oSIST prEN 1762:2026

(Main)Rubber hoses and hose assemblies for liquefied petroleum gas, LPG (liquid or gaseous phase), and natural gas up to 25 bar (2,5 MPa) - Specification

Rubber hoses and hose assemblies for liquefied petroleum gas, LPG (liquid or gaseous phase), and natural gas up to 25 bar (2,5 MPa) - Specification

This document specifies the requirements for rubber hoses and rubber hose assemblies used for the transfer of liquefied petroleum gas (LPG) in liquid or gaseous phase and natural gas with a maximum working pressure of 25 bar (2,5 MPa) and vacuum within the temperature range of −30 °C to +70 °C and, when designated -LT, −50 °C to +70 °C.

Gummischläuche und -schlauchleitungen für Flüssiggas LPG (flüssig oder gasförmig) und Erdgas bis 25bar (2,5 MPa) - Spezifikation

Dieses Dokument legt die Anforderungen für Gummischläuche und Gummischlauchleitungen fest, die für den Transport von Flüssiggas(LPG) in der flüssigen oder gasförmigen Phase verwendet werden, sowie für Erdgas mit einem maximalen Betriebsdruck von 25bar (2,5MPa) und einem Vakuum in einem Temperaturbereich von −30°Cbis+70°C und −50°Cbis+70°C, wenn es mit −LT bezeichnet wird.

Tuyaux et flexibles en caoutchouc pour le gaz de pétrole liquéfié GPL (en phase liquide ou gazeuse) et le gaz naturel jusqu'à 25 bar (2,5 MPa) - Spécification

Le présent document spécifie les exigences relatives aux tuyaux et assemblages flexibles en caoutchouc destinés au transfert de gaz de pétrole liquéfié (GPL) en phase liquide ou gazeuse et de gaz naturel avec une pression maximale de service de 25 bar (2,5 MPa) et sous vide dans la plage de température de −30 °C à +70 °C et, pour le type LT, de −50 °C à +70 °C.

Gumene cevi in cevni priključki za utekočinjeni naftni plin LPG (tekoča ali plinska faza) in zemeljski plin do 25 barov (2,5 MPa) - Specifikacija

General Information

- Status

- Not Published

- Public Enquiry End Date

- 19-Jan-2026

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 20-Nov-2025

- Due Date

- 09-Apr-2026

Relations

- Effective Date

- 08-Jan-2025

Overview

The oSIST prEN 1762:2026 standard, developed by CEN/TC 218, specifies stringent requirements for rubber hoses and hose assemblies used in the transfer of liquefied petroleum gas (LPG) – both liquid and gaseous phases – and natural gas under pressures up to 25 bar (2.5 MPa). Applicable within a temperature range of −30 °C to +70 °C, and extended down to −50 °C for -LT (low temperature) designated hoses, this specification ensures safety, durability, and performance for critical gas transfer applications.

This European Standard supersedes EN 1762:2018 and incorporates important updates such as expanded lining materials, revised test protocols, and enhanced marking requirements. The oSIST prEN 1762:2026 is essential guidance for manufacturers, distributors, and end users of LPG and natural gas rubber hoses operating under strict safety and quality controls.

Key Topics

Scope and Classification

Hoses covered by oSIST prEN 1762:2026 are classified into five types based on application and construction:- D (delivery hose)

- D-LT (delivery hose, low temperature)

- SD (suction and delivery, helix reinforced)

- SD-LTS (smooth suction and delivery, helix reinforced, low temperature)

- SD-LTR (rough bore suction and delivery, helix reinforced, low temperature)

Additionally, hoses are graded by electrical properties into:

- M (electrically bonded via metallic wire)

- Ω (electrically conductive with a conductive rubber layer)

- Discontinuous (electrically insulated or bond at one fitting end only)

