SIST EN 15085-5:2023

(Main)Railway applications - Welding of railway vehicles and components - Part 5: Inspection, testing and documentation

Railway applications - Welding of railway vehicles and components - Part 5: Inspection, testing and documentation

This series of standards applies to welding of metallic materials in the manufacture and maintenance of railway vehicles and their parts.

This part of the series defines the classification levels as well as the requirements for manufacturers of welded railway vehicles and components.

This part of the series specifies:

- inspections and testing to be executed on the welds;

- destructive as well as non-destructive tests to be performed;

- necessary documentation to issue to declare the conformity of the products.

Bahnanwendungen - Schweißen von Schienenfahrzeugen und -fahrzeugteilen - Teil 5: Prüfung und Dokumentation

Diese Normenreihe gilt für das Schweißen metallischer Werkstoffe bei der Herstellung und Instandsetzung von Schienenfahrzeugen und -fahrzeugteilen.

Dieses Dokument

— definiert die an den Schweißnähten durchzuführenden Prüfungen,

— legt die Durchführung der zerstörenden und zerstörungsfreien Prüfungen fest, und

— definiert die notwendigen Dokumentationen zur Herausgabe der Produktkonformitätserklärung.

Applications ferroviaires - Soudage des véhicules et des composants ferroviaires - Partie 5 : Vérification, contrôles et documentations

Le présent document spécifie :

— les contrôles et les essais à effectuer sur les soudures ;

— les contrôles destructifs et non destructifs à réaliser ;

— la documentation nécessaire à la déclaration de conformité des produits.

Železniške naprave - Varjenje železniških vozil in sestavnih delov - 5. del: Nadzor, preskušanje in dokumentacija

Ta skupina standardov se uporablja za varjenje kovinskih materialov pri izdelavi in vzdrževanju železniških vozil ter njihovih delov.

Ta del skupine standardov določa stopnje razvrstitve in zahteve za proizvajalce varjenih železniških vozil in komponent.

Ta del skupine standardov določa:

– pregled in preskušanje zvarov;

– porušitvene in neporušitvene preskuse, ki jih je treba izvesti;

– dokumentacijo, ki jo je treba izdati za potrditev skladnosti izdelkov.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Dec-2020

- Publication Date

- 28-Mar-2023

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Mar-2023

- Due Date

- 28-May-2023

- Completion Date

- 29-Mar-2023

Relations

- Effective Date

- 01-May-2023

Overview

EN 15085-5:2023 - part of the CEN EN 15085 series - specifies inspection, testing and documentation requirements for welding of metallic materials in the manufacture and maintenance of railway vehicles and components. It defines how manufacturers must plan and execute inspections (destructive and non‑destructive), record results, manage non‑conformities and demonstrate conformity through traceable documentation. The standard supports safety‑relevant classification of components and links weld quality to required personnel qualifications and process control.

Key topics and requirements

- Inspection scope: Specifies inspections and testing to be carried out on welded joints throughout manufacture and maintenance.

- Destructive and non‑destructive testing (NDT): Defines types and extent of tests, responsibilities for performing them, and requirements for independent inspection for higher classification levels.

- Pre‑, during‑ and post‑weld checks:

- Pre‑weld checks by the welding coordination team and welder (e.g., WPS validity, consumables, machine calibration, fit‑up).

- During welding surveillance (weld profile, cleaning, compliance with WPS and welding sequence).

- Post‑weld checks (completion, cleaning, dimensional conformance).

- Qualification of inspection personnel: Visual inspection and NDT personnel qualifications are aligned with EN ISO 9712:2022 and related competency requirements; independent inspectors are required for higher criticality classes.

- First Article Inspection (FAI): Requirements for planning, execution and documentation of FAI to verify production readiness.

- Test planning and acceptance: Test plans, acceptance criteria and periodic surveillance by the welding coordinator are required (without prescribing specific numerical criteria).

- Documentation and traceability: Specifies the documentation necessary to declare conformity, including records of tests, qualifications and traceability of materials and welds.

- Non‑conformity management: Procedures for identifying, recording, dispositioning and reworking welding defects.

- Roles and responsibilities: Emphasises the role of the welding coordinator/welding coordination team in audits, supervision and continuity of control.

Applications and who uses it

- Welding manufacturers of railway vehicles and subassemblies

- Maintenance workshops performing repair welding

- Welding coordinators, QA managers and production supervisors

- NDT and visual inspection personnel and certification bodies

- Procurement and regulatory compliance teams verifying supplier conformity

Practical benefits include improved safety, consistent weld quality, demonstrable conformity for audits, and clearer responsibilities across manufacturing and maintenance workflows.

