions;

— same location;

— repetition over a short period of time.

Note 2 to entry: Repeatability can be expressed quantitatively in terms of the dispersion characteristics of the

results.

Note 3 to entry: In this document the repeatability is expressed as a value with a level of confidence of 95 %.

3.28

repeatability in the field

closeness of the agreement between the results of simultaneous measurements of the same measurand

carried out with two sets of equipment under the same conditions of measurement

[SOURCE: EN 15058:2017]

Note 1 to entry: These conditions include:

— same measurement method;

— two sets of equipment, the performances of which are fulfilling the requirements of the measurement

method, used under the same conditions;

— same location;

— implemented by the same laboratory;

— typically calculated on short periods of time in order to avoid the effect of changes of influence

parameters (e.g. 30 min).

Note 2 to entry: Repeatability can be expressed quantitatively in terms of the dispersion characteristics of the

results.

Note 3 to entry: In this document, the repeatability under field conditions is expressed as a value with a level of

confidence of 95 %.

3.29

reproducibility in the field

closeness of the agreement between the results of simultaneous measurements of the same measurand

carried out with several sets of equipment under the same conditions of measurement

[SOURCE: EN 15058:2017]

Note 1 to entry: These conditions are called field reproducibility conditions and include:

— same measurement method;

— several sets of equipment, the performances of which are fulfilling the requirements of the measurement

method, used under the same conditions;

— same location;

— implemented by several laboratories.

Note 2 to entry: Reproducibility can be expressed quantitatively in terms of the dispersion characteristics of the

results.

Note 3 to entry: In this document, the reproducibility under field conditions is expressed as a value with a level

of confidence of 95 %.

3.30

residence time in the measuring system

time period for the sample gas to be transported from the inlet of the probe to the inlet of the

measurement cell

[SOURCE: EN 15058:2017]

3.31

uncertainty

parameter associated with the result of a measurement, that characterises the dispersion of the values

that could reasonably be attributed to the measurand

[SOURCE: EN 15058:2017]

3.32

standard uncertainty

u

uncertainty of the result of a measurement expressed as a standard deviation

[SOURCE: EN 15058:2017]

3.33

combined uncertainty

u

c

standard uncertainty attached to the measurement result calculated by combination of several standard

uncertainties

Note 1 to entry: This is according to the principles laid down in ISO/IEC Guide 98-3 (GUM)

[SOURCE: EN 15058:2017]

3.34

expanded uncertainty

U

quantity defining an interval about the result of a measurement that may be expected to encompass a

large fraction of the distribution of values that could reasonably be attributed to the measurand

U ku×

c

[SOURCE: EN 15058:2017]

Note 1 to entry: In this document, the expanded uncertainty is calculated with a coverage factor of k = 2, and with

a level of confidence of 95 %.

Note 2 to entry: The expression overall uncertainty is sometimes used to express the expanded uncertainty.

3.35

uncertainty budget

calculation table combining all the sources of uncertainty according to EN ISO 14956 or

ISO/IEC Guide 98-3 in order to calculate the combined uncertainty of the method at a specified value

[SOURCE: EN 15058:2017]

=

4 Symbols and abbreviated terms

4.1 Symbols

For the purposes of this document, the following symbols apply.

A(t ) (result given by the analyser after adjustment at t at span point – result given by the

0 0

analyser after adjustment at t at zero point) / (calibration gas concentration at span point

– calibration gas concentration at zero point)

B(t ) result given by the analyser after adjustment at t at zero point

0 0

C measured concentration

C measured concentration corrected for drift

corr

Drift(A) {[(result given by the analyser during the drift check at t at span point – result given by

end

the analyser during the drift check at t at zero point) / (calibration gas concentration at

end

span point – calibration gas concentration at zero point)] – A(t )} / (t – t )

0 end 0

Drift(B) (result given by the analyser during the drift check at t at zero point – result given by

end

the analyser after adjustment at t at zero point) / (t – t )

