SIST EN 14792:2017

(Main)Stationary source emissions - Determination of mass concentration of nitrogen oxides - Standard reference method: chemiluminescence

Stationary source emissions - Determination of mass concentration of nitrogen oxides - Standard reference method: chemiluminescence

This European Standard specifies the standard reference method (SRM) based on the chemiluminescence principle for the determination of the nitrogen oxides (NOx) in flue gases emitted to the atmosphere from ducts and stacks. It includes the sampling and the gas conditioning system, as well as the analyser.

This European Standard specifies the characteristics to be determined and the performance criteria to be fulfilled by measuring systems based on this measurement method. It applies for periodic monitoring and for the calibration or control of automatic measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

This European Standard specifies criteria for demonstration of equivalence of an alternative method to the SRM by application of prEN 14793.

This European standard has been validated during field tests on waste incineration, co-incineration and large combustion installations and on a recognized test-bench. It has been validated for sampling periods of 30 min in the range of 0 mg/m3 to 1 300 mg/m3 of NO2 for large combustion plants and 0 mg/m3 to 400 mg/m3 of NO2 for waste incineration, according to emission limit values (ELV) laid down in the Directive 2010/75/EC.

The ELV for NOx (NO + NO2) in EU directives are expressed in mg/m3 of NO2 on a dry basis, at a specified value for oxygen and at reference conditions (273 K and 101,3 kPa).

NOTE The characteristics of installations, the conditions during field tests and the values of repeatability and reproducibility in the field are given in Annex F.

Emissionen aus stationären Quellen - Bestimmung der Massenkonzentration von Stickstoffoxiden - Standardreferenzverfahren: Chemilumineszenz

Diese Europäische Norm legt das Standardreferenzverfahren (SRM) auf Basis des Chemilumineszenz-Verfahrens zur Bestimmung der Stickstoffoxide (NOx) in Abgasen, die aus Abgaskanälen in die Atmosphäre emittiert werden, fest. Es beinhaltet die Einrichtungen zur Probenahme und zur Probengasaufbereitung sowie das Analysegerät.

Diese Europäische Norm legt zu bestimmende Verfahrenskenngrößen und Mindestanforderungen fest, die von portablen automatischen Messeinrichtungen (P AMS) auf Basis dieses Messverfahrens eingehalten werden müssen. Sie gilt für wiederkehrende Messungen und für die Kalibrierung oder Überprüfung von automatischen Messeinrichtungen (AMS), die aus gesetzgeberischen oder anderen Gründen stationär an einem Abgaskanal installiert sind.

Diese Europäische Norm legt Anforderungen zum Nachweis der Gleichwertigkeit von Alternativverfahren (AM) mit dem Standardreferenzverfahren (SRM) durch Anwendung der EN 14793:2017 fest.

Diese Europäische Norm wurde in Feldversuchen an Abfallverbrennungsanlagen, Mitverbrennungsanlagen und Großfeuerungsanlagen sowie an einem anerkannten Prüfstand validiert. Sie wurde mit Probenahmedauern von 30 min für NOx-Konzentrationen im Bereich von 0 mg/m3 bis 1 300 mg/m3 für Großfeuerungsanlagen und im Bereich von 0 mg/m3 bis 400 mg/m3 für Abfallverbrennungsanlagen, jeweils gemessen als NO2, entsprechend den in der Richtlinie 2010/75/EU geforderten Emissionsgrenzwerten (ELV) validiert.

In den EU-Richtlinien wird der Grenzwert für NOx (NO + NO2) gemessen als NO2 in Milligramm je Kubikmeter (mg/m3) für trockenes Gas bei einem Bezugssauerstoffgehalt und Normbedingungen (273 K und 101,3 kPa) angegeben.

ANMERKUNG Die Einzelheiten der Anlagen, die Bedingungen bei den Feldversuchen und die Werte der Wiederhol- und der Vergleichpräzision im Feld werden in Anhang A aufgeführt.

Emissions de sources fixes - Détermination de la concentration massique des oxydes d'azote - Méthode de référence normalisée : chimiluminescence

La présente Norme européenne spécifie la méthode de référence normalisée (SRM) basée sur le principe de chimiluminescence pour la détermination des oxydes d'azote (NOx) des effluents gazeux émis dans l'atmosphère par les conduits et cheminées. Elle inclut le système de prélèvement et de conditionnement du gaz ainsi que l'analyseur.

La présente Norme européenne spécifie les caractéristiques devant être déterminées et les critères de performance devant être remplis par les systèmes de mesurage fondés sur cette méthode de mesurage. Elle s'applique à la surveillance périodique et à l'étalonnage ou au contrôle des systèmes de mesurage automatisés (AMS, Automatic Measuring Systems) installés à demeure sur une cheminée, à des fins réglementaires ou à d'autres fins.