Related standards

- EN 15085 series (Parts 1–6) - General, Manufacturer requirements, Design, Production, Maintenance

- EN ISO 3834 (quality requirements for fusion welding)

- EN ISO 9712:2022 (NDT personnel qualification)

- EN ISO 17635 / EN ISO 17637 (NDT and visual testing of welds)

- EN ISO 5817 / EN ISO 10042 (weld quality levels)

Keywords: EN 15085-5:2023, railway welding, welding inspection, non‑destructive testing, welding documentation, welding coordinator, FAI, traceability, welding quality.

Frequently Asked Questions

SIST EN 15085-5:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Welding of railway vehicles and components - Part 5: Inspection, testing and documentation". This standard covers: This series of standards applies to welding of metallic materials in the manufacture and maintenance of railway vehicles and their parts. This part of the series defines the classification levels as well as the requirements for manufacturers of welded railway vehicles and components. This part of the series specifies: - inspections and testing to be executed on the welds; - destructive as well as non-destructive tests to be performed; - necessary documentation to issue to declare the conformity of the products.

This series of standards applies to welding of metallic materials in the manufacture and maintenance of railway vehicles and their parts. This part of the series defines the classification levels as well as the requirements for manufacturers of welded railway vehicles and components. This part of the series specifies: - inspections and testing to be executed on the welds; - destructive as well as non-destructive tests to be performed; - necessary documentation to issue to declare the conformity of the products.

SIST EN 15085-5:2023 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15085-5:2023 has the following relationships with other standards: It is inter standard links to SIST EN 15085-5:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15085-5:2023 is associated with the following European legislation: EU Directives/Regulations: 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15085-5:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2023

Železniške naprave - Varjenje železniških vozil in sestavnih delov - 5. del: Nadzor,

preskušanje in dokumentacija

Railway applications - Welding of railway vehicles and components - Part 5: Inspection,

testing and documentation

Bahnanwendungen - Schweißen von Schienenfahrzeugen und -fahrzeugteilen - Teil 5:

Prüfung und Dokumentation

Applications ferroviaires - Soudage des véhicules et des composants ferroviaires - Partie

5 : Vérification, contrôles et documentations

Ta slovenski standard je istoveten z: EN 15085-5:2023

ICS:

25.160.10 Varilni postopki in varjenje Welding processes

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15085-5

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2023

EUROPÄISCHE NORM

ICS 25.160.10; 45.060.01 Supersedes EN 15085-5:2007

English Version

Railway applications - Welding of railway vehicles and

components - Part 5: Inspection, testing and

documentation

Applications ferroviaires - Soudage des véhicules et des Bahnanwendungen - Schweißen von

composants ferroviaires - Partie 5 : Vérification, Schienenfahrzeugen und -fahrzeugteilen - Teil 5:

contrôles et documentation Prüfung und Dokumentation

This European Standard was approved by CEN on 23 January 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15085-5:2023 E

worldwide for CEN national Members.

