SIST EN 17003:2022

(Main)Road vehicles - Roller brake testers for vehicles of more than 3,5 tons GVW - Safety requirements

Road vehicles - Roller brake testers for vehicles of more than 3,5 tons GVW - Safety requirements

This document applies to roller brake testers (brake test benches) that are designed for roadworthiness tests on categories M2, M3, N2, N3, O3 and O4 vehicles (as defined in Regulation (EU) 2018/858) and that might be also used to test M1, N1 categories.

This document covers fixed-bed roller brake testers with or without inspection pits and whose chassis are inside or outside the building.

This document does not cover mobile roller or plate brake testers.

These roller brake testers are used to take measurements for testing and assessing the efficiencies of the brake systems fitted to vehicles in the above-cited vehicle categories.

The users of the roller brake tester are all kinds of staff that for any reason operate the roller brake testers (e.g. staff working in public transport, vehicle rental, vehicle maintenance, vehicle repair, training, test laboratories and vehicle inspection sectors ...). This document is not applicable to roller brake testers manufactured before the date of its publication.

Straßenfahrzeuge - Rollen-Bremsprüfstände für Fahrzeuge mit zulässigem Gesamtgewicht größer als 3,5 Tonnen - Sicherheitsanforderungen

Dieses Dokument ist anwendbar auf Rollen-Bremsprüfstände (Bremsprüfstände), die für Verkehrssicherheitsprüfungen an Fahrzeugen der Kategorien M2, M3, N2, N3, O3 und O4 (wie in der Verordnung (EU) 2018/858 definiert) entwickelt wurden und die auch zur Prüfung der Kategorien M1, N1 verwendet werden könnten.

Dieses Dokument deckt Festbett-Rollen-Bremsprüfstände mit oder ohne Inspektionsgrube ab und solche, deren Chassis innerhalb oder außerhalb des Gebäudes liegen.

Dieses Dokument deckt keine mobilen Bremsprüfstände oder Platten-Bremsprüfstände ab.

Diese Bremsprüfstände werden für Messungen verwendet, die der Prüfung und Bewertung des Wirkungsgrades von Bremssystemen dienen, mit denen Fahrzeuge der oben genannten Kategorien ausgestattet sind.

Die Anwender der Rollen-Bremsprüfstände sind jegliche Art von Personal, das die Bremsprüfstände bedient (z. B. Personal bei öffentlichen Verkehrsmitteln, bei Fahrzeugvermietungen, bei Fahrzeuginstandhaltungs- und Reparaturwerkstätten, in Ausbildungsstätten, in Prüflaboren und auf dem Gebiet der Fahrzeuginspektion, ...). Dieses Dokument ist nicht anwendbar für Rollen-Bremsprüfstände, die vor der Veröffentlichung dieses Dokuments hergestellt wurden.

Véhicules routiers - Freinomètres à rouleaux pour véhicules supérieurs à 3,5 t - Exigences de sécurité

Le présent document s'applique aux freinomètres à rouleaux (bancs d'essais de freinage) conçus pour des essais de contrôle technique pour les catégories de véhicules M2, M3, N2, N3, O3 et O4 (conformément au Règlement (EU) 2018/858) et qui pourraient également être utilisés pour soumettre à essai les catégories M1 et N1.

Le présent document couvre les freinomètres à rouleaux, fixes, associés ou non à des fosses de visite et dont les châssis sont installés à l’intérieur ou à l’extérieur d’un bâtiment.

Le présent document ne couvre pas les freinomètres à rouleaux mobiles ou à plaques.

Ces freinomètres à rouleaux sont utilisés pour prendre des mesures afin de contrôler et d’évaluer l’efficacité des dispositifs de freinage des véhicules des catégories précitées.

Les utilisateurs des freinomètres à rouleaux sont tous les types de personnel qui, pour une raison ou une autre, utilisent ces freinomètres (par exemple, personnel des activités de transport, de location de véhicules, de maintenance, de réparation, de formation, de laboratoires d’essais et de contrôle technique). Le présent document ne s’applique pas aux freinomètres à rouleaux fabriqués avant sa date de publication.

Cestna vozila - Valjasti preskuševalniki zavor za vozila z nosilnostjo nad 3,5 t - Varnostne zahteve

Ta evropski standard se uporablja za valjaste preskuševalnike zavor (preskusne mize), zasnovane za tehnične preglede vozil v kategorijah M2, M3, N2, N3, O3 in O4, ki se lahko uporabljajo tudi za preskušanje kategorij M1 in N1.

