SIST EN 16340:2014

(Main)Combustion product sensing devices for gas burners and gas burning appliances

Combustion product sensing devices for gas burners and gas burning appliances

This European Standard specifies the safety, construction and performance requirements for combustion product sensing devices intended to be used in combustion control systems, hereinafter referred to as CPSD.

This European Standard applies to sensing devices for the measurement of combustion products from burners and appliances for domestic, commercial and industrial use burning:

- gaseous fuels according to EN 437; or

- liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomisation.

This European Standard applies to all types of stationary sensing devices measuring flue gas components O2, CO, CO2, H2, CxHy, NOX, SO2 or for a combination of them (multiple gasses).

This European Standard applies also to sensing devices for extractive systems.

This European Standard does not cover sensor requirements for combustible gas, combustible gas mixture and oil quality.

Sensoren zur Detektion von gasförmigen Verbrennungsprodukten in Gasbrennern und Gasgeräten

Diese Europäische Norm legt die Anforderungen für Sicherheit, Konstruktion und Funktion von Abgasfühlern für die Verwendung in Systemen zur Feuerungsregelung/Überwachung fest, nachfolgend als CPSD bezeichnet.

Diese Europäische Norm gilt für Messfühler von Verbrennungsprodukten für privat, gewerblich und industriell genutzte Brenner und Brennstoffgeräte für die Verbrennung von:

- gasförmigen Brennstoffen nach EN 437; oder

- Flüssigbrennstoffen mit einer Viskosität am Brennereintritt von 1,6 mm2/s (cSt) bis 6 mm2/s (cSt) bei 20 °C, höhersiedenden Erstraffinaten von Erdöl (Viskosität 6 mm2/s), für die eine Vorwärmung notwendig ist, um eine ordnungsgemäße Zerstäubung zu erreichen.

Diese Europäische Norm gilt für alle Arten von stationären Messfühlern für die Messung der Rauchgaskomponenten O2, CO, CO2, H2, CxHy, NOx, SO2 oder eine Kombination daraus (Gasgemische).

Diese Europäische Norm gilt ebenfalls für Messfühler in Absaugsystemen (extraktiven Systemen).

Diese Europäische Norm enthält keine Anforderungen an Messfühler für brennbares Gas, brennbares Gas¬gemisch sowie die Ölqualität.

Dispositifs de détection des produits de combustion pour brûleurs à gaz et appareils à gaz

La présente Norme européenne prescrit les exigences de sécurité, de construction et de fonctionnement relatives aux

dispositifs de détection des produits de combustion destinés à être utilisés dans des systèmes de contrôle de combustion,

ci-après désignés par l'acronyme DDPC.

La présente Norme européenne s'applique aux dispositifs de détection utilisés pour mesurer les produits de combustion

des brûleurs et des appareils à usage domestique, commercial et industriel utilisant :

- des combustibles gazeux selon l'EN 437 ou

- des combustibles liquides dont la viscosité à l'admission du brûleur est comprise entre 1,6 mm2/s (cSt)

et 6 mm2/s (cSt) à 20 °C, et les premiers raffinats du pétrole à point d'ébullition plus élevé (viscosité

supérieure à 6 mm2/s), qui nécessitent un préchauffage pour assurer une atomisation adéquate.

La présente Norme européenne s'applique à tous les types de dispositifs de détection fixes mesurant les composants des

gaz de combustion O2, CO, CO2, H2, CxHy, NOX, SO2 ou un mélange de ces derniers (plusieurs gaz).

La présente Norme européenne s'applique également aux dispositifs de détection pour systèmes à extraction.

La présente Norme européenne ne couvre pas les spécifications des capteurs au regard de la qualité du gaz combustible,

du mélange gazeux combustible ou du fioul.

