SIST EN 88-2:2022+A1:2025

(Main)Safety and control devices for gas burners and gas burning appliances - Part 2: Pressure regulators for inlet pressures above 50 kPa up to and including 500 kPa

Safety and control devices for gas burners and gas burning appliances - Part 2: Pressure regulators for inlet pressures above 50 kPa up to and including 500 kPa

EN 13611:2019, Clause 1 applies with the following modification and addition:

Modification:

The 1st paragraph of EN 13611:2019, Clause 1 is replaced by:

This document specifies the safety, design, construction, and performance requirements and testing for

pneumatic pressure regulators and safety devices for burners and appliances burning one or more

gaseous fuels, hereafter referred to as “pressure regulators”.

This document is applicable to pressure regulators with declared maximum inlet pressures above 50 kPa

up to and including 500 kPa and of nominal connection sizes up to and including DN 250.

Addition:

This document is applicable to:

— pressure regulators incorporating safety devices;

— pressure regulators and safety devices which use auxiliary energy;

— stand-alone pressure regulators or pressure regulators equipped with a control device for maximum

or minimum gas pressure.

This document is not applicable to:

— pressure regulators connected directly to a gas distribution network or to a container that maintains

a standard distribution pressure;

— pressure regulators intended for gas appliances to be installed in the open air and exposed to the

environment.

The 4th paragraph of EN 13611:2019, Clause 1 is removed.

Sicherheits- und Regeleinrichtungen für Gasbrenner und Gasgeräte - Teil 2: Druckregler für Eingangsdrücke über 50 kPa bis einschließlich 500 kPa

EN 13611:2019, Abschnitt 1, gilt mit folgender Änderung und Ergänzung:

Änderung:

Der erste Absatz von EN 13611:2019, Abschnitt 1, wird ersetzt durch:

Dieses Dokument legt die Sicherheits , Auslegungs , Konstruktions- und Leistungsanforderungen sowie die Prüfung von pneumatischen Druckreglern und Sicherheitseinrichtungen für Brenner und Brennstoffgeräte für einen oder mehrere gasförmige Brennstoffe, nachstehend als „Druckregler“ bezeichnet, fest.

Dieses Dokument gilt für Druckregler mit angegebenen höchsten Eingangsdrücken über 50 kPa bis einschließlich 500 kPa und mit Anschlussnennweiten bis einschließlich DN 250.

Ergänzung:

Dieses Dokument gilt für:

- Druckregler, die Sicherheitseinrichtungen enthalten;

- Druckregler und Sicherheitseinrichtungen, die Hilfsenergie benötigen;

- unabhängige Druckregler oder Druckregler, die mit einer Regeleinrichtung für den höchsten oder niedrigsten Gasdruck ausgestattet sind.

Dieses Dokument gilt nicht für:

- Druckregler, die unmittelbar an ein Gasverteilungsnetz oder an einen Behälter mit genormtem Verteilungsdruck angeschlossen sind;

- Druckregler für Gasgeräte in Freiluftausführung, die Umwelteinflüssen ausgesetzt sind.

Der vierte Absatz von EN 13611:2019, Abschnitt 1, entfällt.

Dispositifs de sécurité et de contrôle pour les brûleurs à gaz et appareils utilisant des combustibles gazeux - Partie 2 : Régulateurs de pression pour pressions amont comprises entre 50 kPa et 500 kPa

Varnostne in nadzorne naprave za plinske gorilnike in plinske aparate - 2. del: Regulatorji tlaka za vstopne tlake nad 50 kPa do vključno 500 kPa (vključno z dopolnilom A1)

Točka 1 standarda EN 13611:2019 se uporablja z naslednjo spremembo in dodatkom:

Sprememba:

Prvi odstavek točke 1 standarda EN 13611:2019 nadomešča naslednje besedilo:

Ta dokument določa zahteve za varnost, načrtovanje, izdelavo in delovanje ter preskušanje pnevmatskih regulatorjev tlaka in varnostnih naprav za gorilnike in aparate, ki uporabljajo eno ali več plinastih goriv (v nadaljnjem besedilu »regulatorji tlaka«).

Ta dokument se uporablja za regulatorje tlaka z določenim največjim vstopnim tlakom nad 50 kPa do največ 500 kPa in nazivno velikostjo priključkov do vključno DN 250.

Dodatek:

Ta dokument se uporablja za:

– regulatorje tlaka, ki vključujejo varnostne naprave;

– regulatorje tlaka in varnostne naprave, ki uporabljajo pomožno energijo;

– samostojne regulatorje tlaka ali regulatorje tlaka, opremljene z nadzorno napravo za največji oziroma najmanjši tlak plina.

Ta dokument se ne uporablja za:

– regulatorje tlaka, priključene neposredno na omrežje za distribucijo plina ali vsebnik, ki ohranja tlak pri običajni distribuciji;

– regulatorje tlaka, namenjene za plinske aparate, ki jih je treba namestiti na odprtem in so izpostavljeni okolju.

