SIST EN 17507:2021

(Main)Road Vehicles - Portable Emission Measuring Systems (PEMS) - Performance Assessment

Road Vehicles - Portable Emission Measuring Systems (PEMS) - Performance Assessment

This document defines the procedures for assessing the performance of test equipment that is used for the on-road measurement of tailpipe emissions of light-duty vehicles, on the basis of a common test procedure that simulates the range of conditions experienced during on-road tests.

This document prescribes:

- the tests to be conducted, and,

- a procedure to determine, for any type of PEMS equipment, an appropriate uncertainty margin to reflect its performance over those conditions.

The key test variables are as follows (but not limited to the ones mentioned):

a) temperature, humidity and pressure and step-wise or gradual changes,

b) acceleration and deceleration (longitudinal and lateral),

c) vibration, inclination and shock tests,

d) instrument positioning on a vehicle,

e) combinations of (1) to (4),

f) cross-interferences,

g) signal-processing, data treatment and time alignment, and

h) calculation methods (excluding the regulatory post-processing of data).

Straßenfahrzeuge - Mobile Abgasmesssysteme (PEMS) - Leistungsbewertung

Véhicules routiers - Systèmes portatifs de mesure des émissions (PEMS) - Vérification de la performance

Le présent document définit les procédures d'évaluation de la performance des équipements d’essai qui sont utilisés pour les mesures sur route d'émissions d'échappement de véhicules légers, sur la base d'une procédure d’essai commune simulant la gamme des conditions rencontrées pendant des essais sur route.

Le présent document spécifie :

- les essais à réaliser, et

- une procédure permettant de déterminer, pour tout type d’équipement PEMS donné, une marge d'incertitude appropriée afin de refléter sa performance dans toutes les conditions suivantes.

Les variables d'essai clés sont les suivantes (mais non limitées à celles mentionnées) :

a) température, humidité et pression (y compris des variations échelonnées ou progressives),

b) accélération et décélération (longitudinale et latérale),

c) essai de vibrations, d'inclinaison et de chocs,

d) positionnement de l'instrument sur un véhicule,

e) combinaisons de (a) à (d),

f) brouillages réciproques,

g) traitement des signaux, traitement des données et alignement temporel, et

h) méthodes de calcul (sauf post-traitement réglementaire des données).

Cestna vozila - Prenosni sistemi za merjenje emisij (PEMS) - Ocenjevanje delovanja

General Information

- Status

- Published

- Public Enquiry End Date

- 22-Jul-2020

- Publication Date

- 22-Sep-2021

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Sep-2021

- Due Date

- 27-Nov-2021

- Completion Date

- 23-Sep-2021

Overview

SIST EN 17507:2021 - Road Vehicles - Portable Emission Measuring Systems (PEMS) - Performance Assessment - defines standardized procedures to evaluate the performance and measurement uncertainty of PEMS used for on‑road tailpipe emission testing of light‑duty vehicles. Published by CEN and adopted by SIST, the standard prescribes the tests to be conducted and a method to derive an uncertainty margin that reflects PEMS performance across the range of real‑world driving conditions.

Keywords: PEMS, EN 17507:2021, portable emission measuring systems, on‑road emissions, PEMS performance assessment, measurement uncertainty, RDE.

Key technical topics and requirements

The standard sets out test protocols, performance criteria and uncertainty evaluation following GUM principles (ISO/IEC Guide 98‑3). Major technical topics include:

- Environmental stress tests: temperature, humidity and pressure variations (step-wise and gradual).

- Dynamic driving effects: acceleration/deceleration (longitudinal and lateral), vibrations, inclinations and shocks.

- Installation factors: instrument positioning on a vehicle and combined stress scenarios.

- Analytical performance: requirements for gaseous analysers and particle number (PN) analysers.

- Ancillary systems: exhaust mass flow meters (EFM), Global Navigation Satellite Systems (GNSS) for distance, and auxiliary equipment.

- Interferences and signal integrity: cross‑interferences, signal‑processing, data treatment and time alignment.

- Uncertainty assessment: procedures to determine an appropriate uncertainty margin for each PEMS type, including Type A (experimental) and Type B (non‑experimental) evaluations.

- Scope exclusions: regulatory post‑processing of data is not covered by the calculation methods in this standard.

Practical applications and users

EN 17507:2021 is intended to support reliable, traceable on‑road emission measurement and to inform compliance, development and procurement decisions. Typical users include:

- Vehicle manufacturers validating on‑road emissions and RDE (Real Driving Emissions) compliance.

- PEMS manufacturers developing or verifying instrument performance.

- Test laboratories and independent measurement service providers performing PEMS validation and on‑road campaigns.

- Regulatory and certification bodies assessing measurement quality and issuing approvals.

- Research institutions studying real‑world emissions and instrument behavior.

Related standards

Normative references and complementary documents cited in EN 17507:2021 include:

- EN ISO 29463 (high‑efficiency filters)

- ISO 27891:2015 (CPC calibration)

- ISO/IEC Guide 98‑3:2008 (GUM - Guide to the expression of uncertainty in measurement)

EN 17507:2021 provides a harmonized, practical framework to quantify PEMS performance and uncertainty, improving transparency and comparability of on‑road emission measurements.