Zaznavala produktov zgorevanja za plinske gorilnike in plinske aparate

Standard EN 16340 določa varnostne zahteve, konstrukcijske zahteve in zahteve glede zmogljivosti za zaznavala produktov zgorevanja, namenjena uporabi v sistemih za nadzorovanje zgorevanja. Ta evropski standard se uporablja za zaznavala za merjenje produktov zgorevanja iz gorilnikov in aparatov za gospodinjsko, komercialno in industrijsko kurjenje: – plinasta goriva v skladu s standardom EN 437; ali – tekoča goriva z viskoznostjo pri dovodu gorilnika 1,6 mm2/s (cSt) do 6 mm2/s (cSt) pri 20 °C, prvi rafinati z višjim vreliščem na osnovi nafte (viskoznost večja od 6 mm2/s), ki jih je treba predhodno segreti za ustrezno atomizacijo. Ta evropski standard se uporablja za vse vrste stacionarnih zaznaval, ki merijo komponente dimnega plina O2, CO, CO2, H2, CxHy, NOX, SO2, ali za njihovo kombinacijo (več plinov). Ta evropski standard se uporablja tudi za zaznavala za ekstraktivne sisteme. Ta evropski standard ne zajema zahtev glede senzorjev za vnetljivi plin, mešanico vnetljivih plinov in kakovost olja.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Feb-2012

- Publication Date

- 10-Aug-2014

- Technical Committee

- PLN - Gas appliances for domestic use

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Jul-2014

- Due Date

- 14-Sep-2014

- Completion Date

- 11-Aug-2014

EN 16340:2014 - Overview

EN 16340:2014 (CEN) specifies safety, construction and performance requirements for combustion product sensing devices (CPSD) used in combustion control systems. It applies to stationary sensing devices for domestic, commercial and industrial burners and appliances burning gaseous fuels (per EN 437) and specified liquid fuels (viscosity 1.6–6 mm2/s at 20 °C; higher-boiling first raffinates that require preheating). The standard covers sensors and systems measuring flue gas components such as O2, CO, CO2, H2, CxHy, NOX, SO2, and combinations thereof, and it also applies to extractive systems. It does not cover sensors for combustible gas mixtures or oil quality.

Key Topics and Requirements

- Scope & classification: Defines CPSD components (CPSE sensing element, control unit, signal conditioner) and classes of control and function.

- Construction requirements: Mechanical parts, materials, gas connections, electronic components and protection against internal faults for functional safety.

- Measurement & test conditions: Units of measurement, test environments, pressure and dimensional tolerances.

- Performance testing: Leak-tightness (volumetric and pressure-loss methods), rated flow, torsion/bending, response time, durability, endurance and long-term stability for electronic controls.

- EMC and electrical: Immunity to supply variations, surges, electrostatic discharge, radiated fields and other EMC tests.

- Marking & documentation: Mandatory marking, installation and operating instructions, and warning notices.

- Annexes: Practical test methods (Annex B/C), fault-mode analysis, materials for pressurized parts, and requirements for DC-supplied burners and safety accessories.

Applications and Who Uses It

- Manufacturers of combustion product sensing devices and CPSEs to design and certify compliant products.

- Appliance and burner OEMs integrating CPSDs into gas or liquid-fuel equipment for domestic, commercial or industrial use.

- Test laboratories and conformity assessment bodies performing performance, leak-tightness and EMC testing to EN 16340 criteria.

- Installers, technical specifiers and safety engineers who select sensors for flue gas monitoring, combustion control and safety interlocks.

- Regulatory and compliance teams ensuring products meet European safety directives (see relationship to Directive 2009/142/EC in Annex ZA).

Related Standards

- EN 13611:2007+A2:2011 - general safety and control device requirements (EN 16340 is intended for use in conjunction).

- EN 437 - gaseous fuel reference standard.

- EN 1856‑1, EN 10088‑1, EN 14241‑1, EN 60529 - referenced for chimneys, materials and enclosure protection.

EN 16340:2014 is essential for anyone involved in design, testing or regulatory approval of combustion product sensing devices and ensures reliable, safe flue gas measurement and control in heating and combustion systems.

