SIST EN 1657:2025

(Main)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)

This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance.

This document applies to products that are used in the veterinary area - i.e. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection.

EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations".

NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used.

NOTE 2 This method corresponds to a phase 2 step 1 test.

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der fungiziden oder levuroziden Wirkung chemischer Desinfektionsmittel und Antiseptika für den Veterinärbereich - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

Dieses Dokument legt ein Prüfverfahren und die Mindestanforderungen an die fungizide oder levurozide Wirkung von chemischen Desinfektionsmitteln und Antiseptika fest, die in Wasser standardisierter Härte oder – im Fall gebrauchsfertiger Produkte – in Wasser eine homogene, physikalisch stabile Zubereitung bilden. Die Produkte können nur bis zu einer Konzentration von 80 % geprüft werden, da immer eine bestimmte Verdünnung durch Zugabe der Prüforganismen oder der Belastungssubstanz erfolgt.

Dieses Dokument ist anwendbar für Produkte für die Anwendung im Veterinärbereich, d. h. bei der Aufzucht, Haltung, Produktion, in veterinärmedizinischen Gesundheitseinrichtungen und beim Transport von Tieren sowie bei der Tierkörperbeseitigung, außer wenn die Tiere nach der Tötung durch Zuführung in die weiterverarbeitende Industrie in die Lebensmittelkette gelangen. Dieses Dokument ist auch anwendbar für Produkte, die bei der Zitzendesinfektion verwendet werden.

EN 14885 legt im Einzelnen die Beziehung der verschiedenen Prüfungen untereinander sowie zu den „Anwendungsempfehlungen“ fest.

ANMERKUNG 1 Das beschriebene Verfahren ist zur Bestimmung der Wirkung von handelsüblichen Zubereitungen oder Wirkstoffen unter deren Anwendungsbedingungen vorgesehen.

ANMERKUNG 2 Dieses Verfahren entspricht einer Prüfung der Phase 2, Stufe 1.

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité fongicide ou levuricide des antiseptiques et des désinfectants chimiques utilisés dans le domaine vétérinaire - Méthode d'essai et prescriptions (ph

Le présent document spécifie une méthode d’essai et les exigences minimales relatives à l’activité fongicide et levuricide des désinfectants chimiques et des produits antiseptiques qui forment une préparation homogène, physiquement stable, lorsqu’ils sont dilués dans de l’eau dure ou, dans le cas de produits prêts à l’emploi, dans de l’eau. Les produits ne peuvent être soumis à l’essai qu’à la concentration de 80 % ou à des concentrations inférieures, car l’ajout des micro-organismes d’essai et de la substance interférente s’accompagne forcément d’une dilution.

Le présent document s’applique aux produits utilisés dans le domaine vétérinaire, à savoir la reproduction, l’élevage, la production, les services de soins vétérinaires, le transport et l’abattage de tous les animaux, hors de la chaîne alimentaire qui suit l’abattage et l’entrée dans l’industrie de transformation. Le présent document s’applique également aux produits utilisés pour la désinfection des trayons.

L’EN 14885 spécifie en détail la relation entre les différents essais et les « recommandations d’usage ».

NOTE 1 La méthode décrite vise à déterminer l’activité des formulations commerciales ou des substances actives dans leurs conditions d’utilisation.

NOTE 2 Cette méthode correspond à un essai de type phase 2, étape 1.

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za vrednotenje fungicidnega delovanja ali delovanja kemičnih razkužil in antiseptikov na kvasovke v veterini - Preskusna metoda in zahteve (faza 2, stopnja 1)

Ta dokument določa preskusno metodo in minimalne zahteve za fungicidno delovanje ali delovanje kemičnih razkužil in antiseptikov na kvasovke, ki tvorijo homogen, fizikalno stabilen pripravek, če so razredčeni s trdo vodo oziroma z vodo pri izdelkih, ki so pripravljeni za uporabo.

Izdelke je mogoče preskušati samo pri 80-odstotni ali nižji koncentraciji, ker dodajanje preskusnih organizmov in moteče snovi vedno povzroči razredčenje.

Ta dokument se uporablja za izdelke v veterini, tj. pri vzreji, živinoreji, proizvodnji, v veterinarskih ambulantah, pri prevozu in odstranjevanju vseh živali, razen če so v prehrambeni verigi po smrti in so del predelovalne industrije. Ta dokument se uporablja tudi za izdelke, namenjene razkuževanju seskov.

Standard EN 14885 podrobno določa razmerje med različnimi preskusi in priporočili za uporabo.