Frequently Asked Questions

SIST EN 17507:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Road Vehicles - Portable Emission Measuring Systems (PEMS) - Performance Assessment". This standard covers: This document defines the procedures for assessing the performance of test equipment that is used for the on-road measurement of tailpipe emissions of light-duty vehicles, on the basis of a common test procedure that simulates the range of conditions experienced during on-road tests. This document prescribes: - the tests to be conducted, and, - a procedure to determine, for any type of PEMS equipment, an appropriate uncertainty margin to reflect its performance over those conditions. The key test variables are as follows (but not limited to the ones mentioned): a) temperature, humidity and pressure and step-wise or gradual changes, b) acceleration and deceleration (longitudinal and lateral), c) vibration, inclination and shock tests, d) instrument positioning on a vehicle, e) combinations of (1) to (4), f) cross-interferences, g) signal-processing, data treatment and time alignment, and h) calculation methods (excluding the regulatory post-processing of data).

This document defines the procedures for assessing the performance of test equipment that is used for the on-road measurement of tailpipe emissions of light-duty vehicles, on the basis of a common test procedure that simulates the range of conditions experienced during on-road tests. This document prescribes: - the tests to be conducted, and, - a procedure to determine, for any type of PEMS equipment, an appropriate uncertainty margin to reflect its performance over those conditions. The key test variables are as follows (but not limited to the ones mentioned): a) temperature, humidity and pressure and step-wise or gradual changes, b) acceleration and deceleration (longitudinal and lateral), c) vibration, inclination and shock tests, d) instrument positioning on a vehicle, e) combinations of (1) to (4), f) cross-interferences, g) signal-processing, data treatment and time alignment, and h) calculation methods (excluding the regulatory post-processing of data).

SIST EN 17507:2021 is classified under the following ICS (International Classification for Standards) categories: 43.180 - Diagnostic, maintenance and test equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17507:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2021

Cestna vozila - Prenosni sistemi za merjenje emisij (PEMS) - Ocenjevanje

delovanja

Road Vehicles - Portable Emission Measuring Systems (PEMS) - Performance

Assessment

Straßenfahrzeuge - Mobile Abgasmesssysteme (PEMS) - Leistungsbewertung

Véhicules routiers - Systèmes portatifs de mesure des émissions (PEMS) - Vérification

de la performance

Ta slovenski standard je istoveten z: EN 17507:2021

ICS:

43.180 Diagnostična, vdrževalna in Diagnostic, maintenance and

preskusna oprema test equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17507

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2021

EUROPÄISCHE NORM

ICS 43.180

English Version

Road vehicles - Portable Emission Measuring Systems

(PEMS) - Performance assessment

Véhicules routiers - Systèmes portatifs de mesure des Straßenfahrzeuge - Mobile Abgasmesssysteme (PEMS)

émissions (PEMS) - Vérification de la performance - Leistungsbewertung

This European Standard was approved by CEN on 11 July 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17507:2021 E

worldwide for CEN national Members.

