SIST EN 16952:2018+A1:2021

(Main)Agricultural machinery - Rough-terrain Work Platforms for Orchard’s operations (WPO) - Safety

Agricultural machinery - Rough-terrain Work Platforms for Orchard’s operations (WPO) - Safety

1.1 This European Standard, when used together with EN ISO 4254 1 and EN 15811, specifies safety requirements and measures for self-propelled rough-terrain work platforms for orchard’s operations (WPO) operating at a maximum of 3 m high as defined in 3.1, where the vertical projection of the centre of the area of the platform in all platform configurations at the maximum chassis inclination specified by the manufacturer is always inside the tipping lines, used in agriculture, designed to work on unimproved natural terrain and/or disturbed terrain and intended to move at least two persons to working positions in an orchard where they are carrying out fruit picking, thinning out, pruning, or other operations related to orchard from the work platform.

NOTE For examples of rough-terrain work platforms for orchard’s operations (WPO), see Figures E. 1 to E.3.

This European Standard describes methods for the elimination or reduction of hazards arising from the intended use of these machines in the course of normal operation and service, except hazards related to conveyor belts and elevators for the bin. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer.

When requirements of this document are different from those which are stated in EN ISO 4254 1, the requirements of this document take precedence over the requirements of EN ISO 4254 1 for machines that have been designed and built according to the provisions of this document.

This European Standard, taken together with EN ISO 4254 1 and EN 15811, deals with all the significant hazards, hazardous situations and events (as listed in Table 1) relevant to WPOs, when they are used as intended and under the conditions of misuse foreseeable by the manufacturer.

It does not cover the hazards arising from:

a) use in potentially explosive atmospheres;

b) getting on and off the work platform at changing levels;

c) environmental aspects;

d) road safety.

1.2 This European Standard does not apply to:

a) Mobile Elevating Work Platforms (MEWPs) (see EN 280);

NOTE 1 Figure E.4 gives an example of this type of machine.

b) boom-type MEWPs (see EN 280);

NOTE 2 Figure E.5 and E.6 give examples of this type of machine.

c) tail lifts (see EN 1756-1 and EN 1756-2);

d) mast climbing work platforms (see EN 1495);

e) lifting tables (see EN 1570-1);

f) aircraft ground support equipment (see e.g. EN 1915-1 and EN 1915-2);

g) elevating operator positions on industrial trucks (see EN 1726-2);

h) unguided work cages suspended from lifting appliances (see e.g. EN 1808);

i) machines having centre of the area of the platform outside the tipping lines.

NOTE 3 Figure E.7 gives an example of this type of machine.

Landmaschinen - Geländearbeitsbühnen für Obstplantagearbeiten (WPO) - Sicherheit

1.1 Diese Europäische Norm legt, wenn sie zusammen mit EN ISO 4254-1 und EN 15811 verwendet wird, Sicherheitsanforderungen und Sicherheitsmaßnahmen für alle Arten und Größen von selbstfahrenden Geländearbeitsbühnen für Obstplantagearbeiten (WPO), wie in 3.1 definiert, fest, die in der Landwirtschaft verwendet werden, die für die Arbeit auf naturbelassenem gewachsenem und/oder aufgewühltem Gelände konstruiert sind und die dafür vorgesehen sind, mindestens zwei Personen zu Arbeitspositionen in einer Obstplantage zu bewegen, in denen sie Fruchtpflücke-, Plenter-, Beschneide-Arbeiten oder andere Arbeiten der Obstplantagenpflege von der Arbeitsbühne aus ausführen, bei denen vorgesehen ist, dass Personen die Arbeitsbühne nur in Grundstellungen auf Bodenebene oder auf dem Fahrgestell betreten und verlassen.

Sie beschreibt Verfahren zur Beseitigung oder Reduzierung von Gefährdungen, die durch die vorgesehene Verwendung dieser Maschinen durch mindestens zwei Personen (Bediener) im Verlauf von normalem Betrieb und Wartung entstehen, ausgenommen Gefährdungen in Bezug auf Förderbänder und Gabelzinken. Außerdem legt sie die Art der Informationen über sicheres Arbeiten fest (einschließlich Restrisiken), die vom Hersteller zur Verfügung zu stellen sind.

Unterscheiden sich Anforderungen aus diesem Dokument von denen, die in EN ISO 4254-1 angegeben sind, haben die Anforderungen dieses Dokumentes, für Maschinen, die nach den Festlegungen aus diesem Dokument ausgelegt und gebaut worden sind, Vorrang vor den Anforderungen von EN ISO 4254-1.

Diese Europäische Norm behandelt, zusammen mit EN 4254-1 und EN 15811, alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse (wie in Tabelle 1 aufgelistet) zu WPOs, wenn diese wie vorgesehen verwendet werden und unter Bedingungen von Fehlanwendung, die vom Hersteller vorhersehbar sind.

Sie deckt nicht die Gefährdungen ab, die entstehen durch:

a) die Verwendung in potentiell explosiven Atmosphären;

b) Aufsteigen auf und Absteigen von der Arbeitsbühne bei sich ändernden Höhen.

1.2 Diese Europäische Norm gilt nicht für:

[...]

Matériel agricole - Plateformes élévatrices tout terrain pour arboriculture (PEMPA) - Sécurité

1.1 La présente Norme européenne, utilisée conjointement avec l'EN ISO 4254 1 et l'EN 15811, spécifie des prescriptions et mesures techniques de sécurité pour plates-formes élévatrices tout terrain automotrices pour arboriculture (PEMPA) opérant à une hauteur maximale de 3 m telles que définies en 3.1, dont la projection verticale du centre de la surface de la plate-forme se trouve toujours à l'intérieur des lignes de renversement, dans toutes les configurations de la plate-forme et à l'inclinaison maximale du châssis spécifiée par le fabricant, utilisées en agriculture, conçues pour le travail sur un terrain naturel non aménagé et/ou terrain non nivelé, et destinées à déplacer au minimum deux personnes dans un verger vers des positions de travail où les travaux de récolte, d'éclaircissage, d'élagage ou d'autres opérations en rapport avec l'entretien du verger depuis la plate-forme élévatrice sont réalisés.