Četrti odstavek točke 1 standarda EN 13611:2019 je odstranjen.

General Information

- Status

- Published

- Publication Date

- 12-Feb-2025

- Technical Committee

- PLN - Gas appliances for domestic use

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 07-Feb-2025

- Due Date

- 14-Apr-2025

- Completion Date

- 13-Feb-2025

Relations

- Effective Date

- 01-Mar-2025

Overview

SIST EN 88-2:2022+A1:2025 (equivalent to EN 88-2:2022+A1:2024) sets safety, design, construction and performance requirements and test methods for pneumatic pressure regulators and associated safety devices used with gas burners and gas-burning appliances. The standard applies to pressure regulators with declared maximum inlet pressures above 50 kPa up to and including 500 kPa and with nominal connection sizes up to and including DN 250. It incorporates Amendment A1 and modifies the scope of EN 13611:2019 to clarify applicability and exclusions.

Key topics and technical requirements

- Scope and applicability

- Regulates pneumatic pressure regulators for gaseous fuels, including regulators that incorporate safety devices, use auxiliary energy, or are supplied as stand-alone units or with maximum/minimum pressure controls.

- Not applicable to regulators directly connected to a gas distribution network or containers maintaining standard distribution pressure, or to regulators for appliances installed outdoors and exposed to the environment.

- Classification and control functions

- Defines classes and groups of control, control functions and types of DC-supplied controls.

- Design and construction

- Requirements for mechanical parts, moving parts, housings, materials (including pressurized parts), seals, breather holes, and presetting devices.

- Performance and testing

- Leak-tightness tests (volumetric and pressure loss methods), rated flow, torsion/bending, durability (including elastomer resistance), and long-term performance for electronic controls.

- Specific performance tests for pressure regulators and for over‑pressure and under‑pressure safety shut-off devices, plus endurance testing.

- Electrical and EMC requirements

- Electrical components, protection by enclosure, plug connections, and electromagnetic compatibility (EMC) immunity/surge tests.

- Functional safety

- Annexes provide methods for determining Safety Integrity Level (SIL) and Performance Level (PL), fault modes for electronic components, and reset functions.

- Marking and documentation

- Mandatory marking, user instructions and warning notices for safe installation and operation.

Practical applications and users

This standard is essential for:

- Manufacturers of pressure regulators and safety accessories for gas appliances (design, testing and certification).

- Test laboratories and conformity assessment bodies performing compliance and type testing.

- System integrators, OEMs and specifiers selecting regulators for commercial and industrial burners where inlet pressures exceed 50 kPa.

- Safety engineers, installers and procurement teams ensuring components meet regulatory and performance expectations.

Related standards and regulatory links

- Modifies scope of EN 13611:2019 (Clause 1) as noted in the standard text.

- Includes annexed requirements referencing EU Directive 2014/68/EU for pressure accessories.

- See EN 88 series for related requirements on other pressure ranges and device types.

Keywords: pressure regulators, gas burners, gas burning appliances, safety devices, EN 88-2, leak-tightness tests, SIL, PL, EMC, DN 250, inlet pressure 50–500 kPa.

Frequently Asked Questions

SIST EN 88-2:2022+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety and control devices for gas burners and gas burning appliances - Part 2: Pressure regulators for inlet pressures above 50 kPa up to and including 500 kPa". This standard covers: EN 13611:2019, Clause 1 applies with the following modification and addition: Modification: The 1st paragraph of EN 13611:2019, Clause 1 is replaced by: This document specifies the safety, design, construction, and performance requirements and testing for pneumatic pressure regulators and safety devices for burners and appliances burning one or more gaseous fuels, hereafter referred to as “pressure regulators”. This document is applicable to pressure regulators with declared maximum inlet pressures above 50 kPa up to and including 500 kPa and of nominal connection sizes up to and including DN 250. Addition: This document is applicable to: — pressure regulators incorporating safety devices; — pressure regulators and safety devices which use auxiliary energy; — stand-alone pressure regulators or pressure regulators equipped with a control device for maximum or minimum gas pressure. This document is not applicable to: — pressure regulators connected directly to a gas distribution network or to a container that maintains a standard distribution pressure; — pressure regulators intended for gas appliances to be installed in the open air and exposed to the environment. The 4th paragraph of EN 13611:2019, Clause 1 is removed.