La présente Norme européenne spécifie les critères permettant de démontrer l'équivalence entre une méthode « alternative » et la méthode de référence normalisée par l'application du prEN 14793.

La présente Norme européenne a été validée au cours d'essais sur site pratiqués sur des installations destinées à l'incinération des déchets, à la coincinération et sur de grandes installations de combustion ainsi que sur un banc d'essai reconnu. Elle a été validée pour des périodes de prélèvement de 30 min, dans la gamme comprise entre 0 mg/m3 et 2 000 mg/m3 de NO2 pour de grandes installations de combustion et entre 0 mg/m3 à 400 mg/m3 of NO2 pour l'incinération des déchets, conformément aux valeurs limites d'émission (VLE) spécifiées dans la Directive 2010/75/CE.

Les VLE des Directives UE pour NOx (NO + NO2) sont exprimées en mg/m3 de NO2 sur sec, à une valeur spécifiée de l'oxygène et dans les conditions de référence (273 K et 101,3 kPa).

NOTE Les caractéristiques des installations, les conditions des essais sur site et les valeurs de répétabilité et de reproductibilité sur site sont indiquées à l'Annexe F.

Emisije nepremičnih virov - Določevanje masne koncentracije dušikovih oksidov - Standardna referenčna metoda: kemiluminiscenca

Ta evropski standard določa standardno referenčno metodo (SRM) na podlagi kemoluminiscence za določanje dušikovih oksidov (NOx) v dimnih plinih, ki prehajajo v ozračje iz vodov in odvodnikov. Vključuje sistem za vzorčenje in kondicioniranje plinov ter tudi analizator.

Ta evropski standard določa lastnosti in merila zmogljivosti, ki jih morajo izpolnjevati merilni sistemi na podlagi te merilne metode. Uporablja se za redno spremljanje in kalibracijo ali nadzor avtomatskih merilnih sistemov (AMS), ki so trajno nameščeni na odvodnik, in sicer za zakonske ter druge namene.

Ta evropski standard določa merila za prikaz enakovrednosti alternativne metode standardni referenčni metodi z uporabo standarda prEN 14793.

Ta evropski standard je bil potrjen med preskusi sežiganja odpadkov, sosežiga in velikih kurilnih naprav na terenu ter na ustrezni preskusni mizi. Potrjen je bil za 30-minutna obdobja vzorčenja v razponu od 0 mg/m3 do 1300 mg/m3 NO2 za velike kurilne naprave in od 0 mg/m3 do 400 mg/m3 NO2 za sežig odpadkov glede na mejne vrednosti emisij (ELV), opredeljene v Direktivi 2010/75/ES.

Mejne vrednosti emisij za NOx (NO + NO2) v direktivah EU so izražene v mg/m3 NO2 na suhi osnovi pri podani vrednosti kisika in referenčnih pogojih (273 K in 101,3 kPa).

OPOMBA: Lastnosti naprav, pogoji med preskusi na terenu ter vrednosti ponovljivosti in reprodukcije na terenu so podani v dodatku F.

General Information

- Status

- Published

- Public Enquiry End Date

- 08-Feb-2015

- Publication Date

- 01-Feb-2017

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 19-Jan-2017

- Due Date

- 26-Mar-2017

- Completion Date

- 02-Feb-2017

Relations

- Effective Date

- 01-Mar-2017

Overview

EN 14792:2017 - “Stationary source emissions: Determination of mass concentration of nitrogen oxides - Standard reference method: chemiluminescence” - is a CEN standard that defines the standard reference method (SRM) for measuring nitrogen oxides (NOx) in flue gases from ducts and stacks using the chemiluminescence principle. The standard covers the complete measurement chain: sampling probe, gas conditioning, analyser (converter, ozone generator, reaction chamber, photomultiplier), performance criteria and quality control. It is validated for 30-minute sampling periods and ranges applicable to large combustion plants (0–1 300 mg/m3 NO2) and waste incineration (0–400 mg/m3 NO2) in line with emission limit values under Directive 2010/75/EU.

Key topics and requirements

- Measurement principle: Chemiluminescence-based detection of NO and NO2 after appropriate conversion and reaction with ozone.

- Complete system specification: Sampling probe, filters, sample lines, conditioning system, pump, flow controller and analyser components are described.

- Performance and validation: Characteristics to be determined, field validation results, repeatability and reproducibility data (see Annex A and F).