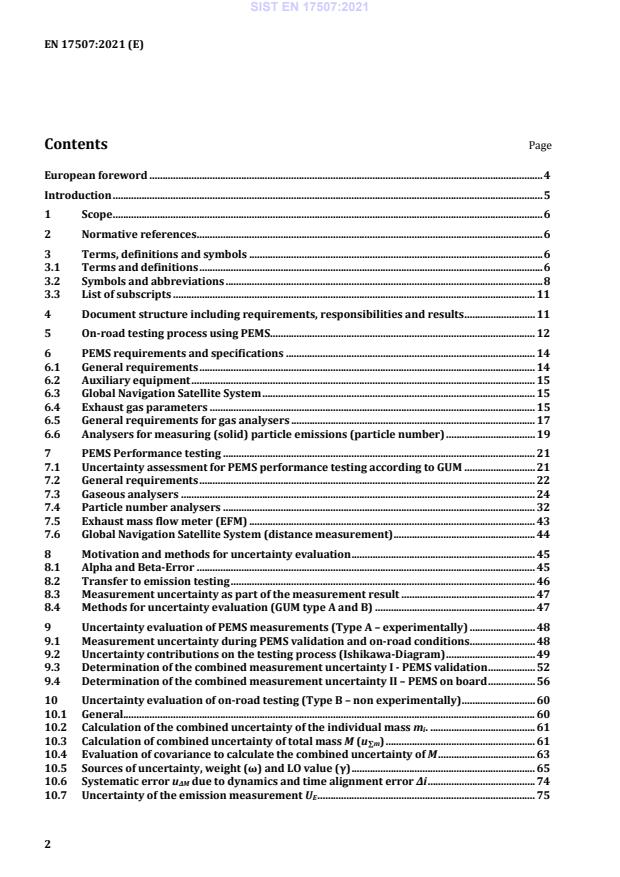

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols . 6

3.1 Terms and definitions . 6

3.2 Symbols and abbreviations . 8

3.3 List of subscripts . 11

4 Document structure including requirements, responsibilities and results . 11

5 On-road testing process using PEMS . 12

6 PEMS requirements and specifications . 14

6.1 General requirements . 14

6.2 Auxiliary equipment . 15

6.3 Global Navigation Satellite System . 15

6.4 Exhaust gas parameters . 15

6.5 General requirements for gas analysers . 17

6.6 Analysers for measuring (solid) particle emissions (particle number) . 19

7 PEMS Performance testing . 21

7.1 Uncertainty assessment for PEMS performance testing according to GUM . 21

7.2 General requirements . 22

7.3 Gaseous analysers . 24

7.4 Particle number analysers . 32

7.5 Exhaust mass flow meter (EFM) . 43

7.6 Global Navigation Satellite System (distance measurement) . 44

8 Motivation and methods for uncertainty evaluation . 45

8.1 Alpha and Beta-Error . 45

8.2 Transfer to emission testing . 46

8.3 Measurement uncertainty as part of the measurement result . 47

8.4 Methods for uncertainty evaluation (GUM type A and B) . 47

9 Uncertainty evaluation of PEMS measurements (Type A – experimentally) . 48

9.1 Measurement uncertainty during PEMS validation and on-road conditions . 48

9.2 Uncertainty contributions on the testing process (Ishikawa-Diagram) . 49

9.3 Determination of the combined measurement uncertainty I - PEMS validation . 52

9.4 Determination of the combined measurement uncertainty II – PEMS on board . 56

10 Uncertainty evaluation of on-road testing (Type B – non experimentally) . 60

10.1 General. 60

10.2 Calculation of the combined uncertainty of the individual mass m . . 61

i

10.3 Calculation of combined uncertainty of total mass M (u∑m) . 61

10.4 Evaluation of covariance to calculate the combined uncertainty of M . 63

10.5 Sources of uncertainty, weight (ω) and LO value (γ) . 65

10.6 Systematic error u due to dynamics and time alignment error Δi . 74

ΔM

10.7 Uncertainty of the emission measurement U . 75

E

Annex A (normative) Procedure of linearity verification . 77

Annex B (normative) Additional requirements for gas analysers . 79

Annex C (normative) Determination of the reference uncertainty of chassis dynos u . 84

CAL

Bibliography . 85

European foreword

This document (EN 17507:2021) has been prepared by Technical Committee CEN/TC 301 “Road

vehicles”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2022, and conflicting national standards shall be

withdrawn at the latest March 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The intention of this document is to determine the measurement uncertainty of mobile vehicle exhaust

emission testing equipment (e.g. Portable Emissions Measurement Systems, PEMS) under consideration

of applicable legal requirements (e.g. European Legislation on Light-Duty Real Driving Emission

measurement, RDE).

The specific aims include the following:

— To be able to assess PEMS (for gaseous and particle number emissions) under various operating

environments with the intention of predicting PEMS performance and uncertainty over the whole

range of conditions used. For the time being, it focusses on light-duty-vehicle application and serves

as a basis for assessing the uncertainty of heavy-duty emission measurement using PEMS.

— To be able to evaluate the deviation of gaseous PEMS under various light-duty on-road test

conditions and heavy-duty PEMS test conditions against known analyser systems under standard

laboratory conditions for the specified gas, which is traceable to national or international primary

standards.

— To be able to evaluate the deviation of Particle Number (PN) - PEMS under various light-duty on-

road test conditions and heavy-duty PEMS test conditions against a known analyser system under

standard laboratory conditions for the same sample, which is traceable to national or international

primary or secondary standards.

— To define the means for demonstrating that the PEMS equipment is stable and the measurement

quality is sufficient between PEMS equipment service intervals.

— To provide input to the development of future specifications and quantified information about

instrument and process accuracy to help improve the accuracy and robustness of PEMS systems and

on-road measurements.

— To set a framework for determining the measurement uncertainty by analysing available data and

providing a method for data evaluation.

In particular, the derivation of the uncertainty according to all parts of the document allows the following:

— The instrument measurement uncertainty can be evaluated.

— The instrument measurement uncertainty on-road can be reported as a part of the measurement

result following ISO 10012:2003.

— The results of an investigation based on this document provides information about the suitability of

the equipment for the intended use.

— Transparency with respect to the instrument measurement uncertainty of currently available

equipment.

— Transparency with respect to the testing processes for the measurement uncertainty.

— Assessment of the statistical significance of the difference of measurement results.

1 Scope

This document defines the procedures for assessing the performance of test equipment that is used for

the on-road measurement of tailpipe emissions of light-duty vehicles, on the basis of a common test

procedure that simulates the range of conditions experienced during on-road tests.

This document prescribes:

— the tests to be conducted, and

— a procedure to determine, for any type of PEMS equipment, an appropriate uncertainty margin to

reflect its performance over those conditions.

