SIST EN 15233:2007

(Main)Methodology for functional safety assessment of protective systems for potentially explosive atmospheres

Methodology for functional safety assessment of protective systems for potentially explosive atmospheres

This European Standard provides guidance on the procedure and information required to allow functional safety assessment to be carried out for the design of protective systems.

The purpose of this European Standard is to assist technical standardization committees responsible for specific families of protective systems in preparing safety standards. Such standards shall be as homogenous as possible and shall have the basic structure of functional safety assessment as it is stated in this standard.

If there are no specific standards for a particular protective system, the manufacturer shall use this standard for functional safety assessment of this protective system.

In this procedure the following information is to be taken into account to ensure a sufficient level of functional safety:

a) intended use,

b) possible operating faults,

c) reliability of protective systems,

d) misuse which can reasonably be anticipated.

A sufficient level of functional safety is characterized by the following objectives:

1) System can stop an explosion at a very early stage or reduce the impact of an explosion to an acceptable level.

2) In the event of faults, failures and/or interference ) the capacity to function remains effective by use e.g. of fail safe techniques or redundancy.

This European Standard does not cover identification of possible ignition sources.

NOTE 1 The identification of possible ignition sources is covered by EN 15198.

This European Standard only deals with the functional behaviour of the protective system i.e. hazards caused by malfunctions, e.g. false activations are excluded.

This European Standard specifies neither specific methods to analyse fault conditions, nor specific requirements for a given type of protective system (see EN 1127 1). It specifies the methodology of functional safety assessment.

(continued)

Methodik zur Bewertung der funktionalen Sicherheit von Schutzsystemen für explosionsgefährdete Bereiche

Méthodologie relative a l'évaluation de la sécurité fonctionnelle des systemes de protection pour atmospheres explosibles

La présente norme européenne donne des lignes directrices relatives au mode opératoire et aux informations requises pour permettre la mise en oeuvre de l'évaluation de la sécurité fonctionnelle pour la conception des systèmes de protection.

La présente Norme européenne a pour objet d'aider les comités techniques de normalisation, responsables de familles spécifiques de systèmes de protection, à préparer les normes de sécurité. Il est recommandé que ces normes soient aussi homogènes que possible et qu’elles aient la structure de base indiquée dans la présente norme pour l’évaluation de la sécurité fonctionnelle.

En l’absence de normes spécifiques pour un système de protection donné, il est recommandé que le fabricant utilise cette norme pour l’évaluation de la sécurité fonctionnelle de ce système de protection.

Dans ce mode opératoire, les informations suivantes doivent être prises en compte pour assurer un niveau de sécurité fonctionnelle suffisant :

a) l'utilisation prévue ;

b) les défauts de fonctionnement possibles ;

c) la fiabilité des systèmes de protection ;

d) le mauvais usage pouvant être raisonnablement attendu.

Un niveau de sécurité fonctionnelle suffisant est caractérisé par les objectifs suivants :

1) le système peut arrêter l'explosion dès son tout début ou réduire l'impact d'une explosion à un niveau acceptable ;

2) en cas de défauts, de défaillances et/ou d'interférences ) la capacité de fonctionner reste effective par l'utilisation, par exemple, de techniques de sécurité ou de redondance.

La présente Norme européenne ne traite pas de l'identification des sources d'inflammation possibles.

Metodologija za varnostno oceno delovanja zaščitnih sistemov za potencialno eksplozivne atmosfere

General Information

- Status

- Published

- Publication Date

- 09-Sep-2007

- Technical Committee

- EXP - Product for explosive atmospheres

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 31-Aug-2007

- Due Date

- 05-Nov-2007

- Completion Date

- 10-Sep-2007

Overview - EN 15233:2007 (CEN)

EN 15233:2007 is a CEN Type A standard giving a systematic methodology for functional safety assessment of protective systems used in potentially explosive atmospheres. It provides guidance on the procedure and the information manufacturers and standards committees need to assess whether a protective system achieves an adequate level of functional safety for its intended use. The standard focuses on functional behaviour and reliability of protection (not on identifying ignition sources).

Key topics and requirements

- Four-step assessment procedure:

- Description of the protective system and intended use (life cycle, performance limits, maintenance).

- Identification of failures through functional/state analysis (design, installation, operation, maintenance, modification).

- Functional safety estimation (functionality and reliability assessment using qualitative and, where appropriate, quantitative data).

- Functional safety evaluation against predefined acceptance criteria and documentation of results.

- Information to consider: intended use, safety design characteristics, maintenance requirements, surrounding conditions, design drawings, test reports, accident history and relevant literature.

- Safety objectives: the system should either stop an explosion at a very early stage or reduce the impact to an acceptable level; and retain effective operation under faults/failures by means such as fail-safe techniques or redundancy.

