SIST EN 13160-2:2003

(Main)Leak detection systems - Part 2: Pressure and vacuum systems

Leak detection systems - Part 2: Pressure and vacuum systems

This standard specifies the requirements for leak detection systems - class I for use with double-skin systems, designed for water polluting fluids.

Leckanzeigesysteme - Teil 2: Über- und Unterdrucksysteme

Diese Europäische Norm legt die Anforderungen an Leckanzeigesysteme der Klasse I, die für den Einsatz an doppelwandigen Systemen für wassergefährdende Stoffe bestimmt sind, fest.

Systemes de détection de fuites - Partie 2: Systemes en pression et en dépression

La présente Norme européenne spécifie les prescriptions relatives aux systèmes de détection de fuites de classe I pour une utilisation avec des systèmes à double paroi, conçus pour des liquides polluant l'eau.

Sistemi za kontrolo tesnosti - 2. del: Tlačni in vakuumski sistemi

General Information

- Status

- Withdrawn

- Publication Date

- 30-Nov-2003

- Withdrawal Date

- 09-Oct-2016

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 07-Oct-2016

- Due Date

- 30-Oct-2016

- Completion Date

- 10-Oct-2016

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Nov-2016

Frequently Asked Questions

SIST EN 13160-2:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Leak detection systems - Part 2: Pressure and vacuum systems". This standard covers: This standard specifies the requirements for leak detection systems - class I for use with double-skin systems, designed for water polluting fluids.

This standard specifies the requirements for leak detection systems - class I for use with double-skin systems, designed for water polluting fluids.

SIST EN 13160-2:2003 is classified under the following ICS (International Classification for Standards) categories: 23.020.01 - Fluid storage devices in general; 23.160 - Vacuum technology. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13160-2:2003 has the following relationships with other standards: It is inter standard links to SIST EN 13160-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13160-2:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 73/23/EEC, 89/106/EEC, 92/31/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13160-2:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.LLeckanzeigesysteme - Teil 2: Über- und UnterdrucksystemeSystemes de détection de fuites - Partie 2: Systemes en pression et en dépressionLeak detection systems - Part 2: Pressure and vacuum systems23.160Vakumska tehnologijaVacuum technology23.020.01Fluid storage devices in generalICS:Ta slovenski standard je istoveten z:EN 13160-2:2003SIST EN 13160-2:2003en,fr,de01-december-2003SIST EN 13160-2:2003SLOVENSKI

