SIST EN 13530-2:2003

(Main)Cryogenic vessels - Large transportable vacuum insulated vessels - Part 2: Design, fabrication, inspection and testing

Cryogenic vessels - Large transportable vacuum insulated vessels - Part 2: Design, fabrication, inspection and testing

This European Standard specifies requirements for the design, fabrication, inspection and testing of large transportable vacuum insulated cryogenic vessels of more than 1 000 l volume, which are permanently (fixed tanks) or not permanently (demountable tanks) attached to a vehicle, for carriage by road. However, it can be used for other mode of transport providing the specific regulations/requirements are complied with.

This European Standard applies to large transportable vacuum insulated cryogenic vessels for fluids specified in prEN 13530-1:2001 and does not apply to vessels designed for toxic fluids.

This European Standard does not include the general vehicle requirements e.g. running gear, brakes, lighting etc. that should be in accordance with the relevant standards/regulations.

Kryo-Behälter - Große ortsbewegliche vakuum-isolierte Behälter - Teil 2: Bemessung, Herstellung und Prüfung

Diese Europäische Norm gilt für die Bemessung, Herstellung und Prüfung von großen ortsbeweglichen, vakuum-isolierten Kryo-Behältern mit einem Fassungsraum von mehr als 1000 Liter für festverbundene Tanks (von Tank-oder Schienenfahrzeugen), Aufsetztanks, Tanks von Batterie-Fahrzeugen und Tankcontainern (TC) für tiefgekühlte verflüssigte Gase im Sinne der Regelungen für die Beförderung gefährlicher Güter.

Diese Norm gilt für große ortsbewegliche, vakuum-isolierte Kryo-Behälter mit Fluiden, die in EN 13530-1:2002 festgelegt sind, und sie gilt nicht für giftige Fluide.

Diese Europäische Norm enthält keine allgemeinen Anforderungen an Fahrzeuge wie z. B. an Fahrgestell, Bremsen, Beleuchtung usw., diese müssen mit den relevanten Normen/Gesetzen übereinstimmen.

Récipients cryogéniques - Grands récipients transportables isolés sous vide - Partie 2 : Conception, fabrication, inspection et essais

La présente Norme européenne s'applique à la conception, à la fabrication, aux contrôles et aux essais des grands récipients cryogéniques transportables, isolés sous vide, d'un volume excédant 1 000 l, fixés sur un véhicule de manière permanente (réservoirs fixes) ou non (réservoirs démontables), pour le transport routier. Elle peut cependant être utilisée pour d'autres modes de transport à condition que soient respectées les lois et exigences correspondantes.

La présente Norme européenne s'applique aux grands récipients cryogéniques transportables, isolés sous vide, pour les fluides spécifiés dans l'EN 13530-1:2002 et ne s'applique pas à des récipients prévus pour contenir des fluides toxiques.

La présente Norme européenne ne couvre pas les exigences générales relatives aux véhicules, par exemple les organes de roulement, les freins, les feux, etc., qui doivent être conformes aux normes/règlements correspondants.

Kriogene posode - Velike premične, vakuumsko izolirane posode - 2. del: Načrtovanje, izdelava, nadzor in preskus

General Information

- Status

- Published

- Publication Date

- 30-Nov-2003

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Dec-2003

- Due Date

- 01-Dec-2003

- Completion Date

- 01-Dec-2003

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 04-Oct-2023

- Effective Date

- 22-Dec-2008

Overview

EN 13530-2:2002 is a CEN European Standard that specifies requirements for the design, fabrication, inspection and testing of large transportable, vacuum‑insulated cryogenic vessels (greater than 1 000 L). It covers both fixed tanks (permanently attached to a vehicle) and demountable tanks (non‑permanently attached) intended primarily for road carriage, and may be applied to other transport modes when applicable regulations are met. The standard applies to cryogenic fluids listed in EN 13530‑1 and excludes vessels designed for toxic fluids. General vehicle requirements (running gear, brakes, lighting) are not included.

Key topics and technical requirements

- Scope & design options

- Applies to large transportable vacuum‑insulated vessels >1 000 L.

- Three permitted design approaches: design by calculation, design by calculation with pressure‑strengthening (for austenitic stainless steels, see Annex C), or calculation supplemented by experimental methods.

- Materials

- Metallic materials for cryogenic service must meet EN 1252‑1 / EN 1252‑2 requirements.

- 9 % Ni steel has additional normative requirements (Annex B).

- Structural design

- Requirements for inner vessel, outer jacket, supporting frames, allowable pressures, and allowances for dynamic loads.

- Definitions and symbols for pressure, thickness, buckling, material properties included.

- Fabrication

- Detailed coverage of cutting, cold/hot forming, tolerances, welding (procedures & qualification), and non‑welded joints.

- Inspection & testing

- Mandatory quality plan, production control test plates, non‑destructive testing (radiography, radioscopy), rectification rules, and pressure testing procedures.