NOTE Pour des exemples de plates-formes élévatrices tout terrain pour arboriculture (PEMPA), voir les Figures E.1 à E.3.

La présente Norme européenne décrit les méthodes permettant de réduire ou d’éliminer les phénomènes dangereux liés à l'utilisation prévue de ces machines dans des conditions normales de fonctionnement et de service, à l'exception des phénomènes dangereux liés aux bandes transporteuses et aux appareils de levage pour le palox. En outre, elle spécifie le type d'informations que le fabricant doit donner sur les pratiques d'utilisation sûre (y compris les risques résiduels).

Lorsque des exigences du présent document diffèrent de celles indiquées dans l'EN ISO 4254 1, les exigences du présent document prévalent sur celles de l'EN ISO 4254 1, et ce pour les machines conçues et fabriquées conformément aux exigences du présent document.

La présente Norme européenne, utilisée conjointement avec l'EN ISO 4254 1 et l'EN 15811, traite de tous les phénomènes dangereux, situations et événements dangereux significatifs (tels qu'énumérés au Tableau 1), relatifs aux plates-formes élévatrices tout terrain pour arboriculture (PEMPA) lorsqu'elles sont utilisées normalement et dans les conditions de mauvais usage prévisible par le fabricant.

Elle ne couvre pas les phénomènes dangereux résultant :

a) de l'utilisation dans des atmosphères explosibles ;

b) de niveaux différents d'accès et de sortie de la plate-forme ;

c) d'aspects liés à l'environnement ;

d) de la sécurité routière.

1.2 La présente Norme européenne ne s'applique pas :

a) aux plates-formes élévatrices mobiles de personnel (PEMP) (voir l'EN 280) ;

NOTE 1 La Figure E.4 présente un exemple de ce type de machine.

b) aux PEMP de type à rampes (voir l'EN 280) ;

NOTE 2 Les Figure E.5 et E.6 présentent un exemple de ce type de machine.

c) aux hayons élévateurs (voir l'EN 1756-1 et l'EN 1756-2) ;

d) aux plates-formes de travail se déplaçant le long de mâts (voir l'EN 1495) ;

e) aux tables élévatrices (voir l'EN 1570-1) ;

f) au matériel au sol pour aéronefs (voir par exemple l'EN 1915-1 et l'EN 1915-2) ;

g) aux postes de conduite élevables des chariots de manutention (voir l'EN ISO 3691-3) ;

h) aux nacelles non guidées, suspendues à des appareils de levage (voir par exemple l'EN 1808) ;

i) aux machines dont le centre de la surface de la plate-forme se trouve hors des lignes de renversement.

NOTE 3 La Figure E.7 présente un exemple de ce type de machine.

Kmetijski stroji - Grobe terenske delovne platforme za dejavnosti v sadovnjakih (WPO) - Varnost

General Information

- Status

- Published

- Publication Date

- 07-Nov-2021

- Technical Committee

- IMKG - Machinery for agriculture and forestry

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 28-Oct-2021

- Due Date

- 02-Jan-2022

- Completion Date

- 08-Nov-2021

Relations

- Effective Date

- 26-May-2021

- Effective Date

- 26-May-2021

Overview

SIST EN 16952:2018+A1:2021 specifies safety requirements for self‑propelled rough‑terrain work platforms for orchard operations (WPO). It covers WPOs that operate up to 3 m platform height, are designed for unimproved or disturbed natural terrain, and are intended to carry at least two persons while performing orchard tasks such as fruit picking, pruning or thinning. The standard describes methods to eliminate or reduce hazards arising during normal operation and service (excluding certain conveyor/elevator hazards) and defines the manufacturer information required for safe use.

Key topics and technical requirements

This type‑C standard (per EN ISO 12100) supplements general agricultural machinery standards and, when different, takes precedence over EN ISO 4254‑1 for machines built to its provisions. Core technical topics include:

- Stability and structural calculations - requirements for tipping lines, chassis inclination and structural strength.

- Chassis and extending structures - design, extension/retraction, position retention and measures to avoid overturning or exceeding stresses.

- Work platform design - platform area, load projection, protective elements and occupant safety.

- Controls and electrical systems - safe control layouts, including provisions for wireless operator stations (Annex C).

- Hydraulic systems and cylinders - structural design, load‑holding and safety devices for hydraulic actuation.

- Safety devices and protective equipment - requirements and verification for guarding, curtains and wear/perforation resistance (Annex B).

- Verification, testing and type tests - design checks, manufacturing checks, tests before placing on the market and validation of safety functions/performance levels.

- Information for use and marking - required instruction handbook content and labels to communicate safe working practices and residual risks.

Annexes provide calculation methods, test examples (kerb test, factor "z"), examples of machines covered/excluded, and relationship to EU Directive 2006/42/EC.

Practical applications - who uses this standard

SIST EN 16952:2018+A1:2021 is essential for:

- Manufacturers of rough‑terrain orchard work platforms to design and certify safe machines.

- Safety engineers and compliance officers ensuring conformity with EU machinery directives.

- Test laboratories and notified bodies conducting type tests and validations.

- Service providers and maintenance teams that need to understand safety devices and hydraulic system requirements.

- Procurement specialists and orchard operators selecting compliant WPOs for safe field operations.

Related standards

- EN ISO 4254‑1 (general safety of agricultural machines) - used together; this WPO standard takes precedence where provisions differ.

- EN 15811 - referenced for additional safety aspects.

Exclusions include MEWPs (EN 280), tail lifts, mast climbers, lifting tables and certain elevating equipment as listed in the scope.