Ta evropski standard zajema fiksne valjaste preskuševalnike zavor z jaškom za preglede oziroma brez njega, pri katerih je ohišje znotraj ali zunaj stavbe.

Ta evropski standard ne zajema premičnih valjastih preskuševalnikov zavor.

Valjasti preskuševalniki zavor so nameščeni za izvajanje meritev za preskušanje in ocenjevanje učinkovitosti zavornih sistemov, s katerimi so opremljena vozila v zgoraj navedenih kategorijah.

Uporabnik valjastega preskuševalnika zavor je katero koli osebje, ki iz kakršnega koli razloga upravlja valjaste preskuševalnike zavor (npr. osebje, ki dela na področju javnega prevoza, najema, vzdrževanja in popravila vozil, usposabljanja, v preskusnem laboratoriju, na področju preverjanja vozil itd.).

Ta dokument se uporablja za valjaste preskuševalnike zavor, izdelane 12 mesecev po datumu njegove objave kot standard EN.

General Information

- Status

- Published

- Public Enquiry End Date

- 15-Sep-2016

- Publication Date

- 24-Nov-2021

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 24-Nov-2021

- Due Date

- 29-Jan-2022

- Completion Date

- 25-Nov-2021

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

SIST EN 12464-1:2021 - Light and lighting - Lighting of work places - Part 1: Indoor work places - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 17003:2021 - published by CEN - specifies safety requirements for roller brake testers (brake test benches) intended for roadworthiness testing of vehicles with more than 3.5 t GVW (categories M2, M3, N2, N3, O3 and O4 as per Regulation (EU) 2018/858). The standard applies to fixed-bed roller brake testers, with or without inspection pits, and covers installations where the chassis can be inside or outside the building. It excludes mobile roller/plate testers and equipment manufactured before publication.

Key topics and technical requirements

- Safety functions and risk reduction: definition of required protections to prevent contact with moving parts and reduce trapping hazards.

- Protection of chassis/pit zones: measures for guarding access around rollers and inspection pits (including light curtains, covers and installation rules) are covered in informative and normative annexes.

- Axle presence detection: requirements for reliable detection of vehicle axles before tester operation to avoid unintended movement.

- Control console and operating modes: safe placement, operator controls, start-up behaviour, calibration and maintenance modes.

- Emergency stop & re-engagement: mandatory emergency stop functions and procedures for safe re-start after interruption.

- Electrical and EMC requirements: conformity and electromagnetic compatibility expectations for installed equipment.

- Noise and exhaust emission tests: Annex E provides noise test code and guidance on measuring A‑weighted sound pressure at workstations and on documenting exhaust emissions during testing.

- Verification, inspection and documentation: requirements for verification of safety specifications, marking, instructions for use, installation, acceptance testing, maintenance and end-of-life disposal.

- Performance level determination: Annex D explains assessment of safety performance levels for critical functions.

Applications and users

EN 17003 is practical for:

- Manufacturers and integrators of fixed roller brake testers

- Vehicle inspection stations, MOT test centres and technical testing laboratories

- Public transport operators, vehicle rental and fleet maintenance organizations

- Vehicle repair shops, training centers and safety/regulatory bodies

Use cases include ensuring safe installation, commissioning, operator training, maintenance regimes, and compliance for equipment used in roadworthiness testing of heavy vehicles.

Related standards and regulatory links

- EN ISO 12100 (machine safety / risk assessment principles)

- Directive 2006/42/EC (machinery directive) - see Annex ZA relation

- Regulation (EU) 2018/858 (vehicle categories referenced)

- CEN technical committee CEN/TC 301 (road vehicles)

EN 17003:2021 is essential for stakeholders aiming to meet recognised safety requirements for roller brake testers, reduce operational risk and support compliant roadworthiness testing of heavy vehicles.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

SIST EN 17003:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Road vehicles - Roller brake testers for vehicles of more than 3,5 tons GVW - Safety requirements". This standard covers: This document applies to roller brake testers (brake test benches) that are designed for roadworthiness tests on categories M2, M3, N2, N3, O3 and O4 vehicles (as defined in Regulation (EU) 2018/858) and that might be also used to test M1, N1 categories. This document covers fixed-bed roller brake testers with or without inspection pits and whose chassis are inside or outside the building. This document does not cover mobile roller or plate brake testers. These roller brake testers are used to take measurements for testing and assessing the efficiencies of the brake systems fitted to vehicles in the above-cited vehicle categories. The users of the roller brake tester are all kinds of staff that for any reason operate the roller brake testers (e.g. staff working in public transport, vehicle rental, vehicle maintenance, vehicle repair, training, test laboratories and vehicle inspection sectors ...). This document is not applicable to roller brake testers manufactured before the date of its publication.

