SIST EN 1949:2022

(Main)Specification for the installation of LPG systems for habitation purposes in leisure accommodation vehicles and accommodation purposes in other vehicles

Specification for the installation of LPG systems for habitation purposes in leisure accommodation vehicles and accommodation purposes in other vehicles

This document specifies the requirements for the installation of liquefied petroleum gas systems for habitation purposes in leisure accommodation vehicles and for accommodation purposes in other vehicles.

It details health and safety requirements on:

— the selection of materials;

— components and appliances;

— design considerations;

— tightness testing of installations;

— the contents of the user's handbook.

This document only covers installations supplied with 3rd family gases (LPG).

It does not cover:

— water connections or electrical power supplies to the appliance(s);

— portable appliances, incorporating their own LPG supply;

— the installation of LPG appliances to be used for commercial purposes;

— LPG installations on boats;

— LPG supply equipment and LPG appliances separate from and external to the body of the vehicle.

This document covers LPG tanks fulfilling the requirements of the Pressure Equipment Directive (2014/68/EU).

Attention is drawn to the Pressure Equipment Directive (2014/68/EU) for any parts of the installation operating above 0,5 bar.

Festlegungen für die Installation von Flüssiggasanlagen in bewohnbaren Freizeitfahrzeugen und zu Wohnzwecken in anderen Fahrzeugen

Dieses Dokument legt die Anforderungen an die Installation von Flüssiggasanlagen in bewohnbaren Freizeitfahrzeugen und für Wohnzwecke in anderen Fahrzeugen fest.

Im Einzelnen sind Anforderungen an Gesundheit und Sicherheit zu Folgendem beschrieben:

— Auswahl der Werkstoffe;

— Bauteile und Geräte;

— Bauweise;

— Dichtheitsprüfung von Installationen;

— Inhalt der Bedienungsanleitung.

Dieses Dokument gilt nur für solche Installationen, die mit Gasen der 3. Gasfamilie (Flüssiggas) betrieben werden.

Es gilt nicht für:

— Wasseranschlüsse oder Stromversorgungen des Geräts bzw. der Geräte;

— tragbare Geräte mit eigener Flüssiggasversorgung;

— die Installation von Flüssiggasgeräten zu gewerblichen Zwecken;

— Flüssiggasinstallationen auf Booten;

— Flüssiggasversorgungseinrichtungen und Flüssiggasgeräte, die sich außerhalb des Fahrzeugs befinden.

Dieses Dokument gilt für Flüssiggastanks, die die Anforderungen der Druckgeräterichtlinie (2014/68/EU) erfüllen.

Für alle Teile der Installation, die mit Drücken über 0,5 bar betrieben werden, wird auf die Druckgeräterichtlinie (2014/68/EU) hingewiesen.

Spécifications relatives aux installations des systèmes GPL pour les besoins domestiques dans les véhicules habitables de loisirs et dans les autres véhicules

La présente Norme européenne spécifie les exigences applicables à l'installation de systèmes fonctionnant aux gaz de pétrole liquéfiés pour les besoins d’habitation dans les véhicules habitables de loisirs, et à des fins d’hébergement dans les autres véhicules.

Elle détaille les exigences relatives à la santé et à la sécurité pour :

— le choix des matériaux ;

— les composants et appareils d'utilisation ;

— les considérations de conception ;

— les essais d'étanchéité des installations ;

— le contenu du manuel d'utilisation.

Ce document ne s'applique qu’aux installations alimentées par des gaz appartenant à la troisième famille (GPL).

Elle ne couvre pas :

— les raccordements en eau ou en énergie électrique des appareils ;

— les appareils portatifs disposant d'une alimentation en gaz incorporée ;

— l'installation des appareils GPL utilisés pour les besoins commerciaux ;

— les installations GPL dans les bateaux ;

— l'équipement d'alimentation en GPL et les appareils GPL séparés et extérieurs au corps du véhicule.

Ce document couvre les réservoirs GPL qui satisfont aux exigences de la Directive Équipements sous Pression (2014/68/UE).

L’attention est portée sur la Directive Équipements sous pression (2014/68/UE) pour toute partie de l’installation fonctionnant au-delà de 0,5 bar.

Specifikacija za vgradnjo sistemov na utekočinjeni naftni plin (UNP) v bivalna vozila za prosti čas in druga bivalna vozila

Ta evropski standard določa zahteve za vgradnjo sistemov na utekočinjeni naftni plin v bivalna vozila za prosti čas in druga bivalna vozila. Podrobno določa varnostne in zdravstvene zahteve za izbiro materialov, komponent in aparatov, izdelavo in preskušanje trdnosti vgradenj ter vsebino uporabniškega priročnika.

Ta evropski standard ne zajema vgradenj, ki ne uporabljajo plinov tretje družine (LPG), vodovodnih priključkov ali električnega napajanja aparatov. Prenosni aparati z lastno oskrbo s plinom niso obravnavani kot del vgradnje in ne spadajo na področje uporabe tega standarda. Standard ne vključuje vgradnje aparatov na utekočinjeni naftni plin za komercialne namene ali plovila. Ta standard prav tako ne obravnava opreme za dovajanje plina in aparatov na plin, ki so ločeni od karoserije vozila in nameščeni zunaj nje.