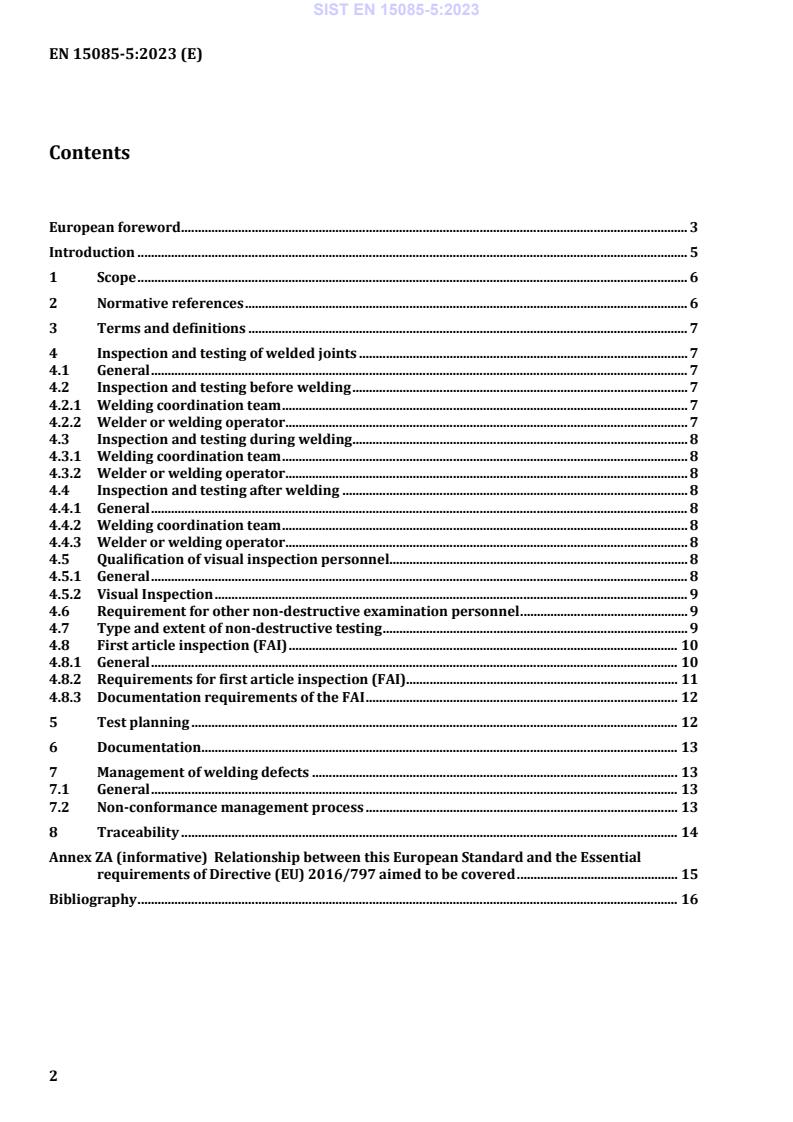

Contents

European foreword . 3

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Inspection and testing of welded joints . 7

4.1 General . 7

4.2 Inspection and testing before welding . 7

4.2.1 Welding coordination team . 7

4.2.2 Welder or welding operator . 7

4.3 Inspection and testing during welding . 8

4.3.1 Welding coordination team . 8

4.3.2 Welder or welding operator . 8

4.4 Inspection and testing after welding . 8

4.4.1 General . 8

4.4.2 Welding coordination team . 8

4.4.3 Welder or welding operator . 8

4.5 Qualification of visual inspection personnel. 8

4.5.1 General . 8

4.5.2 Visual Inspection . 9

4.6 Requirement for other non-destructive examination personnel . 9

4.7 Type and extent of non-destructive testing . 9

4.8 First article inspection (FAI) . 10

4.8.1 General . 10

4.8.2 Requirements for first article inspection (FAI). 11

4.8.3 Documentation requirements of the FAI . 12

5 Test planning . 12

6 Documentation . 13

7 Management of welding defects . 13

7.1 General . 13

7.2 Non-conformance management process . 13

8 Traceability . 14

Annex ZA (informative) Relationship between this European Standard and the Essential

requirements of Directive (EU) 2016/797 aimed to be covered . 15

Bibliography . 16

European foreword

This document (EN 15085-5:2023) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2023, and conflicting national standards shall

be withdrawn at the latest by September 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15085-5:2007.

This series of European Standards EN 15085 “Railway applications — Welding of railway vehicles and

components” consists of the following parts:

— Part 1: General;

— Part 2: Requirements for welding manufacturers;

— Part 3: Design requirements;

— Part 4: Production requirements;

— Part 5: Inspection, testing and documentation;

— Part 6: Maintenance welding requirements.

a) Normative references have been updated;

b) Clause 3, Terms and definitions has been updated;

c) Clause 4, Inspection and testing of welded joints has been revised;

d) Clause 5, Test planning and acceptance criteria has been revised;

e) Clause 6, Documentation has been revised;

f) Clause 7, Non-conformity has been revised;

g) Clause 8, Sub-contractors has been removed;

h) Clause 9, Declaration of conformity has been removed;

i) Clause 10, Traceability has been revised and renamed in Clause 8;

j) Annex A has been removed;

k) Annex ZA has been added.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Welding is a special process in the manufacture of railway vehicles and their parts. The required

provisions for this process are defined in the standards series EN ISO 3834. The basis of these provisions

is the basic technical welding standards with respect to the special requirements for the construction of

railway vehicles.

This series of standards applies to welding of metallic materials in the manufacture and maintenance of

railway vehicles and their parts.

It describes the control for the welding process for railway vehicles and their components for new

manufacture and maintenance.

With respect to the railway environment, this series of standards defines the quality requirements for the

welding manufacturer to undertake new building and repair work.

Components, parts and subassemblies are assigned a classification level, based on their safety relevance.

According to these levels, qualifications for welding personnel of the manufacturer are specified.

This series provides an essential link between the weld performance class defined during design, the

quality of the weld, and the demonstration of the required quality by inspection.