0 end 0

f volume fraction

k coverage factor

M molar mass

mol

s reproducibility standard deviation

R

s

maximum allowable repeatability standard deviation

r,limit

t time

t time of adjustment

t time of check for drift at the end of the measurement period

end

u standard uncertainty

u combined uncertainty

c

U expanded uncertainty

V molar volume

mol

4.2 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

AM alternative method

AMS automated measuring system

P-AMS portable automated measuring system

PTFE polytetrafluoroethene

PFA perfluoroalkoxy

SRM standard reference method

5 Principle

5.1 General

This document describes the reference method (RM) for sampling, and determining the carbon dioxide

(CO ) concentration in ducts and stacks emitted to atmosphere by means of an automatic analyser using

the IR absorption principle. The specific components and the requirements for the sampling system and

the IR analyser are described in Clause 6 and Clause 7. A number of performance characteristics with

associated performance criteria are specified for the analyser. These performance characteristics are

determined according to EN 15267-4:2017 and the expanded uncertainty of the method shall meet the

performance criteria given in this document. Requirements and recommendations for quality assurance

and quality control are given in Clause 10 for measurements in the field.

5.2 Measuring principle

The attenuation of infrared light passing through a sample of the stack gas is a measure of the

concentration of CO in the measurement path, according to the Lambert-Beer law. Not only CO but also

2 2

most hetero-atomic molecules absorb infrared light, in particular H O has broad bands that can interfere

with the measurement of CO . Different technical solutions have been developed to suppress cross-

sensitivity in order to design automatic monitoring systems with acceptable performance.

For example, the non-dispersive infrared (NDIR) method is suitable for CO measurements. The following

describes an example of an NDIR configuration measuring CO : gas concentration is measured electro-

optically by its absorption of a specific wavelength in the infrared (IR). The IR light is directed through

the sample chamber towards the detector. In parallel there is another chamber with an enclosed

reference gas, typically nitrogen. The detector has an optical filter in front of it that eliminates all light

except the wavelength that the selected gas molecules can absorb. Ideally other gas molecules do not

absorb light at this wavelength, and do not affect the amount of light reaching the detector to compensate

for interfering components. For instance, H O often initiates cross sensitivity in the infrared spectrum.

Different technical solutions have been developed to suppress, cross-sensitivity, instability and drift in

order to design automatic monitoring systems with acceptable properties (e.g. gas filter correlation

technique).

Special attention shall be paid to IR radiation absorbing-gases such as water vapour.

IR analysers are associated to an extractive sampling system and typically a gas conditioning system. In

an extractive sampling system a sample of gas is taken from the stack with a sampling probe and

conveyed to the analyser through the sample gas line and gas conditioning system. The values from the

analyser are recorded and/or stored by means of electronic data processing.

6 Description of the measuring system

6.1 General

A volume is extracted from the flue gas for a fixed period of time at a controlled flow rate. The measuring

system typically consists of:

— sampling probe;

— filter;

— sample gas line;

— conditioning system;

— analytical instrument.

A filter removes the dust in the sampled volume before the sample is conditioned and passed to the

analyser.

Different sampling and conditioning configurations are available in order to avoid the water vapour

condensation in the measuring system.

Possible configurations are:

— configuration 1: removal of water vapour by condensation using a cooling system;

— configuration 2: removal of water vapour through elimination using a permeation drier;

— configuration 3: dilution with dry, clean, ambient air or nitrogen with zero levels of CO ;

— configuration 4: heating of the complete sampling system from the nozzle to the heated analyser at a

temperature above the dew point.

Configurations 1 to 3 require that the user shall check that the dew point temperature or the outlet

temperature of the conditioning system is lower or equal to 4 °C at the inlet of the analyser.

For configuration 4 the user may correct the results for the remaining water content in order to report

results on a dry basis (see Annex B in EN 14790:2017).

It is important that all parts of the sampling equipment upstream of the analyser are made of materials

that do not react with or change the CO content.