EN 13611:2019, Clause 1 applies with the following modification and addition: Modification: The 1st paragraph of EN 13611:2019, Clause 1 is replaced by: This document specifies the safety, design, construction, and performance requirements and testing for pneumatic pressure regulators and safety devices for burners and appliances burning one or more gaseous fuels, hereafter referred to as “pressure regulators”. This document is applicable to pressure regulators with declared maximum inlet pressures above 50 kPa up to and including 500 kPa and of nominal connection sizes up to and including DN 250. Addition: This document is applicable to: — pressure regulators incorporating safety devices; — pressure regulators and safety devices which use auxiliary energy; — stand-alone pressure regulators or pressure regulators equipped with a control device for maximum or minimum gas pressure. This document is not applicable to: — pressure regulators connected directly to a gas distribution network or to a container that maintains a standard distribution pressure; — pressure regulators intended for gas appliances to be installed in the open air and exposed to the environment. The 4th paragraph of EN 13611:2019, Clause 1 is removed.

SIST EN 88-2:2022+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators; 27.060.20 - Gas fuel burners. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 88-2:2022+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 88-2:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 88-2:2022+A1:2025 is associated with the following European legislation: EU Directives/Regulations: 2016/426; Standardization Mandates: M/595. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 88-2:2022+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Nadomešča:

SIST EN 88-2:2022

Varnostne in nadzorne naprave za plinske gorilnike in plinske aparate - 2. del:

Regulatorji tlaka za vstopne tlake nad 50 kPa do vključno 500 kPa (vključno z

dopolnilom A1)

Safety and control devices for gas burners and gas burning appliances - Part 2: Pressure

regulators for inlet pressures above 50 kPa up to and including 500 kPa

Sicherheits- und Regeleinrichtungen für Gasbrenner und Gasgeräte - Teil 2: Druckregler

für Eingangsdrücke über 50 kPa bis einschließlich 500 kPa

Dispositifs de sécurité et de contrôle pour les brûleurs à gaz et appareils utilisant des

combustibles gazeux - Partie 2 : Régulateurs de pression pour pressions amont

comprises entre 50 kPa et 500 kPa

Ta slovenski standard je istoveten z: EN 88-2:2022+A1:2024

ICS:

23.060.40 Tlačni regulatorji Pressure regulators

27.060.20 Plinski gorilniki Gas fuel burners

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 88-2:2022+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2024

EUROPÄISCHE NORM

ICS 23.060.40

English Version

Safety and control devices for gas burners and gas burning

appliances - Part 2: Pressure regulators for inlet pressures

above 50 kPa up to and including 500 kPa

Dispositifs de sécurité et de contrôle pour les brûleurs Sicherheits- und Regeleinrichtungen für Gasbrenner

à gaz et appareils utilisant des combustibles gazeux - und Gasgeräte - Teil 2: Druckregler für Eingangsdrücke

Partie 2 : Régulateurs de pression pour pressions über 50 kPa bis einschließlich 500 kPa

amont comprises entre 50 kPa et 500 kPa

This European Standard was approved by CEN on 8 August 2022 and includes Amendment 1 approved by CEN on 3 July 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 88-2:2022+A1:2024 E

worldwide for CEN national Members.