STANDARD

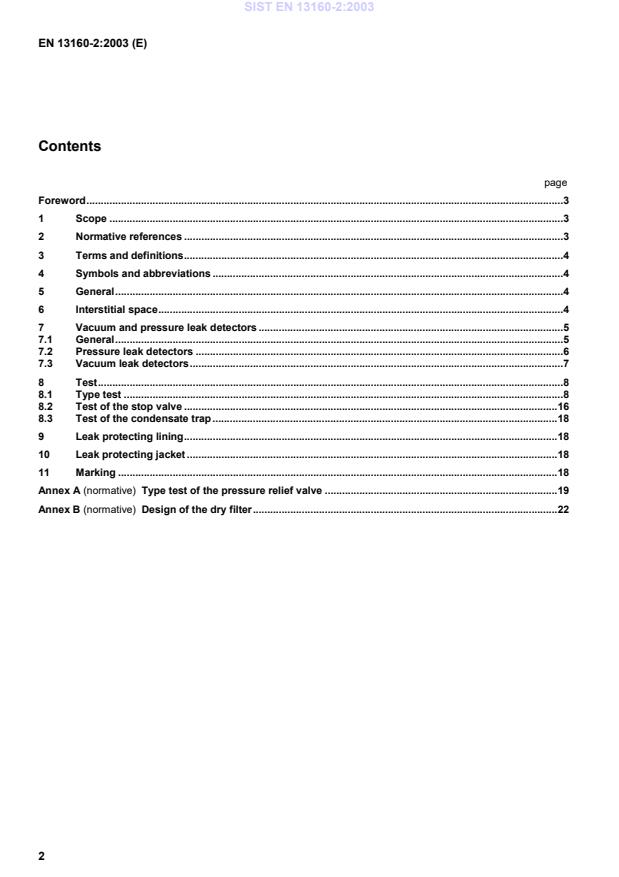

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13160-2May 2003ICS 23.020.01; 23.040.99; 29.260.20English versionLeak detection systems - Part 2: Pressure and vacuum systemsSystèmes de détection de fuites - Partie 2: Systèmes enpression et en dépressionLeckanzeigesysteme - Teil 2: Über- undUnterdrucksystemeThis European Standard was approved by CEN on 10 March 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13160-2:2003 ESIST EN 13160-2:2003

Type test of the pressure relief valve.19Annex B (normative)

Design of the dry filter.22SIST EN 13160-2:2003

8 m3 ; for pipes with an interstitial space volume

10 m3.SIST EN 13160-2:2003

50 m for an inner diameter of the interconnecting line of 6 mm.The leak detector-to-interstitial space interconnecting lines shall be colour-coded as follows: measuring line:red suction and pressure line:white or clear exhaust line: green.A vacuum leak detector shall only serve one tank or pipework.A pipework may consist of several sections of a pipework where the interstitial spaces are connected.In the alarm pressure a leak detector shall deliver a volume flow of (85 ± 15) l/h, see Figure 1.SIST EN 13160-2:2003

h

g + p0 (1)pAE = 3000 Pa + G

hG

g

(2)SIST EN 13160-2:2003

) - Pa 100000 - Pa 100000 - (1AEPApp = V

in %(3)Due to the alarm pressure pAE the interstitial space is filled (in the case of a leak) up to the height h1 compared withthe lowest point of the tank, see Equation (4):GAE1PAE1

=

or

= gphgph (4)Under consideration of tank geometry the volume of the interstitial space V1 at filling height h1 has to be determinedby calculation (or by measurement in litres), see EN 13160-7.The alarm is considered reliable, if the following condition is fulfilled, see Equation (5):VV < V01 (5)NOTEThe above mentioned calculation would be carried out for tanks with a suction line down to the lowest point of theinterstitial space. An analog application is required for tanks without a suction line or for pipework, i. e. the line of reference forthe height h1 is the horizontal line through the lowest point, at which the suction line is connected with or ends in the interstitialSIST EN 13160-2:2003

g

h(6) 3 kPa, if the evacuating line in the interstitial space is led down to the lowest point; 25 kPa for flat-bottom tanks with double bottom.In the suction line a liquid operated or sensor operated device (stop valve) shall be fitted as near as possible to thetank, which in case of suction of liquid avoids further evacuating of the interstitial space and prevents penetrating ofliquid in the leak detector.7.3.4Vacuum leak detectors without integrated vacuum generatorFor the application of these systems the following conditions shall be fulfilled: a suction line (for the vacuum pump to be installed outside) which shall be led down to the lowest point of theinterstitial space; or at above-ground tanks, as an alternative, a control nozzle may be installed at the lowest point of the interstitialspace.The vacuum pressure (relative value) in the alarm control point shall be at least 35 kPa.The vacuum pressure (relative value) of the operating pressure shall be at least 70 kPa.To avoid false alarm the alterations in pressure due to temperature shall be considered when determining theswitching points.8 Test8.1 Type test8.1.1Test objectiveThe testing of the leak detection systems shall prove that the presented systems are able to indicate any leak in theinternal and in the external wall of the tank or pipe below the maximum filling level under all working conditions.The tests shall be deemed to have been passed where: the function in the indicated pressure range in view of the temperature range is ensured; the system also works in a longer period of time reliably.The following tests shall be carried out: function test; test of the reliability.SIST EN 13160-2:2003

2 s time delay; the pump capacity of the leak detector is PAE = (80 ± 15) l/h at the alarm setting; the device or the components do not fail during the load tests.SIST EN 13160-2:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...