SIST EN 16952:2018+A1:2021 is the definitive reference for safe design, testing and use of rough‑terrain work platforms in orchards, helping reduce risks and support regulatory compliance.

Frequently Asked Questions

SIST EN 16952:2018+A1:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Agricultural machinery - Rough-terrain Work Platforms for Orchard’s operations (WPO) - Safety". This standard covers: 1.1 This European Standard, when used together with EN ISO 4254 1 and EN 15811, specifies safety requirements and measures for self-propelled rough-terrain work platforms for orchard’s operations (WPO) operating at a maximum of 3 m high as defined in 3.1, where the vertical projection of the centre of the area of the platform in all platform configurations at the maximum chassis inclination specified by the manufacturer is always inside the tipping lines, used in agriculture, designed to work on unimproved natural terrain and/or disturbed terrain and intended to move at least two persons to working positions in an orchard where they are carrying out fruit picking, thinning out, pruning, or other operations related to orchard from the work platform. NOTE For examples of rough-terrain work platforms for orchard’s operations (WPO), see Figures E. 1 to E.3. This European Standard describes methods for the elimination or reduction of hazards arising from the intended use of these machines in the course of normal operation and service, except hazards related to conveyor belts and elevators for the bin. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer. When requirements of this document are different from those which are stated in EN ISO 4254 1, the requirements of this document take precedence over the requirements of EN ISO 4254 1 for machines that have been designed and built according to the provisions of this document. This European Standard, taken together with EN ISO 4254 1 and EN 15811, deals with all the significant hazards, hazardous situations and events (as listed in Table 1) relevant to WPOs, when they are used as intended and under the conditions of misuse foreseeable by the manufacturer. It does not cover the hazards arising from: a) use in potentially explosive atmospheres; b) getting on and off the work platform at changing levels; c) environmental aspects; d) road safety. 1.2 This European Standard does not apply to: a) Mobile Elevating Work Platforms (MEWPs) (see EN 280); NOTE 1 Figure E.4 gives an example of this type of machine. b) boom-type MEWPs (see EN 280); NOTE 2 Figure E.5 and E.6 give examples of this type of machine. c) tail lifts (see EN 1756-1 and EN 1756-2); d) mast climbing work platforms (see EN 1495); e) lifting tables (see EN 1570-1); f) aircraft ground support equipment (see e.g. EN 1915-1 and EN 1915-2); g) elevating operator positions on industrial trucks (see EN 1726-2); h) unguided work cages suspended from lifting appliances (see e.g. EN 1808); i) machines having centre of the area of the platform outside the tipping lines. NOTE 3 Figure E.7 gives an example of this type of machine.

1.1 This European Standard, when used together with EN ISO 4254 1 and EN 15811, specifies safety requirements and measures for self-propelled rough-terrain work platforms for orchard’s operations (WPO) operating at a maximum of 3 m high as defined in 3.1, where the vertical projection of the centre of the area of the platform in all platform configurations at the maximum chassis inclination specified by the manufacturer is always inside the tipping lines, used in agriculture, designed to work on unimproved natural terrain and/or disturbed terrain and intended to move at least two persons to working positions in an orchard where they are carrying out fruit picking, thinning out, pruning, or other operations related to orchard from the work platform. NOTE For examples of rough-terrain work platforms for orchard’s operations (WPO), see Figures E. 1 to E.3. This European Standard describes methods for the elimination or reduction of hazards arising from the intended use of these machines in the course of normal operation and service, except hazards related to conveyor belts and elevators for the bin. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer. When requirements of this document are different from those which are stated in EN ISO 4254 1, the requirements of this document take precedence over the requirements of EN ISO 4254 1 for machines that have been designed and built according to the provisions of this document. This European Standard, taken together with EN ISO 4254 1 and EN 15811, deals with all the significant hazards, hazardous situations and events (as listed in Table 1) relevant to WPOs, when they are used as intended and under the conditions of misuse foreseeable by the manufacturer. It does not cover the hazards arising from: a) use in potentially explosive atmospheres; b) getting on and off the work platform at changing levels; c) environmental aspects; d) road safety. 1.2 This European Standard does not apply to: a) Mobile Elevating Work Platforms (MEWPs) (see EN 280); NOTE 1 Figure E.4 gives an example of this type of machine. b) boom-type MEWPs (see EN 280); NOTE 2 Figure E.5 and E.6 give examples of this type of machine. c) tail lifts (see EN 1756-1 and EN 1756-2); d) mast climbing work platforms (see EN 1495); e) lifting tables (see EN 1570-1); f) aircraft ground support equipment (see e.g. EN 1915-1 and EN 1915-2); g) elevating operator positions on industrial trucks (see EN 1726-2); h) unguided work cages suspended from lifting appliances (see e.g. EN 1808); i) machines having centre of the area of the platform outside the tipping lines. NOTE 3 Figure E.7 gives an example of this type of machine.

SIST EN 16952:2018+A1:2021 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment; 65.060.99 - Other agricultural machines and equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16952:2018+A1:2021 has the following relationships with other standards: It is inter standard links to SIST EN 16952:2018, SIST EN 16952:2018/kFprA1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16952:2018+A1:2021 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16952:2018+A1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Kmetijski stroji - Grobe terenske delovne platforme za dejavnosti v sadovnjakih

(WPO) - Varnost

Agricultural machinery - Rough-terrain Work Platforms for Orchard’s operations (WPO) -

Safety

Landmaschinen - Geländearbeitsbühnen für Obstplantagearbeiten (WPO) - Sicherheit

Matériel agricole - Plateformes élévatrices tout terrain pour arboriculture (PEMPA) -

Sécurité

Ta slovenski standard je istoveten z: EN 16952:2018+A1:2021

ICS:

53.020.99 Druga dvigalna oprema Other lifting equipment

65.060.99 Drugi kmetijski stroji in Other agricultural machines

oprema and equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16952:2018+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2021

EUROPÄISCHE NORM

ICS 53.020.99; 65.060.99 Supersedes EN 16952:2018

English Version

Agricultural machinery - Rough-terrain Work Platforms

for Orchard's operations (WPO) - Safety

Matériel agricole - Plateformes élévatrices tout terrain Landmaschinen - Geländearbeitsbühnen für

pour arboriculture (PEMPA) - Sécurité Obstplantagearbeiten (WPO) - Sicherheit

This European Standard was approved by CEN on 18 September 2017 and includes Amendment 1 approved by CEN on 14 June

2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16952:2018+A1:2021 E

worldwide for CEN national Members.