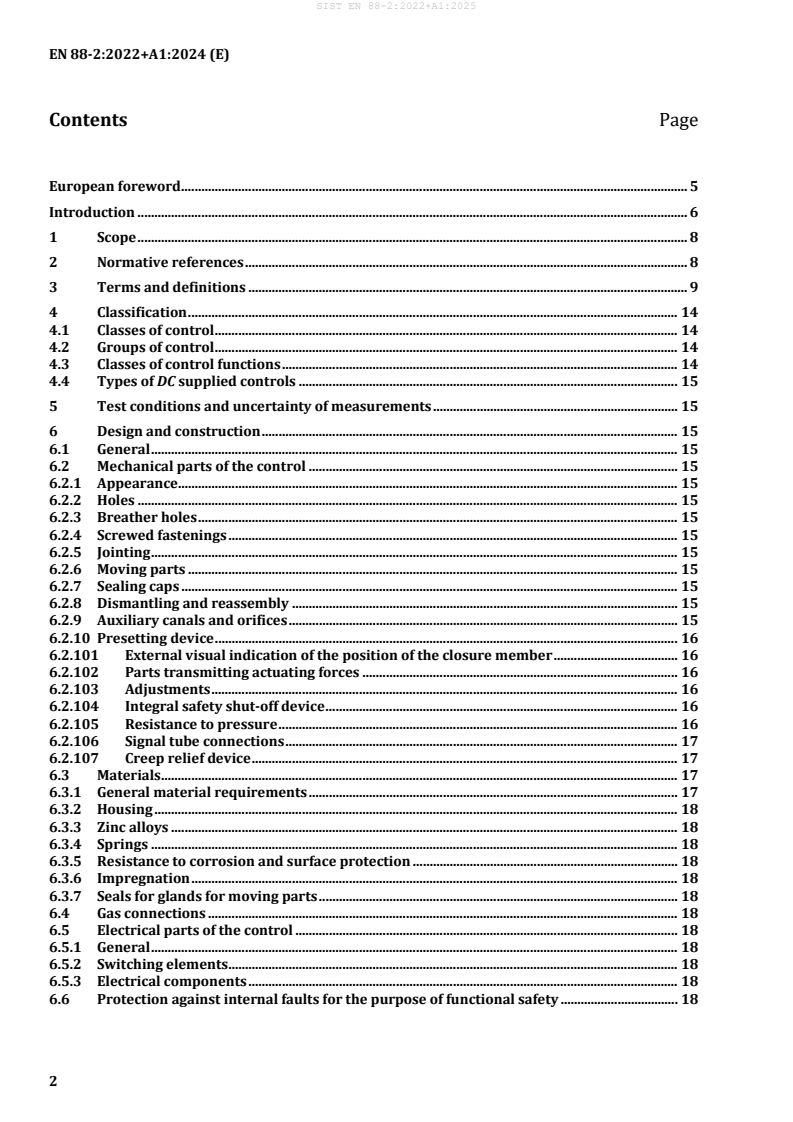

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Classification . 14

4.1 Classes of control . 14

4.2 Groups of control . 14

4.3 Classes of control functions . 14

4.4 Types of DC supplied controls . 15

5 Test conditions and uncertainty of measurements . 15

6 Design and construction . 15

6.1 General . 15

6.2 Mechanical parts of the control . 15

6.2.1 Appearance . 15

6.2.2 Holes . 15

6.2.3 Breather holes . 15

6.2.4 Screwed fastenings . 15

6.2.5 Jointing . 15

6.2.6 Moving parts . 15

6.2.7 Sealing caps . 15

6.2.8 Dismantling and reassembly . 15

6.2.9 Auxiliary canals and orifices . 15

6.2.10 Presetting device . 16

6.2.101 External visual indication of the position of the closure member . 16

6.2.102 Parts transmitting actuating forces . 16

6.2.103 Adjustments . 16

6.2.104 Integral safety shut-off device . 16

6.2.105 Resistance to pressure . 16

6.2.106 Signal tube connections . 17

6.2.107 Creep relief device . 17

6.3 Materials . 17

6.3.1 General material requirements . 17

6.3.2 Housing . 18

6.3.3 Zinc alloys . 18

6.3.4 Springs . 18

6.3.5 Resistance to corrosion and surface protection . 18

6.3.6 Impregnation . 18

6.3.7 Seals for glands for moving parts . 18

6.4 Gas connections . 18

6.5 Electrical parts of the control . 18

6.5.1 General . 18

6.5.2 Switching elements . 18

6.5.3 Electrical components . 18

6.6 Protection against internal faults for the purpose of functional safety . 18

7 Performance . 18

7.1 General . 18

7.2 Leak-tightness . 19

7.2.1 Requirements . 19

7.2.2 Tests . 19

7.3 Torsion and bending . 19

7.4 Rated flow rate . 19

7.4.1 Requirements . 19

7.4.2 Test . 19

7.4.3 Conversion of air flow rate . 20

7.5 Durability. 20

7.5.1 Elastomers in contact with gas . 20

7.5.2 Marking . 20

7.5.3 Resistance to scratching . 20

7.5.4 Resistance to humidity . 20

7.6 Performance tests for electronic controls . 20

7.7 Long-term performance for electronic controls . 20

7.8 Data exchange . 20

7.101 Pressure regulator performance . 20

7.101.1 General . 20

7.101.2 General test procedure . 20

7.102 Safety devices . 26

7.102.1 Over-pressure safety shut-off devices . 26

7.102.2 Under-pressure safety shut-off devices . 30

7.102.3 Endurance of safety device . 30

8 Electrical requirements . 31

8.1 General . 31

8.2 Protection by enclosure . 31

8.101 Plug connections . 31

9 Electromagnetic compatibility (EMC) . 32

9.1 Protection against environmental influences . 32

9.2 Supply voltage variations below 85 % of rated voltage. 32

9.3 Voltage dips and interruptions . 32

9.4 Supply frequency variations . 32

9.5 Surge immunity tests . 32

9.6 Electrical fast transient/burst . 32

9.7 Immunity to conducted disturbances induced by radio frequency fields . 32

9.8 Immunity to radiated disturbances induced by radio frequency fields . 32

9.9 Electrostatic discharge tests . 32

9.10 Power frequency magnetic field immunity tests . 32

9.11 Harmonics and interharmonics including mains signalling at a. c. power port, low

frequency immunity tests . 32

10 Marking, instructions . 33

10.1 Marking . 33

10.2 Instructions . 33

10.3 Warning notice . 34

Annex A (informative) Abbreviations and Symbols . 35

Annex B (informative) Leak-tightness tests for gas controls – volumetric method . 36

Annex C (informative) Leak-tightness tests for gas controls – pressure loss method . 37