- Scope limits: does not cover ignition source identification (see EN 15198) and does not prescribe specific analytical methods or specific protective-system requirements (see EN 1127-1). Focus is on methodology and documentation.

- Lifecycle and misuse: assessment must cover foreseeable misuse and maintenance deficiencies; any safety-related modification requires reassessment.

Practical applications and users

Who uses EN 15233:2007:

- Manufacturers of protective systems for explosive atmospheres (when no specific product standard exists).

- Technical standardization committees preparing harmonized safety standards for families of protective systems.

- Safety engineers, design teams and assessors conducting functional safety evaluations for explosion protection systems. Practical uses:

- Creating technical documentation and instructions for use that record functional safety assessment results.

- Structuring design reviews and risk assessments to ensure protective systems meet functional and reliability requirements.

- Supporting conformity work related to EU Directive 94/9/EC by documenting functional safety rationale.

Related standards

- EN 15198 - identification of possible ignition sources / equipment-related aspects

- EN 1127-1 - basic principles for explosion protection (general requirements)

- EN 13237 - terms and definitions for equipment and protective systems

- EU Directive 94/9/EC (ATEX) - regulatory context supported by EN 15233

By following EN 15233:2007 manufacturers and assessors achieve a consistent, documented approach to demonstrating functional safety of protective systems in explosive atmospheres, improving reliability, maintainability and regulatory coherence.

Frequently Asked Questions

SIST EN 15233:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Methodology for functional safety assessment of protective systems for potentially explosive atmospheres". This standard covers: This European Standard provides guidance on the procedure and information required to allow functional safety assessment to be carried out for the design of protective systems. The purpose of this European Standard is to assist technical standardization committees responsible for specific families of protective systems in preparing safety standards. Such standards shall be as homogenous as possible and shall have the basic structure of functional safety assessment as it is stated in this standard. If there are no specific standards for a particular protective system, the manufacturer shall use this standard for functional safety assessment of this protective system. In this procedure the following information is to be taken into account to ensure a sufficient level of functional safety: a) intended use, b) possible operating faults, c) reliability of protective systems, d) misuse which can reasonably be anticipated. A sufficient level of functional safety is characterized by the following objectives: 1) System can stop an explosion at a very early stage or reduce the impact of an explosion to an acceptable level. 2) In the event of faults, failures and/or interference ) the capacity to function remains effective by use e.g. of fail safe techniques or redundancy. This European Standard does not cover identification of possible ignition sources. NOTE 1 The identification of possible ignition sources is covered by EN 15198. This European Standard only deals with the functional behaviour of the protective system i.e. hazards caused by malfunctions, e.g. false activations are excluded. This European Standard specifies neither specific methods to analyse fault conditions, nor specific requirements for a given type of protective system (see EN 1127 1). It specifies the methodology of functional safety assessment. (continued)

This European Standard provides guidance on the procedure and information required to allow functional safety assessment to be carried out for the design of protective systems. The purpose of this European Standard is to assist technical standardization committees responsible for specific families of protective systems in preparing safety standards. Such standards shall be as homogenous as possible and shall have the basic structure of functional safety assessment as it is stated in this standard. If there are no specific standards for a particular protective system, the manufacturer shall use this standard for functional safety assessment of this protective system. In this procedure the following information is to be taken into account to ensure a sufficient level of functional safety: a) intended use, b) possible operating faults, c) reliability of protective systems, d) misuse which can reasonably be anticipated. A sufficient level of functional safety is characterized by the following objectives: 1) System can stop an explosion at a very early stage or reduce the impact of an explosion to an acceptable level. 2) In the event of faults, failures and/or interference ) the capacity to function remains effective by use e.g. of fail safe techniques or redundancy. This European Standard does not cover identification of possible ignition sources. NOTE 1 The identification of possible ignition sources is covered by EN 15198. This European Standard only deals with the functional behaviour of the protective system i.e. hazards caused by malfunctions, e.g. false activations are excluded. This European Standard specifies neither specific methods to analyse fault conditions, nor specific requirements for a given type of protective system (see EN 1127 1). It specifies the methodology of functional safety assessment. (continued)

SIST EN 15233:2007 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15233:2007 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC, EUR-PUB; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15233:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Methodology for functional safety assessment of protective systems for potentially explosive atmospheresRWHQFLDOQRMéthodologie relative a l'évaluation de la sécurité fonctionnelle des systemes de protection pour atmospheres explosiblesMethodik zur Bewertung der funktionalen Sicherheit von Schutzsystemen für explosionsgefährdete BereicheTa slovenski standard je istoveten z:EN 15233:2007SIST EN 15233:2007en,fr,de13.230Varstvo pred eksplozijoExplosion protectionICS:SLOVENSKI