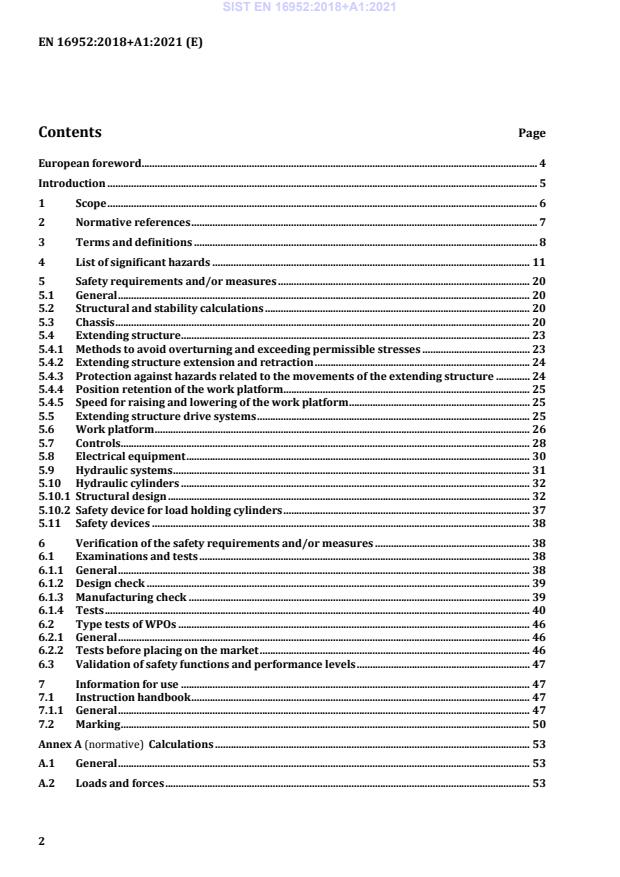

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 8

4 List of significant hazards . 11

5 Safety requirements and/or measures . 20

5.1 General . 20

5.2 Structural and stability calculations . 20

5.3 Chassis . 20

5.4 Extending structure . 23

5.4.1 Methods to avoid overturning and exceeding permissible stresses . 23

5.4.2 Extending structure extension and retraction . 24

5.4.3 Protection against hazards related to the movements of the extending structure . 24

5.4.4 Position retention of the work platform . 25

5.4.5 Speed for raising and lowering of the work platform . 25

5.5 Extending structure drive systems . 25

5.6 Work platform . 26

5.7 Controls . 28

5.8 Electrical equipment . 30

5.9 Hydraulic systems . 31

5.10 Hydraulic cylinders . 32

5.10.1 Structural design . 32

5.10.2 Safety device for load holding cylinders . 37

5.11 Safety devices . 38

6 Verification of the safety requirements and/or measures . 38

6.1 Examinations and tests . 38

6.1.1 General . 38

6.1.2 Design check . 39

6.1.3 Manufacturing check . 39

6.1.4 Tests . 40

6.2 Type tests of WPOs . 46

6.2.1 General . 46

6.2.2 Tests before placing on the market . 46

6.3 Validation of safety functions and performance levels . 47

7 Information for use . 47

7.1 Instruction handbook . 47

7.1.1 General . 47

7.2 Marking . 50

Annex A (normative) Calculations . 53

A.1 General . 53

A.2 Loads and forces . 53

A.3 Determination of loads and forces . 53

A.4 Stability calculations . 57

A.5 Structural calculations . 58

Annex B (normative) Requirements for protective curtains . 65

B.1 General . 65

B.2 Tensile resistance test . 65

B.3 Perforation resistance test . 65

B.4 Wear resistance test . 65

Annex C (normative) Additional requirements for wireless controls and control systems . 66

C.1 General . 66

C.2 Unauthorized use . 66

C.3 Control limitation . 66

C.4 Stop . 66

C.5 Serial data communication . 67

C.6 Use of more than one operator control station . 67

C.7 Battery-powered operator control stations . 67

C.8 Receiver . 67

C.9 Warnings . 67

C.10 Information for use . 67

Annex D (informative) Calculation examples - factor "z", kerb test . 68

Annex E (informative) Examples of Machines . 72

E.1 Examples of Machines covered by the standard. 72

E.2 Examples of Machines excluded from the scope of the standard . 74

Annex ZA (informative) !Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC aimed to be covered" . 78

Bibliography . 82

European foreword

This document (EN 16952:2018+A1:2021) has been prepared by Technical Committee CEN/TC 144

“Tractors and machinery for agriculture and forestry”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2022 and conflicting national standards shall be

withdrawn at the latest by April 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 14 June 2021.

This document supersedes !EN 16952:2018".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as specified in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

Significant hazards that are common to all the agricultural machines (self-propelled, mounted, semi-

mounted and trailed) are dealt with in EN ISO 4254-1.

When provisions of this type C standard are different from those which are stated in type A or B

standards, the provisions of this type C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type C

standard.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

1 Scope

1.1 This European Standard, when used together with EN ISO 4254-1 and EN 15811, specifies safety

requirements and measures for self-propelled rough-terrain work platforms for orchard’s operations

(WPO) operating at a maximum of 3 m high as defined in 3.1, where the vertical projection of the centre

of the area of the platform in all platform configurations at the maximum chassis inclination specified by

the manufacturer is always inside the tipping lines, used in agriculture, designed to work on unimproved

natural terrain and/or disturbed terrain and intended to move at least two persons to working positions

in an orchard where they are carrying out fruit picking, thinning out, pruning, or other operations related

to orchard from the work platform.