Annex D (normative) Conversion of pressure loss into leakage rate . 38

Annex E (normative) Electrical/electronic component fault modes . 39

Annex F (normative) Additional requirements for safety accessories and pressure

accessories as defined in EU Directive 2014/68/EU . 40

Annex G (normative) Materials for pressurized parts . 41

Annex H (normative) Additional materials for pressurized parts . 42

Annex I (normative) Requirements for controls used in DC supplied burners and

appliances burning gaseous or liquid fuels . 43

Annex J (normative) Method for the determination of a Safety Integrity Level (SIL) . 44

Annex K (normative) Method for the determination of a Performance Level (PL). 45

Annex L (informative) Relationship between Safety Integrity Level (SIL) and Performance

Level (PL) . 46

Annex M (normative) Reset functions . 47

Annex N (informative) Guidance document on Environmental Aspects . 48

Annex O (normative) Seals of elastomer, cork and synthetic fibre mixtures . 49

Annex AA (informative) Typical pressure regulators and safety devices . 50

AA.1 Main components of a pressure regulator . 50

AA.2 Main components of a safety shut-off device . 53

Annex BB (informative) Overview of requirements and test conditions (as given in 7.101),

and examples of performance curves for pressure regulators . 55

Annex CC (normative) Creep relief device . 58

CC.1 General . 58

CC.2 Design and construction . 58

CC.3 Performance requirements . 58

CC.4 Marking, instructions . 58

Annex DD (informative) Comparison between EN 334:2019 and !EN 88-

2:2022+A1:2024" . 59

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2016/426 aimed to be covered . 60

Bibliography . 63

European foreword

This document (EN 88-2:2022+A1:2024) has been prepared by Technical Committee CEN/TC 58 “Safety

and control devices for burners and appliances burning gaseous or liquid fuels”, the secretariat of which

is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2025, and conflicting national standards shall be

withdrawn at the latest by November 2027.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 3 July 2024.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document supersedes !EN 88-2:2022.

This standard differs from EN 88:2022 as follows:

a) Annex ZA has been brought in line with Mandate M/595 and the normative references are updated."

!deleted text"

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

The EN 88 series consists of the following parts:

— EN 88-1, Safety and control devices for gas burners and gas burning appliances — Part 1: Pressure

regulators for inlet pressures up to and including 50 kPa;

— EN 88-2, Safety and control devices for gas burners and gas burning appliances — Part 2: Pressure

regulators for inlet pressures above 50 kPa up to and including 500 kPa;

— EN 88-3, Safety and control devices for gas burners and gas burning appliances — Part 3: Pressure

and/or flow rate regulators for inlet pressures up to and including 500 kPa, electronic types.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is intended to be used in conjunction with EN 13611:2019.

EN 13611:2019 recognizes the safety level specified by CEN/TC 58 and is regarded as a horizontal

standard dealing with the safety, construction, performance and testing of controls for burners and

appliances burning gaseous and/or liquid fuels.

The general requirements for controls are given in EN 13611:2019, and methods for classification and

assessment for new controls and control functions are given in EN 14459:2021 (see Figure 1).

EN 126:2012 (see Figure 1) specifies multifunctional controls combining two or more controls and

Application Control Functions, one of which is a mechanical control function. The requirements for

controls and Application Control Functions are given in the specific control standard (see Figure 1,

control functions).

Figure 1 — Interrelation of control standards

EN 13611:2019 should be used in conjunction with the specific standard for a specific type of control (e.g.

!EN 88-1:2022+A1:2023", !EN 88-2:2022+A1:2024", !EN 88-3:2022+A1:2024",

!EN 125:2022+A1:2024", EN 126:2012, EN 161:2022, !EN 257:2022+A1:2023", EN 298:2022,

!EN 1106:2022+A1:2023", EN 1643:2022, !EN 1854:2022+A1:2023", EN 12067-2:2022,

!EN 16304:2022+A1:2024", EN 16340:2014, EN 16678:2022 and

!EN 16898:2022+A1:2023"), or for controls for specific applications.

EN 13611:2019 can also be applied, so far as reasonable, to controls not mentioned in a specific standard

and to controls designed on new principles, in which case additional requirements can be necessary.

EN 14459:2021 provides methods for classification and assessment of new control principles.

Primarily in industrial applications it is common practice to rate the safety of a plant based on values

describing the likelihood of a dangerous failure. These values are being used to determine Safety Integrity

Levels or Performance Levels when the system is being assessed in its entirety.

CEN/TC 58 standards for safety relevant controls do go beyond this approach, because for a certain life

time for which the product is specified, designed and tested a dangerous failure is not allowed at all.

Failure modes are described and assessed in greater detail.

Measures to prevent from dangerous situations are defined. Field experience over many decades is

reflected in the CEN/TC 58 standards. Requirements of EN 13611:2019 can be considered as proven in

practice.