OPOMBA 1: Opisana metoda je namenjena določevanju dejavnosti komercialnih oblik ali aktivnih snovi pod pogoji, v katerih se uporabljajo.

OPOMBA 2: Ta metoda ustreza 1. stopnji preskusa faze 2.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-May-2023

- Publication Date

- 28-Jan-2025

- Technical Committee

- KDS - Cosmetics, chemical disinfectants and surface active agents

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 28-Jan-2025

- Due Date

- 04-Apr-2025

- Completion Date

- 29-Jan-2025

Relations

- Effective Date

- 01-Mar-2025

Overview

EN 1657:2024 (CEN) specifies a quantitative suspension test (phase 2, step 1) to evaluate the fungicidal and yeasticidal activity of chemical disinfectants and antiseptics used in the veterinary area. The standard covers commercial formulations or active substances that form a homogeneous, physically stable preparation when diluted with hard water (or water for ready‑to‑use products). It defines test methods, validation controls and minimum performance requirements for products used in breeding, husbandry, veterinary care, transport, disposal of animals (except when they enter the food‑processing chain after death), and for teat disinfection.

Key topics and technical requirements

- Test type: Quantitative suspension test - Phase 2, Step 1.

- Performance criterion: Minimum 4‑log (10^4) reduction of viable fungi/yeast under specified conditions.

- Maximum test concentration: Products may only be tested at concentrations of ≤ 80%, since some dilution occurs during testing.

- Test organisms: Includes Aspergillus brasiliensis (fungicidal) and Candida albicans (yeasticidal); additional relevant strains may be used.

- Interfering substances (soiling):

- Low-level: 3.0 g/L bovine albumin

- High-level: 10 g/L yeast extract + 10 g/L bovine albumin

- Teat disinfectants: 10.0 g/L milk (post‑milking) or 3.0 g/L bovine albumin (pre‑milking)

- Test conditions: Temperature range 5°C to 40°C (varies by application); contact times from 30 s to 120 min, with specific shorter times for teat disinfectants.

- Methods described:Dilution‑neutralization and membrane filtration procedures, with full validation, controls and calculation methods.

- Reporting & verification: Detailed requirements for controls, weighted mean counts, precision, expression of reduction and a standard test report format.

Applications and who uses it

- Manufacturers of veterinary disinfectants and antiseptics (product development, claims substantiation).

- Regulatory bodies and laboratories conducting standardized efficacy testing.

- Quality assurance teams in animal husbandry, veterinary clinics, transport and disposal services, and dairy operations (teat disinfectants).

- Test data support product use recommendations and help compare efficacy across products and laboratories.

Related standards

- EN 14885 - relationship between standards and guidance on application and use recommendations.

- EN 12353 - preservation of test organisms used in efficacy testing.

- Relevant ISO/IEC terminology resources noted in EN 1657.

Keywords: EN 1657:2024, chemical disinfectants, antiseptics, quantitative suspension test, fungicidal, yeasticidal, veterinary disinfectants, teat disinfection, CEN.

Frequently Asked Questions

SIST EN 1657:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in the veterinary area - Test method and requirements (phase 2, step 1)". This standard covers: This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance. This document applies to products that are used in the veterinary area - i.e. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test.

This document specifies a test method and the minimum requirements for fungicidal or yeasticidal activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable preparation when diluted with hard water or - in the case of ready-to-use-products - with water. Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by adding the test organisms and interfering substance. This document applies to products that are used in the veterinary area - i.e. in the breeding, husbandry, production, veterinary care facilities, transport and disposal of all animals except when in the food chain following death and entry into processing industry. This document also applies to products used for teat disinfection. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test.

SIST EN 1657:2025 is classified under the following ICS (International Classification for Standards) categories: 11.080.20 - Disinfectants and antiseptics; 11.220 - Veterinary medicine; 71.100.35 - Chemicals for industrial and domestic disinfection purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1657:2025 has the following relationships with other standards: It is inter standard links to SIST EN 1657:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1657:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Nadomešča:

SIST EN 1657:2016

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za

vrednotenje fungicidnega delovanja ali delovanja kemičnih razkužil in antiseptikov

na kvasovke v veterini - Preskusna metoda in zahteve (faza 2, stopnja 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation

of fungicidal or yeasticidal activity of chemical disinfectants and antiseptics used in the

veterinary area - Test method and requirements (phase 2, step 1)

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur

Bestimmung der fungiziden oder levuroziden Wirkung chemischer Desinfektionsmittel

und Antiseptika für den Veterinärbereich - Prüfverfahren und Anforderungen (Phase 2,

Stufe 1)