- Ranges and sampling: Validated for 30 min sampling; reporting on a dry basis at specified oxygen and reference conditions (273 K, 101.3 kPa).

- Quality assurance: Procedures for on-site setup, zero/span checks, ongoing quality control and uncertainty estimation (Annexes C, E, F).

- Equivalence of alternative methods: Criteria and procedures for demonstrating equivalence to the SRM using EN 14793 (demonstration of equivalence).

- Components detail: Converter types, ozone generator, reaction chamber and optical detection are identified and referenced (Annexes C–D).

Applications and users

EN 14792:2017 is intended for:

- Regulatory monitoring: Compliance testing against EU emission limit values (ELVs) for NOx (expressed as NO2 on a dry basis).

- Periodic stack monitoring: Portable Automated Measuring Systems (P-AMS) and spot checks at combustion, waste incineration and co‑incineration plants.

- Calibration and control: Calibration and performance control of permanently installed Automated Measuring Systems (AMS).

- Instrument manufacturers and laboratories: Designing, certifying and validating chemiluminescence analysers and sampling systems.

- Environmental consultants and operators: Preparing measurement plans, executing field tests and reporting results with documented uncertainty.

Related standards

- EN 14793:2017 - Demonstration of equivalence of an alternative method with a reference method (used to assess alternative techniques).

- EN 15259:2007 - Requirements for measurement sections, sites and measurement planning.

- EN 15267-4:2017 - Certification of automated measuring systems (relevant for AMS implementation).

EN 14792:2017 is essential for accurate, traceable NOx measurement, stack monitoring and compliance with EU air quality and industrial emissions requirements.

Frequently Asked Questions

SIST EN 14792:2017 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Stationary source emissions - Determination of mass concentration of nitrogen oxides - Standard reference method: chemiluminescence". This standard covers: This European Standard specifies the standard reference method (SRM) based on the chemiluminescence principle for the determination of the nitrogen oxides (NOx) in flue gases emitted to the atmosphere from ducts and stacks. It includes the sampling and the gas conditioning system, as well as the analyser. This European Standard specifies the characteristics to be determined and the performance criteria to be fulfilled by measuring systems based on this measurement method. It applies for periodic monitoring and for the calibration or control of automatic measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes. This European Standard specifies criteria for demonstration of equivalence of an alternative method to the SRM by application of prEN 14793. This European standard has been validated during field tests on waste incineration, co-incineration and large combustion installations and on a recognized test-bench. It has been validated for sampling periods of 30 min in the range of 0 mg/m3 to 1 300 mg/m3 of NO2 for large combustion plants and 0 mg/m3 to 400 mg/m3 of NO2 for waste incineration, according to emission limit values (ELV) laid down in the Directive 2010/75/EC. The ELV for NOx (NO + NO2) in EU directives are expressed in mg/m3 of NO2 on a dry basis, at a specified value for oxygen and at reference conditions (273 K and 101,3 kPa). NOTE The characteristics of installations, the conditions during field tests and the values of repeatability and reproducibility in the field are given in Annex F.

This European Standard specifies the standard reference method (SRM) based on the chemiluminescence principle for the determination of the nitrogen oxides (NOx) in flue gases emitted to the atmosphere from ducts and stacks. It includes the sampling and the gas conditioning system, as well as the analyser. This European Standard specifies the characteristics to be determined and the performance criteria to be fulfilled by measuring systems based on this measurement method. It applies for periodic monitoring and for the calibration or control of automatic measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes. This European Standard specifies criteria for demonstration of equivalence of an alternative method to the SRM by application of prEN 14793. This European standard has been validated during field tests on waste incineration, co-incineration and large combustion installations and on a recognized test-bench. It has been validated for sampling periods of 30 min in the range of 0 mg/m3 to 1 300 mg/m3 of NO2 for large combustion plants and 0 mg/m3 to 400 mg/m3 of NO2 for waste incineration, according to emission limit values (ELV) laid down in the Directive 2010/75/EC. The ELV for NOx (NO + NO2) in EU directives are expressed in mg/m3 of NO2 on a dry basis, at a specified value for oxygen and at reference conditions (273 K and 101,3 kPa). NOTE The characteristics of installations, the conditions during field tests and the values of repeatability and reproducibility in the field are given in Annex F.