This document refers to clauses of EN 13611:2019 or adapts clauses by stating “with the following

modification”, “with the following addition”, “is replaced by the following” or “is not applicable” in the

corresponding clause.

This document adds clauses or subclauses to the structure of EN 13611:2019 which are particular to this

document. Subclauses which are additional to those in EN 13611:2019 are numbered starting from 101.

Additional Annexes are designated as Annex AA, BB, CC, etc. It should be noted that these clauses,

subclauses and Annexes are not indicated as an addition.

If by reference to EN 13611:2019 the term “control” is given, this term should be read as “pressure

regulator”.

1 Scope

EN 13611:2019, Clause 1 applies with the following modification and addition:

Modification:

st

The 1 paragraph of EN 13611:2019, Clause 1 is replaced by:

This document specifies the safety, design, construction, and performance requirements and testing for

pneumatic pressure regulators and safety devices for burners and appliances burning one or more

gaseous fuels, hereafter referred to as “pressure regulators”.

This document is applicable to pressure regulators with declared maximum inlet pressures above 50 kPa

up to and including 500 kPa and of nominal connection sizes up to and including DN 250.

Addition:

This document is applicable to:

— pressure regulators incorporating safety devices;

— pressure regulators and safety devices which use auxiliary energy;

— stand-alone pressure regulators or pressure regulators equipped with a control device for maximum

or minimum gas pressure.

This document is not applicable to:

— pressure regulators connected directly to a gas distribution network or to a container that maintains

a standard distribution pressure;

— pressure regulators intended for gas appliances to be installed in the open air and exposed to the

environment.

th

The 4 paragraph of EN 13611:2019, Clause 1 is removed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 161:2022, Automatic shut-off valve for gas burners and gas appliances

!EN 549:2019+A2:2024", Rubber materials for seals and diaphragms for gas appliances and gas

equipment

EN 682:2002, Elastomeric seals — Materials requirements for seals used in pipes and fittings carrying gas

and hydrocarbon fluids

EN 13611:2019, Safety and control devices for burners and appliances burning gaseous and/or liquid fuels

— General requirements

As impacted by EN 682:2002/A1:2005.

As impacted by EN 13611:2019/AC:2021.

EN 60534-2-3:2016, Industrial-process control valves — Part 2-3: Flow capacity — Test procedures

(IEC 60534-2-3:2015)

EN 175301-803:2006, Detail Specification: Rectangular connectors — Flat contacts, 0,8 mm thickness,

locking screw not detachable

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13611:2019 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.101

pressure regulator

device which maintains the outlet pressure constant independent of the variations in inlet pressure

and/or flow rate within defined limits

[SOURCE: !EN 88-1:2022+A1:2023", 3.101]

3.102

control member

movable part of the pressure regulator which varies flow rate and/or outlet pressure directly

[SOURCE: !EN 88-1:2022+A1:2023", 3.107]

3.103

safety shut-off device

SSD

device having the function of staying in the open position under normal operating conditions and to shut

off the gas flow automatically and completely when the monitored pressure deviates above or below the

pre-set value

3.104

housing

part of the pressure regulator and/or SSD that is the main pressure containing envelope

3.105

controller

device which normally includes a setting element, normally a spring, to obtain a set value of the outlet

pressure, and a pressure detector element, normally a diaphragm for the outlet pressure

3.106

actuator

device or mechanism which changes the signal from the controller into a corresponding movement

controlling the position of the control member

3.107

working diaphragm

flexible member which, under the influence of the forces arising from loading and pressure, operates the

control member

Note 1 to entry: Diaphragms used as a control member are not covered by this definition.

[SOURCE: !EN 88-1:2022+A1:2023", 3.122, modified – Note 1 to entry added]

3.108

pressure containing part

part where failure would result in release of gas to the atmosphere

Note 1 to entry: Such parts comprise housings, inner partition walls, control member, bonnets, the housing of the

actuator, blind flanges and pipes for process and sensing lines.

3.109

signal connection

connection that is used to convey pressure from part of an installation to the signal chamber

[SOURCE: !EN 88-1:2022+A1:2023", 3.128]

3.110

breather line

line between the controller and/or pilot regulator and atmosphere which equalizes the pressure on a

detector element when it changes its position

3.111

fixture

functional device connected to the main components of the pressure regulator or SSD

3.112

exhaust line

line to atmosphere between the pressure regulator or fixtures for the safe venting of gas in the event of a

working diaphragm failure

3.113

trip mechanism

mechanism that releases the closure member when activated by the controller

3.114

SSD-actuator

device that is activated by the trip mechanism which shuts the closure member

3.115

relatching device

device that enables the complete opening of an SSD

3.116

motorization chamber

chamber at the higher pressure of two chambers under pressure within the housing of actuator