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour

l'évaluation de l'activité fongicide ou levuricide des antiseptiques et des désinfectants

chimiques utilisés dans le domaine vétérinaire - Méthode d'essai et prescriptions (ph

Ta slovenski standard je istoveten z: EN 1657:2024

ICS:

11.080.20 Dezinfektanti in antiseptiki Disinfectants and antiseptics

11.220 Veterinarstvo Veterinary medicine

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1657

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 71.100.35 Supersedes EN 1657:2016

English Version

Chemical disinfectants and antiseptics - Quantitative

suspension test for the evaluation of fungicidal or

yeasticidal activity of chemical disinfectants and

antiseptics used in the veterinary area - Test method and

requirements (phase 2, step 1)

Antiseptiques et désinfectants chimiques - Essai Chemische Desinfektionsmittel und Antiseptika -

quantitatif de suspension pour l'évaluation de l'activité Quantitativer Suspensionsversuch zur Bestimmung der

fongicide ou levuricide des antiseptiques et des fungiziden oder levuroziden Wirkung chemischer

désinfectants chimiques utilisés dans le domaine Desinfektionsmittel und Antiseptika für den

vétérinaire - Méthode d'essai et exigences (phase 2, Veterinärbereich - Prüfverfahren und Anforderungen

étape 1) (Phase 2, Stufe 1)

This European Standard was approved by CEN on 18 November 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1657:2024 E

worldwide for CEN national Members.

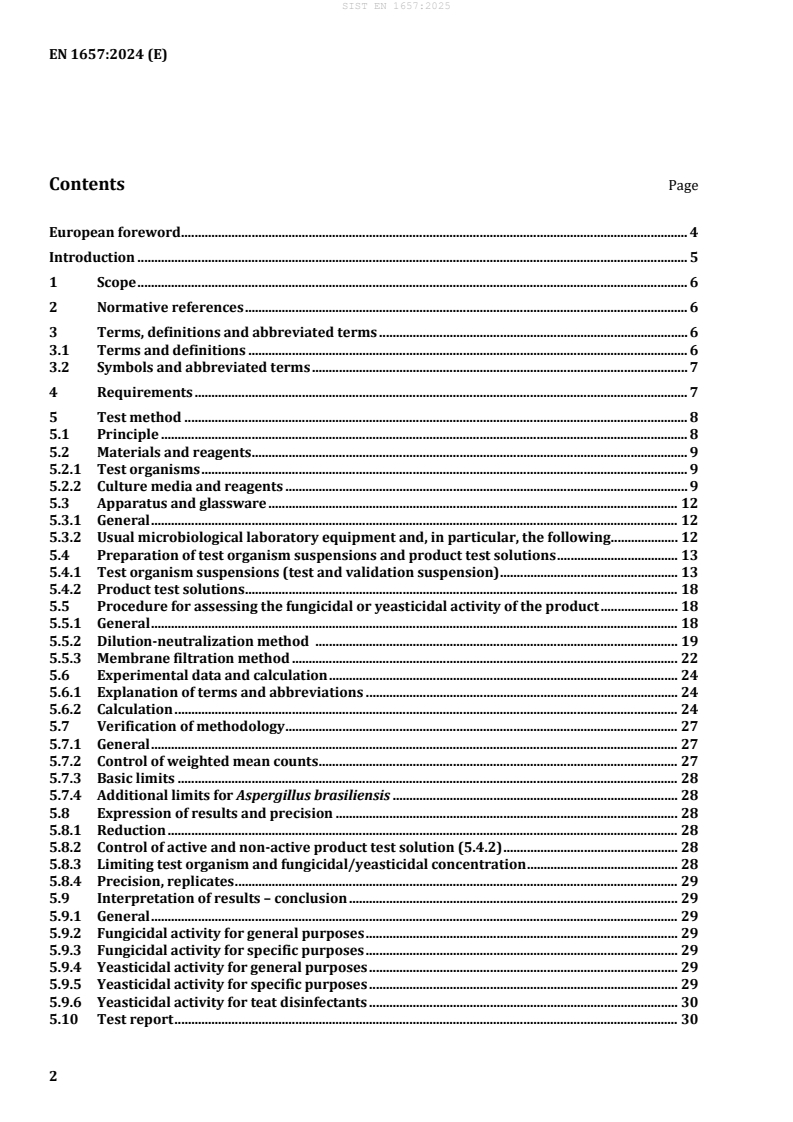

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Symbols and abbreviated terms . 7