General Information

- Status

- Published

- Public Enquiry End Date

- 09-May-2018

- Publication Date

- 14-Mar-2022

- Technical Committee

- PLN - Gas appliances for domestic use

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Mar-2022

- Due Date

- 16-May-2022

- Completion Date

- 15-Mar-2022

Relations

- Effective Date

- 01-Apr-2022

Overview

EN 1949:2021 is a CEN European Standard specifying safety and installation requirements for LPG systems for habitation purposes in leisure accommodation vehicles (motorhomes, caravans, campervans) and for accommodation purposes in other vehicles. The standard covers installations supplied with 3rd family gases (LPG) and applies to LPG tanks that meet the Pressure Equipment Directive (2014/68/EU). EN 1949:2021 supersedes EN 1949:2011+A1:2013 and introduces updated requirements including mandatory manufacturer declaration of conformity and expanded tank and compartment provisions.

Key topics and technical requirements

- Scope & exclusions

- Applies only to fixed LPG systems for habitation (not portable appliances, boats, commercial appliances, or external LPG equipment).

- Does not cover water or electrical connections to appliances.

- Materials and components

- Selection of suitable materials and components (hoses, pipes, fittings, valves) compatible with 3rd family gases.

- Design considerations

- Layout, pipe routing, protection against mechanical damage and corrosion, pipe sizing, and bonding requirements.

- Separate clauses for road vehicles vs. caravan holiday homes, and specific rules for slide-outs.

- Pressure regulation & tanks

- Requirements for pressure regulation systems, working pressures, over‑pressure protection and marking.

- Covers LPG tanks complying with the Pressure Equipment Directive (2014/68/EU); attention to parts operating above 0.5 bar.

- Tightness testing & leak detection

- Tightness testing of installations and detection measures to ensure occupant safety.

- Compartments & ventilation

- Requirements for LPG cylinder compartments and newly added LPG tank compartment rules, including ventilation and electrical equipment restrictions.

- Appliances & flueing

- Suitability and installation rules for space heaters, water heaters, cookers, refrigerators, fuel cells and generators, and flueing requirements.

- Documentation

- Contents and requirements for the user’s handbook and mandatory declaration of conformity (manufacturer).

Applications and users

- Primary users:

- Vehicle OEMs, converters and manufacturers of motorhomes, caravans and accommodation vehicles.

- LPG system installers, service technicians, safety inspectors and conformity assessors.

- Design engineers and maintenance personnel responsible for on-board gas systems.

- Practical uses:

- Designing compliant LPG installations, sizing and selecting components, commissioning and leak testing, preparing user handbooks, and ensuring regulatory compliance with PED (2014/68/EU).

Related standards and references

- Pressure Equipment Directive (2014/68/EU)

- Normative references cited in EN 1949: EN 331, EN 624, EN 732, EN 751‑2, EN 751‑3, EN 1057, EN 1254‑1, EN 1254‑2 (and others listed in the standard).

Keywords: EN 1949:2021, LPG installation, leisure accommodation vehicles, caravan LPG safety, pressure equipment directive, LPG tank compartment, tightness testing, user’s handbook.

Frequently Asked Questions

SIST EN 1949:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Specification for the installation of LPG systems for habitation purposes in leisure accommodation vehicles and accommodation purposes in other vehicles". This standard covers: This document specifies the requirements for the installation of liquefied petroleum gas systems for habitation purposes in leisure accommodation vehicles and for accommodation purposes in other vehicles. It details health and safety requirements on: — the selection of materials; — components and appliances; — design considerations; — tightness testing of installations; — the contents of the user's handbook. This document only covers installations supplied with 3rd family gases (LPG). It does not cover: — water connections or electrical power supplies to the appliance(s); — portable appliances, incorporating their own LPG supply; — the installation of LPG appliances to be used for commercial purposes; — LPG installations on boats; — LPG supply equipment and LPG appliances separate from and external to the body of the vehicle. This document covers LPG tanks fulfilling the requirements of the Pressure Equipment Directive (2014/68/EU). Attention is drawn to the Pressure Equipment Directive (2014/68/EU) for any parts of the installation operating above 0,5 bar.

This document specifies the requirements for the installation of liquefied petroleum gas systems for habitation purposes in leisure accommodation vehicles and for accommodation purposes in other vehicles. It details health and safety requirements on: — the selection of materials; — components and appliances; — design considerations; — tightness testing of installations; — the contents of the user's handbook. This document only covers installations supplied with 3rd family gases (LPG). It does not cover: — water connections or electrical power supplies to the appliance(s); — portable appliances, incorporating their own LPG supply; — the installation of LPG appliances to be used for commercial purposes; — LPG installations on boats; — LPG supply equipment and LPG appliances separate from and external to the body of the vehicle. This document covers LPG tanks fulfilling the requirements of the Pressure Equipment Directive (2014/68/EU). Attention is drawn to the Pressure Equipment Directive (2014/68/EU) for any parts of the installation operating above 0,5 bar.

