SIST EN 14197-3:2004

(Main)Cryogenic vessels - Static non-vacuum insulated vessels - Part 3: Operational requirements

Cryogenic vessels - Static non-vacuum insulated vessels - Part 3: Operational requirements

This European Standard specifies operational requirements for static non vacuum insulated vessels for cryogenic fluids according to prEN 14197-1, designed for a maximum allowable pressure greater than 0,5 bar. It can be used as a guideline for vessels designed for a maximum allowable pressure of not more than 0,5 bar.

The scope includes installation, putting into service, inspection, filling, maintenance and emergency procedures.

This European Standard applies to vessels for cryogenic fluids as specified in prEN 14197-1.

Kryo-Behälter - Ortsfeste nicht vakuum-isolierte Kryo-Behälter - Teil 3: Betriebsanforderungen

Diese Europäische Norm legt Betriebsanforderungen für ortsfeste nicht vakuum-isolierte Kryo-Behälter nach prEN 14197-1 fest, die für den Betrieb mit einem max. zulässigen Druck von über 0,5 bar ausgelegt sind. Sie kann als Richtlinie für Behälter mit einem max. zulässigen Druck von weniger als 0,5 bar verwendet werden.

Der Anwendungsbereich beinhaltet Inbetriebnahme, Befüllen, Instandhaltung, Prüfungen und das Verhalten im Notfall.

Die Norm gilt für Behälter für tiefkalte Fluide wie in prEN 14197-1 festgelegt.

Récipients cryogéniques - Récipients statiques non isolés sous vide - Partie 3: Exigences de fonctionnement

Kriogene posode – Stabilne, vakuumsko neizolirane posode - 3. del: Zahteve za obratovanje

General Information

- Status

- Published

- Publication Date

- 31-May-2004

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Jun-2004

- Due Date

- 01-Jun-2004

- Completion Date

- 01-Jun-2004

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Overview

EN 14197-3:2004 is the CEN European Standard that defines operational requirements for static, non‑vacuum insulated cryogenic vessels (as defined in EN 14197‑1). It applies primarily to vessels designed for a maximum allowable pressure greater than 0.5 bar, and may be used as guidance for lower‑pressure vessels. The standard covers practical operational lifecycle topics including installation, commissioning (putting into service), inspection, filling, maintenance, taking out of service and emergency procedures.

Key topics and technical requirements

- Scope & applicability: Static non‑vacuum insulated cryogenic vessels for fluids specified in EN 14197‑1; intended for >0.5 bar (guidance for ≤0.5 bar).

- Personnel training: Only trained staff may install, operate, fill or maintain vessels. Training must address:

- normal operating procedures

- product and hazard identification

- safe operating limits and emergency procedures

- physical/chemical properties and PPE requirements

- General safety: Marking/labels must remain intact; no oil/grease contamination (see EN 12300 cleanliness); avoid direct heat sources for de‑icing; depressurize before disconnecting.

- Installation rules:

- Prefer outdoor installation where reasonably possible.

- Maintain safety distances (Annex B) and ensure ventilation to prevent oxygen enrichment/deficiency or flammable atmospheres.

- Nameplate visibility, access for inspection on all sides, and space for maintenance (recommended minimum ~0.5 m clearance).

- Non‑flammable flooring under vessels and liquid‑phase connections for oxidising gases.

- Inspection & testing:

- Pre‑commissioning checks: marking, handover documents, equipment, installation.

- Periodic inspections and specific checks for safety valves and bursting discs (visual and performance tests, certificates).

- Operational procedures: Defined processes for filling, withdrawal, taking out of service, maintenance/repairs and documented emergency procedures (example in Annex A).

Applications and practical value

- Ensures safe everyday operation and regulatory compliance for cryogenic storage and supply systems used in industrial gas plants, laboratories, medical gas installations, food processing and speciality gas distribution.

- Helps facility designers, plant operators and maintenance teams implement robust safety controls (venting, relief systems, safe siting, PPE, training).

- Provides a framework to reduce incidents from gas release, cold embrittlement, oxygen enrichment and flammability risks.

Who should use this standard

- Cryogenic equipment manufacturers and installers

- Site owners and plant operators

- Safety managers, maintenance engineers and commissioning teams

- Compliance officers and inspectors in industries handling liquid nitrogen, oxygen, argon, LNG and other cryogens

Related standards

- EN 14197‑1:2003 (Fundamental requirements)

- EN 14197‑2 (Design, fabrication, inspection & testing)

- EN 12300 (Cleanliness for cryogenic service)

- EN 60079‑10 / EN 60079‑14 (hazardous area classifications and electrical installations)

Using EN 14197‑3:2004 helps reduce operational risk and supports consistent, auditable practices for safe handling of static non‑vacuum insulated cryogenic vessels.

Frequently Asked Questions

SIST EN 14197-3:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cryogenic vessels - Static non-vacuum insulated vessels - Part 3: Operational requirements". This standard covers: This European Standard specifies operational requirements for static non vacuum insulated vessels for cryogenic fluids according to prEN 14197-1, designed for a maximum allowable pressure greater than 0,5 bar. It can be used as a guideline for vessels designed for a maximum allowable pressure of not more than 0,5 bar. The scope includes installation, putting into service, inspection, filling, maintenance and emergency procedures. This European Standard applies to vessels for cryogenic fluids as specified in prEN 14197-1.

This European Standard specifies operational requirements for static non vacuum insulated vessels for cryogenic fluids according to prEN 14197-1, designed for a maximum allowable pressure greater than 0,5 bar. It can be used as a guideline for vessels designed for a maximum allowable pressure of not more than 0,5 bar. The scope includes installation, putting into service, inspection, filling, maintenance and emergency procedures. This European Standard applies to vessels for cryogenic fluids as specified in prEN 14197-1.