STANDARDSIST EN 15233:200701-oktober-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15233August 2007ICS 13.230 English VersionMethodology for functional safety assessment of protectivesystems for potentially explosive atmospheresMéthodologie relative à l'évaluation de la sécuritéfonctionnelle des systèmes de protection pour atmosphèresexplosiblesMethodik zur Bewertung der funktionalen Sicherheit vonSchutzsystemen für explosionsgefährdete BereicheThis European Standard was approved by CEN on 13 July 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15233:2007: E

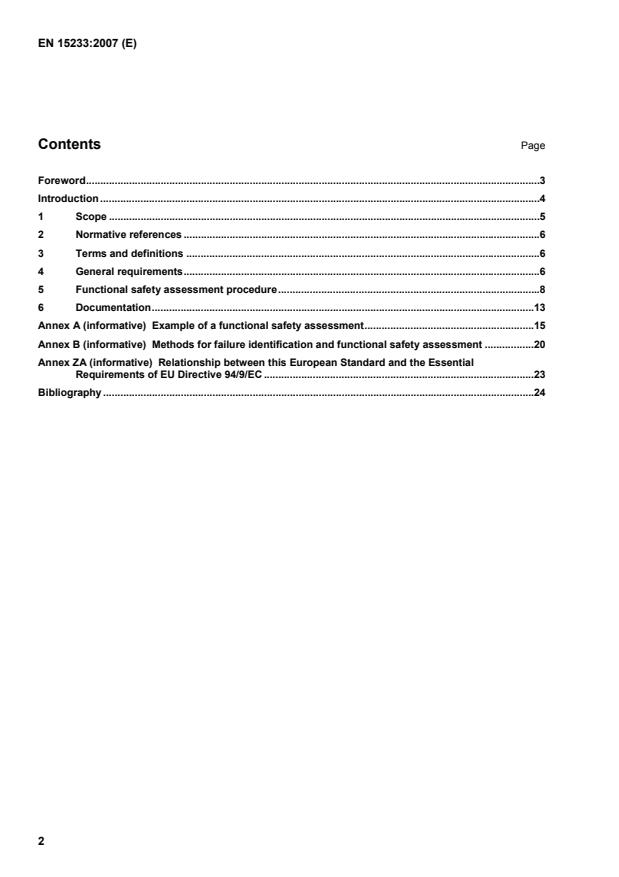

Example of a functional safety assessment.15 Annex B (informative)

Methods for failure identification and functional safety assessment.20 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC.23 Bibliography.24

For relationship with EU Directive 94/9/EC, see informative Annex ZA, which is an integral part of this document. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

1) Interference is everything in normal operation that can disturb the normal operation of the system e.g. electromagnetic waves, heat, flames and pressure waves.

NOTE 1 Functional safety covers all aspects where safety depends on the correct functioning of the protective system and other technology safety-related systems.

NOTE 2 This definition deviates from the definition in EN 61508-4 to reflect differences in explosion safety terminology. 3.3 protective system device other than components of the equipment, which is intended to halt incipient explosions immediately and/or to limit the effective range of an explosion and which is placed separately on the market as autonomous system [EN 13237:2003, A.5] 3.4 functional safety estimation determination of the probability of occurrence of the failures violating the functional safety of the protective system 3.5 functional safety evaluation procedure to determine whether the functional safety of the protective system meets the predefined acceptance criteria 4 General requirements 4.1 Basic concept Functional safety assessment is a series of logical steps (see Figure 1) that enable designers and safety engineers to examine in a systematic way, the function of a protective system or a part of it. The objective shall be to achieve an adequate level of functionality and reliability according to the state of the art and technical and economic requirements at the time of construction.

a) description of the protective system (5.2); b) identification of failures (5.3); c) functional safety estimation (5.4); 1) functionality; 2) reliability; d) functional safety evaluation (5.5). These four steps are the basis for the decision whether the intended level of functional safety necessary for the intended use is achieved. The result of the assessment shall be detailed in the technical documentation (see Clause 6). If the required function and level of reliability is not achieved, it shall be necessary to improve the protective system or to define an appropriate intended use.

NOTE The choice of the suitable measures is not part of the standard. If the assessment is done by the manufacturer the result of the assessment shall be detailed in the technical documentation (see Clause 6). Decisions in functional safety assessment shall be supported by qualitative methods complemented, where appropriate, by quantitative methods. 4.2 Extent of functional safety assessment The protective system shall be assessed on the basis of the information specified in 4.3.