The key test variables are as follows (but not limited to the ones mentioned):

a) temperature, humidity and pressure (including step-wise or gradual changes),

b) acceleration and deceleration (longitudinal and lateral),

c) vibration, inclination and shock tests,

d) instrument positioning on a vehicle,

e) combinations of (a) to (d),

f) cross-interferences,

g) signal-processing, data treatment and time alignment, and

h) calculation methods (excluding the regulatory post-processing of data).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 29463 (all parts), High-efficiency filters and filter media for removing particles in air (ISO 29463

(all parts))

ISO 27891:2015, Aerosol particle number concentration - Calibration of condensation particle counters

ISO/IEC Guide 98-3:2008, Uncertainty of measurement - Part 3: Guide to the expression of uncertainty in

measurement (GUM:1995)

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

analyser

component of a Measurement Module(s) for detecting the gaseous or particle emission concentrations

Note 1 to entry: The type is defined by the specific analyser model and the applied analytical principle or the

combination of multiple analytical principles.

3.1.2

filtered air

air filtered with a high efficiency filter according to EN ISO 29463-1, class 35H

3.1.3

inspection decision

result of an inspection

3.1.4

inspection

inspection process

conformity evaluation by observation and judgement accompanied as appropriate by measurement,

testing or gauging

3.1.5

limit of error

maximum permissible error

extreme value of measurement error, with respect to a known reference quantity value, permitted by

specifications or regulations for a given measurement, measuring instrument, or measuring system

3.1.6

measurement standard

realization of the definition of a given quantity, with stated quantity value and associated measurement

uncertainty, used as a reference

3.1.7

measuring and test equipment

device used for making measurements, alone or in conjunction with one or more supplementary devices

3.1.8

measuring system

set of one or more measuring instruments and often other devices, including any reagent and supply,

assembled and adapted to give information used to generate measured quantity values within specified

intervals for quantities of specified kinds

3.1.9

measurement uncertainty

non-negative parameter characterizing the dispersion of the quantity values being attributed to a

measurand, based on the information used

3.1.10

module

discrete or integrated sub-component within a PEMS, which supports the analyser(s) with the necessary

supplementary components to fulfil the necessary requirements for each pollutant being measured

3.1.11

Portable Emission Measurement System

PEMS

system that can measure exhaust emissions from a vehicle on the road, allowing real-world testing

Note 1 to entry: For regulatory purposes, a PEMS comprises all the components necessary to monitor, process and

report the real-driving emissions of the regulated pollutants in accordance with the relevant regulation. The PEMS

used for emissions regulatory purposes typically integrate Measurement Module(s) (for example, for gaseous,

particulate and exhaust-mass-flow). Additional accessories to fulfil the regulatory monitoring and processing

functions are also included (for example, a weather station, Global Navigation Satellite System (GNSS) and, if

required, connection to the vehicle networks).

3.1.12

uncertainty budget

statement of a measurement uncertainty, of the components of that measurement uncertainty, and of

their calculation and combination

3.2 Symbols and abbreviations

A Accuracy

c concentration

CLD Chemiluminescence Detector

CPC Condensation Particle Counter

D Drift

d distance or diameter

DMA Differential Mobility Analyser

E Specific mass emission

ECU Engine Control Unit

EFM Exhaust Flow Meter

FS Full Scale

GMD Geometric Mean Mobility Diameter

GRR Gauge Repeatability Reproducibility

GSD Geometric Standard Deviation

GUM Guide to the Expression of Uncertainty in Measurement

i index

k k-factor

LSL Lower Limit of Specification

m mass

MFC Mass Flow Controller

MPE Maximum Permissible Error

NDIR Non-Dispersive Infra-Red

NDUV Non-dispersive Ultra Violet

NMC Non-Methane Cutter

NMHC Non-Methane Hydrocarbons

p pressure

P Precision

PAS Photoacoustic Spectroscopy

PEMS Portable Emission Measurement Systems

PMP Particle Measurement Programme

PN Particle Number from exhaust emission according to relevant legal definition

PSD Power Spectral Density

PSU Power Supply Unit

Q flow

R&R Repeatability and Reproducibility

RDE Real Driving Emissions

RE Resolution (of measurement system)

RH Relative Humidity

SOC State of Charge

T Temperature

t time at end of test

e

t time

TOL Tolerance

u uncertainty

u Uncertainty contribution of operator

AV

u Uncertainty contribution of bias

Bi

u Uncertainty contribution of calibration

CAL

u Uncertainty contribution of repeatability at the object

EVO

u Uncertainty contribution of repeatability on standards

EVR

U Uncertainty contribution of interdependence

IAI

u Uncertainty contribution by measurement procedure

MP

U Extended measurement uncertainty contribution by measurement procedure

MP

u Uncertainty contribution by measurement system

MS

U Extended measurement uncertainty contribution by measurement system

MS

u Uncertainty contribution by resolution

RE

USL Upper Limit of Specification

VDE Verband der Elektrotechnik, Elektronik und Informationstechnik (Association for

Electrical, Electronic & Information Technologies)

VDI Verein Deutscher Ingenieure (Association of German Engineers)

VIM Vocabulary of Metrology

VPR Volatile Particle Remover

Δc Concentration offset

Δt Test duration

e

Δt Time offset

Sensor or monitoring device for indicated entity (e.g. temperature sensor)

Controlling device for indicated entity (e.g. pressure controller or release valve)

3.3 List of subscripts

act actual value (value that would be displayed by a perfect instrument)

amb ambient, referring to ambient conditions

cur current value

drift concerning drift

err error

gas gas

i index

j index

m mass (e.g. for flow)

meas measured value

mono monodisperse

poly polydisperse

rd relative density

ref reference, referring to values of a reference device (if used)

s sample

set set value

span span

T Test duration

true true value

V Volume

zero zero

4 Document structure including requirements, responsibilities and results

The whole document is structured according to the following table. This table also includes

recommendations, which party should be responsible to conduct the tests and evaluate the uncertainty

following the procedures which are described in this document.