This document applies to roller brake testers (brake test benches) that are designed for roadworthiness tests on categories M2, M3, N2, N3, O3 and O4 vehicles (as defined in Regulation (EU) 2018/858) and that might be also used to test M1, N1 categories. This document covers fixed-bed roller brake testers with or without inspection pits and whose chassis are inside or outside the building. This document does not cover mobile roller or plate brake testers. These roller brake testers are used to take measurements for testing and assessing the efficiencies of the brake systems fitted to vehicles in the above-cited vehicle categories. The users of the roller brake tester are all kinds of staff that for any reason operate the roller brake testers (e.g. staff working in public transport, vehicle rental, vehicle maintenance, vehicle repair, training, test laboratories and vehicle inspection sectors ...). This document is not applicable to roller brake testers manufactured before the date of its publication.

SIST EN 17003:2022 is classified under the following ICS (International Classification for Standards) categories: 43.180 - Diagnostic, maintenance and test equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17003:2022 has the following relationships with other standards: It is inter standard links to SIST EN ISO 13850:2016, SIST EN 614-1:2006+A1:2009, SIST EN ISO 12100:2011, SIST EN 12464-1:2021, SIST EN ISO 11688-1:2009, SIST EN ISO 4871:2009, SIST EN 614-2:2001+A1:2008, SIST EN ISO 13849-1:2016, SIST EN ISO 14120:2016, SIST EN ISO 11201:2010, SIST EN ISO 14122-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 17003:2022 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17003:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2022

Cestna vozila - Valjasti preskuševalniki zavor za vozila z nosilnostjo nad 3,5 t -

Varnostne zahteve

Road vehicles - Roller brake testers for vehicles of more than 3,5 tons GVW - Safety

requirements

Straßenfahrzeuge - Rollen-Bremsprüfstände für Fahrzeuge mit zulässigem

Gesamtgewicht größer als 3,5 Tonnen - Sicherheitsanforderungen

Véhicules routiers - Freinomètres à rouleaux pour véhicules supérieurs à 3,5 t -

Exigences de sécurité

Ta slovenski standard je istoveten z: EN 17003:2021

ICS:

43.180 Diagnostična, vdrževalna in Diagnostic, maintenance and

preskusna oprema test equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17003

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2021

EUROPÄISCHE NORM

ICS 43.180

English Version

Road vehicles - Roller brake testers for vehicles of more

than 3,5 tons GVW - Safety requirements

Véhicules routiers - Freinomètres à rouleaux pour Straßenfahrzeuge - Rollen-Bremsprüfstände für

véhicules supérieurs à 3,5 t - Exigences de sécurité Fahrzeuge mit zulässigem Gesamtgewicht größer als

3,5 Tonnen - Sicherheitsanforderungen

This European Standard was approved by CEN on 13 September 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17003:2021 E

worldwide for CEN national Members.

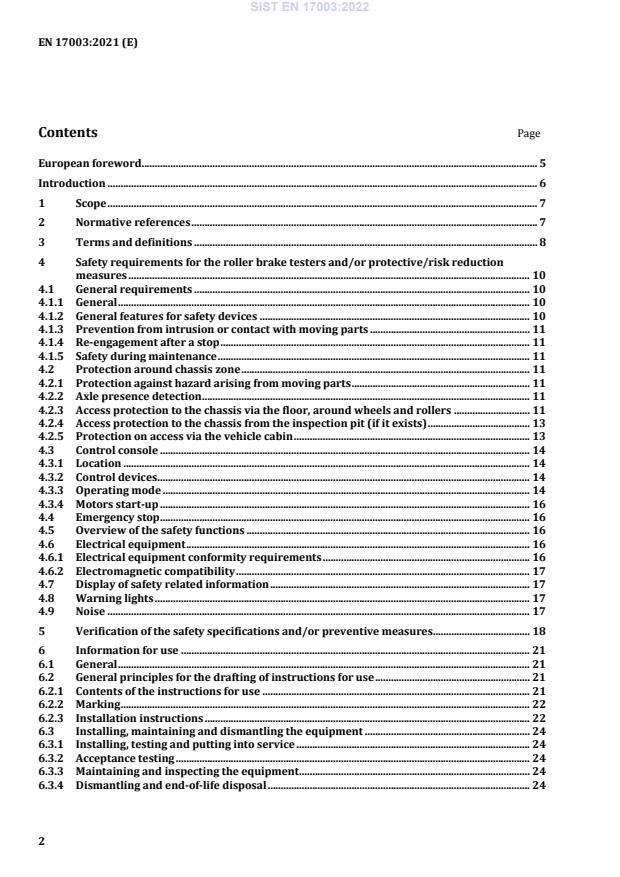

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Safety requirements for the roller brake testers and/or protective/risk reduction