NOTE For examples of rough-terrain work platforms for orchard’s operations (WPO), see Figures E.1 to E.3.

This European Standard describes methods for the elimination or reduction of hazards arising from the

intended use of these machines in the course of normal operation and service, except hazards related to

conveyor belts and elevators for the bin. In addition, it specifies the type of information on safe working

practices (including residual risks) to be provided by the manufacturer.

When requirements of this document are different from those which are stated in EN ISO 4254-1, the

requirements of this document take precedence over the requirements of EN ISO 4254-1 for machines

that have been designed and built according to the provisions of this document.

This European Standard, taken together with EN ISO 4254-1 and EN 15811, deals with all the significant

hazards, hazardous situations and events (as listed in Table 1) relevant to WPOs, when they are used as

intended and under the conditions of misuse foreseeable by the manufacturer.

It does not cover the hazards arising from:

a) use in potentially explosive atmospheres;

b) getting on and off the work platform at changing levels;

c) environmental aspects;

d) road safety.

1.2 This European Standard does not apply to:

a) Mobile Elevating Work Platforms (MEWPs) (see EN 280);

NOTE 1 Figure E.4 gives an example of this type of machine.

b) boom-type MEWPs (see EN 280);

NOTE 2 Figure E.5 and E.6 give examples of this type of machine.

c) tail lifts (see EN 1756-1 and EN 1756-2);

d) mast climbing work platforms (see EN 1495);

e) lifting tables (see EN 1570-1);

f) aircraft ground support equipment (see e.g. EN 1915-1 and EN 1915-2);

g) elevating operator positions on industrial trucks (see EN ISO 3691-3);

h) unguided work cages suspended from lifting appliances (see e.g. EN 1808);

i) machines having centre of the area of the platform outside the tipping lines.

NOTE 3 Figure E.7 gives an example of this type of machine.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 349:1993+A1:2008, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

EN 15811:2014, Agricultural machinery - Fixed guards and interlocked guards with or without guard

locking for moving transmission parts (ISO/TS 28923:2012, modified)

EN 60204-1:2006, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016)

EN 60204-32:2008, Safety of machinery - Electrical equipment of machines - Part 32: Requirements for

hoisting machines (IEC 60204-32:2008)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN ISO 4254-1:2015, Agricultural machinery - Safety - Part 1: General requirements (ISO 4254-1:2013)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 14982:2009, Agricultural and forestry machinery - Electromagnetic compatibility - Test methods

and acceptance criteria (ISO 14982:1998)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13849-2:2012, Safety of machinery - Safety-related parts of control systems - Part 2: Validation (ISO

13849-2:2012)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 13857:2008, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2008)

ISO 525:2013, Bonded abrasive products - General requirements

ISO 845:2006, Cellular plastics and rubbers - Determination of apparent density

ISO 3864-1:2011, Graphical symbols - Safety colours and safety signs - Part 1: Design principles for safety

signs and safety markings

ISO 4302:2016, Cranes - Wind load assessment

ISO 4305:2014, Mobile cranes - Determination of stability

ISO 16001:2017, Earth-moving machinery - Object detection systems and visibility aids - Performance

requirements and tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

EN ISO 4254-1:2015 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

rough-terrain work platforms for orchard’s operations (WPO)

self-propelled machine used in agriculture, designed to work on unimproved natural terrain and/or

disturbed terrain, which consists as a minimum of a work platform with controls, an extending structure

and a chassis, where the vertical projection of the center of the area of the platform in all platform

configurations at the maximum chassis inclination specified by the manufacturer is always inside the

tipping lines, for which travelling is allowed with lowered and with raised work platform and it is

controlled from a point of control at the chassis or at the work platform, which is intended to move at

least two persons to working positions in an orchard where they are carrying out fruit picking, thinning

out, pruning, or other operations related to the orchard from the work platform

Note 1 to entry: See Figure 1.

3.2

work platform

fenced platform or a cage which can be moved under load to the required working position and from

which carrying out fruit picking, thinning out, pruning, or other operations related to orchard’s upkeep

can be carried out

Note 1 to entry: See Figure 1.

3.3

platform extension

extension

part of the work platform which can shift laterally in respect of the direction of motion of the WPO, and

which extends the work platform in order to facilitate the approach to the orchard to perform the

necessary operations

3.4

extending structure

structure which is connected to the chassis and supports the work platform. It allows vertical movement

of the work platform to its required position

Note 1 to entry: Example of extending structure: scissors mechanism.

Note 2 to entry: See Figure 1.

3.5

chassis

base of the WPO

Note 1 to entry: See Figure 1.

3.6

access position

position(s) to provide access to and from the work platform

3.7

transport position

position of the elements of the WPO prescribed by the manufacturer in which the WPO is intended to

travel without working on the trees and the extensions are retracted

3.8

lowering

all operations to move the work platform to a lower level

3.9

raising

all operations to move the work platform to a higher level

3.10

self-levelling rough-terrain work platforms for orchard’s operations (self-levelling WPO)

WPO which can compensate variation of terrain slope with variation of work platform’s inclination in

respect of a longitudinal or transversal axis, or both

3.11

rated load

load for which the WPO has been designed for normal operation and which is composed of persons, tools

and products acting vertically on the work platform

Note 1 to entry: A WPO usually has more than one rated load (e.g. for work platform and platform extensions if

any, or for transport and working position).

3.12

load cycle

cycle starting from the access position, carrying out work and returning to the access position

3.13

type test

test on the representative model of a new design or one incorporating significant changes to an existing

design, carried out by or on behalf of the manufacturer or his authorized representative

3.14

load sensing system

system of monitoring the vertical load and vertical forces on the work platform

Note 1 to entry: The system includes the measuring device(s), the way the measuring devices are incorporated

in the machinery and the signal processing system.