Table 1 — Document structure

# Requirement Responsible Result

party

5 On-road testing process using PEMS --- ---

6 PEMS requirements and specifications of PEMS PEMS technical specifications and

PEMS manufacturers test procedures for each type of

PEMS component under ideal

laboratory conditions

7 PEMS performance testing PEMS PEMS performance test procedure

manufacturers for the evaluation of each type of

PEMS component under simulated

boundary conditions of use

(in the laboratory)

8 Motivation and methods for uncertainty --- ---

evaluation

9 Uncertainty evaluation of on-road testing --- ---

(Type A – experimentally)

9.3

Determination of the combined Individual PEMS Combined measurement

measurement uncertainty I – PEMS User uncertainty of the PEMS

validation validation

9.4 Determination of the measurement PEMS User Combined measurement

uncertainty of the measurement II – Community uncertainty of the on-road

measurement process

on-road measurement process

10 Uncertainty evaluation of on-road testing Individual PEMS Combined measurement

User uncertainty of the PEMS validation

(Type B – non experimentally)

5 On-road testing process using PEMS

The basis for this document is a common understanding of the on-road inspection process including all

influencing parameters. The general description of the test procedure is defined in the relevant

regulations. However, the following process chart (Figure 1) summarizes the most important steps.

Key

1 vehicle and equipment set-up 3b on-road test (e.g. RDE test) consisting of

multiple phases (e.g. A, B, C, D)

2a pre-test; consisting of leak check, PN zero check, 3c post-test; similar to 2c

zero calibration, span calibration, EFM-function

check

2b validation test 4 evaluation of results

2c post-test; consisting of PN zero check, zero drift 5 results of test, power specific or distance

check (relative to pre-test), span drift check (relative specific mass emissions

to pre-test)

3a pre-test; similar to 2a S soak time of the vehicle (typically) between 6 to

56h, PEMS stays installed on the vehicle

Figure 1 — Example of general on-road measurement process (based on the European

Legislation on Light-Duty Real Driving Emission measurement, RDE)

The final result of the exhaust emission measurement is the distance specific mass of an emission

component limited by the relevant regulations. These results are given in the unit g/km or mg/km for

gaseous species, or in the unit 1/km for particle number for light-duty vehicles. Therefore, the

uncertainty has to be derived with respect to these final values.

As the applicable testing scheme may vary due to legally defined procedures, this process is taken as a

minimum reference for the description of errors, their dependencies and propagation. If the testing

procedure does significantly deviate from this process, the approach of uncertainty assessment shall be

reassessed accordingly based on the recommendations of this document.

6 PEMS requirements and specifications

6.1 General requirements

6.1.1 General

The technical requirements in this Clause are based on PEMS capabilities at the time of writing of this

document. It is up to the instrument manufacturer to prove the compliance to relevant legal requirements

or to prove an even better performance (lower uncertainty) for a specific analyser type, based on

appropriate testing and statistical methods.

6.1.2 Boundary conditions

PEMS are used in a wide range of conditions. Table 2 below gives the main parameters that should be

taken into account with their possible range according to the on-road procedure and their real range of

variation during a real test.

Table 2 — Parameters of the boundary conditions

Possible range for on- Possible variation during

Boundary conditions

road testing single test

± 12 °C during one test

Temperature - 7 °C to 35 °C up to - 30 °C if soaked in a

garage

+ 1 200 m / 100 km

Altitude 0 m to 1 300 m

as positive altitude gain

850 hPa to 1 050 hPa (sea up to ± 150 hPa

Pressure

level) variation during the test

Humidity 5 % to 90 % non-condensing relative humidity (RH)

Vibrations See 7.2.1 See 7.2.1

Duration of the test 1,5 h to 2 h 1,5 h to 2 h

6.1.3 Temperature

During the test, according to the real life, the vehicle with the installed measurement equipment can be

soaked in a garage at 23 °C and go outside with a temperature at - 7 °C, the direct variation can be up to

30 °C.

According to extreme atmospheric conditions and the fact that the vehicle can climb a mountain, the

variation of temperature during the test can be negative (decrease of the temperature at the top of the

mountain) and positive (increase of the temperature at the bottom of the mountain).

A variation of - 30 °C and + 12 °C shall be considered during a test to check the impact of the measurement

accuracy and drift.