SIST EN 14792:2017 is classified under the following ICS (International Classification for Standards) categories: 13.040.40 - Stationary source emissions. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14792:2017 has the following relationships with other standards: It is inter standard links to SIST EN 14792:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14792:2017 is associated with the following European legislation: EU Directives/Regulations: 2016-01-0285. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14792:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Emissionen aus stationären Quellen - Bestimmung der Massenkonzentration von Stickstoffoxiden - Standardreferenzverfahren: ChemilumineszenzEmissions de sources fixes - Détermination de la concentration massique des oxydes d'azote - Méthode de référence normalisée : chimiluminescenceStationary source emissions - Determination of mass concentration of nitrogen oxides - Standard reference method: chemiluminescence13.040.40Stationary source emissionsICS:Ta slovenski standard je istoveten z:EN 14792:2017SIST EN 14792:2017en,fr,de01-marec-2017SIST EN 14792:2017SLOVENSKI

STANDARDSIST EN 14792:20061DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14792

January

t r s y ICS

s uä r v rä v r Supersedes EN

s v y { tã t r r wEnglish Version

Stationary source emissions æ Determination of mass concentration of nitrogen oxides æ Standard reference methodã chemiluminescence Emissions de sources fixes æ Détermination de la concentration massique des oxydes d 5azote æ Méthode de référence normalisée ã chimiluminescence

Emissionen aus stationären Quellen æ Bestimmung der Massenkonzentration von Stickstoffoxiden æ Standardreferenzverfahrenã Chemilumineszenz This European Standard was approved by CEN on

t x September

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v y { tã t r s y ESIST EN 14792:2017

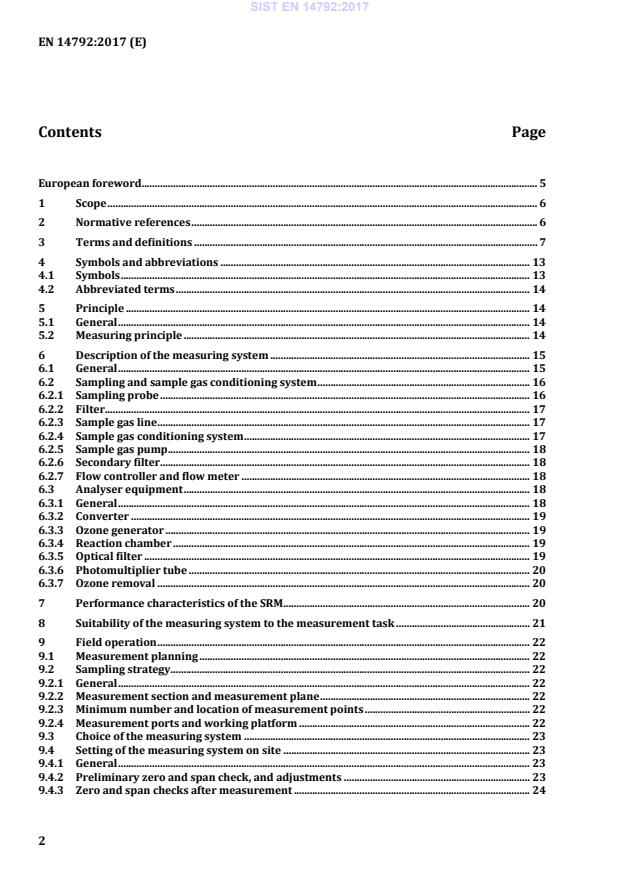

European foreword . 5 1 Scope . 6 2 Normative references . 6 3 Terms and definitions . 7 4 Symbols and abbreviations . 13 4.1 Symbols . 13 4.2 Abbreviated terms . 14 5 Principle . 14 5.1 General . 14 5.2 Measuring principle . 14 6 Description of the measuring system . 15 6.1 General . 15 6.2 Sampling and sample gas conditioning system . 16 6.2.1 Sampling probe . 16 6.2.2 Filter . 17 6.2.3 Sample gas line . 17 6.2.4 Sample gas conditioning system . 17 6.2.5 Sample gas pump . 18 6.2.6 Secondary filter . 18 6.2.7 Flow controller and flow meter . 18 6.3 Analyser equipment . 18 6.3.1 General . 18 6.3.2 Converter . 19 6.3.3 Ozone generator . 19 6.3.4 Reaction chamber . 19 6.3.5 Optical filter . 19 6.3.6 Photomultiplier tube . 20 6.3.7 Ozone removal . 20 7 Performance characteristics of the SRM . 20 8 Suitability of the measuring system to the measurement task . 21 9 Field operation . 22 9.1 Measurement planning . 22 9.2 Sampling strategy. 22 9.2.1 General . 22 9.2.2 Measurement section and measurement plane . 22 9.2.3 Minimum number and location of measurement points . 22 9.2.4 Measurement ports and working platform . 22 9.3 Choice of the measuring system . 23 9.4 Setting of the measuring system on site . 23 9.4.1 General . 23 9.4.2 Preliminary zero and span check, and adjustments . 23 9.4.3 Zero and span checks after measurement . 24 SIST EN 14792:2017