measures . 10

4.1 General requirements . 10

4.1.1 General . 10

4.1.2 General features for safety devices . 10

4.1.3 Prevention from intrusion or contact with moving parts . 11

4.1.4 Re-engagement after a stop . 11

4.1.5 Safety during maintenance . 11

4.2 Protection around chassis zone . 11

4.2.1 Protection against hazard arising from moving parts . 11

4.2.2 Axle presence detection . 11

4.2.3 Access protection to the chassis via the floor, around wheels and rollers . 11

4.2.4 Access protection to the chassis from the inspection pit (if it exists) . 13

4.2.5 Protection on access via the vehicle cabin . 13

4.3 Control console . 14

4.3.1 Location . 14

4.3.2 Control devices . 14

4.3.3 Operating mode . 14

4.3.4 Motors start-up . 16

4.4 Emergency stop . 16

4.5 Overview of the safety functions . 16

4.6 Electrical equipment . 16

4.6.1 Electrical equipment conformity requirements . 16

4.6.2 Electromagnetic compatibility . 17

4.7 Display of safety related information . 17

4.8 Warning lights . 17

4.9 Noise . 17

5 Verification of the safety specifications and/or preventive measures . 18

6 Information for use . 21

6.1 General . 21

6.2 General principles for the drafting of instructions for use . 21

6.2.1 Contents of the instructions for use . 21

6.2.2 Marking . 22

6.2.3 Installation instructions . 22

6.3 Installing, maintaining and dismantling the equipment . 24

6.3.1 Installing, testing and putting into service . 24

6.3.2 Acceptance testing . 24

6.3.3 Maintaining and inspecting the equipment . 24

6.3.4 Dismantling and end-of-life disposal . 24

Annex A (informative) Trapping zone . 25

Annex B (normative) Definition and protection of the pit hazard zone . 26

B.1 General . 26

B.2 Means of protection . 26

B.2.1 General . 26

B.2.2 Protection by light curtain . 26

B.2.3 Protection by a covering . 29

B.3 Installation of protection means . 30

B.3.1 Roller brake tester installed over a pit . 30

B.3.2 Roller brake tester installed after the pit . 30

B.3.3 Roller brake tester installed before the pit. 31

B.3.4 Installation height of light curtains . 31

Annex C (informative) Examples of access protection to the chassis via the floor, around

wheels and rollers . 33

C.1 General . 33

C.2 Opto-electronic device . 33

..................................................................................................... 36

Annex D (informative) Determination of PLr

D.1 General . 36

D.2 Axle presence detection function . 36

D.3 Pit presence detection function . 36

D.4 Deadman switch mode selector. 36

D.5 Calibration mode selector . 36

D.6 Emergency stop . 37

Annex E (normative) Noise and vehicle exhaust emissions . 38

E.1 Noise test code for roller brake tester . 38

E.1.1 Introduction. 38

E.1.2 Determination of the A-weighted emission sound pressure level at workstation(s) . 38

E.1.2.1 Measurement procedure . 38

E.1.2.2 Measurement positions . 38

E.1.2.3 Measurement uncertainty . 39

E.1.3 Mounting and operating conditions. 39

E.1.4 Information to be recorded and reported . 39

E.1.4.1 General . 39

E.1.4.2 General data. 39

E.1.4.3 Mounting and operating conditions. 39

E.1.4.4 Standards . 39

E.1.4.5 Noise data . 40

E.1.5 Declaration and verification of noise emission values . 40

E.2 Exhaust emissions from the tested vehicle . 41

Annex F (informative) List of significant hazards. 42

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 45

Bibliography . 47

European foreword

This document (EN 17003:2021) has been prepared by Technical Committee CEN/TC 301 “Road

vehicles”, and its working group WG11, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2022, and conflicting national standards shall be

withdrawn at the latest by May 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved by means of the document by the above-

mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate in the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document. In addition, machinery should comply as

appropriate with EN ISO 12100:2010 for hazards which are not covered by this document.

When provisions of this type-C standard are different from those which are stated in type-A or -B

standards, the provisions of this type-C standard take precedence over the provisions of the other

standards, for machines that have been designed and built according to the provisions of this type-C

standard.