Frequently Asked Questions

SIST EN 16340:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Combustion product sensing devices for gas burners and gas burning appliances". This standard covers: This European Standard specifies the safety, construction and performance requirements for combustion product sensing devices intended to be used in combustion control systems, hereinafter referred to as CPSD. This European Standard applies to sensing devices for the measurement of combustion products from burners and appliances for domestic, commercial and industrial use burning: - gaseous fuels according to EN 437; or - liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomisation. This European Standard applies to all types of stationary sensing devices measuring flue gas components O2, CO, CO2, H2, CxHy, NOX, SO2 or for a combination of them (multiple gasses). This European Standard applies also to sensing devices for extractive systems. This European Standard does not cover sensor requirements for combustible gas, combustible gas mixture and oil quality.

This European Standard specifies the safety, construction and performance requirements for combustion product sensing devices intended to be used in combustion control systems, hereinafter referred to as CPSD. This European Standard applies to sensing devices for the measurement of combustion products from burners and appliances for domestic, commercial and industrial use burning: - gaseous fuels according to EN 437; or - liquid fuels having a viscosity at the burner inlet of 1,6 mm2/s (cSt) up to 6 mm2/s (cSt) at 20 °C, higher boiling petroleum based first raffinates (viscosity greater than 6 mm2/s), that require preheating for proper atomisation. This European Standard applies to all types of stationary sensing devices measuring flue gas components O2, CO, CO2, H2, CxHy, NOX, SO2 or for a combination of them (multiple gasses). This European Standard applies also to sensing devices for extractive systems. This European Standard does not cover sensor requirements for combustible gas, combustible gas mixture and oil quality.

SIST EN 16340:2014 is classified under the following ICS (International Classification for Standards) categories: 27.060.20 - Gas fuel burners. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16340:2014 is associated with the following European legislation: EU Directives/Regulations: 2009/142/EC; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16340:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zaznavala produktov zgorevanja za plinske gorilnike in plinske aparateSensoren zur Detektion von gasförmigen Verbrennungsprodukten in Gasbrennern und GasgerätenDispositifs de détection des produits de combustion pour brûleurs à gaz et appareils à gazCombustion product sensing devices for gas burners and gas burning appliances27.060.20Plinski gorilnikiGas fuel burnersICS:Ta slovenski standard je istoveten z:EN 16340:2014SIST EN 16340:2014en,fr,de01-september-2014SIST EN 16340:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16340

June 2014 ICS 27.060.20 English Version

Safety and control devices for burners and appliances burning gaseous or liquid fuels - Combustion product sensing devices

Dispositifs de commande et de sécurité pour brûleurs et appareils utilisant des combustibles gazeux ou liquides - Dispositifs de détection des produits de combustion

Sicherheits- und Regeleinrichtungen für Brenner und Brennstoffgeräte für gasförmige oder flüssige Brennstoffe - Abgasfühler This European Standard was approved by CEN on 14 May 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16340:2014 ESIST EN 16340:2014

Gas connections in common use in the various countries . 39 Annex B (informative)

Leak-tightness test — volumetric method . 40 Annex C (informative)

Leak-tightness test — pressure loss method . 41 Annex D (normative)

Conversion of pressure loss into leakage rate . 42 Annex E (normative)

Electrical/electronic component fault modes . 43 Annex F (normative)

Additional requirements for safety accessories and pressure accessories as defined in EU Directive 97/23/EC . 44 Annex G (normative)

Materials for pressurized parts . 45 Annex H (informative)

Additional materials for pressurized parts. 46 Annex I (normative)

Requirements for controls used in DC supplied gas burners and gas burning appliances . 47 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2009/142/EC relating to appliances burning gaseous fuels . 48 Bibliography . 50