6.1.4 Altitude / Pressure

To cover applicable altitudes between sea level and 1 300 m above sea level under various atmospheric

conditions the pressure during the test can show negative gradients (climbing during test) or positive

gradients (increase of pressure at sea level).

The testing range is therefore defined as starting from 1 013 mbar (± 5 %) and reaching < 850 mbar and

at least 150 mbar less than the starting point. Based on a duration of an on-road measurement of 2 h and

a closed route, the gradient shall be at least 75 hPa/h.

6.1.5 Humidity

The range of humidity shall be checked for each pollutant taking into account the analyser technology.

The impact on its performance (e.g. interference, drift, correction) shall be identified. The main variation

in terms of hygrometry is linked to the exhaust gas humidity concentration for the analyser.

During the engine start, condensation may occur in the exhaust pipe line and exhaust gases are of low

humidity. Depending on the fuel and the combustion process, the relative humidity of the exhaust gas

may also reach up to 35 %. The ambient humidity however, can vary according to Table 1.

6.2 Auxiliary equipment

Auxiliary equipment includes sensors like the ones used for determination of ambient temperature,

ambient pressure, ambient humidity and or, if applicable, according values from the vehicles cabin.

Accuracy requirements for measurement parameters

Measurement parameter MPE value

Temperatures ≤ 600 K ± 2 K absolute

Temperatures > 600 K ± 0,4 % of reading in Kelvin

Ambient pressure ± 0,2 kPa absolute

Relative humidity ± 5 % absolute

Absolute humidity ± 10 % of reading or, 1 gH O/kg dry air,

whichever is larger

6.3 Global Navigation Satellite System

Global Navigation Satellite Systems (for example a Global Positioning System) receivers used in the PEMS

should meet, or exceed, the specifications as defined in the Global Positioning System Standard

Positioning Service Performance Standard (5th edition, Table 3.8.3, April 2020) or any other similar

standard. All Global Navigation Satellite Systems receivers used shall be supported with the receiver

manufacturer information stating clear and unambiguous compliance to the related standard.

6.4 Exhaust gas parameters

6.4.1 Exhaust flow meter

6.4.1.1 General

The determination of the exhaust mass flow is critical for the calculation of the distance specific emission

mass of a vehicle. Therefore, it is required that the signals used for the calculation of the mass flow are of

the best available quality. The sensitivity of instruments, sensors and signals to shocks, vibration, aging,

variability in temperature, ambient air pressure, electromagnetic interferences and other impacts related

to vehicle, installation and instrument operation shall be on a level as to minimize additional errors.

6.4.1.2 Specification

The exhaust mass flow rate shall be determined by a direct measurement method applied in either of the

following instruments:

a) Pitot-based flow devices,

b) Pressure differential devices like flow nozzle (for details see the appropriate part of ISO 5167),

c) Ultrasonic flow meter,

d) Vortex flow meter.

Each individual exhaust mass flow meter shall fulfil the linearity requirements set out in point 6.4.1.2.

Furthermore, the instrument manufacturer shall demonstrate the compliance of each type of exhaust

mass flow meter with the specifications in points 6.4.1.5 to 6.4.1.11.

6.4.1.3 Linearity

All flow-measuring instruments shall comply with the linearity requirements given in Table A.1 of

Annex A.

6.4.1.4 Calibration and verification standards

The measurement performance of exhaust mass flow meters shall be verified with air or exhaust gas

against a traceable standard such as, e.g. a calibrated exhaust mass flow meter or a full flow dilution

tunnel.

6.4.1.5 Frequency of verification

The compliance of exhaust mass flow meters with points 6.4.1.5 to 6.4.1.11 shall be verified no longer

than what is required at the relevant regulations or one year before the actual test.

6.4.1.6 Accuracy

Under steady state conditions in the laboratory, the accuracy of the EFM, defined as the deviation of the

EFM reading from the reference flow value, shall not exceed ± 3 % of the reading, 0,5 % of full scale or ±

1,0 % of the maximum flow at which the EFM has been calibrated, whichever is larger.

6.4.1.7 Precision

The precision, defined as 2,5 times the standard deviation of 10 repetitive responses to a given nominal

flow, approximately in the middle of the calibration range, shall not exceed 1 % of the maximum flow at

which the EFM has been calibrated.

6.4.1.8 Noise

The noise shall not exceed 2 % of the maximum calibrated flow value. Each of the 10 measurement

periods shall be interspersed with an interval of 30 s in which the EFM is exposed to the maximum

calibrated flow.

6.4.1.9 Zero response drift

The zero response drift is defined as the mean response to zero flow during a time interval of at least

30 s. The zero response drift can be verified based on the reported primary signals, e.g. pressure. The

drift of the primary signals over a period of 4 h shall be less than ± 2 % of the maximum value of the

primary signal recorded at the flow at which the EFM was calibrated.

6.4.1.10 Span response drift

The span response drift is defined as the mean response to a span flow during a time interval of at least

30 s. The span response drift can be verified based on the reported primary signals, e.g. pressure. The

drift of the primary signals over a period of 4 h shall be less than ± 2 % of the maximum value of the

primary signal recorded at the flow at which the EFM was calibrated.