Validation of the method in the field . 28 A.1 General . 28 A.2 Characteristics of installations . 28 A.3 Repeatability and reproducibility in the field . 29 A.3.1 General . 29 A.3.2 Repeatability . 30 A.3.3 Reproducibility . 31 Annex B (informative)

Sampling and conditioning configurations . 32 Annex C (normative)

Determination of conversion efficiency . 33 C.1 General . 33 C.2 First method: cylinder gases for calibration . 33 C.3 Second method: gaseous phase titration . 33 Annex D (informative)

Examples of different types of converters . 35 D.1 Quartz converter . 35 D.2 Low temperature converter (molybdenum) . 35 D.3 Stainless steel converter . 35 Annex E (informative)

Calculation of the uncertainty associated with a concentration expressed for dry gas and at an oxygen reference concentration . 36 E.1 Uncertainty associated with a concentration expressed on dry gas . 36 E.2 Uncertainty associated with a concentration expressed at a oxygen reference concentration . 38 Annex F (informative)

Example of assessment of compliance of chemiluminescence method for NOx with requirements on emission measurements . 40 F.1 General . 40 F.2 Elements required for the uncertainty determinations . 40 F.2.1 Model equation . 40 F.2.2 Combined uncertainty . 41 F.2.3 Expanded uncertainty . 41 F.2.4 Determination of uncertainty contributions in case of rectangular distributions . 43 F.2.5 Determination of uncertainty contributions by use of sensitivity coefficients . 44 F.3 Example of an uncertainty calculation. 44 F.3.1 Site specific conditions . 44 SIST EN 14792:2017

Significant technical changes . 55 Bibliography . 56

This European Standard specifies the characteristics to be determined and the performance criteria to be fulfilled by portable automated measuring systems (P-AMS) based on this measurement method. It applies for periodic monitoring and for the calibration or control of automated measuring systems (AMS) permanently installed on a stack, for regulatory or other purposes.

This European Standard specifies criteria for demonstration of equivalence of an alternative method to the SRM by application of EN 14793:2017. This European Standard has been validated during field tests on waste incineration, co-incineration and large combustion installations and on a recognized test-bench. It has been validated for sampling periods of 30 min in the range of 0 mg/m3 to 1 300 mg/m3 of NOx for large combustion plants and 0 mg/m3 to 400 mg/m3 of NOx for waste incineration, according to emission limit values (ELV) laid down in the Directive 2010/75/EU. The ELV for NOx (NO + NO2) in EU Directives is expressed in mg/m3 of NO2 on a dry basis, at a specified value for oxygen and at standard conditions (273 K and 101,3 kPa). NOTE The characteristics of installations, the conditions during field tests and the values of repeatability and reproducibility in the field are given in Annex A. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 14793:2017, Stationary source emission – Demonstration of equivalence of an alternative method with a reference method EN 15259:2007, Air quality - Measurement of stationary source emissions - Requirements for measurement sections and sites and for the measurement objective, plan and report EN 15267-4:2017, Air quality — Certification of automated measuring systems — Part 4: Performance criteria and test procedures for automated measuring systems for periodic measurements of emissions from stationary sources EN ISO 14956:2002, Air quality - Evaluation of the suitability of a measurement procedure by comparison with a required measurement uncertainty (ISO 14956:2002) ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995) SIST EN 14792:2017

SRM reference method prescribed by European or national legislation

[SOURCE: EN 15259:2007] 3.2 reference method RM measurement method taken as a reference by convention, which gives the accepted reference value of the measurand Note 1 to entry: A reference method is fully described. Note 2 to entry: A reference method can be a manual or an automated method. Note 3 to entry: Alternative methods can be used if equivalence to the reference method has been demonstrated. [SOURCE: EN 15259:2007] 3.3 measurement method method described in a written procedure containing all the means and procedures required to sample and analyse, namely: field of application, principle and/or reactions, definitions, equipment, procedures, presentation of results, and other requirements and measurement report [SOURCE: EN 14793:2017] 3.4 alternative method

AM

measurement method which complies with the criteria given by this European Standard with respect to the reference method

Note 1 to entry: An alternative method can consist of a simplification of the reference method. [SOURCE: EN 14793:2017] 3.5 measuring system set of one or more measuring instruments and often other devices, including any reagent and supply, assembled and adapted to give information used to generate measured quantity values within specified intervals for quantities of specified kinds [SOURCE: JCGM 200:2012] SIST EN 14792:2017

Note 2 to entry: The P-AMS can be configured at the measurement site for the special application but can be also set-up in a van or mobile container. The probe and the sample gas lines are installed often just before the measurement task is started.