- Annexes

- Informative: Elastic stress analysis (A), specific weld details (D), outer jacket relief devices (F).

- Normative: 9 % Ni requirements (B), pressure strengthening for austenitic steels (C), increased austenitic properties (E).

Practical applications and users

- Typical applications: transport of cryogenic liquids such as industrial gases and liquefied natural gas (non‑toxic), mobile tank vehicles, demountable tank containers, and large vacuum‑insulated trailers.

- Primary users:

- Design engineers and pressure‑vessel manufacturers

- Fabricators and welding specialists

- NDT and inspection personnel

- Fleet operators, QA managers, conformity assessors and regulatory authorities implementing RID/ADR referenced standards

Related standards (examples)

- EN 13530‑1:2002 (Fundamental requirements)

- EN 1252‑1 / EN 1252‑2 (Cryogenic material toughness)

- EN 1626 (Valves for cryogenic service)

- EN 1435 / EN 13068‑3 (Radiography / radioscopy)

- prEN 13445‑3 (Unfired pressure vessels – design)

Keywords: EN 13530‑2:2002, cryogenic vessels, large transportable vacuum insulated vessels, design fabrication inspection testing, 9 % Ni, austenitic stainless steel, CEN, road tankers, demountable tanks.

Frequently Asked Questions

SIST EN 13530-2:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cryogenic vessels - Large transportable vacuum insulated vessels - Part 2: Design, fabrication, inspection and testing". This standard covers: This European Standard specifies requirements for the design, fabrication, inspection and testing of large transportable vacuum insulated cryogenic vessels of more than 1 000 l volume, which are permanently (fixed tanks) or not permanently (demountable tanks) attached to a vehicle, for carriage by road. However, it can be used for other mode of transport providing the specific regulations/requirements are complied with. This European Standard applies to large transportable vacuum insulated cryogenic vessels for fluids specified in prEN 13530-1:2001 and does not apply to vessels designed for toxic fluids. This European Standard does not include the general vehicle requirements e.g. running gear, brakes, lighting etc. that should be in accordance with the relevant standards/regulations.

This European Standard specifies requirements for the design, fabrication, inspection and testing of large transportable vacuum insulated cryogenic vessels of more than 1 000 l volume, which are permanently (fixed tanks) or not permanently (demountable tanks) attached to a vehicle, for carriage by road. However, it can be used for other mode of transport providing the specific regulations/requirements are complied with. This European Standard applies to large transportable vacuum insulated cryogenic vessels for fluids specified in prEN 13530-1:2001 and does not apply to vessels designed for toxic fluids. This European Standard does not include the general vehicle requirements e.g. running gear, brakes, lighting etc. that should be in accordance with the relevant standards/regulations.

SIST EN 13530-2:2003 is classified under the following ICS (International Classification for Standards) categories: 23.020.40 - Cryogenic vessels. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13530-2:2003 has the following relationships with other standards: It is inter standard links to SIST EN 13530-2:2003/A1:2004, SIST EN 13530-2:2003/AC:2007, oSIST prEN ISO 20421-1:2025; is excused to SIST EN 13530-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13530-2:2003 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13530-2:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kryo-Behälter - Große ortsbewegliche vakuum-isolierte Behälter - Teil 2: Bemessung, Herstellung und PrüfungRécipients cryogéniques - Grands récipients transportables isolés sous vide - Partie 2 : Conception, fabrication, inspection et essaisCryogenic vessels - Large transportable vacuum insulated vessels - Part 2: Design, fabrication, inspection and testing23.020.40Proti mrazu odporne posode (kriogenske posode)Cryogenic vesselsICS:Ta slovenski standard je istoveten z:EN 13530-2:2002SIST EN 13530-2:2003en01-december-2003SIST EN 13530-2:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13530-2September 2002ICS 23.020.40English versionCryogenic vessels - Large transportable vacuum insulatedvessels - Part 2: Design, fabrication, inspection and testingRécipients cryogéniques - Grands récipients transportablesisolés sous vide - Partie 2: Conception, fabrication,contrôles et essaisKryo-Behälter - Große ortsbewegliche, vakuum-isolierteBehälter - Teil 2: Bemessung, Herstellung und PrüfungThis European Standard was approved by CEN on 29 May 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13530-2:2002 ESIST EN 13530-2:2003