The objective of this document is to define rules for safeguarding persons against the risk of accidents

associated with the operation of roller brake testers.

While elaborating this document, it was assumed that only authorized persons operate the roller brake

testers.

1 Scope

This document applies to roller brake testers (brake test benches) that are designed for roadworthiness

tests on categories M , M , N , N , O and O vehicles (as defined in Regulation (EU) 2018/858) and that

2 3 2 3 3 4

might be also used to test M , N categories.

1 1

This document covers fixed-bed roller brake testers with or without inspection pits and whose chassis

are inside or outside the building.

This document does not cover mobile roller or plate brake testers.

These roller brake testers are used to take measurements for testing and assessing the efficiencies of the

brake systems fitted to vehicles in the above-cited vehicle categories.

The users of the roller brake tester are all kinds of staff that for any reason operate the roller brake testers

(e.g. staff working in public transport, vehicle rental, vehicle maintenance, vehicle repair, training, test

laboratories and vehicle inspection sectors …). This document is not applicable to roller brake testers

manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 614-1:2006+A1:2009, Safety of machinery - Ergonomic design principles - Part 1: Terminology and

general principles

EN 614-2:2000+A1:2008, Safety of machinery - Ergonomic design principles - Part 2: Interactions between

the design of machinery and work tasks

EN 12464-1:2021, Light and lighting - Lighting of work places - Part 1: Indoor work places

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016)

EN 61000-6-2:2005, Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments (IEC 61000-6-2:2005)

EN 61000-6-3:2007, Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments (IEC 61000-6-3:2006)

EN 61496-1:2013, Safety of machinery - Electro-sensitive protective equipment - Part 1: General

requirements and tests (IEC 61496-1:2012)

EN 61496-2:2013, Safety of machinery - Electro-sensitive protective equipment - Part 2: Particular

requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2013)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

As impacted by EN 61000-6-3:2007/A1:2011.

EN ISO 11201:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO 13850:2015)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-2:2016, Safety of machinery - Permanent means of access to machinery - Part 2: Working

platforms and walkways (ISO 14122-2:2016)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

roller brake tester

roller brake test bench

system utilised to produce brake force measurements for testing and assessing the efficiencies of vehicle

braking systems

3.2

brake tester

term that, in this document, refers to roller brake tester (or brake test bench)

3.3

chassis

term that, in this document, refers to embedded or mounted mechanical floor units comprising the

measuring rollers, drive and gearbox motors, and measuring devices, and that support the wheel or axle

under test

3.4

fixed-bed control console

console that features as a minimum the human-machine interface: display, control devices, data storage

3.5

remote control

remote control which is used to navigate and control the human-machine interface at a distance

3.6

electrical box

box which provides the interface between the control console and the chassis, which may be integrated

into the fixed-bed control console and which comprises at least:

— the main switch;

— the motor control devices;

— electrical safety components

3.7

wheel presence sensor

term used for a sensor whose function is to provide guaranteed confirmation that a wheel is detected as

being safely located in the rollers, in compliance with the required test conditions

Note 1 to entry: The axle weight measurement can be used to confirm the reading or to detect a failure of the

presence detection device.

3.8

inspection pit

cavity excavated into the floor, in which a technician stands to inspect the underside of a vehicle

Note 1 to entry: Brake testers do not require an inspection pit in order to operate.

Note 2 to entry: When an inspection pit is required the brake tester roller bed is split and a set of rollers are

installed on either side of the pit’s cavity.

3.9

active opto-electronic protective device

AOPD

device whose sensing function is performed by optoelectronic emitting and receiving elements detecting

the interruption of optical radiation, generated within the device, by an opaque object present in the

specified detection zone

[SOURCE: EN ISO 12100:2010]

3.10

light curtain

AOPD comprising an integrated assembly of one or more emitting element(s) and one or more receiving

element(s) forming a detection zone with a detection capability specified by the supplier

Note 1 to entry: A light curtain with a large detection capability is sometimes referred to as a light grid.

[SOURCE: EN 61496-2:2013, 3.205]

3.11

trapping zone

area or zone at the interface between a road wheel of the axle under test and the brake tester rollers,

which are spinning in the opposite direction towards the nip

Note 1 to entry: The trapping zone creates a draw-in and crushing hazard (see the Informative Annex A).

Note 2 to entry: The trapping zone is sometimes called angle or re-entrant point.

Note 3 to entry: The trapping zone shall be measured from the rotating axis of the rollers.