6.4.1.11 Rise time

The rise time of the exhaust flow instruments and methods should match as far as possible the rise time

of the gas analysers but shall not exceed 1 s.

6.4.1.12 Response time check

The response time of exhaust mass flow meters shall be determined by applying similar parameters as

those applied for the emissions test (i.e. pressure, flow rates, filter settings and all other response time

influences). The response time determination shall be done with gas switching directly at the inlet of the

exhaust mass flow meter. The gas flow switching shall be done as fast as possible, but highly

recommended in less than 0,1 s. The gas flow rate used for the test shall cause a flow rate change of at

least 60 % full scale of the exhaust mass flow meter. The gas flow shall be recorded. The delay time is

defined as the time from the gas flow switching (t ) until the response is 10 % (t ) of the final reading.

0 10

The rise time is defined as the time between 10 % and 90 % response (t to t ) of the final reading. The

90 10

response time (t ) is defined as the sum of the delay time and the rise time. The exhaust mass flow meter

response time (t ) shall be ≤ 3 s with a rise time (t to t ) of ≤ 1 s.

90 90 10

As an alternative to the change of gas flow rate check method above, the speed of EFM response can be

validated by a pressure change at the inlet of the EFM Sensor Box which is equivalent to at least 60 % of

the EFM tube flow range. The change of pressure should be as fast as possible but highly recommended

to be less than 0,1 s.

6.5 General requirements for gas analysers

6.5.1 Permissible types of analysers

6.5.1.1 Standard analysers

The analysers measuring CO and/or CO shall be Non-Dispersive Infrared analyser (NDIR) type.

The analyser measuring NO shall be either of the chemi-luminescent (CLD) or of the non-dispersive

x

ultra-violet resonance absorption (NDUV) type, both with NO -NO converters. If a NDUV analyser

x

measures both NO and NO or a CLD is combined with a photoacoustic spectroscopy (PAS) analyser, a

NO /NO converter is not required.

6.5.1.2 Alternative analysers

Any analyser not meeting the design specifications of a standard analyser (e.g. photoacoustic

spectroscopy) is permissible provided that it fulfils the requirements of this standard. The manufacturer

shall ensure that the alternative analyser achieves an equivalent or better measurement performance

compared to a standard analyser over the range of pollutant concentrations and co-existing gases that

can be expected from vehicles operated with permissible fuels under moderate and extended conditions

of valid on-road testing as specified in the relevant regulations. Upon request, the manufacturer of the

analyser shall submit in writing supplemental information, demonstrating that the measurement

performance of the alternative analyser is consistently and reliably in line with the measurement

performance of standard analysers.

6.5.2 Analyser specifications

6.5.2.1 General

The analyser manufacturer shall demonstrate compliance of analyser types with the specifications of this

document. Analysers shall have a measuring range and response time appropriate to measure with

adequate accuracy the concentrations of the exhaust gas components at the applicable emissions

standard under transient and steady state conditions. The sensitivity of the analysers to shocks, vibration,

aging, variability in temperature and air pressure as well as electromagnetic interferences and other

impacts related to vehicle and analyser operation shall be limited as far as possible and at minimum to

provide the analyser performance specified in this section.

6.5.2.2 Linearity of analysers

All gas analysers shall comply with the linearity requirements given in Table A.1 of Annex A.

6.5.2.3 Accuracy

The accuracy, defined as the deviation of the analyser reading from the reference value, shall not exceed

2 % of reading or 0,3 % of full scale, whichever is larger.

6.5.2.4 Precision

The precision, defined as 2,5 times the standard deviation of 10 repetitive responses to a given calibration

or span gas, shall be no greater than 1 % of the full scale concentration for a measurement range equal or

above 155 ppm (or ppmC1) and 2 % of the full scale concentration for a measurement range of below

155 ppm (or ppmC1).

6.5.2.5 Noise

The noise shall not exceed 2 % of full scale. Each of the 10 measurement periods shall be interspersed

with an interval of 30 s in which the analyser is exposed to an appropriate span gas. Before each sampling

period and before each span period, sufficient time shall be given to purge the analyser and the sampling

lines.

6.5.2.6 Zero response drift

The drift of the zero response, defined as the mean response to a zero gas during a time interval of at least

30 s, shall comply with the specifications given in Table 3.

6.5.2.7 Span response drift

The drift of the span response, defined as the mean response to a span gas during a time interval of at

least 30 s, shall comply with the specifications given in Table 3.

Table 3 — Permissible zero and span response drift of analysers for measuring gaseous

components under laboratory conditions

Pollutant Absolute Zero response Absolute Span response drift

drift

CO ≤ 1 000 ppm over 4 h ≤ 2 % of reading or ≤ 1 000 ppm over

4 h, whichever is larger

NO ≤ 5 ppm over 4 h ≤ 2 % of reading or 5 ppm over 4 h,

x

whichever is larger

6.5.2.8 Rise time

The rise time, defined as the time between the 10 % and 90 % response of the final reading (t to t ; see

90 10

point 6.5.3), shall not exceed 3 s.