The functional safety assessment shall be limited to the intended use and the misuse, which can reasonably be anticipated for a particular protective system. NOTE Misuse which can reasonably be anticipated means an incorrect use and/or operation of the protective system by the operator due to negligence or misunderstanding. Misuse is not part of the normal operation. Intent is not included in foreseeable misuse. 4.3 Information needed The information needed to perform the functional safety assessment shall include the following where appropriate: a) intended use; b) safety characteristics used for the design of protective systems;

c) requirements for maintenance; d) actual and foreseeable surrounding area conditions; e) relevant design drawings; f) results of design calculations made, examinations carried out; if available:

NOTE The data is used to define foreseeable operation requirements related to reliability, serviceability, durability, disposability, benign failure and failsafe characteristics and labelling, warnings, identification, traceability requirements and instructions. Data based on the consensus of expert opinion derived indirectly from experience as opposed to measured data, may be used to supplement qualitative assessment. 5 Functional safety assessment procedure 5.1 Principle The principal steps for the functional safety assessment procedure are shown in Figure 1. It is comprised of four steps taking into consideration the information in the oval blocks. Maintenance requirements shall also be considered in the assessment. The manufacturer shall consider all necessary maintenance requirements in the instruction manual and shall also consider lack of maintenance relevant for the intended use.

Key a Conformity is not part of functional safety assessment. NOTE Dotted lines are not part of this standard. Figure 1 — Functional safety assessment for design of protective systems 5.2 Description of the protective system The step-approach (by following flow-chart in Figure 1) shall be carried out with an understanding of the function of the protective system and of the types of explosions.

Intended use shall consider, for example, the following items: a) life cycles of the protective system;

b) limits in terms of use, time, space; c) accurate definition of the function; d) selection of materials for construction;

e) performance, lifetime and configuration; f) description of the type of explosions;

5.3.1 General Generally, a protective system shall be assessed by potential sources of failure of the protective system. A functional and state analysis for the intended use shall be undertaken for this purpose. Protective systems are distinguished in the following way: a) passive systems (e.g. flame arrester, venting system), b) active systems (e.g. suppression system). An illustrative example of such an approach is given in Annex A. The possible failures shall be assessed through a functional and systematic analysis and shall be considered separately with regard to whole lifecycle: NOTE The listed possible failures are examples. Additional failures may occur. 5.3.2 Assessment 5.3.2.1 Design and manufacturing In the phase of planning and design the following shall be considered: a) that the compliance of the intended use shall be achieved. Examples are: 1) sufficient heat conduction of flame arresters, 2) effective pressure release of venting devices, 3) sufficient suppression efficacy of suppression systems. b) mechanical dimensioning of the protective system is adequate. Failures can occur due to e.g.: 1) insufficient pressure resistance, 2) insufficient temperature resistance, 3) insufficient resistance against vibration and shock, 4) insufficient resistance against ageing or corrosion. c) incorrect installation location, an incorrect installation position or an installation method with regard to the nature of the explosion shall be avoided. d) correct mode with regard to the process, the ambient temperature, the ambient pressure shall be taken into account as well as the correct operating threshold or sensitivity. e) use of non appropriate software and controlling equipment (hardware). f) resistance of the hardware against electromagnetic disturbance.

To be able to provide proper information on the installation the manufacturer shall consider the following possible failures: a) lacking or deficient consideration of effects due to the intended function (e.g. vacuum breakers, danger areas in front of pressure-relief devices, recoil forces, risk of injuries); b) insufficient sealing or possible circumvention; c) insufficient electric conditions (e.g. short circuit, open circuit, overload and earth faults); d) insufficient energy supply and/or back-up power supply for controlling and indicating equipment (CIE). 5.3.2.3 Operational and maintenance requirements The possible failures that can occur during the use and maintenance of the protective system, shall be considered. The manufacturer shall advise the user how to prevent them. Possible failures, which may arise during the use and maintenance, are: a) Contamination; b) incorrect or insufficient intervention by persons (faulty operation, faulty mounting, incorrect maintenance, unintended interventions); c) indication of fault messages and lack of emergency stop procedures. Such lacking or deficient situations and the possible failures that may occur shall be described clearly in the instructions for use. 5.3.2.4 Modification Any safety related modification of a protective system shall be considered a new system which shall require a reassessment. 5.4 Functional safety estimation 5.4.1 General After the failure identification the functional safety of the protective system has to be estimated by determining the probability of failure occurrence. The functional safety estimation can be done qualitatively, semi-quantitative or quantitative depending on the criticality of the protective system in reducing the probability of failure and/or the complexity of the system and the safety related devices. The required performance of the protective system shall be considered in terms of its: a) function, i.e. the ability to perform the functions required by the intended use of the system (e.g. halt an incipient explosion, reduce explosion pressure), and b) integrity, i.e. the reliability in performing those functions (on demand or in time).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...