3.12

operator

person performing test sequences

3.13

driver

person who drives the vehicle during the test sequences who may be also the operator

3.14

hazard zone

danger zone

space within and/or around machinery in which a person can be exposed to a hazard

Note 1 to entry: A list of significant hazards can be found in Annex F.

[SOURCE: EN ISO 12100:2010, 3.11]

3.15

no-trespassing area

area with permanent fully marked surface (yellow and black) on the ground, and where access is

prohibited during vehicle test

4 Safety requirements for the roller brake testers and/or protective/risk

reduction measures

4.1 General requirements

4.1.1 General

The machinery shall comply with the requirements and/or preventive measures of this clause.

In addition, the machinery shall be designed according to the principles of EN ISO 12100:2010 for

relevant but non-significant hazards which are not dealt with by this document.

4.1.2 General features for safety devices

Safety devices necessary for the safe functioning of the roller brake tester shall be considered part of the

machinery itself. In some cases, as the correct functioning of safety devices can depend on specific

installation conditions, the characteristic of such devices shall be evaluated according to the specificity of

the installation.

All safety devices controlling the start-up and/or emergency-stop of the motors (Stop Category 0 or

Category 1 under EN 60204-1:2018) shall deliver performance level according to Table 1 (see 4.5).

If safety devices are not able to eliminate every risk completely, then residual risks shall be described and

adequately addressed in the user manual.

4.1.3 Prevention from intrusion or contact with moving parts

Safety devices shall ensure that any risk of intrusion in a trapping zone and/or contact with moving parts

(from brake tester and vehicle moving parts, such as drive shaft that is rotated, by the roller brake tester)

is reduced to the lowest possible level.

When machinery runs, in the case of a chassis fitted over an inspection pit, the safety devices shall prevent

or detect access to the area below the floor level close to the bench to prevent contact with the moving

parts of the machinery and the vehicle under test.

4.1.4 Re-engagement after a stop

If a safety device stops the brake tester running, the system shall only be re-engaged by a deliberate action

from the operator via a control device of the roller brake tester. The automatic restart of the system after

a stop caused by a safety device shall not be possible under any circumstances.

Safety devices shall be designed in a way to authorize the test bench motor start and control the stop,

taking into account the possibility of stops by unintended response of the safety device (e.g. by dust, snow

or smoke, by slight movements of the vehicle, by sensor cables, loss of electrical power).

4.1.5 Safety during maintenance

The option of operating the machinery without the vehicle and with the safety devices disabled shall be

only foreseen for maintenance and calibration operations, with dedicated procedures carried out only by

trained personnel, as foreseen in 4.3.3.4 and 4.3.3.5.

4.2 Protection around chassis zone

4.2.1 Protection against hazard arising from moving parts

The chassis of the brake tester shall be designed to make impossible the access to the internal moving

parts (drive chains, gears) except by authorized personnel using dedicated tools.

The fixed guards shall be designed according to EN ISO 14120:2015.

4.2.2 Axle presence detection

Each side of the roller brake tester shall be fitted with a wheel presence sensor. The 2-wheel presence

sensors shall be both activated to allow the bench to start.

The axle presence detection device shall prohibit the roller brake tester to start when no axle is detected

and shall interrupt roller brake tester rollers and operation if axle presence detection is lost.

If the roller brake tester is equipped with weight measurement, a crosscheck with the presence detection

sensors can be used to identify a sensor failure.

The system shall deliver a PL = c.

r

4.2.3 Access protection to the chassis via the floor, around wheels and rollers

The chassis shall be provided with appropriate means to prevent any unintentional entrance into the no-

trespassing area (for examples of access protection, see Annex C).

The lateral access to the chassis via the floor, around the wheels and the rollers shall be prevented by

barriers.

There shall be an open access way of at least 0,8 m wide between the barriers and the wall or other fixed

object. The 2 physical barriers shall be installed on each side of the bench, at a distance of 0,2 m from the

bench. These 2 safeguards shall have a height of 1,40 m and a minimum total length of 3,0 m centred on

the mid-axle of the rollers. Such barriers shall have no holes, or holes not larger than 30 mm.

The risk of front and rear access to the chassis shall be managed by (at least) signalling the no-trespassing

area using adequate visual elements like designated hazard stripes on the floor, warning lights, or similar

(see Figure 1).

The no-trespassing area shall be at least the area delimited by the physical barriers (see Figure 1).

Key

a area of danger identified with the area of the rollers

b physical barriers

c no-trespassing area

d lamp with active yellow flashing linked to the rotation of the rollers

Figure 1 — Surface protection

In the case of an installation to replace a roller brake tester that is installed in an existing installation pit

which is located closer than 0,8 m from a wall or other fixed object then the barriers shall be replaced by

specific measures (e.g. AOPD, other physical barriers, …) to prevent access to the hazard zone.