3.117

monitored pressure

pressure monitored and safeguarded by the SSD

3.118

trip pressure

pressure value at which the closing member starts to move

3.119

upper trip pressure

p

2o

upper limit of the monitored over-pressure

3.120

lower trip pressure

p

2u

lower limit of the monitored under-pressure

3.121

outlet setting pressure

p

2s

outlet pressure at which the pressure regulator is set for test purposes

[SOURCE: !EN 88-1:2022+A1:2023", 3.115]

3.122

maximum outlet pressure

p

2max

upper limit of the outlet pressure, as stated in the instructions, at which the pressure regulator can be

operated

[SOURCE: !EN 88-1:2022+A1:2023", 3.111]

3.123

minimum outlet pressure

p

2min

lower limit of the outlet pressure, as stated in the instructions, at which the pressure regulator can be

operated

[SOURCE: !EN 88-1:2022+A1:2023", 3.112]

3.124

outlet pressure range

difference between maximum and minimum values of the outlet pressure, as stated in the instructions

[SOURCE: !EN 88-1:2022+A1:2023", 3.111]

3.125

maximum inlet pressure

p

1max

highest inlet pressure, as stated in the instructions, at which the pressure regulator can be operated

Note 1 to entry: The definition of “maximum inlet pressure” is also known as “maximum allowable pressure PS”.

Note 2 to entry: In accordance with the strength requirements of this document.

3.126

minimum inlet pressure

p

1min

lowest inlet pressure, as stated in the instructions, at which the pressure regulator can be operated

[SOURCE: !EN 88-1:2022+A1:2023", 3.110]

3.127

inlet pressure range

difference between the maximum and minimum values of the inlet pressure, as stated in the instructions

[SOURCE: !EN 88-1:2022+A1:2023", 3.108]

3.128

maximum rated flow rate

q

max

upper limit of the rated air flow rate, corrected to standard conditions, as stated in the instructions

[SOURCE: !EN 88-1:2022+A1:2023", 3.116]

3.129

minimum rated flow rate

q

min

lower limit of the rated air flow rate, corrected to standard conditions, as stated in the instructions

[SOURCE: !EN 88-1:2022+A1:2023", 3.117]

3.130

steady state value

outlet pressure measured after step response remains constant

[SOURCE: !EN 88-1:2022+A1:2023", 3.131, modified – Note 1 to entry removed]

3.131

settling tolerance

maximum difference between the current outlet pressure and its steady state value

[SOURCE: !EN 88-1:2022+A1:2023", 3.132 , modified – Note 1 to entry removed]

3.132

performance curve

graphic representation of the outlet pressure as a function of the rated flow rate

Note 1 to entry: This curve is determined by increasing and then decreasing the rated flow rate with constant

inlet pressure and constant outlet setting pressure (see Figure BB.1).

3.133

family of performance curves

set of the performance curves for each value of inlet pressure determined for a given outlet setting

pressure

Note 1 to entry: See Figure BB.2.

3.134

accuracy

percentage of the outlet pressure relative to the outlet setting pressure within the operation range

3.135

accuracy class

AC

maximum permissible value of the accuracy

3.136

lock-up time

t

f

time taken for the control member to move from an open position to the closed position

3.137

lock-up pressure

p

2f

outlet pressure at which a pressure regulator closes when the outlet of the pressure regulator is sealed

[SOURCE: !EN 88-1:2022+A1:2023", 3.124]

3.138

lock-up pressure class

SG

maximum permissible positive difference between the actual lock-up pressure(s) p and the

2f

corresponding outlet setting pressure(s) at a certain percentage of the maximum rated flow rate q ,

max

expressed as a percentage of the outlet setting pressure

Note 1 to entry: The lock-pressure pressure class SG is given by the following equation:

pp−

( )

2f 2s

SG 100⋅ (1)

p

2s

where

SG is the lock-up pressure class;

p is the lock-up pressure; and

2f

p is the outlet setting pressure.

2s

=

3.139

limit pressure

p

l

pressure at which yielding becomes apparent in any component of the pressure regulator or its fixtures

3.140

safety factor

S , S

b

ratio of the value of the limit pressure p to the value of the maximum allowable pressure PS

l

Note 1 to entry: This term applies to two separate discrete regions of the pressure regulator:

— applied to the pressure regulator housing: S ;

b

— applied to the other pressure containing parts of the pressure regulator: S.

3.141

creep relief device

CRD

small spring-loaded valve in the actuator of a direct acting pressure regulator which opens automatically

if the controlled pressure is higher than the lock-up pressure (including tolerance)

3.142

opening pressure

[creep relief device]

pressure at which the first internal leak occurs

3.143

closing pressure

[creep relief device]

pressure at which the creep relief device is leak tight after re-seating

4 Classification

4.1 Classes of control

EN 13611:2019, 4.1 is replaced by the following:

Pressure regulators shall be classified

— AC 1, AC 2,5, AC 5, AC 10, and AC 20 according to the pressure regulator accuracy class (7.101.2.4);

and / or

— SG 5, SG 10, SG 20, and SG 30 according to the lock-up pressure class (7.101.2.5); and / or

— AG 5, AG 10, AG 20, and AG 30 according to the over-pressure shut-off accuracy group (7.102.1).