SIST EN 14197-3:2004 is classified under the following ICS (International Classification for Standards) categories: 23.020.40 - Cryogenic vessels. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14197-3:2004 has the following relationships with other standards: It is inter standard links to SIST EN 14197-3:2004/A1:2005, SIST EN 14197-3:2004/AC:2004; is excused to SIST EN 14197-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14197-3:2004 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14197-3:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Cryogenic vessels - Static non-vacuum insulated vessels - Part 3: Operational requirementsKriogene posode – Stabilne, vakuumsko neizolirane posode - 3. del: Zahteve za obratovanjeRécipients cryogéniques - Récipients statiques non isolés sous vide - Partie 3: Exigences de fonctionnementKryo-Behälter - Ortsfeste nicht vakuum-isolierte Kryo-Behälter - Teil 3: BetriebsanforderungenTa slovenski standard je istoveten z:EN 14197-3:2004SIST EN 14197-3:2004en23.020.40ICS:SLOVENSKI

STANDARDSIST EN 14197-3:200401-junij-2004

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14197-3March 2004ICS 23.020.40English versionCryogenic vessels - Static non-vacuum insulated vessels - Part3: Operational requirementsRécipients cryogéniques - Récipients fixes, non isolés sousvide - Partie 3: Exigences de serviceKryo-Behälter - Ortsfeste nicht vakuum-isolierte Kryo-Behälter - Teil 3: BetriebsanforderungenThis European Standard was approved by CEN on 1 August 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14197-3:2004: E

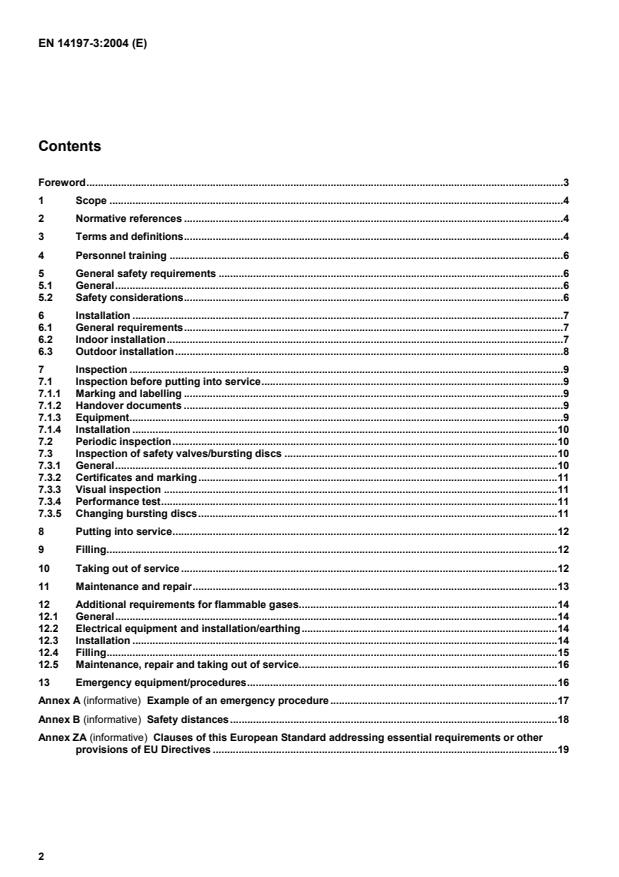

Example of an emergency procedure.17Annex B (informative)

Safety distances.18Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of EU Directives.19

Personnel trainingOnly persons trained for the specific task shall be allowed to install, put into service, fill, handle, operate or maintainthe vessel.The training programme shall include :¾ normal operating procedures ;¾ product and hazard identification ;¾ safe operating limits ;¾ emergency procedures ;¾ physical and chemical properties of the vessel's contents and their effects on the human body ;¾ personnel protective equipment (e.g. safety boots/goggles/gloves).Training shall be repeated as necessary to ensure that personnel remain competent. A training record should bemaintained which details the information personnel have received.5 General safety requirements5.1 GeneralIdentification labels and plates shall not be removed or defaced. Appropriate warning signs regarding product andoperational hazards and personnel protective equipment requirements should be displayed. Parts under pressureshall be disconnected only if they have been previously depressurized. When under pressure leaking valves orconnections shall only be tightened using suitable tools and procedures. Direct flame or intense heat shall never beused to raise the pressure or to de-ice frozen valves.Vessels shall be kept free from oil and grease ; for cleanliness requirements EN 12300 applies. Valve outlets shallbe kept clean, dry and free from contaminants. Vessels shall not be modified without proper authorization.5.2 Safety considerationsIn all operations and training the following safety considerations shall be taken into account :¾ small amounts of cryogenic fluids will produce large volumes of vaporized gas. Spillage of cryogenic fluids canresult in an oxygen deficient atmosphere, or in the case of vaporizing oxygen, in an oxygen enrichedatmosphere. Provision is to be made for appropriate measures for this, e.g. ventilation ;¾ due to the possibility of cold embrittlement, cryogenic fluids shall not come in contact with materials (metals orplastics) which are not suitable for low temperatures ;¾ because of their extremely low temperatures, cryogenic fluids will produce cold burns when coming in contactwith the skin. Cold burns can also be produced from contact with uninsulated equipment ;¾ oxygen enrichment due to liquefaction of ambient air can occur on the cold surfaces of uninsulated equipmentwhich contain fluids with a boiling point lower than oxygen.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...