Materials and Construction

The hose structure includes an n-pentane resistant lining, robust textile or stainless steel wire reinforcement, and an abrasion- and weather-resistant synthetic rubber cover. Screw and hose assembly fittings must adhere to electrical continuity requirements and avoid chlorinated materials that could degrade stainless steel components.Dimensions and Physical Characteristics

oSIST prEN 1762:2026 precisely defines internal and external diameter tolerances, minimum bend radii, lining and cover thicknesses (minimum 1.6 mm), and hose concentricity ensuring reliable mechanical performance and safe operation with LPG and natural gas.Testing and Marking

The standard mandates hydrostatic testing, vacuum resistance, abrasion tests, electrical conductivity tests, and flammability assessments, including water as a test fluid to simulate real-world conditions. Marking of hoses and assemblies includes essential identification details to maintain traceability and compliance, excluding the year of publication as per recent updates.

Applications

oSIST prEN 1762:2026-compliant rubber hoses are critical components in:

- LPG delivery and refilling stations

- Natural gas transfer in industrial and commercial facilities

- Fuel loading and unloading systems involving liquid or gaseous propane and butane

- Applications requiring low-temperature flexibility as low as −50 °C under the -LT designation

- Systems demanding tailored electrical safety features to prevent static discharge during gas transfer

The high-quality, standardized hoses ensure safe and efficient operation in environments exposed to mechanical stress, temperature variations, and potential chemical exposure from hydrocarbons.

Related Standards

To achieve compliance and harmonized quality, reference is made to complementary standards, including:

- EN ISO 1402 – Hydrostatic testing of rubber and plastics hoses and assemblies

- EN ISO 4671 – Measurement of hose dimensions

- EN ISO 8031 & 8033 – Electrical resistance and component adhesion testing

- ISO 37 – Tensile strength and elongation properties for rubber compounds

- ISO 188 – Accelerated ageing and heat resistance tests

- EN ISO 10619-1 & 10619-2 – Flexibility and stiffness tests at ambient and sub-ambient temperatures

These related international standards provide detailed methodologies essential for validating the safety, dimensional accuracy, mechanical strength, and electrical conductivity aspects required by oSIST prEN 1762:2026.

By adhering to oSIST prEN 1762:2026, manufacturers and users ensure that rubber hoses and hose assemblies deliver reliable, compliant, and safe solutions for handling LPG and natural gas at pressures up to 25 bar, fostering operational safety and product longevity in diverse industrial and commercial environments.

Frequently Asked Questions

oSIST prEN 1762:2026 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Rubber hoses and hose assemblies for liquefied petroleum gas, LPG (liquid or gaseous phase), and natural gas up to 25 bar (2,5 MPa) - Specification". This standard covers: This document specifies the requirements for rubber hoses and rubber hose assemblies used for the transfer of liquefied petroleum gas (LPG) in liquid or gaseous phase and natural gas with a maximum working pressure of 25 bar (2,5 MPa) and vacuum within the temperature range of −30 °C to +70 °C and, when designated -LT, −50 °C to +70 °C.

This document specifies the requirements for rubber hoses and rubber hose assemblies used for the transfer of liquefied petroleum gas (LPG) in liquid or gaseous phase and natural gas with a maximum working pressure of 25 bar (2,5 MPa) and vacuum within the temperature range of −30 °C to +70 °C and, when designated -LT, −50 °C to +70 °C.

oSIST prEN 1762:2026 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies; 75.200 - Petroleum products and natural gas handling equipment; 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 1762:2026 has the following relationships with other standards: It is inter standard links to SIST EN 1762:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 1762:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Gumene cevi in cevni priključki za utekočinjeni naftni plin LPG (tekoča ali plinska

faza) in zemeljski plin do 25 barov (2,5 MPa) - Specifikacija

Rubber hoses and hose assemblies for liquefied petroleum gas, LPG (liquid or gaseous

phase), and natural gas up to 25 bar (2,5 MPa) - Specification

Gummischläuche und -schlauchleitungen für Flüssiggas LPG (flüssig oder gasförmig)

und Erdgas bis 25bar (2,5 MPa) - Spezifikation

Tuyaux et flexibles en caoutchouc pour le gaz de pétrole liquéfié GPL (en phase liquide

ou gazeuse) et le gaz naturel jusqu'à 25 bar (2,5 MPa) - Spécification

Ta slovenski standard je istoveten z: prEN 1762

ICS:

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

83.140.40 Gumene cevi Hoses

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2025

ICS 23.040.70 Will supersede EN 1762:2018

English Version

Rubber hoses and hose assemblies for liquefied petroleum

gas, LPG (liquid or gaseous phase), and natural gas up to

25 bar (2,5 MPa) - Specification

Tuyaux et flexibles en caoutchouc pour le gaz de Gummischläuche und -schlauchleitungen für Flüssiggas

pétrole liquéfié GPL (en phase liquide ou gazeuse) et le LPG (flüssig oder gasförmig) und Erdgas bis 25 bar (2,5

gaz naturel jusqu'à 25 bar (2,5 MPa) -Spécification MPa) - Spezifikation

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 218.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 1762:2025 E

worldwide for CEN national Members.

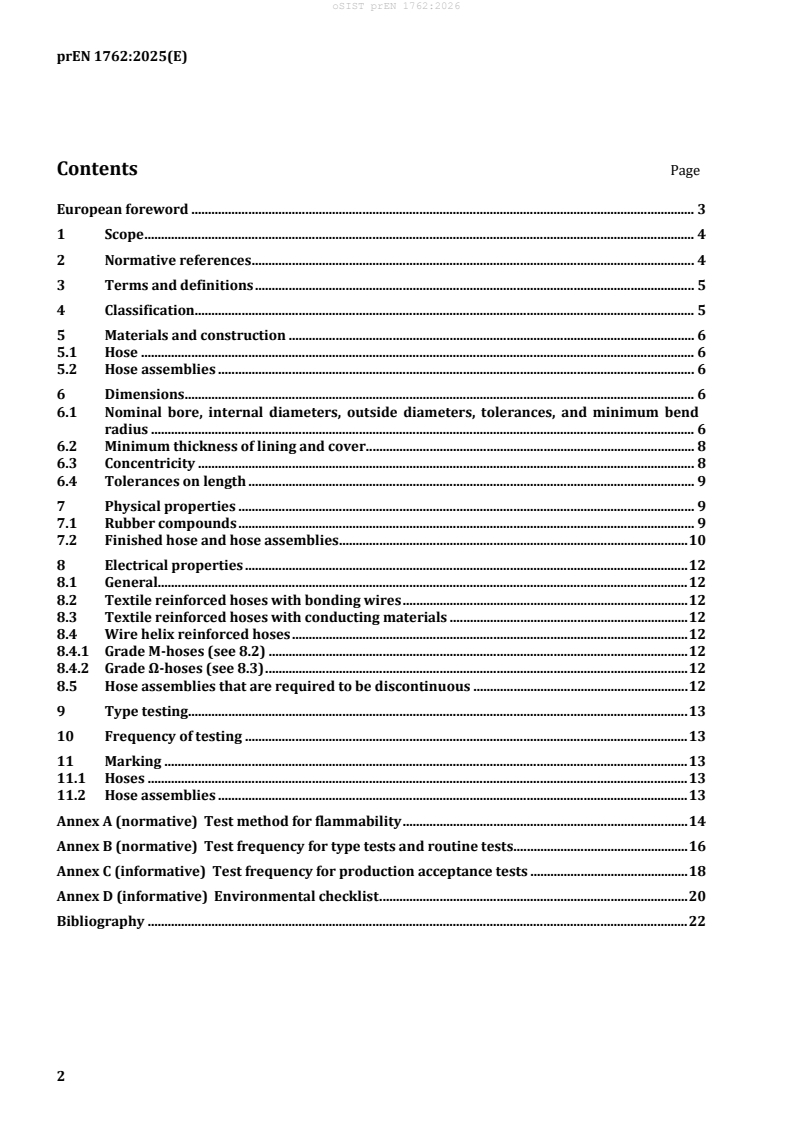

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 5

4 Classification. 5

5 Materials and construction . 6

5.1 Hose . 6

5.2 Hose assemblies . 6

6 Dimensions. 6

6.1 Nominal bore, internal diameters, outside diameters, tolerances, and minimum bend

radius . 6

6.2 Minimum thickness of lining and cover . 8

6.3 Concentricity . 8

6.4 Tolerances on length . 9

7 Physical properties . 9

7.1 Rubber compounds . 9

7.2 Finished hose and hose assemblies . 10

8 Electrical properties . 12

8.1 General. 12

8.2 Textile reinforced hoses with bonding wires . 12

8.3 Textile reinforced hoses with conducting materials . 12

8.4 Wire helix reinforced hoses . 12

8.4.1 Grade M-hoses (see 8.2) . 12

8.4.2 Grade Ω-hoses (see 8.3) . 12

8.5 Hose assemblies that are required to be discontinuous . 12

9 Type testing . 13

10 Frequency of testing . 13

11 Marking . 13

11.1 Hoses . 13

11.2 Hose assemblies . 13

Annex A (normative) Test method for flammability . 14

Annex B (normative) Test frequency for type tests and routine tests . 16

Annex C (informative) Test frequency for production acceptance tests . 18

Annex D (informative) Environmental checklist . 20

Bibliography . 22

European foreword

This document (prEN 1762:2025) has been prepared by Technical Committee CEN/TC 218

“Rubber and plastics hoses and hose assemblies”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 1762:2018.

EN 1762:2018:

a) extension of the material of the lining material

b) additional dimensions added in Table 1 and Table 2

c) revision of routine tests

d) in Clause 11, the requirement to include the year of publication of this document in the

marking has been deleted