4.2.4 Access protection to the chassis from the inspection pit (if it exists)

When the roller brake tester is fitted over an inspection pit or close to an inspection pit, the protection

distance before the bench from the axis of the first roller shall be minimum 2,4 m and 5,0 m (see Figure 2)

after the bench from the axis of the second roller, to prevent the presence of persons in dangerous areas

of the rotating drive shafts, the vehicle wheels, or the brake tester's rollers.

This can be achieved by using:

— Permanently fixed covering, or sliding covering interlocked with the brake tester.

For both of them, it prevents access to the dangerous area. If the sliding covering is motorized, it shall

not create additional risk. When the sliding covering is opened, rollers shall not start.

— Protective devices stopping the rotation of the rollers and preventing the rollers from starting.

Refer to Normative Annex B for details.

The design of all auxiliary equipment, like air pressure sensors, should not interfere with the functioning

of the protective devices.

The system shall have a PL = d according to EN ISO 13849-1:2015 (see Annex D).

r

Figure 2 — Protection distance geometry

4.2.5 Protection on access via the vehicle cabin

For the access from the cabin to the hazard zone, without available measures for protection, the risk is

residual and shall be underlined and adequately addressed in the user manual.

4.3 Control console

4.3.1 Location

The brake tester control console shall be moved away from the chassis in order to make impossible for

the operator to access to the no-trespassing area and to the vehicle while activating a start-up command.

A fixed or portable control (or repeater) station shall remain in the vehicle driver‘s field of view at all

times throughout the entire testing cycle and test procedure.

The control console shall be located so that the operator is able to keep watching over the entire test zone

via all appropriate means (such as mirrors, webcams, etc.). Control console location shall meet the

ergonomics requirements as defined in EN 614-1:2006+A1:2009, EN 614-2:2000+A1:2008.

4.3.2 Control devices

When a machine is fitted with several control devices, each device shall be equipped with all the

necessary controls, including an emergency stop device (see 4.4) without mutual interference between

operators and without operators placing each other in a hazard situation.

When there are several active control devices, the control system shall be designed so that:

— the start-up command can only be given by the control device selected to lead the test in progress,

— the stop and emergency stop devices are active on all control devices.

Regardless the type of control device installed, the stop command shall override the start command.

All control devices shall be safeguarded against inadvertent actuation.

NOTE 1 For example, the start commands can be fitted with flush-mounted or embedded controls while the stop

commands are fitted with prominent controls.

NOTE 2 On the inadvertent actuation issue, a computer keyboard will by definition propose a series of prominent

pushbuttons and so cannot issue a start command using just one single button.

NOTE 3 When the roller brake tester is PC based, the condition and use of safety devices can be registered on IT

support.

When a wireless control is used, the control circuit shall be designed so that if the remote control is paired

to the brake tester console, it will be able to control only the paired brake tester at any point during the

entire brake test.

Any remote control or auxiliary control with a start-up function shall also have at least normal stop and

emergency stop functions.

When the operator is also the driver using a remote control, he shall be able to keep watching over the

entire test zone via all appropriate means provided (such as mirrors, webcams, etc.).

4.3.3 Operating mode

4.3.3.1 General

If the machine provides various operational modes presenting different safety levels, it shall be equipped

with a selector which is lockable in each position. This safety function shall have PL = c according to

r

EN ISO 13849-1:2015.

4.3.3.2 Normal mode operation

Machine start-up shall only be possible by the deliberate action from the operator on the defined control

actuator, combined with the confirmed presence of a fully-mounted axle in the rollers (as defined in 4.2.2)

and the machine should provide a clear indication that start-up is possible.

When a protective device triggers the roller emergency stop the rollers cannot be restarted until being

re-engaged followed a deliberate action from the operator.

4.3.3.3 Deadman switch mode operation

The machine may be equipped with a deadman switch mode of operation for the use in specific conditions

threatening to disrupt normal operation of the safety devices (rain, snow, etc.).

When operating in deadman switch mode, the pushbutton operating mode shall disable normal mode

operation and only allow the operation in response to a hold-to-run control device on the control console.

This mode of operation shall inhibit the remote control and disrupt protective devices, except the axle

locator detection systems and emergency stops.