6.5.2.9 Gas drying

Exhaust gases may be measured wet or dry. A gas-drying device, if used, shall have a minimal effect on

the composition of the measured gases. Chemical dryers are not permitted.

6.5.2.10 Additional requirements

The effects from additional components, instrument design or methods used for the determination of the

species concentration shall be determined according to Annex B. For alternative analysers quenching,

converter efficiency, and additional response and interference effects etc. if applicable shall be

determined.

6.5.3 Response time check of the analytical system

For the response time check, the settings of the analytical system shall be exactly the same as during the

emissions test (i.e. pressure, flow rates, filter settings in the analysers and all other parameters

influencing the response time). The response time shall be determined with gas switching directly at the

inlet of the sample probe. The gas switching shall be done in less than 0,1 s. The gases used for the test

shall cause a concentration change of at least 60 % full scale of the analyser.

The concentration trace of each single gas component shall be recorded. The delay time is defined as the

time from the gas switching (t ) until the response is 10 % of the final reading (t ). The rise time is

0 10

defined as the time between 10 % and 90 % response of the final reading (t to t ). The system response

90 10

time (t ) consists of the delay time to the measuring detector and the rise time of the detector.

For time alignment of the analyser and exhaust flow signals, the transformation time is defined as the

time from the change (t ) until the response is 50 % of the final reading (t ).

0 50

The system response time shall be ≤ 12 s with a rise time of ≤ 3 s for all components and all ranges used.

When using a NMC for the measurement of NMHC, the system response time may exceed 12 s.

6.6 Analysers for measuring (solid) particle emissions (particle number)

6.6.1 General

The PN analyser shall consist of a pre-conditioning unit and a particle detector that counts from

approximately 23 nm or 10 nm depending on the relevant regulation. It is permissible that the particle

detector also pre-conditions the aerosol. The sensitivity of the analysers to shocks, vibration, aging,

variability in temperature and air pressure as well as electromagnetic interferences and other impacts

related to vehicle and analyser operation shall be limited as far as possible and shall be clearly stated by

the equipment manufacturer in its support material. The PN analyser shall only be permitted to be used

within its manufacturer’s declared parameters of operation.

6.6.2 Efficiency requirements

The complete PN analyser system including the sampling line shall fulfil the efficiency requirements of

Table 4.

Table 4 — 23 nm or 10 nm PN analyser (including the sampling line) system efficiency

requirements with monodisperse aerosol

23 nm PN analyser system

d [nm] 23 30 50 70 100 200

p

E(d )

p

0,2 – 0,6 0,3 – 1,2 0,6 – 1,3 0,7 – 1,3 0,7 – 1,3 0,5 – 2,0

23 nm PN analyser

10 nm PN analyser system

d [nm] 10 15 30 50 70 100 200

p

E(d )

p

0,1 – 0,5 0,3 – 0,7 0,75 – 1,05 0,85 – 1,15 0,85 – 1,15 0,8 – 1,2 0,8 – 2,0

10 nm PN analyser

Efficiency E(dp) is defined as the ratio in the readings of the PN analyser system to a reference

Condensation Particle Counter (CPC)’s (d 50 % = 10 nm or lower for 23 nm PN analysers or 5 nm or lower

for 10 nm PN analysers, checked for linearity and calibrated with an electrometer) or an Electrometer’s

number concentration measuring in parallel monodisperse aerosol of mobility diameter dp and

normalized at the same temperature and pressure conditions.

The material should be thermally stable soot-like (e.g. spark discharged graphite or diffusion flame soot

with thermal pre-treatment). If the efficiency curve is measured with a different aerosol (e.g. NaCl), the

correlation to the soot-like curve shall be provided as a chart, which compares the efficiencies obtained

using both test aerosols. The differences in the counting efficiencies have to be considered by adjusting

the measured efficiencies based on the provided chart to give soot-like aerosol efficiencies. The

correction for multiply charged particles should be applied and documented but shall not exceed 10 %.

These efficiencies refer to the PN analyser systems including the sampling line. The PN analyser system

can also be calibrated in parts (i.e. the pre-conditioning unit separately from the particle detector) as long

as it is proven that the PN analyser and the sampling line together fulfil the requirements of Table 4. The

measured signal from the detector shall be > 2 times the limit of detection (here defined as the zero level

plus 3 standard deviations of the measured value).

6.6.3 Linearity requirements

The PN analyser system including the sampling line shall fulfil the linearity requirements described in

Table A.1 of Annex A - using monodisperse or polydisperse soot-like particles. The particle size (mobility

diameter or count median diameter) should be larger than 45 nm. The reference instrument shall be an

Electrometer or a Condensation Particle Counter (CPC) with detection efficiency > 90 % at that size,

verified for linearity. Alternatively, a particle number counting system compliant with the relevant

regulation can be used.

In addition, the differences of the PN analyser system from the reference instrument at all points checked

(except the zero point) shall be within 15 % of their mean value. At least 5 points equally distributed

(plus the zero) shall be checked. The maximum checked concentration shall be the maximum allowed

concentration of the PN analyser.

If the PN analyser system is calibr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...