This series of standards does not deal with product qualification.

NOTE This series of standards can also be used by internal and external parties, including certification bodies,

to assess the organization's ability to meet customer, regulatory and the organization's own requirements.

1 Scope

This document specifies:

— inspections and testing to be executed on the welds;

— destructive as well as non-destructive tests to be performed;

— necessary documentation to issue to declare the conformity of the products.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 15085-1:— , Railway applications — Welding of railway vehicles and components — Part 1: General

EN 15085-2:2020, Railway applications - Welding of railway vehicles and components - Part 2:

Requirements for welding manufacturer

EN 15085-3:2022, Railway applications - Welding of railway vehicles and components - Part 3: Design

requirements

EN 15085-4:2023, Railway applications - Welding of railway vehicles and components - Part 4: Production

requirements

EN 15085-6:2022, Railway applications - Welding of railway vehicles and components - Part 6:

Maintenance welding requirements

EN 1011-2:2001, Welding - Recommendations for welding of metallic materials - Part 2: Arc welding of

ferritic steels

EN ISO 3834-1:2021, Quality requirements for fusion welding of metallic materials - Part 1: Criteria for the

selection of the appropriate level of quality requirements (ISO 3834-1:2021)

EN ISO 3834-5:2021, Quality requirements for fusion welding of metallic materials - Part 5: Documents

with which it is necessary to conform to claim conformity to the quality requirements of ISO 3834-2, ISO

3834-3 or ISO 3834-4 (ISO 3834-5:2021)

EN ISO 5817:2014, Welding - Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) - Quality levels for imperfections (ISO 5817:2014)

EN ISO 9712:2022, Non-destructive testing - Qualification and certification of NDT personnel

(ISO 9712:2022)

EN ISO 10042:2018, Welding - Arc-welded joints in aluminium and its alloys - Quality levels for

imperfections (ISO 10042:2018)

EN ISO 17635:2016, Non-destructive testing of welds - General rules for metallic materials (ISO

17635:2016)

EN ISO 17637:2016, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO

17637:2016)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 15085-1: — apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

4 Inspection and testing of welded joints

4.1 General

The manufacturer is responsible for the correct implementation of inspection activities according to the

requirements of this document. For maintenance EN 15085-6:2022 shall also be applied.

The tasks of inspection and testing are listed in the responsibilities of the welding coordinator in Annex A

of EN 15085-2:2020. Where these requirements are delegated, they should be continuously supervised

and subject to periodic internal audits by the welding coordinator or welding coordination team.

4.2 Inspection and testing before welding

4.2.1 Welding coordination team

Prior to any type of welding activity, the welding coordination team shall check/confirm the following

items based on EN 15085-2:2020, Annex A:

— suitability and validity of welder’s and welding operator’s qualification certificates;

— suitability and validity of the welding procedure specification;

— suitability of working conditions for welding, including the environment;

— performance and assessment of mock-ups e.g. supplementary weld tests, daily production tests.

4.2.2 Welder or welding operator

Immediately prior to welding the welder or welding operator shall check/confirm the following items:

— The welding machine is within calibration/validation and is not damaged;

— Jigs and fixtures are not damaged;

— The availability of the WPS and/or work instruction and fabrication drawing;

— Condition of the weld preparation (e.g. fit-up, cleanliness, tack welding, etc.);

— Correct identification of the parts to be welded;

— Compliance of the welding consumable with the WPS.

Where any of the above are non-compliant the welding coordination team shall be informed.

4.3 Inspection and testing during welding

4.3.1 Welding coordination team

The welding coordination team shall perform regular surveillance of all welding activities within the

workshop to confirm the required welding process control. The frequency of these surveillances shall be

determined by the welding coordinator and documented.

4.3.2 Welder or welding operator

During welding the welder or welding operator shall check/confirm the following items:

— Suitable weld profile and adequate cleaning between welding passes,

— Compliance with the WPS and/or work instruction, e.g. pre-heating/interpass temperatures, welding

parameters.

Compliance with the welding sequence defined in the welding planning documents.

4.4 Inspection and testing after welding

4.4.1 General

Inspection and testing after welding shall be undertaken by competent personnel. For CT 1 and CT 2 the

personnel shall be independent of welding production.

4.4.2 Welding coordination team

The welding coordination team shall be involved in the non-destructive and destructive testing and any

post welding operations e.g. heat treatment, ageing are performed according to the requirements of the

welding planning documents.

4.4.3 Welder or welding operator

After welding the welder or welding operator shall check/co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...