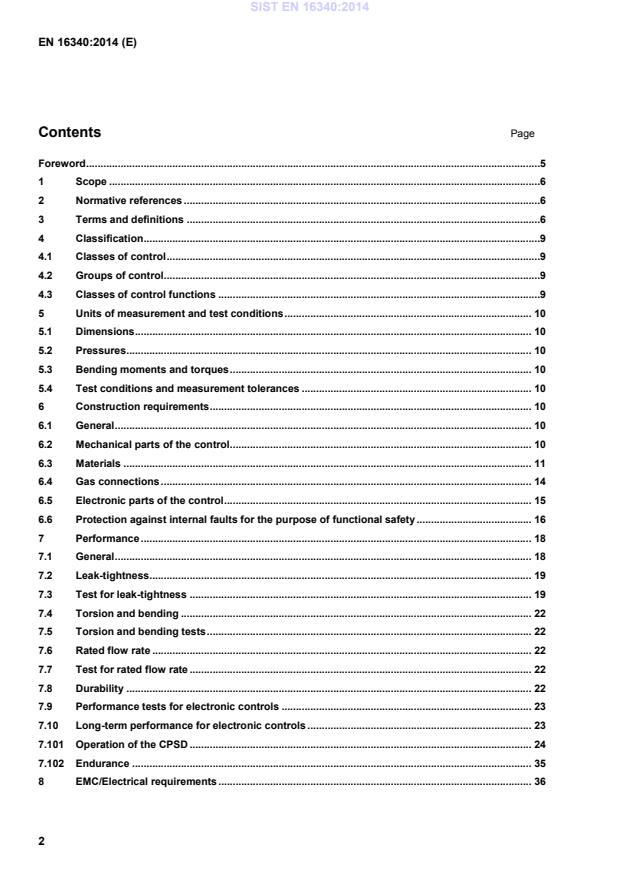

Figures Figure 1 — CPSD coupled with combustion control system . 6 Figure 2 — Clarification of definitions for CPSD . 7 Figure 4 — Leak-tightness provided by the housing and mounting. 19 Figure 5 — Test equipment for influence of leakage on measurement value . 20 Figure 6 — Response times . 27 Figure 7 — Alternative test equipment for response time . 28 Figure 8 — Recovery time R90 . 31

Figure 1 — CPSD coupled with combustion control system 3.102 Combustion Product Sensing Element (CPSE) part of the CPSD, which transforms the concentration of the sensed combustion product into a physical value (e.g. voltage, current, resistance) 3.103 CPSE control unit unit that provides additional functions in order to operate the sensing element Note 1 to entry: Example of additional function is the control of the heating element. 3.104 signal conditioner electronic circuit that transforms the physical value from the sensing element into an output signal Note 1 to entry: The signal conditioner may consist of functional electronics as well as electronics which cause the CPSD to be classified as Class B or C according to EN 13611:2007+A2:2011. 3.105 measuring range declared range between two values that can be measured by the CPSD with the accuracy stated in the installation and operating instructions 3.106 offset positive or negative deviation of the zero point value 3.107 accuracy ability of the CPSD to provide an indicated value close to the true value 3.108 linearity highest value of the deviation between the CPSD output characteristic from the ideal curve 3.109 drift difference between the value indicated/measured value by the CPSD before and after the endurance test SIST EN 16340:2014

Key 1 hysteresis X combustion product concentration Y CPSD output signal Figure 2 — Clarification of definitions for CPSD 3.112 repeatability ability of the CPSD to provide similar output signals whilst measuring the same concentration of combustion product under the same test condition 3.113 flue gas pressure differential pressure from flue gas side to reference (ambient) side 3.114 flue gas velocity speed of the combustion product flow at the location of measurement of the CPSD (m/s) 3.115 warm up time time from power on until specified operation 3.116 stand by mode non-operational mode in which the CPSD is able to come in operation after a start up time SIST EN 16340:2014

To reduce test gas consumption an explosion proof fan may be installed inside the test chamber. In that case a minimum distance of 50 mm between fan and CPSD shall be maintained. — The test gas mixture shall consist of 5 -% (V/V) propane and 95 -% (V/V) air. — The absolute air pressure inside the test chamber shall be 101 kPa ± 10 %. — The gas temperature inside the test chamber shall be at least 20 °C. The installation shall be done as stated in the installation and operating instructions paying particular attention to immersion depth and angle to horizontal. The test gas mixture shall flow continuously through or within the test chamber and the CPSD shall be operated in a way that causes the highest specified temperature of the CPSE (the 5/95 % propane/air mixture is the condition with the highest probability of ignition, so no additional requirements are needed). After temperature stabilisation, the test shall be performed for a minimum period of 5 × T60 or 1 min, whichever is the longer. During the test no ignition shall occur. Dimensions in millimetres