SIST EN 1949:2022 is classified under the following ICS (International Classification for Standards) categories: 43.100 - Passenger cars. Caravans and light trailers; 75.160.30 - Gaseous fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1949:2022 has the following relationships with other standards: It is inter standard links to SIST EN 1949:2011+A1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1949:2022 is associated with the following European legislation: EU Directives/Regulations: 2022-01-0296. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1949:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2022

Nadomešča:

SIST EN 1949:2011+A1:2013

Specifikacija za vgradnjo sistemov na utekočinjeni naftni plin (UNP) v bivalna

vozila za prosti čas in druga bivalna vozila

Specification for the installation of LPG systems for habitation purposes in leisure

accommodation vehicles and accommodation purposes in other vehicles

Festlegungen für die Installation von Flüssiggasanlagen in bewohnbaren

Freizeitfahrzeugen und zu Wohnzwecken in anderen Fahrzeugen

Spécifications relatives aux installations des systèmes GPL pour les besoins

domestiques dans les véhicules habitables de loisirs et dans les autres véhicules

Ta slovenski standard je istoveten z: EN 1949:2021

ICS:

43.100 Osebni avtomobili. Bivalne Passenger cars. Caravans

prikolice in lahke prikolice and light trailers

75.160.30 Plinska goriva Gaseous fuels

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1949

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 43.100; 97.200.30 Supersedes EN 1949:2011+A1:2013

English Version

Specification for the installation of LPG systems for

habitation purposes in leisure accommodation vehicles

and accommodation purposes in other vehicles

Spécifications relatives aux installations des systèmes Festlegungen für die Installation von Flüssiggasanlagen

GPL pour les besoins domestiques dans les véhicules in bewohnbaren Freizeitfahrzeugen und zu

habitables de loisirs et dans les autres véhicules Wohnzwecken in anderen Fahrzeugen

This European Standard was approved by CEN on 23 August 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1949:2021 E

worldwide for CEN national Members.