Deadman switch mode shall deliver PL = d.

r

4.3.3.4 Maintenance–inspection mode operation

If the system manufacturer has fitted the system with a maintenance-inspection mode, then this mode of

operation shall disable normal-mode operation and enable:

— either start-up by a single actuation on a limited movement control device triggering limited rotation

(120°) of the rollers on the purpose-fitted control actuator, inhibiting only the axle presence device,

— or start-up by a hold-to-run command triggering on the dedicated control actuator, allowing the

movement of the rollers if no vehicle is present on the roller brake tester (axle presence sensor not

engaged).

— or a release of the test bench brakes so that the rollers can rotate freely but making start-up

impossible.

= d.

Maintenance-inspection mode shall have a PLr

4.3.3.5 Calibration mode

The machine may be equipped with a calibration mode operation to provide specific calibration routines

according to the local regulation.

The start of the rollers of the brake tester without a vehicle on it, in the case that a calibration has to be

performed with the rollers turning without any mass on it, shall be only possible in a calibration mode.

This mode of operation, which access is limited and protected by means of, e.g. a password or using a

special key combination, shall disable normal mode operation and enable:

— or start-up by a hold-to-run command triggering on the dedicated control actuator, allowing the

movement of the rollers if no vehicle is present on the roller brake tester (axle presence sensor not

engaged);

— or a release of the test bench brakes so that the rollers can rotate freely but making start-up

impossible.

Calibration mode shall deliver PL = c.

r

4.3.4 Motors start-up

The start-up of the machinery shall be possible only through a deliberate action on the control device.

Automatic starting of the motors shall be prohibited in any case.

4.4 Emergency stop

The emergency stop shall be Stop Category 0 or if necessary Stop Category 1 in compliance with

EN 60204-1:2018.

All emergency stops shall comply with EN ISO 13850:2015.

At least one emergency stop shall be provided on each control position, including the remote control.

If a remote control is used, an automatic stop shall be activated when correct control signals are not

received, including loss of communication.

It is not allowed to use a computer user interface (e.g. keyboard, touch screen, mouse, etc.) as an

emergency stop button.

Emergency stop shall deliver PL = d.

r

4.5 Overview of the safety functions

The following table is intended to give an overview of all safety functions required for roller brake testers.

It should summarize all the safety functions described in detail in previous chapters and deliver a

required Performance Level (PL ).

r

Table 1 gives an overview of all safety functions and their PL in respect of EN ISO 13849-1:2015.

r

Table 1 — Overview of all safety functions

Safety function / description Reference Performance

clause level (PL )

r

Axle presence detection function 4.2.2 c

Pit presence detection function 4.2.4 d

Operating mode selector 4.3.3.1 c

Deadman switch mode selector 4.3.3.3 d

Maintenance-inspection mode function 4.3.3.4 d

Calibration mode selector 4.3.3.5 c

Emergency stop 4.4 d

4.6 Electrical equipment

4.6.1 Electrical equipment conformity requirements

The electrical systems and marking shall be compliant with EN 60204-1:2018.

The rated degree of protection of the electrical enclosures shall be at least:

— for the electrical motors: IP 54;

— for the electrical boxes: IP 53 outdoors, IP 32 indoors;

— for the control consoles: IP 53 outdoors, IP 32 indoors;

— for the remote control or auxiliary control: IP 53.

The electrical power supply shall be fixed-mounted.

4.6.2 Electromagnetic compatibility

4.6.2.1 Brake tester immunity

The brake tester’s immunity to electromagnetic disturbance shall be sufficient to enable it to operate as

intended when exposed to the disturbance types and levels specified in EN 61000-6-2:2005. The brake

tester manufacturer shall design, install and wire up all equipment and subassemblies in line with the

recommendations of the relevant subassembly manufacturer(s) in order to guarantee that the effects of

electromagnetic disturbances will not lead to unintended operation and/or dangerous failure.

4.6.2.2 Brake tester emissions

The electromagnetic disturbance generated by the roller brake tester shall not exceed the levels specified

in EN 61000-6-3:2007 .

4.7 Display of safety related information

The equipment display shall systematically warn the operator:

— every time a vehicle axle rolls onto the chassis;

— every time that drive roller start-up is imminent (at least 3 s before moving parts begin to rotate).

4.8 Warning lights

A warning light device shall be installed on the physical barriers on both side of the chassis and shall be

active at least throughout the test sequence (coming on at least 3 s before moving parts begin to rotate

and continue to operate until they stop rotating).

4.9 Noise

Noise emitted from a roller brake tester is mainly generated by tyre-to-roller contact. These noise

emissions can vary according to tyre type (and degree of wear), but also according to climate conditions,

typically humidity and temperature.

Noise is not a significant hazard for roller brake testers, however there is a need to provide informatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...