e) water has been added as a test fluid in Annex A

f) the document has been editorially revised.

1 Scope

This document specifies the requirements for rubber hoses and rubber hose assemblies used for

the transfer of liquefied petroleum gas (LPG) in liquid or gaseous phase and natural gas with a

maximum working pressure of 25 bar (2,5 MPa) and vacuum within the temperature range of

−30 °C to +70 °C and, when designated -LT, −50 °C to +70 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

EN ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the

dimensions of hoses and the lengths of hose assemblies

EN ISO 6179, Rubber, vulcanized or thermoplastic — Rubber sheets and rubber-coated fabrics —

Determination of transmission rate of volatile liquids (gravimetric technique)

EN ISO 7233, Rubber and plastics hoses and hose assemblies — Determination of resistance to

vacuum

EN ISO 7326, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

EN ISO 8031, Rubber and plastics hoses and hose assemblies — Determination of electrical

resistance and conductivity

EN ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

EN ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

EN ISO 10619-1, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 1: Bending tests at ambient temperature

EN ISO 10619-2, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 2: Bending tests at sub-ambient temperatures

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 1817, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 4649, Rubber, vulcanized or thermoplastic — Determination of abrasion resistance using a

rotating cylindrical drum device

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 8330 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

electrically bonded hose/hose assembly

hose/hose assembly that uses a metallic wire connection to conduct static electricity

3.2

electrically conductive hose/hose assembly

hose/hose assembly that is capable of conducting static electrical charges, using a conductive

rubber layer, without the use of a metallic wire

3.3

electrically discontinuous hose/hose assembly

hose/hose assembly that incorporates a metallic wire connection to one end fittings of the

assembly only or is electrically insulated from both end-fittings

4 Classification

Hoses/hose assemblies for this application are classified into 5 types and 3 grades according to

their use, construction, and electrical properties. The maximum working pressure for all

hoses/hose assemblies is 25 bar.