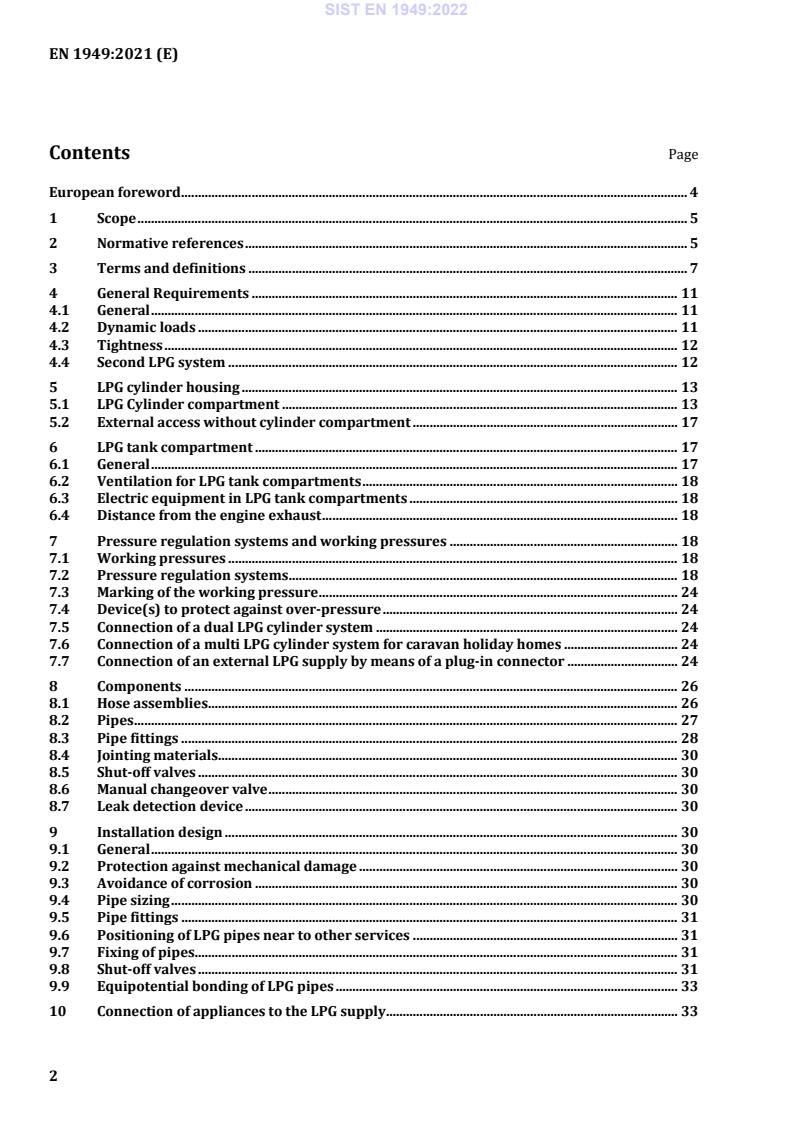

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 7

4 General Requirements . 11

4.1 General . 11

4.2 Dynamic loads . 11

4.3 Tightness . 12

4.4 Second LPG system . 12

5 LPG cylinder housing . 13

5.1 LPG Cylinder compartment . 13

5.2 External access without cylinder compartment . 17

6 LPG tank compartment . 17

6.1 General . 17

6.2 Ventilation for LPG tank compartments . 18

6.3 Electric equipment in LPG tank compartments . 18

6.4 Distance from the engine exhaust . 18

7 Pressure regulation systems and working pressures . 18

7.1 Working pressures . 18

7.2 Pressure regulation systems . 18

7.3 Marking of the working pressure . 24

7.4 Device(s) to protect against over-pressure . 24

7.5 Connection of a dual LPG cylinder system . 24

7.6 Connection of a multi LPG cylinder system for caravan holiday homes . 24

7.7 Connection of an external LPG supply by means of a plug-in connector . 24

8 Components . 26

8.1 Hose assemblies. 26

8.2 Pipes . 27

8.3 Pipe fittings . 28

8.4 Jointing materials . 30

8.5 Shut-off valves . 30

8.6 Manual changeover valve . 30

8.7 Leak detection device . 30

9 Installation design . 30

9.1 General . 30

9.2 Protection against mechanical damage . 30

9.3 Avoidance of corrosion . 30

9.4 Pipe sizing . 30

9.5 Pipe fittings . 31

9.6 Positioning of LPG pipes near to other services . 31

9.7 Fixing of pipes. 31

9.8 Shut-off valves . 31

9.9 Equipotential bonding of LPG pipes . 33

10 Connection of appliances to the LPG supply . 33

10.1 General . 33

10.2 Road vehicles. 34

10.3 Slide outs of road vehicles . 34

10.4 Caravan holiday homes . 35

11 LPG Appliances . 35

11.1 Suitability of LPG appliances . 35

11.2 Installations . 35

11.3 Space heaters . 35

11.4 Water heaters. 36

11.5 Cooking appliances . 37

11.6 Refrigerators . 37

11.7 Gas lights . 37

11.8 LPG fuel cells . 37

11.9 LPG power generators . 38

12 Flueing . 38

12.1 Flues . 38

12.2 Flue terminals . 38

12.3 Weather protection . 40

12.4 Draught diverters . 40

12.5 Accessibility of flues . 40

13 Installation of LPG tanks on road vehicles supplying LPG appliances . 40

13.1 LPG tank and accessories . 40

13.2 Installation of the LPG tank and LPG system requirements . 41

14 User’s handbook. 42

Annex A (informative) National situation concerning the maximum flow rate of pressure

regulating devices for caravan holiday homes . 44

Annex B (informative) National situations in the Member States . 46

Annex C (informative) Manufacturer declaration . 48

Bibliography . 50

European foreword

This document (EN 1949:2021) has been prepared by Technical Committee CEN/TC 181 “Appliances and

leisure vehicle installations using liquefied petroleum gas and appliances using natural gas for outdoor

use”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1949:2011+A1:2013.

The following main technical changes have been made compared to EN 1949:2011+A1:2013:

a) definition for LPG tank compartment has been added;

b) declaration of conformity is now mandatory;

c) several clauses have been separated to clearly state the requirements for road vehicles and caravan

holiday homes;

d) requirements for LPG cylinder compartment with internal access has been amended;

e) requirements for LPG tank compartment have been added;

f) requirements for electric installations inside LPG cylinder/tank compartments have been extended;

g) requirements for slide outs have been added;

h) requirements for LPG tanks and LPG tank installations have been extended;

i) Annex A for national regulation concerning the maximum flow rate of pressure regulating devices

for caravan holiday homes has been added;

j) Annex B (old) has been deleted;

k) former Annex A became Annex B;

l) Annex C has been updated.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies the requirements for the installation of liquefied petroleum gas systems for

habitation purposes in leisure accommodation vehicles and for accommodation purposes in other

vehicles.

It details health and safety requirements on:

— the selection of materials;

— components and appliances;

— design considerations;

— tightness testing of installations;

— the contents of the user's handbook.

This document only covers installations supplied with 3rd family gases (LPG).

It does not cover:

— water connections or electrical power supplies to the appliance(s);

— portable appliances, incorporating their own LPG supply;

— the installation of LPG appliances to be used for commercial purposes;

— LPG installations on boats;

— LPG supply equipment and LPG appliances separate from and external to the body of the vehicle.

This document covers LPG tanks fulfilling the requirements of the Pressure Equipment Directive

(2014/68/EU).

Attention is drawn to the Pressure Equipment Directive (2014/68/EU) for any parts of the installation

operating above 0,5 bar.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 331:2015, Manually operated ball valves and closed bottom taper plug valves for gas installations for

buildings

EN 624, Specification for dedicated LPG appliances - Room sealed LPG space heating equipment for

installation in vehicles and boats

EN 732, Specifications for dedicated liquefied petroleum gas appliances - Absorption refrigerators

EN 751-2, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water - Part 2: Non-hardening jointing compounds

EN 751-3, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water - Part 3: Unsintered PTFE tapes

EN 1057, Copper and copper alloys — Seamless, round copper tubes for water and gas in sanitary and

heating applications

EN 1254-1, Copper and copper alloys - Plumbing fittings - Part 1: Capillary fittings for soldering or brazing

to copper tubes

EN 1254-2, Copper and copper alloys - Plumbing fittings - Part 2: Compression fittings for use with copper

tubes

EN 1254-4, Copper and copper alloys - Plumbing fittings - Part 4: Threaded fittings