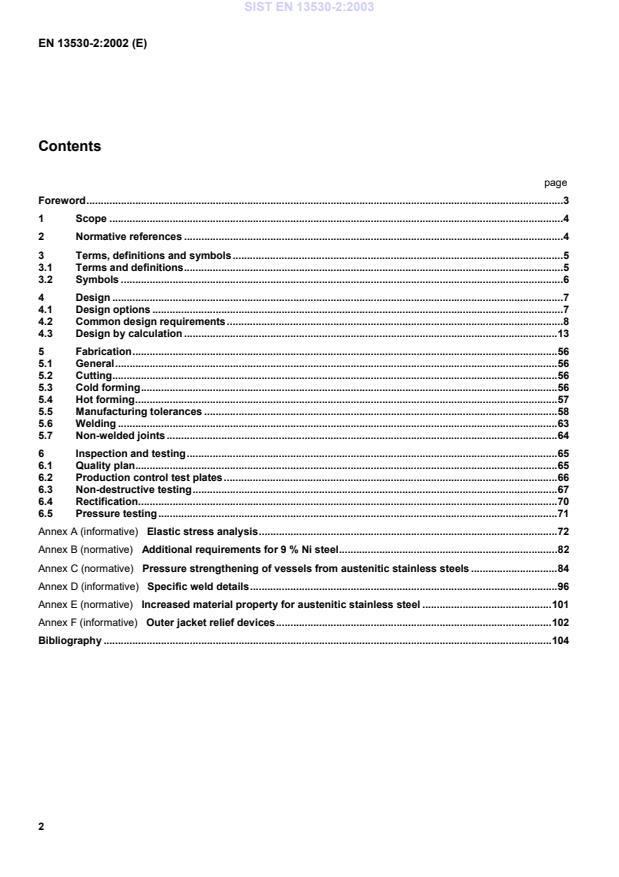

Elastic stress analysis.72Annex B (normative)

Additional requirements for 9 % Ni steel.82Annex C (normative)

Pressure strengthening of vessels from austenitic stainless steels.84Annex D (informative)

Specific weld details.96Annex E (normative)

Increased material property for austenitic stainless steel.101Annex F (informative)

Outer jacket relief devices.102Bibliography.104SIST EN 13530-2:2003

of 10 000.For other materials calculate the minimum thickness using the following formula :325m0)(464ARss´´=whereRm is the minimum tensile strength of the metal chosen, in Newtons per square millimetre at a temperaturenot lower than the saturation temperature of the fluid at pressure Ps ;A5is the elongation at fracture of the metal chosen, in per cent at the same temperature.The minimum thickness shall however not be less than the minimum wall thickness defined in 6.8 of thetechnical annexes of the ADR when other materials are used.Under these condition, the reference steel equivalent thickness of the inner vessel can be determined as follows:464)(235meARss´=(3)whereseis the actual wall thickness of the inner vessel.The Rm and A5 values at a temperature not lower than the saturation temperature of the fluid at pressure ps, shallbe determined from the appropriate material standard or shall be guaranteed by the material manufacturer.4.3.2.2 Design pressure pThe internal design pressure p shall be the greater of pT as defined in 4.2.3.2 a) or pC as defined in 4.2.3.2 b)corrected for operating conditions (i.e. timesT20KK) to take into account the cold properties of the material used. Itfollows that K20 shall be used in the subsequent formulae where p is shown as the design pressure.The inner vessel shall be designed for an external pressure equal to the set pressure of the outer jacket pressurerelief device.SIST EN 13530-2:2003

is the elongation at fracture, in %, at 20 °C.The aggregate reference steel equivalent thicknesses of the outer jacket wall and inner vessel wall shall be not lessthan 5 mm if the diameter of the inner vessel is not more than 1 800 mm and not less than 6 mm if this diameter ismore than 1 800 mm.4.3.3.2 Design pressure pThe internal design pressure p shall be not less than the set pressure of the outer jacket pressure relief device.The external design pressure shall be 1 bar.4.3.3.3 K20See 4.3.2.3.2.SIST EN 13530-2:2003

where x = ()csR-50,Da is the diameter of the end as shown in Figure 4 a) and 4 b).When there are openings outside the area 0,6 Da the required thickness is found from Figures 5 and 6 using theappropriate curve for the relevant value of di /Da.The lower curves of Figures 5 and 6 apply when there are no openings outside the area 0,6 Da.4.3.6.4.2.3If a dished end is welded together from crown and knuckle components, the joint shall be at asufficient distance x from the knuckle. The distance regarded as sufficient is as follows, but with a minimum,however, of at least 100 mm (see Figure 4 c)):¾ crown and knuckle are of different wall thickness:)R (s

-

c ,x

=

50(18)where s is the required wall thickness of the knuckle:¾ the crown and knuckle are of equal wall thickness:¾ for 10 % torispherical endsx = 3,5 s;¾ for 2:1 torispherical endsx = 3,0 s.v = 1,0 may be applied, if the scope of testing corresponds to that specified for a design stress level equal to thepermissible design stress level or in the case of one-piece ends.v = 1,0 may also be applied in the case of welded domed ends - except hemispherical ends - regardless of thescope of testing provided the weld intersects the crown area of 0,6 Da, see Figures 4 e) and 4 f) (left-hand side).4.3.6.4.2.4If the ligament on the connecting line between

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...