[SOURCE: EN 15267-4:2017] 3.8 calibration

set of operations that establish, under specified conditions, the relationship between values of quantities indicated by a measuring method or measuring system, and the corresponding values given by the applicable reference

Note 1 to entry: In case of automated measuring system (AMS) permanently installed on a stack the applicable reference is the standard reference method (SRM) used to establish the calibration function of the AMS. Note 2 to entry: Calibration should not be confused with adjustment of a measuring system. 3.9 adjustment

set of operations carried out on a measuring system so that it provides prescribed indications corresponding to given values of a quantity to be measured

Note 1 to entry: The adjustment can be made directly on the instrument or using a suitable calculation procedure. 3.10 span gas test gas used to adjust and check a specific point on the response line of the measuring system SIST EN 14792:2017

[SOURCE: EN 15259:2007] Note 1 to entry:

The measurand is a quantifiable property of the stack gas under test, for example mass concentration of a measured component, temperature, velocity, mass flow, oxygen content and water vapour content. 3.12 interference negative or positive effect upon the response of the measuring system, due to a component of the sample that is not the measurand 3.13 influence quantity quantity that is not the measurand but that affects the result of the measurement Note 1 to entry: Influence quantities are e.g. presence of interfering gases; ambient temperature, pressure of the gas sample. 3.14 ambient temperature

temperature of the air around the measuring device 3.15 emission limit value ELV limit value given in regulations such as EU Directives, ordinances, administrative regulations, permits, licences, authorisations or consents Note 1 to entry: ELV can be stated as concentration limits expressed as half-hourly, hourly and daily averaged values, or mass flow limits expressed as hourly, daily, weekly, monthly or annually aggregated values. 3.16 measurement site place on the waste gas duct in the area of the measurement plane(s) consisting of structures and technical equipment, for example working platforms, measurement ports, energy supply

Note 1 to entry: Measurement site is also known as sampling site. [SOURCE: EN 15259:2007] 3.17 measurement plane plane normal to the centreline of the duct at the sampling position Note 1 to entry: Measurement plane is also known as sampling plane. [SOURCE: EN 15259:2007] SIST EN 14792:2017

Note 1 to entry: Measurement point is also known as sampling point. [SOURCE: EN 15259:2007] 3.21 performance characteristic one of the quantities (described by values, tolerances, range) assigned to equipment in order to define its performance 3.22 response time duration between the instant when an input quantity value of a measuring instrument or measuring system is subjected to an abrupt change between two specified constant quantity values and the instant when a corresponding indication settles within specified limits around its final steady value

Note 1 to entry: By convention time taken for the output signal to pass from 0 % to 90 % of the final variation of indication. 3.23 short-term zero drift difference between two zero readings at the beginning and at the end of the measurement period 3.24 short-term span drift difference between two span readings at the beginning and at the end of the measurement period SIST EN 14792:2017

used under the same conditions; — same location; — implemented by the same laboratory; — typically calculated on short periods of time in order to avoid the effect of changes of influence

parameters (e.g. 30 min). Note 2 to entry: Repeatability may be expressed quantitatively in terms of the dispersion characteristics of the results. Note 3 to entry: In this European Standard the repeatability under field conditions is expressed as a value with a level of confidence of 95 %. 3.28 reproducibility in the field

closeness of the agreement between the results of simultaneous measurements of the same measurand carried out using several sets of equipment under the same conditions of measurement Note 1 to entry: These conditions are called field reproducibility conditions and include: — same measurement method; — several sets of equipment, the performance of which are fulfilling the requirements of the

measurement method, used under the same conditions; — same location; — implemented by several laboratories. Note 2 to entry: Reproducibility may be expressed quantitatively in terms of the dispersion characteristics of the results. Note 3 to entry: In this European Standard the reproducibility under field conditions is expressed as a value with a level of confidence of 95 %. 3.29 residence time in the measuring system time period for the sample gas to be transported from the inlet of the probe to the inlet of the measurement cell 3.30 conversion efficiency percentage of NO2 present in the sample gas converted to NO by the converter SIST EN 14792:2017

uncertainties according to the principles laid down in ISO/IEC Guide 98-3 (GUM) 3.34 expanded uncertainty U quantity defining an interval about the result of a measurement that may be expected to encompass a large fraction of the distribution of values that could reasonably be attributed to the measurand cUku=× Note 1 to entry: In this European Standard, the expanded uncertainty is calculated with a coverage factor of k = 2, and with a level of confidence of 95 %.