EN 10226-1, Pipe threads where pressure tight joints are made on the threads - Part 1: Taper external

threads and parallel internal threads - Dimensions, tolerances and designation

EN 10305-1, Steel tubes for precision applications - Technical delivery conditions - Part 1: Seamless cold

drawn tubes

EN 10305-2, Steel tubes for precision applications - Technical delivery conditions - Part 2: Welded cold

drawn tubes

EN 10305-3, Steel tubes for precision applications - Technical delivery conditions - Part 3: Welded cold sized

tubes

EN 10305-4, Steel tubes for precision applications - Technical delivery conditions - Part 4: Seamless cold

drawn tubes for hydraulic and pneumatic power systems

EN 12979:2002, Automotive LPG-systems - Installation requirements

EN 14291, Foam producing solutions for leak detection on gas installations

EN 14800, Corrugated safety metal hose assemblies for the connection of domestic appliances using gaseous

fuels

EN 15033, Room sealed storage water heaters for the production of sanitary hot water using LPG for

vehicles and boats

EN 15266, Stainless steel pliable corrugated tubing kits in buildings for gas with an operating pressure up

to 0,5 bar

EN 16129:2013, Pressure regulators, automatic change-over devices, having a maximum regulated

pressure of 4 bar, with a maximum capacity of 150 kg/h, associated safety devices and adaptors for butane,

propane, and their mixtures

EN 16436-2:2018, Rubber and plastics hoses, tubing and assemblies for use with propane and butane and

their mixtures in the vapour phase — Part 2: Assemblies

EN ISO 1127, Stainless steel tubes - Dimensions, tolerances and conventional masses per unit length (ISO

1127)

EN ISO 8434-1, Metallic tube connections for fluid power and general use - Part 1: 24° cone connectors (ISO

8434-1)

ISO 8434-2, Metallic tube connections for fluid power and general use — Part 2: 37 degree flared connectors

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

leisure accommodation vehicle

unit of living accommodation for temporary or seasonal occupation that may meet requirements for

construction and use of road vehicles

[SOURCE: EN 13878:2019, definition 3.19]

3.2

caravan

trailer leisure accommodation vehicle that meets requirements for construction and use of road vehicles

[SOURCE: EN 13878:2019, definition 3.5]

3.3

motor caravan

self-propelled leisure accommodation vehicle that meets requirements for construction and use of road

vehicles. It contains at least seats and table, sleeping accommodation which may be converted from the

seats, cooking facilities and storage facilities

[SOURCE: EN 13878:2019, definition 3.24]

3.4

caravan holiday home

transportable leisure accommodation vehicle that does not meet requirements for construction and use

of road vehicles, that retains means for mobility and is for temporary or seasonal occupation

[SOURCE: EN 13878:2019, definition 3.6]

3.5

liquefied petroleum gas (LPG)

mixture of light hydrocarbons composed mainly of propane, butane and their isomers, gaseous under

conditions of normal temperature and pressure

Note 1 to entry: LPG is maintained in its liquid state by increased pressure or lowered temperature.

Note 2 to entry: In some countries, UN numbers 1011 and 1978 may also be designated LPG.

3.6

LPG appliance

appliance that is designed for heating, cooking, lighting, refrigeration, hot water production or electricity

production (fuel cell or generator), using LPG as its energy source

3.7

LPG system

assembly of an installation and its appliances

3.8

LPG installation

installation usually consisting of fuel container(s), pressure regulator(s), piping, hose assemblies and

shut-off devices, providing liquefied petroleum gas in gaseous phase to appliances

3.9

pressure regulation system

system incorporating one or more regulators with or without change-over device to reduce the supply

pressure of the LPG system to the required working pressure for the appliance(s)

3.10

regulator

device which maintains a regulated pressure within preset limits, whatever the upstream pressure, rate

and temperature

[SOURCE: EN 16129:2013, definition 3.1.1]

3.11

changeover device

device which maintains the gas supply continuity by using gas from a “LPG cylinder”, a “LPG tank” or an

external supply manually chosen by the user or automatically

3.12

room sealed appliance

appliance that has the combustion system, including the air inlet and products outlet, isolated from any

internal area

3.13

open-flue appliance

appliance designed to be connected to a flue via a draught diverter, its combustion air being drawn from

the room or internal space in which it is installed

3.14

closed-flue appliance

appliance where the flue is closed from a room or internal space due to the absence of a draught diverter,

flue break and any draught break within the flue

3.15

flueless appliance

appliance that discharges its products of combustion into the compartment in which it is installed

3.16

flue

duct designed to convey the products of combustion to the exterior of a vehicle

3.17

flue terminal

part of the flue system through which the products of combustion are discharged to the outside (cowl)

3.18

shut-off valve

device to interrupt the flow of gas, having one inlet and one or more individually controlled outlets

3.19

liquefied petroleum gas cylinder

portable container for liquefied petroleum gas

Note 1 to entry: portable containers which are refilled outside the vehicle are considered as cylinders (see

ADR 4.1.4, P200).