4.2 Groups of control

Shall be according to EN 13611:2019, 4.2.

4.3 Classes of control functions

EN 13611:2019, 4.3 is not applicable.

4.4 Types of DC supplied controls

Shall be according to EN 13611:2019, 4.4.

5 Test conditions and uncertainty of measurements

Shall be according to EN 13611:2019, Clause 5.

6 Design and construction

6.1 General

Shall be according to EN 13611:2019, 6.1.

6.2 Mechanical parts of the control

6.2.1 Appearance

Shall be according to EN 13611:2019, 6.2.1.

6.2.2 Holes

Shall be according to EN 13611:2019, 6.2.2.

6.2.3 Breather holes

6.2.3.1 Requirements

Shall be according to EN 13611:2019, 6.2.3.1 with the following addition:

If the vented capacity is greater than 70 dm /h of air, a connection for a vent pipe shall be provided.

6.2.3.2 Test for leakage of breather holes

Shall be according to EN 13611:2019, 6.2.3.2.

6.2.4 Screwed fastenings

Shall be according to EN 13611:2019, 6.2.4.

6.2.5 Jointing

Shall be according to EN 13611:2019, 6.2.5.

6.2.6 Moving parts

Shall be according to EN 13611:2019, 6.2.6.

6.2.7 Sealing caps

Shall be according to EN 13611:2019, 6.2.7.

6.2.8 Dismantling and reassembly

Shall be according to EN 13611:2019, 6.2.8.

6.2.9 Auxiliary canals and orifices

Shall be according to EN 13611:2019, 6.2.9.

6.2.10 Presetting device

Shall be according to EN 13611:2019, 6.2.10.

6.2.101 External visual indication of the position of the closure member

If an external visual device to indicate the closure member position is fitted to an SSD, it shall clearly

indicate whether it is in the open or closed position.

6.2.102 Parts transmitting actuating forces

Parts transmitting actuating forces shall be metallic and designed with a safety factor of ≥ 3 against

permanent deformation.

6.2.103 Adjustments

The adjustments (e.g. outlet pressure, offset and gas/air ratio) shall be readily accessible to authorized

personal, but there shall be provision for sealing after adjustment. Means shall be provided to discourage

interference by unauthorized personal. If it is stated in the instructions that a pressure regulator can be

put out of action, appropriate means shall be provided to put the pressure regulator out of action, and the

information how to do this shall be given in the instructions.

6.2.104 Integral safety shut-off device

An integral safety shut-off device shall be functionally independent from the pressure regulator.

This requirement is met if the function of the safety shut-off device is not affected in the event of failure

and/or loss of functionality of one or more of the following pressure regulator components:

— control member;

— seat ring (see Figures AA.1 to AA.3);

— actuator;

— casing of actuator;

— controller;

— pilot (for pilot-controlled pressure regulator types);

— sensing and process lines.

If the pressure regulator incorporates more than one safety device the functional independence shall be

met by each device.

When the integral safety shut-off device utilizes pipework gas as a source of energy for its operation this

shall be taken from upstream pipework of the pressure regulator. For any kind of pneumatic automation

system there shall be no bypass around the safety shut-off device, also taking fault conditions into

account.

6.2.105 Resistance to pressure

6.2.105.1 Requirements

Parts of the pressure regulator that are subjected to inlet pressure under normal operating conditions,

or could be subjected to inlet pressure in the event of a failure, shall resist a pressure equal to the

maximum allowable pressure PS (see 3.125) multiplied by the safety factor f.

Following safety factors in Table 1 shall be used:

Table 1 — Minimum values of the safety factor f

Group of materials Minimum value of the safety factor f

For parts of the body stressed

by forces from torque and

bending moments (pipelines)

only

Rolled and forged steel 1,70 2,13

Cast steel 2,00 2,50

Spheroidal graphite cast iron 2,50 3,13

and malleable cast iron

Copper-zinc wrought alloys 2,00 2,50

and aluminium alloys

Copper-tin cast alloys and 2,50 3,13

copper-zinc cast alloys

Aluminium cast alloys 2,50 3,13

A 4 %

min

Aluminium cast alloys 3,20 4,00

A 1,5 %

min

6.2.105.2 Test

The hydrostatic pressure test is conducted after leakage and function tests. A pressure of f times the

maximum allowable pressure (PS) is applied to the control for a minimum of 5 min.

After the test there shall be no visible damage.

6.2.106 Signal tube connections

Requirements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...