Note 2 to entry:

The expression overall uncertainty is sometimes used to express the expanded uncertainty. 3.35 uncertainty budget calculation table combining all the sources of uncertainty according to EN ISO 14956 or ISO/IEC Guide 98-3 in order to calculate the combined uncertainty of the method at a specified value 4 Symbols and abbreviations 4.1 Symbols For the purposes of this document, the following symbols apply. A(t0)

(result given by the analyser after adjustment at t0 at span point – result given by the analyser after adjustment at t0 at zero point) / (calibration gas concentration at span point – calibration gas concentration at zero point) B(t0)

result given by the analyser after adjustment at t0 at zero point

C measured concentration Ccorr

measured concentration corrected for drift Drift(A)

{[(result given by the analyser during the drift check at tend at span point – result given by the analyser during the drift check at tend at zero point) / (calibration gas concentration at span point – calibration gas concentration at zero point)] – A(t0)} / (tend – t0) Drift(B) (result given by the analyser during the drift check at tend at zero point – result SIST EN 14792:2017

molar mass sR

reproducibility standard deviation sr,limit

maximum allowable repeatability standard deviation t time t0 time of adjustment tend time of check for drift at the end of the measurement period u standard uncertainty uc combined uncertainty U expanded uncertainty Vmol

molar volume 4.2 Abbreviated terms For the purposes of this document, the following abbreviated terms apply. AM alternative method AMS automated measuring system P-AMS portable automated measuring system PTFE polytetrafluoroethene PFA perfluoroalkoxy SRM standard reference method 5 Principle 5.1 General This European Standard describes the standard reference method (SRM) for sampling and determining NOx (NO and NO2) concentrations in flue gases emitted to atmosphere from ducts and stacks by means of an automatic analyser using chemiluminescence absorption principle. The specific components and the requirements for the sampling system and the chemiluminescence analyser are described in Clause 6 and Clause 7. A number of performance characteristics, together with associated performance criteria are specified for the analyser. These performance characteristics determined according to EN 15267-4:2017 and the expanded uncertainty of the method shall meet the performance criteria given in this European Standard. Requirements and recommendations for quality assurance and quality control are given in Clause 10 for measurements in the field. 5.2 Measuring principle The principle of chemiluminescence to measure NOx is based on the following reaction between nitrogen monoxide and ozone: 32222NO2ONONO*2O+⇒++ SIST EN 14792:2017

For the determination of the amount of nitrogen dioxide, the sampled gas is fed through a converter where the nitrogen dioxide is reduced to nitrogen monoxide and analysed in the same way as described previously. The electric signal obtained from the photomultiplier tube is proportional to the sum of concentrations of nitrogen dioxides and nitrogen monoxides. The amount of nitrogen dioxide is calculated from the difference between this concentration and that obtained for nitrogen monoxide only (when the sampled gas has not passed through the converter). When a dual type analyser is used, both NO and NOx results are determined continuously. On the contrary, with a single type analyser, the reaction chamber is alternatively fed with gas having not passed the converter and with the gas having passed the converter that reduces NO2 to NO. Therefore, NO and NOx are determined alternately. Chemiluminescence analysers are associated to an extractive sampling system and a sample gas conditioning system. A sample of gas is taken from the stack with a sampling probe and conveyed to the analyser through a sample gas line and suitable gas conditioning system. The values from the analyser are recorded and/or stored by means of electronic data processing. Interference due to CO2 in the sample gas is possible, particularly in the presence of water vapour, due to quenching of the chemiluminescence. The extent of the quenching depends on the CO2 and H2O concentrations and the type of analyser used. Any necessary corrections may be made to the analyser output to increase its accuracy for example by reference to correction curves supplied by the manufacturers or by calibrating with gases containing approximately the same concentration of CO2 as the sample gas.

NOTE 1 A vacuum chemiluminescent NOx analyser reduces the CO2 and H2O quenching error. NOTE 2 A correction of the NOx concentration may be necessary if the NH3 concentration is higher than 20 mg/m3. In flue gases from conventional combustion systems the nitrogen oxides consist of more than 95 % NO. The remaining oxide is predominantly NO2. These two oxides (NO + NO2) are designated as NOx. It should be noted, that in other processes, the ratio of NO to NOx may be different and other nitrogen oxides may be present. 6 Description of the measuring system

6.1 General

A volume is extracted from the flue gas for a fixed period of time at a controlled flow rate. The sampling system consists of: — a sampling probe; — a filter; SIST EN 14792:2017

Possible configurations are: — Configuration 1: removal of water vapour by condensation using a cooling system; — Configuration 2: removal of water vapour through elimination within a permeation drier; — Configuration 3: dilution with dry, clean ambient air or nitrogen of the gas to be characterized; — Configuration 4: heating of the complete sampling system from the inlet of the sample gas line to the heated analyser at a temperature above the dew point. Configurations 1 to 3 require that the user shall check that the dew point temperature or the outlet temperature of the conditioning system is lower or equal to 4 °C at the inlet of the analyser.