3.15

wireless control

means by which the WPO operator’s commands are transmitted without any physical connection for at

least part of the distance between the control console and the rest of the control system

3.16

working space

area in which the work platform is designed to work within the specified loads and forces under normal

operating conditions

Note 1 to entry: WPO usually have more than one working space.

3.17

elevator for the bin

front or rear mounted lifting equipment provided to move the bin from ground to the platform and vice-

versa

Note 1 to entry: Fork lift is a possible elevator for the bin.

Key

1 work platform (see 3.2)

2 extending structure (see 3.4)

3 chassis (see 3.5)

Figure 1 — Illustration of some definitions

3.18

side limit slope

maximum slope in degrees perpendicular to the longitudinal axis of the WPO that can be achieved without

tipping of the WPO

3.19

longitudinal limit slope

maximum slope in degrees with the longitudinal axis of the WPO parallel to the slope that can be achieved

without tipping of the WPO

3.20

maximum lateral operating slope

slope 50 (%) of the side limit slope

3.21

maximum longitudinal operating slope

slope 50 (%) of the longitudinal limit slope

3.22

maximum operating slope

minimum value of the maximum lateral operating slope and the maximum longitudinal operating slope

3.23

automatic mode

form of control of the machine which allows travelling in forward direction without continuous action of

the operator on a dedicated control

4 List of significant hazards

Hazards have been identified by the risk assessment procedure and the corresponding requirements

formulated (see Table 1).

A hazard which is not considered significant and for which, therefore, no requirements are formulated, is

shown in the Corresponding Requirements column as NS (not significant).

Table 1 — List of significant hazards

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.1 Mechanical hazard

A.1.1 Crushing hazard — Controls 4.5.3; 5.1.3.2; 5.1.8; 6.1 5.3.12; 5.4.3.2; 5.6.10;

5.7

— Boarding means 4.7.1.1.2; 4.7.1.2.5; 4.7.2; No requirements in

4.8 addition to those in

EN ISO 4254-1:2015

— Platforms 4.7.2 5.4, 5.5, 5.6

— Power transmission 6.4 5.4

— Working tools 4.10 NS

—Service/maintenance 4.11; 4.17.1; 4.17.3; 5.4.4

4.9.2; 4.9.3

—Roll-over 5.1.2.3; 5.7 5.2; 5.3; 5.4.1; 5.4.2

—Shearing/pinching 5.1.4 5.4.3

points

— Moving the machine 5.2 5.3;

— Stability 6.2 5.2; 5.3; 5.4.1, 5.4.2

— Mounting of machines 6.2.2; 6.2.3; 6.3 5.6.11

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.1.2 Shearing hazard — Controls 4.5.3; 5.1.3.2; 5.1.8; 6.1 5.4.3.2; 5.7

— Boarding means 4.7.1.1.2; 4.7.1.2.5; 4.7.2; No requirements in

4.8 addition to those in

EN ISO 4254-1:2015

— Platforms 4.7.2.2 5.4, 5.5, 5.6

— Power transmission 6.4 5.4

— Working tools 4.10 NS

—Service/maintenance 4.11; 4.17.1; 4.17.3; 5.4.4,

4.9.2; 4.9.3

—Roll-over 5.1.2.3; 5.7 5.2; 5.3; 5.4.1; 5.4.2

—Shearing/pinching 5.1.4 5.4.3

points

— Moving the machine 5.2 5.3

— Stability 6.2 5.2; 5.3; 5.4.1, 5.4.2

— Mounting of machines 6.2.2; 6.2.3; 6.3 5.6.11

A.1.3 Cutting or — Working tools 4.9.2; 4.9.3 NS

severing hazard

A.1.4 Entanglement — Power transmission 6.4 5.3.9

hazard

— Working tools 4.9.2; 4.9.3 NS

— Starting/stopping the 5.1.8 NS

engine

A.1.5 Drawing-in or — Power transmission 6.4 5.4.3; 5.5

trapping hazard

— Working tools 4.9.2; 4.9.3 NS

— Starting/stopping the 5.1.8 NS

engine

A.1.6 Impact hazard — Boarding means 4.7.1.2.5 5.1; 5.6.3

— Folding elements 4.9.2; 4.9.3 5.6

— Steering 5.1.3.1 NS

A.1.7 Stabbing or — Working tools 4.9.2; 4.9.3 NS

puncture hazard

A.1.8 Friction or — Controls 4.5.3; 5.1.3.2 5.7.7

abrasion hazard

— Electrical equipment 4.12 5.8.4

— Boarding means 4.7.1.1.2 No requirements in

addition to those in

EN ISO 4254-1:2015

A.1.9 High-pressure — Hydraulic components 4.13; 6.5 5.9; 5.10

fluid injection or

ejection hazard

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.2 Electrical hazards

A.2.1 Contact of — Electrical equipment 4.12; 5.3; 6.5 5.8

persons with live

parts

(direct contact)

A.2.2 Contact of — Electrical equipment 4.12.1 5.8

persons with

parts which

have become

live under fault y

conditions

(indirect

contact)

A.2.3 Approach to — Overhead power lines 8.2.3; 8.3.4 No requirements in

live parts addition to those in

under high EN ISO 4254-1:2015

voltage

A.2.4 Thermal — Electrical equipment 4.12.2; 5.3.1 5.8

radiation or

other

phenomena

such as the

projection of

molten particles

and chemical

effects from

short circuits,

overloads, etc.