The 5 types are as follows:

Type Application

D delivery hose

D-LT delivery hose, low temperature;

SD suction and delivery hose, helix reinforced

SD-LTS suction and delivery hose “smooth hose”, helix reinforced, low temperature

SD-LTR suction and delivery hose, rough bore (having an internal, non-embedded helical

wire of stainless steel), low temperature

Hoses for this application are divided into 3 grades according to their electrical properties:

Grade Electrical property

designation

M Electrically bonded

Ω Electrically conductive using a conductive rubber layer

Discontinuous Electrically discontinuous

5 Materials and construction

5.1 Hose

The hose shall consist of the following:

— a lining resistant to n-pentane;

— a reinforcement of layers of woven, braided or spirally wound textile material or braided or

spirally wound stainless steel wire,

— an embedded stainless steel metallic helix reinforcement (types SD, SD-LTS and SD-LTR only);

— two or more low resistance electrical bonding wires (grade “M” only);

— an outer cover of black or coloured synthetic rubber, resistant to abrasion and outdoor

exposure; the cover may be pricked to allow gas permeation. If the cover is not pricked a

comparative measurement of permeation between the rubber materials of cover and lining

shall be carried out, see Table 3, item 6;

— an internal, non-embedded stainless steel helical wire, suitable for use at –50 °C (type SD-LTR

only).

5.2 Hose assemblies

Hose assemblies shall incorporate metallic fittings attached to the hose by the assembler or built

in by the manufacturer. In order to produce the required electrical properties, the fittings should

be attached in accordance with Clause 8.

Chlorinated materials shall not be used in contact with any stainless steel materials.

6 Dimensions

6.1 Nominal bore, internal diameters, outside diameters, tolerances, and minimum

bend radius

For hoses without built-in couplings, and when measured in accordance with method A of

EN ISO 4671, the internal diameter and outside diameter and their tolerances shall conform to

Table 1 or Table 2, depending on the type.

For hoses with built-in couplings, the outside diameters in Tables 1 and 2 do not apply.

When tested by the method described in EN ISO 10619-1, the value of the minimum bend radius

shall be as given in Table 1 or Table 2, depending on the type.

Table 1 — Dimensions and tolerances of hoses of types D and D-LT

Nominal bore Internal Tolerance Outside Tolerance Design min.

a

diameter diameter bend radius

mm mm mm mm mm

10 10 ±0,5 20,0 ±1,0 90

13 12,7 ±0,5 22,7 ±1,0 100

15 15 ±0,5 25 ±1,0 120

16 15,9 ±0,5 25,9 ±1,0 125

19 19 ±0,5 31 ±1,0 160

25 25 ±0,5 38 ±1,0 200

32 32 ±0,5 45 ±1,0 250

38 38 ±0,5 52 ±1,0 320

50 50 ±0,6 66 ±1,2 400

51 51 ±0,6 67 ±1,2 400

63 63 ±0,6 81 ±1,2 550

75 75 ±0,6 93 ±1,2 650

76 76 ±0,6 94 ±1,2 650

80 80 ±0,6 98 ±1,2 725

100 100 ±1,6 120 ±1,6 800

150 150 ±2,0 174 ±2,0 1200

b

200 200 ±2,0 226 or 232 ±3,0 1600

250 254 ±2,0 — — 2000

300 305 ±2,0 — — 2500

a

The design minimum bend radius is measured to the surface of the hose on the inside of the bend.

b

alternating outer diameter depending on the hose construction.

NOTE Other dimension and measurements possible in accordance with the customer.

Table 2 — Dimensions and tolerances of hoses of types SD, SD-LTS and SD-LTR

Nominal bore Internal Tolerance Outside Tolerance Design min.

a

diameter diameter bend radius

mm mm

mm

mm mm

10 10 ±0,5 20,0 ±1,0 85

13 12,7 ±0,5 22,7 ±1,0 90

15 15 ±0,5 25 ±1,0 95

16 15,9 ±0,5 25,9 ±1,0 95

19 19 ±0,5 31 ±1,0 100

25 25 ±0,5 38 ±1,0 150

32 32

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...