[SOURCE: EN 13878:2019, definition 3.21]

3.20

LPG cylinder compartment

space specially constructed to accommodate liquefied petroleum gas cylinder(s)

3.21

flame supervision device

device that has a sensing element, activated by the presence or absence of a flame, that causes the inlet

of the LPG supply to a burner to be opened or closed

3.22

pilot

small burner that provides a continuously burning flame to ignite a main burner when required

3.23

tightness

absence of leakage greater than the specified limit

3.24

hard soldering

soldering for which the lowest temperature of the melting range, after application, is not less than 450 °C

3.25

fixed ventilation

permanent measures that ensure the minimum provision of fresh air

3.26

free area of ventilation

total area of the apertures in a ventilator or grill

3.27

ventilator

device that allows the passage of air for the ventilation of a compartment

3.28

hose assembly

length of hose with suitably attached end fittings

[SOURCE EN ISO 14113:2013, definition 3.5]

3.29

low pressure hose assembly

hose assembly, LPG resistant, for use at working pressure

3.30

high pressure hose assembly

hose assembly, LPG resistant, for use at high pressure, normally supply pressure

3.31

users handbook

document that provides information to the user of a leisure accommodation vehicle on its operation,

maintenance, repair etc.

3.32

working pressure

pressure at the inlet of a LPG appliance while it is in operation

3.33

readily accessible

item capable of being reached quickly and safely for effective use under emergency conditions without

the use of tools

Note 1 to entry: The key of a lock is not regarded as a tool.

3.34

accessible

item capable of being reached for inspection, removal or maintenance with or without the use of tools

3.35

safety closing device

device which automatically interrupts the flow of gas due to an accidental disconnection of a hose

assembly or pipe installed downstream of the safety closing device

3.36

LPG tank

fixed container which can be refilled whilst in position on a vehicle and suitable for the storage of LPG

Note 1 to entry: This may supply LPG for gas appliances only.

3.37

underfloor flue

flue which discharges all or parts of the products of combustion into the space lying beneath and within

the plan view of the vehicle

3.38

leak detection device

device capable of indicating any downstream leakage

3.39

LPG tank compartment

space specially constructed to accommodate LPG tank(s)

3.40

Extra low voltage

ELV

voltage not exceeding 50 V a.c. or 120 V ripple free d.c. between conductors or to earth, but usually of a

nominal 12 V in leisure accommodation vehicles

[SOURCE EN 13878:2019, definition 3.14]

3.41

slide out

structural element, that can be moved to increase the habitational area of a road vehicle

4 General Requirements

4.1 General

The manufacturer or installer of an LPG system shall issue a declaration of conformity for each leisure

accommodation vehicle or other vehicle stating the compliance with EN 1949, including the test result of

4.3.2, it should include the information shown in Annex C and if applicable, national regulations.

For road vehicles, a label according to Figure 1, stating that all LPG appliances shall be turned off before

refilling (LPG, petrol, diesel or other fuels), shall be affixed inside the vehicle where it can be easily and

readily seen.

Figure 1 — Label stating to turn off all appliances in case of refilling

4.2 Dynamic loads

The LPG system shall be designed to withstand the dynamic loads during normal operation including

movement of the vehicle.

4.3 Tightness

4.3.1 Requirements

Each vehicle manufacturer's LPG system up to the user operated controls of the appliances (taps) shall

fulfil the following tightness requirements when tested at a test pressure of 150 mbar with air. A

detectable pressure loss of at most 5 mbar is permissible. If the volume of the LPG system is below

3 3

700 cm , a test volume shall be added so that the test volume is at least 700 cm .

4.3.2 Test

The test is carried out with air using the connection point for test equipment described in 7.2.1.1 and the

following procedure. In preparation for the test, the taps of the appliances shall be closed but the shut off

valves be left open. The LPG system is then pressurized to 150 mbar and closed. The measurement of the

pressure drop is carried out after a period of 5 minutes to allow for temperature and pressure

stabilization. If the pressure is not stable, additional time shall be necessary or other action needs to be

taken before the pressure is recorded. After another 5 minutes the remaining pressure is compared to

the first pressure.

During the test period the LPG pressure source should be turned off.

All parts of the LPG system operating at pressures above working pressure are tested with an appropriate

leak detection solution according to EN 14291 at operational pressure. No leakage shall be observed

within 30 s.

All parts, which are dismantled during the pressure test, shall be tested with an appropriate leak

detection solution according to EN 14291 at operational pressure after reassembling. No leakage shall be

observed within 30 s.

4.4 Second LPG system

4.4.1 Road vehicles

Only if an LPG power generator is installed and the total LPG consumption including the appliances

exceeds 1,5 kg/h it is allowed to install one additional LPG system.

For tightness test, see 4.3.

There shall be no connection between the both LPG systems.

The LPG containers for both LPG systems may be installed in the same compartment (see 5.1 and 6).

If there are two separate compartments, there shall be a warning sign inside both compartments, which

indicates that there is a second LPG system. Inside the compartment it shall be clearly indicated by a label

which appliances are supplied by each LPG system. Where the LPG tank(s) is/are not fitted within a

compartment, these labels shall be fitted visibly on the LPG tank(s).

If there is a second LPG system, a second manufacture's declaration of conformity is mandatory.

4.4.2 Caravan holiday home

A second LPG system is not allowed.