A.2.5 Electromagnetic — Electrical equipment 4.18 5.8.6

phenomena

A.3 Thermal hazards

Burns, scalds — Operating fluids 4.15 5.3.10

and other

injuries by

possible contact

of persons with — Cab material 5.1.6 5.6.2

objects or

materials with

an extreme high

or low

— Hot surfaces 5.5 No requirements in

temperature, by

addition to those in

f lames

EN ISO 4254-1:2015

or explosions

and also by the

radiation of

heat sources

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.4 Hazards generated by noise

Hearing loss — Noise 4.3 No requirements in

(deafness), addition to those in

other EN ISO 4254-1:2015

physiological

disorders (e.g.

loss of balance,

loss of

awareness)

Accidents due to

interference

with speech

communication

and acoustic

warning signals

A.5 Vibration hazards

A.5.1 Discomfort, low- — Machine design 4.4 5.6.9;

back morbidity

— Seat 5.1.2 NS

A.6 Hazards generated by materials and substances

A.6.1 Hazards from — Operating fluids 4.15; 5.4 5.9; 5.10

contact with, or

inhalation, of

— Cab material 5.1.6 NS

harmful fluids,

gases, mists, — Battery 5.3.1 5.3.13;

fumes and

— Exhaust gases 5.6 5.3.10

dusts

A.6.2 Fire or explosion — Cab material 5.1.6 NS

hazard

A.7 Hazards generated by neglecting ergonomic principles in machinery design

A.7.1 Unhealthy — Controls 4.5 5.7.1 letter b

postures or

excessive

effort — Boarding means 4.7; 4.8 5.6.3

— Service and 4.11; 4.17.4 NS

maintenance

— Operator station 5.1.1; 5.1.3; 5.1.5.2 5.6.2

A.7.2 Inadequate — Controls 4.5 NS

consideration of

hand–

— Boarding means 4.7; 4.8 NS

arm or foot–leg

anatomy

— Operator station 5.1 NS

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.7.3 Neglected use of — Operator’s manual 8.2.3 NS

personal

protective

equipment

A.7.4 Inadequate local — Visibility 5.1.7. 3 NS

lighting

A.7.5 Mental overload — Controls 4.5 NS

and under load,

stress

A.7.6 Human error, — Controls 4.5 5.7

human

behaviour

— Operator’s manual 8.2 7.1

— Signs 8.3 7.2

A.7.7 Inadequate — Controls 4.5; 5.1.3; 6.1 5.7

design, location

or identification

manual controls

A.8 Combination of — Individual assemblies 4.16 No requirements in

hazards addition to those in

EN ISO 4254-1:2015

— Operator’s manual 8.1; 8.2 7.2

A.9 Unexpected start-up, unexpected overrun/overspeed

A.9.1 Failure/disorder — Service and 4.11 No requirements in

of the control maintenance addition to those in

EN ISO 4254-1:2015

system

— Electrical equipment 4.12 5.11

— Connections 6.5 5.8

A.9.2 Restoration of — Controls 4.5; 6.1 5.7

energy supply

after

an interruption

A.9.3 External — Cables 4.12.1 5.8

influences on

electrical

equipment

A.9.4 Other external — Stability 6.2.1.1; 6.2.1.2 5.4.1

influences

(gravity, wind,

etc.)

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.9.5 Errors made by — Controls 4.5; 6.1.2 5.7

the operator

(due to

— Boarding means 4.7; 4.8 NS

mismatch of

machinery with

human

— Operator station 5.1 NS

characteristics

and abilities

— Moving the machine 5.2 No requirements in

addition to those in

EN ISO 4254-1:2015

— Mounting of machines 6.2; 6.3 5.6.11

— Service and 4.17 No requirements in

maintenance addition to those in

EN ISO 4254-1:2015

— Operator’s manual 8.2.3 7.2

A.10 Impossibility of — Controls 4.5; 4.19; 6.1 5.3; 5.5; 5.7

stopping the

machine in the

best possible

— Starting/stopping the 5.1.8

conditions

engine

A.11 Variations in — PTO drive shaft 6.4; 8.1; 8.2 NS

the rotational

speed of tools

A.12 Failure of power — Supports 4.11 5.5

supply

— Electrical equipment 4.12 5.8

— Connections 6.5 No requirements in

addition to those in

EN ISO 4254-1:2015

- Others 5.7.6, 5.7.8

A.13 Failure of the — Electrical equipment 4.12; 4.20 5.11

control circuit

A.14 Errors of fitting — Mounting of machines 6.2; 6.3 5.6.11

— Operator’s manual 8.1; 8.2 7.2

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.15 — Guards and barriers 4.10 5.6;

Break-up during

operation

— Supports 4.11 5.4.1

— Hydraulic components 4.13 5.9

— Pneumatic components 4.14 No requirements in

addition to those in

EN ISO 4254-1:2015

A.16 Falling or ejected — Supports 4.11 NS

objects or fluids

— Hydraulic components 4.13 5.9

— Folding elements 4.9.2; 4.9.3 NS

A.17 Loss of — Stability 6.2 5.2; 5.3; 5.4; 5.6

stability/ov

erturning of

— Roll-over 5.1.2.3; 5.7 5.2; 5.3; 5.4; 5.6

machinery

A.18 Slip, trap and — Boarding means 4.7; 4.8 5.6

fall of persons

(related to

machinery)

Additional hazards, hazardous situations and hazardous events due to mobility

A.19 Related to the travelling function

A.19.1 Movement when — Propulsion of machine 5.1.2.3 No requirements in

starting the addition to those in

engine EN ISO 4254-1:2015

— Starting/stopping the 5.1.8 5.7.7

engine

A.19.2 Moving without — Propulsion of machine 5.1.3 5.7.1

a driver at the

driving position

— Starting/stopping the 5.1.8 5.3.6

engine

A.19.3 Movement — Folding elements 4.9.2; 4.9.3 5.3

without all parts

in a safe

position

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.19.4 Insufficient — Propulsion of machine 5.1.3 5.3

ability of

machinery to

be slowed

down,

stopped and

immobilized

A.20 Link to the work position

A.20.1 Fall of persons — Boarding means 4.7; 4.8 5.1; 5.6

during access

to (or at/from)

the work

position

A.20.2 Exhaust — Gases 5.4.1; 5.6 5.3.9

gases/lack of

oxygen at the

work position

A.20.3 Fire — Cab material 5.1.6 5.6.2

(flammability of

the cab, lack of

extinguishing

means)