The temperature of all components of the sampling equipment coming into contact with the wet sample

gas shall be maintained at a sufficiently high temperature to avoid any condensation.

Conditions and layout of the sampling equipment contribute to the combined uncertainty of the

measurement. In order to minimize this contribution to the combined measurement uncertainty,

performance criteria for the sampling equipment and sampling conditions are given in 6.2 and

in Clause 7.

Some other sample gas conditioning systems may exist and could be acceptable, provided they fulfil the

requirements of this document and have been validated with success during the certification process. For

example, some systems put gas in depression using a simple Sonic nozzle in the collection probe in order

to create a partial vacuum (between 50 hPa absolute and 100 hPa absolute) so that the head of collection

and the sample gas line does not need to be heated and water vapour condensation is avoided.

6.2 Extractive sampling and sample gas conditioning system

6.2.1 Sampling probe

In order to reach the measurement points of the measurement plane, probes of different lengths and

inner diameters may be used. The design and configuration of the probe used shall ensure the residence

time of the sample gas within the probe is minimized in order to reduce the response time of the

measuring system.

NOTE 1 The probe can be marked before sampling in order to demonstrate that the measurement points in the

measurement plane have been reached.

NOTE 2 A sealable connection can be installed on the probe in order to introduce test gases for adjustment.

6.2.2 Filter

The filter and filter holder shall be made of an inert material (e.g. ceramic or sinter metal filter with an

appropriate pore size). It shall be heated above the sample water and acid dew point temperature,

whichever is the greater. The particle filter shall be changed or cleaned periodically depending on the

dust loading in the measurement plane.

NOTE Overloading of the particle filter can increase the pressure drop in the sample gas line.

6.2.3 Sample gas line

The sample gas line shall be heated up to the conditioning system. It shall be made of a suitable corrosion

resistant material (e.g. PTFE or PFA is suitable for flue gas temperature lower than 200 °C).

6.2.4 Sample gas conditioning system

6.2.4.1 Sample gas cooler (configuration 1) and permeation drier (configuration 2)

The sample gas cooler or the permeation drier are used before the gas enters the analyser in order to

separate water vapour from the flue gas.

Due to ammonium-salt deposition on the permeation tube, the permeation system cannot be used when

the NH concentration is outside the range specified by the manufacturer.

6.2.4.2 Dilution system (configuration 3)

The dilution technique is an alternative to hot gas monitoring or sample gas drying. The flue gas is diluted

with dry, clean, ambient air or nitrogen. The dilution gas shall be dry and free from carbon dioxide. The

dilution ratio shall be chosen according to the objectives of the measurement and shall be compatible

with the range of the analytical unit. It shall remain constant through the period of the test.

The contribution of the dilution system to the uncertainty shall be added to the uncertainty budget.

6.2.4.3 Heated line and heated analyser (configuration 4)

To avoid condensation, the sample gas line up to the analyser and the analyser itself shall be heated.

The concentrations are given on wet basis and shall be corrected so that they are expressed on dry basis.

The correction shall be made from the water vapour concentration measured in the flue gases and the

uncertainty attached to this correction shall be added to the uncertainty budget (see Clause 8).

6.2.5 Sample gas pump

When a pump is not an integral part of the analyser, an external pump is necessary to draw the sampled

gas through the apparatus. It shall be capable of operating according to the specified flow requirements

of the manufacturer of the analyser and pressure conditions required for the reaction chamber. The pump

shall be resistant to corrosion and consistent with the requirements of the analyser to which it is

connected. The whole sampling system associated to the analyser, including the pump, shall meet the

criterion in Table 1 related to the influence of gas pressure.

NOTE The quantity of sample gas required can vary between 15 l/h and 500 I/h, depending upon the analyser

and the expected response time.

6.2.6 Secondary filter

The secondary filter is used to separate fine dust, with a pore size of 1 μm to 2 μ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...