5 LPG cylinder housing

5.1 LPG Cylinder compartment

5.1.1 General

For road vehicles, LPG cylinders shall be installed in LPG cylinder compartments or LPG tank

compartments (see Clause 6), except when they are installed according to 5.2 or when they are used in

the conditions of 7.7.

For caravan holiday homes, cylinders are not required to be installed in cylinder compartments, but if a

cylinder compartment is used it shall fulfil the following appropriate requirements.

With the exception of 5.1.7, cylinder compartments shall be sealed against the accommodation space and

shall have external access only.

5.1.2 Requirements for the construction of cylinder compartments

5.1.2.1 General

The cylinder compartment shall be designed so that:

a) access to any connections, changeover devices and pressure regulation systems is not obstructed;

b) the replacement of LPG cylinders can be made without disturbing the installation or ancillary

equipment;

c) it is possible for any LPG cylinder securing device to be opened and closed without the use of tools;

d) it can accommodate LPG cylinder(s) of sufficient capacity to supply the total installed appliance

consumption.

A label shall be placed with a pictogram of a LPG cylinder and a sign “read instructions”, see Figure 2, in

the vicinity of the LPG cylinder(s).

Figure 2 — Sign “read instructions”

5.1.2.2 Road vehicles

In addition to 5.1.2.1 each LPG cylinder shall be secured rigidly in an upright position with the valve

uppermost to operate only in the gaseous phase and to prevent inadvertent movement when the vehicle

is in motion. In order to ensure the location of each LPG cylinder there shall be securing or fixing means,

one at high level and one at low level.

A pull-out tray for the placement of the LPG cylinder(s) is permitted inside the LPG cylinder compartment

to facilitate the exchange of LPG cylinders.

5.1.2.3 Caravan holiday homes

In addition to 5.1.2.1 each LPG cylinder shall be in an upright position with the valve uppermost to

operate only in the gaseous phase.

5.1.3 Ventilation for LPG cylinder compartments

Permanent ventilation of any LPG cylinder compartment shall be provided to the exterior.

If the ventilation is provided only at low level, the free area shall be at least 2 % of the compartment floor

area with a minimum of 10 000 mm . If the ventilation is provided at high and low level the free area

shall be at least 1 % of the compartment floor area at each level and not less than 5 000 mm at each level.

It shall not be possible for any part of the ventilation area to be obstructed by a LPG cylinder.

NOTE Low level means in the floor, or if in the side wall touching the floor. The longer dimension of the

ventilation is on the floor level

5.1.4 Electric equipment in LPG cylinder compartments

No electrical equipment, including wiring systems, shall be installed in any LPG cylinder compartment,

except:

a) ELV (extra low voltage) equipment for gas supply control;

b) other electric equipment which is proofed for at least category II 3 G Ex IIA T2 (see Directive

2014/34/EU, Annex II, B);

c) cables running through a LPG cylinder compartment without connection.

Such electrical installations and components shall be constructed and installed so that they are not a

potential source of ignition.

Where cables have to run through such a compartment such cables shall be protected against mechanical

damage by installation within conduit or duct passing through the compartment.

Where installed in a position where it is likely to be subject to mechanical damage, this conduit or duct

shall be able to withstand an impact equivalent to AG3.

5.1.5 Distance from the engine exhaust

Any LPG cylinder placement shall provide a minimum distance from the engine exhaust system as shown

in Figure 3.

a) Top view

b) Side view

Key

1 example of allowed position of the exhaust

2 LPG cylinder compartment

3 LPG cylinders

4 outside the vehicle

R = D = D ≥ 250 mm

D ≥ 300 mm

The shaded areas represent the volume where no part of exhaust system shall be located without

installation of the protection shield.

Figure 3 — Minimum distance from the engine exhaust system

Alternatively, thermal shielding shall be installed to prevent entry of exhaust heat gases into the

compartment, or projection of the exhaust heat flow towards the LPG cylinder(s) (see Figure 4).

Key

1 exhaust

2 LPG cylinder compartment

3 LPG cylinders

4 outside the vehicle

5 inside the vehicle

6 ventilation

7 driving direction

8 thermal shielding

E ≥ 25 mm

Figure 4 — Example of shielding that can be installed

Dimension E shall not be smaller than 25 mm. The minimum area of low level ventilation shall be

maintained, as specified in 5.1.3.

NOTE In Figure 4, the area of low-level ventilation is based on 10 000 mm .

5.1.6 LPG Cylinder compartment part of garage or storage compartment

Even in case the cylinder compartment is part of the garage or the storage compartment, it shall be

accessible from the outside of the vehicle.

The access from the garage/storage compartment to the LPG cylinder compartment is only provided via

an attached sealed door. The height of the bottom edge of the door opening is at least 50 mm, measured

from the bottom of the LPG cylinder compartment.

The door of the LPG cylinder compartment shall be positioned directly (not more than 50 mm) behind

the outside door of the garage / storage compartment. It shall be constructively ensured that the door

cannot be opened to the inside of the vehicle and cannot be blocked at any time.

The door shall be secured in its closed position. The outside door of the garage / storage compartment

may be the door of the LPG cylinder compartment too.

The requirements of 5.1.3, 5.1.4 and 5.1.5 shall be fulfilled.