A.20.4 Mechanical — Shearing/pinching 4.5.3; 4.7. 1.2.5; 5.1.4 NS

hazards at the points

working

position:

— Wheels 4.7.1.1.2 NS

a) contact with

wheels;

— PTO drive shaft 4.8.2.3 NS

b) rollover;

c) fall of objects,

penetration by

— Supports 4.11 NS

objects;

— Roll-over 5.1.2.3; 5.7 NS

A.20.5 Insufficient — Visibility 5.1.7 5.3.1

visibility from

the work

positions

A.20.6 Inadequate — Visibility 5.1.7. 3 NS

lighting

A.20.7 Inadequate — Operator’s seat 5.1.2 NS

seating

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.20.8 Noise at work — Operator’s work station 4.3 5.1

position

A.20.9 Insufficient — Emergency exit 5.1.5 5.7.7

means for

evacuation/

emergency exit

A.21 Due to the control system

A.21.1 Inadequate — Controls 4.5; 4.11.1.2; 5.1.2.1; 5.7

location of 6.1.1; 6.1.2

manual

controls

A.21.2 Inadequate — Controls 4.5; 5.1.3; 5.1.8 5.7; 5.11

design of

manual con-

trols and their

mode of

operation

A.22 From handling — Stability 6.2 5.3; 5.4; 5.7

the machine

(lack of

— Roll-over 5.1.2.3; 5.7 5.3; 5.4; 5.7

stability)

A.23 Due to the power source and to the transmission of power

A.23.1 Hazards from the — Starting/stopping the 5.1.8 5.7.7;

engine and the engine

batteries

— Battery 5.3 5.3

A.23.2 Hazards from — Power transmission 6.4 No requirements in

transmission addition to those in

power EN ISO 4254-1:2015

between

machines

A.23.3 Hazards from — Mounting of machines 6.2.2; 6.2.3; 6.3 5.3.4

coupling and

towing

Hazardous situation Clause/subclause of Clause/subclause of

a

Hazard

No.

and event EN ISO 4254-1:2015 this Standard

A.24 From/to third persons

A.24.1 Unauthorized — Starting/stopping the 5.1.8.1 5.3.6

start-up and use engine

A.24.2 Lack or — Visibility 5.1.7 5.3.1

inadequacy of

visual or

acoustic warning

means

A.25 Insufficient — Operator’s manual 8.1; 8.2 7.1; 7.2

instructions for

the

driver/operator

a

With reference to EN ISO 4254-1:2015, Table A.1.

5 Safety requirements and/or measures

5.1 General

The WPO shall be in accordance with the safety requirements and/or protective measures of this clause.

In addition, the WPO shall be designed according to the principles of EN ISO 12100, for hazards relevant,

but not significant, which are not dealt with by this document.

Unless otherwise specified in this European Standard, the machine shall comply with the requirements

of EN ISO 4254-1.

Means of access from the ground level to the work platform when lowered shall be provided.

5.2 Structural and stability calculations

Structural and stability calculations shall be performed according to Annex A.

5.3 Chassis

5.3.1 An audible alarm shall start when the machine starts to travel in reverse direction and shall last

as long as the machine travels in reverse direction or a rear view camera according to ISO 16001 shall be

provided, with which the danger zone behind the machine can be in clear view of the operator.

5.3.2 Every WPO shall have an easily identifiable visual and acoustic signal clearly perceivable at least

by the driver to indicate that the inclination of the machine in any direction is approaching the maximum

operating slope given in the manufacturer's instruction handbook.

The triggering of the visual and acoustic signal shall be preferably performed in a graduated manner. At

least, the visual signal shall be triggered at 70% of the maximum operating slope and the acoustic signal

shall reach full intensity at 90% of the maximum operating slope.

When travelling out of the transport position the maximum operating slope given in the manufacturer's

instruction handbook and determined according to 6.1.4.2 is reached, the WPO shall have a device that

stops automatically the WPO and restart of travelling and any other movement which leads to further

instability shall be prevented. A tolerance of ±10% of the maximum operating slope is allowed.

Movements to reduce instability shall be permitted. Restart of travelling and other movements shall be

allowed only when stability is ensured again and after an intentional action by the operator. The device

shall be constructed to meet the requirements of 5.11.

5.3.3 Any locking elements shall be secured against unintentional disengagement and loss.

5.3.4 All WPOs shall be equipped with service brakes on at least two wheels on the same axis.

In addition, all WPOs shall be equipped with brakes on at least two wheels on the same axis which

— shall engage automatically when power to the brakes is removed or fails,

and

— shall engage automatically when the travel drive is in neutral position,

and

— shall be able to stop the WPO in accordance with 5.3.8 and keep it in stopped position,

and

— shall not rely on hydraulic or pneumatic pressure or electric power to remain engaged.

These brakes also act as parking brakes and shall be tested according to 6.1.4.2.6.3.

Brakes shall be designed taking into account the environment and the normal use of a WPO in an orchard

in order to avoid unexpected deterioration (e.g. due to frost, humidity).

For attaching of a tow bar a coupling device shall be provided.

Attachment points for tying down shall be provided; if specified by the manufacturer, the wheels axles of

the machine can be used as attachment points for tying down.

For towing the machine in case of a failure, provisions shall be available (e.g. a means of releasing an

automatically applied brake).

5.3.5 WPOs shall be stable during travelling both in transport and extended position. The extended

position shall be verified as specified in 6.1.4.2.

WPOs shall also be stable while travelling on a horizontal surface in all working positions. This

requirement is met if the WPO does not become unstable during the kerb and depression tests

(6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...