Key 1 CPSD under test 2 Test chamber 3 flame arrester of the test chamber 4 flow metre 5 throttle 6 valve 7 burst foil 8 free space surrounding the CPSD Figure 3 — Ignition test fixture SIST EN 16340:2014

(according to EN 10088–1:2005) Symbol 1.4301 X5CrNi 18–10 1.4307 X2CrNi 18–9 1.4401 X5CrNiMo 17–12–2 1.4404 X2CrNiMo 17–12–2 1.4571 X6CrNiMoTi 17–12–2 1.4432 X2CrNiMo 17–12–3 1.4539 X1NiCrMoCu 25–20–5 The suitability of metallic materials others than listed in Table 2 shall be proven according to EN 1856-1:2009, A.2. 6.4 Gas connections 6.4.1 Making connections EN 13611:2007+A2:2011, 6.4.1 is not applicable. 6.4.2 Connection sizes EN 13611:2007+A2:2011, 6.4.2 is not applicable. 6.4.3 Threads EN 13611:2007+A2:2011, 6.4.3 is not applicable. 6.4.4 Union joints Shall be according to EN 13611:2007+A2:2011, 6.4.4 with the following addition. This requirement is only applicable when the gases are extracted from a main flow. 6.4.5 Flanges EN 13611:2007+A2:2011, 6.4.5 is not applicable. 6.4.6 Compression fittings Shall be according to EN 13611:2007+A2:2011, 6.4.6. 6.4.7 Nipples for pressure test EN 13611:2007+A2:2011, 6.4.7 is not applicable. SIST EN 16340:2014

Key 1 flue gas 2 CPSD 3 inner sealing 4 outer sealing 5 mounting element 6 inner leakage 7 outer leakage Figure 4 — Leak-tightness provided by the housing and mounting Carry out the test with a test pressure of 200 Pa (2 mbar) in respect to ambient or at a higher pressure if stated in the installation and operating instructions. Measure the flow from test equipment to ambient, using a method which gives reproducible results. Examples of such methods are shown in: — Annex B (volumetric method) for test pressures up to and including 15 kPa (150 mbar); — Annex C (pressure loss method) for test pressures above 15 kPa (150 mbar). — The formula for conversion from the pressure loss method to the volumetric method is given in Annex D. Measured flow shall meet the requirements of 7.2.101. 7.3.102 Influence of leakage on measurement value 7.3.102.1 General The CPSD shall be mounted into the test equipment as shown in Figure 5 and as stated in the installation and operating instructions, with all connections to the CPSD in place. SIST EN 16340:2014

Key 1 CPSD 2 reference chamber 3 test chamber 4 bulkhead cable gland 5 air 6 test gas 7 throttle 8 flow meter 9 test gas velocity m/s 10 differential pressure Figure 5 — Test equipment for influence of leakage on measurement value 7.3.102.2 Flue pipe to ambient Dismantle the closure head of the reference chamber (2). The pressure (10) between test chamber (3) and ambient should be 200 Pa (2 mbar) or higher if stated in the installation and operating instructions. The test gas velocity (9) in the test chamber shall be the minimum flue gas velocity stated in the installation and operating instructions or 0,1 m/s if not stated. The test gas concentration shall be 1/3 and 2/3 of the measurement range stated in the installation and operating instructions. Measurement of the output signal of the CPSD shall meet the requirement of 7.2.102. 7.3.102.3 Ambient to flue pipe The differential pressure (10) between reference chamber (2) and test chamber (3) should be +100 mbar. The test gas velocity (9) in the test chamber shall be the minimum flue gas velocity stated in the installation and operating instructions or 0,1 m/s if not stated. The test gas concentration shall be 1/3 and 2/3 of the measurement range stated in the installation and operating instructions. Measurement of the output signal of the CPSD shall meet the requirement of 7.2.102. SIST EN 16340:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...