5.1.7 LPG Cylinder compartments with internal access

For road vehicles where penetration of a type approved base vehicle bodywork would be required to

provide external access, internal access to the compartment is permitted provided the following

conditions are met:

a) The access from the habitable area to the LPG cylinder compartment is only provided via an attached

sealed door or hatch. The height of the bottom edge of the door opening is at least 50 mm, measured

from the bottom of the LPG cylinder compartment.;

b) the door or hatch of the compartment shall be readily accessible;

c) the requirements of 5.1.4 and 5.1.5 shall be fulfilled;

d) the compartment can contain a maximum of two cylinders, each having a capacity of not more than

11 kg. The requirements of 5.1.3 shall be fulfilled;

e) the compartment can contain a maximum of two cylinders with a maximum combined capacity of

7 kg. The fixed ventilation for LPG cylinder compartments may be reduced via one vent provided the

following conditions are complied with:

1) the vent shall have a minimum internal diameter of 20 mm;

2) where a duct is attached to the ventilation opening the maximum length of the duct shall not

exceed 5 times the internal diameter of the duct. It may be extended to ten times the internal

diameter of the duct, if it is necessary, to avoid interference with under floor flue outlets;

3) the duct shall be positioned at low level in the floor and be resistant to LPG;

4) the duct shall fall throughout its entire length to the outside of the vehicle.

5.2 External access without cylinder compartment

For vehicles of category N (see Regulation (EU) 2018/858), support shall be provided to secure cylinders

outside the vehicle, but within the body contour unless a compartment complying with 5.1.7 is provided.

The requirements of 5.1.2.1 and 5.1.2.2 also apply.

6 LPG tank compartment

6.1 General

LPG tank compartments shall be sealed against the accommodation space and shall have external access

only.

The LPG tank compartment shall be designed so that access to any connections, changeover devices and

pressure regulation systems is not obstructed.

The LPG tank compartment shall be designed so that each LPG tank can be installed in accordance to

Clause 13.

A label shall be placed with a sign “read instructions”, see Figure 5, in the vicinity of the LPG tank(s).

Figure 5 — Sign “read instructions”

6.2 Ventilation for LPG tank compartments

The requirements of 5.1.3 shall be fulfilled.

6.3 Electric equipment in LPG tank compartments

The requirements of 5.1.4 shall be fulfilled.

6.4 Distance from the engine exhaust

The requirements of 5.1.5 shall be fulfilled.

7 Pressure regulation systems and working pressures

7.1 Working pressures

Road vehicles shall have a fixed working pressure of 30 mbar.

Caravan holiday homes shall have a fixed working pressure as specified in Annex B.

7.2 Pressure regulation systems

7.2.1 General

7.2.1.1 Where a LPG cylinder compartment is provided, the pressure regulation system shall be

inside the compartment; for LPG tank pressure regulation systems see 13.2.

A suitable connection point for test equipment (test point) shall be provided to verify the tightness of the

LPG system from the outlet of the regulator to the inlet of the appliances. The connection point for test

equipment may be a part of the regulator or in every case as close as possible to the regulator.

7.2.1.2 The pressure regulation system shall be designed either to be fitted:

a) directly fitted to the LPG cylinder valve, see Figure 6;

Key

1 LPG cylinder

2 regulator

3 +50

hose assembly class 2 (EN 16436-2:2018) with a maximum length of 400 mm

( )

−100

4 pipework

Figure 6 — LPG Cylinder mounted regulator

b) remotely fitted from the LPG cylinder valve at the wall of the LPG cylinder compartment, see Figure 7

and Figure 8;

Key

1 LPG cylinder

+50

hose assembly class 3 (EN 16436-2:2018) with a maximum length of 400 mm

( )

−100

3 wall mounted regulator with integrated test point

4 optional: separate test point

5 pipework

Figure 7 — Wall mounted regulator - single LPG cylinder

Key

1 LPG cylinder

+50

hose assembly class 3 (EN 16436-2:2018) with a maximum length of 400 mm

( )

−100

3 change over device with integrated test point

4 optional: separate test point

5 pipework

Figure 8 — Wall mounted pressure regulation system - two LPG cylinders

c) remotely fitted from the LPG cylinder valve on a pull-out tray + pipe work on the pull-out tray, see

Figure 9;

Key

1 LPG cylinder

+50

(high-pressure hose) hose assembly class 3 (EN 16436-2:2018) with a maximum length of mm

( )

−100

3 for single LPG cylinder regulator with integrated test point or for two LPG cylinders change over device with

integrated test point

4 optional: separate test point

5 pipework

6 (low-pressure hose) hose assembly class 2 (EN 16436-2:2018) with a maximum length of 750 mm

7 pipework

8 pull-out tray

9 LPG cylinder compartment

Figure 9 — On a pull-out tray mounted pressure regulation system (with pipework on the pull-

out tray)

d) directly fitted to the LPG cylinder valve on a pull-out tray, see Figure 10;

Key

1 LPG cylinder

2 regulator

3 hose assembly class 2 (EN 16436-2:2018) with a maximum length of 750 mm

4 pipework

5 pull-out tray

6 LPG cylinder compa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...