For configuration 4 the user may correct the results for the remaining water content in order to report results on a dry basis (see Annex B in EN 14790:2017). It is important that all parts of the sampling equipment upstream of the analyser are made of materials that do not react with or absorb NOx.

The temperature of all components of the sampling equipment coming into contact with the wet sample gas shall be maintained at a sufficiently high temperature to avoid any condensation. Conditions and layout of the sampling equipment contribute to the combined uncertainty of the measurement. In order to minimize this contribution to the combined measurement uncertainty, performance criteria for the sampling equipment and sampling conditions are given in 6.2 and Clause 7. Some other sample gas conditioning systems may exist and could be acceptable, provided they fulfil the requirements of this European Standard and have been validated with success during the certification process. For example, some systems put gas in depression using a simple Sonic nozzle in the collection probe in order to create a partial vacuum (between 50 hPa and 100 hPa absolute) so that the head of collection and the sample gas line does not need to be heated and water vapour condensation is avoided. 6.2 Sampling and sample gas conditioning system 6.2.1 Sampling probe In order to reach the measurement points of the measurement plane, probes of different lengths and inner diameters may be used. The design and configuration of the probe used shall ensure the residence time of the sample gas within the probe is minimised in order to reduce the response time of the measuring system. NOTE 1 The probe can be marked before sampling in order to demonstrate that the measurement points in the measurement plane have been reached. NOTE 2 A sealable connection can be installed on the probe in order to introduce test gases for adjustment. SIST EN 14792:2017

The sample gas line shall be heated up to the conditioning system. It shall be made of a suitable corrosion resistant material (e.g. stainless steel, borosilicate glass, ceramic; PTFE or PFA is only suitable for flue-gas temperature lower than 200 °C). At temperatures greater than 250 °C, stainless steel and certain other materials can alter the ratio of NO2/NOx. In this case, ceramic, glass, quartz or titanium should be used.

6.2.4 Sample gas conditioning system 6.2.4.1 Sample gas cooler (configuration 1) The design of the sample gas cooler shall be such that absorption of NO2 in the condensates is minimised. Because overpressure in the cooling system increases losses of NO2 in the condensates, the pump shall be situated between the cooling system and the analyser. In the case that the concentration of NO2 in the sample gas becomes too high, the use of a sample gas cooler can produce errors on the NO2 measurement. This can occur because of the solubility of NO2 in the condensed water and shall also depend on the content of water vapour in the flue gas.

6.2.4.2 Permeation drier (configuration 2) The permeation drier is used before the gas enters the analyser in order to separate water vapour from the flue gas. The dew point at the outlet of the system shall be sufficiently below the ambient temperature.

Due to ammonium salts deposition on the permeation tube, the permeation system shall not be used when the NH3 concentration is outside the range specified by the manufacturer. 6.2.4.3 Dilution system (configuration 3) The dilution technique is an alternative to hot-gas monitoring or sample gas drying. The flue gas is diluted with dry, clean, ambient air or nitrogen. The dilution gas shall be dry and free from nitrogen oxides. The dilution ratio shall be chosen according to the objectives of the measurement and shall be compatible with the range of the analytical unit. It shall remain constant through the period of the test. The water dew point shall be reduced so to avoid the risks of condensation.

The contribution of the dilution system to the uncertainty shall be added to the uncertainty budget. NOTE 1

Configuration 3 was not included in the validation of the method in the field. NOTE 2 Analysers that are used in combination with dilution probes, work with measurement ranges, which are typical for ambient air analysers (0 mg/m3 –1 mg/m3 – 5 mg/m3 – 10 mg/m3 – 25 mg/m3). 6.2.4.4 Heated line and heated analyser (configuration 4) To avoid condensation, the sample gas line up to the analyser and the analyser itself shall be heated. SIST EN 14792:2017

Configuration 4 was not included in the validation of the method in the field. 6.2.5 Sample gas pump

When a pump is not an integral part of the chemiluminescence analyser, an external pump is necessary to draw the sampled gas through the apparatus. It shall be capable of operating to the specified flow requirements of the manufacturer of the analyser and pressure conditions required for the reaction chamber. The pump shall be resistant to corrosion and shall be of materials that do not react with or absorb NOx. It shall be consistent with the requirements of the analyse

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...