4 Requirements . 7

5 Test method . 8

5.1 Principle . 8

5.2 Materials and reagents . 9

5.2.1 Test organisms . 9

5.2.2 Culture media and reagents . 9

5.3 Apparatus and glassware . 12

5.3.1 General . 12

5.3.2 Usual microbiological laboratory equipment and, in particular, the following . 12

5.4 Preparation of test organism suspensions and product test solutions . 13

5.4.1 Test organism suspensions (test and validation suspension) . 13

5.4.2 Product test solutions . 18

5.5 Procedure for assessing the fungicidal or yeasticidal activity of the product . 18

5.5.1 General . 18

5.5.2 Dilution-neutralization method . 19

5.5.3 Membrane filtration method . 22

5.6 Experimental data and calculation . 24

5.6.1 Explanation of terms and abbreviations . 24

5.6.2 Calculation . 24

5.7 Verification of methodology . 27

5.7.1 General . 27

5.7.2 Control of weighted mean counts . 27

5.7.3 Basic limits . 28

5.7.4 Additional limits for Aspergillus brasiliensis . 28

5.8 Expression of results and precision . 28

5.8.1 Reduction . 28

5.8.2 Control of active and non-active product test solution (5.4.2) . 28

5.8.3 Limiting test organism and fungicidal/yeasticidal concentration . 28

5.8.4 Precision, replicates . 29

5.9 Interpretation of results – conclusion . 29

5.9.1 General . 29

5.9.2 Fungicidal activity for general purposes . 29

5.9.3 Fungicidal activity for specific purposes . 29

5.9.4 Yeasticidal activity for general purposes . 29

5.9.5 Yeasticidal activity for specific purposes . 29

5.9.6 Yeasticidal activity for teat disinfectants . 30

5.10 Test report . 30

Annex A (informative) Referenced strains in national collections . 32

Annex B (informative) Neutralizers and rinsing liquids . 33

Annex C (informative) Graphical representation of test procedures . 35

C.1 Dilution-neutralization method . 35

C.2 Membrane filtration method . 37

Annex D (informative) Example of a typical test report . 40

Annex E (informative) Precision of the test result. 45

Bibliography . 48

European foreword

This document (EN 1657:2024) has been prepared by Technical Committee CEN/TC 216 “Chemical

disinfectants and antiseptics”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1657:2016.

This document was revised to correct obvious errors and ambiguities, to harmonize the structure and

wording with other tests of CEN/TC 216 (existing or in preparation), and to improve the readability of

the standard and thereby make it more understandable.

The obligatory conditions have been removed and the preparation of the milk interfering substance has

been amended.

The data obtained using the 2016 version of EN 1657 are still valid.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document specifies a suspension test method for establishing whether a chemical disinfectant or

antiseptic has a fungicidal or yeasticidal activity in the areas described in the scope.

This laboratory test takes into account practical conditions of application of the product, including

contact time, temperature, test organisms and interfering substances, i.e. conditions which may influence

its action in practical situations.

The conditions are intended to cover general purposes and to allow reference between laboratories and

product types. Each utilization concentration of the chemical disinfectant or antiseptic found by this test

corresponds to defined experimental conditions. However, for some applications the recommendations

of use of a product may differ and therefore additional test conditions need to be used.

1 Scope

This document specifies a test method and the minimum requirements for fungicidal or yeasticidal

activity of chemical disinfectant and antiseptic products that form a homogeneous, physically stable

preparation when diluted with hard water or — in the case of ready-to-use-products — with water.

Products can only be tested at a concentration of 80 % or less, as some dilution is always produced by

adding the test organisms and interfering substance.

This document applies to products that are used in the veterinary area – i.e. in the breeding, husbandry,

production, veterinary care facilities, transport and disposal of all animals except when in the food chain

following death and entry into processing industry. This document also applies to products used for teat

disinfection.

EN 14885 specifies in detail the relationship of the various tests to one another and to “use

recommendations”.

NOTE 1 The method described is intended to determine the activity of commercial formulations or active

substances under the conditions in which they are used.

NOTE 2 This method corresponds to a phase 2 step 1 test.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 12353, Chemical disinfectants and antiseptics — Preservation of test organisms used for the

determination of bactericidal (including Legionella), mycobactericidal, sporicidal, fungicidal and virucidal

(including bacteriophages) activity

EN 14885, Chemical disinfectants and antiseptics — Application of European Standards for chemical

disinfectants and antiseptics

ISO 4793, Laboratory sintered (fritted) filters — Porosity grading, classification and designation

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14885 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online Browsing Platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.2 Symbols and abbreviated terms

For the purposes of this document, the following symbols and abbreviated terms apply.

c is the sum of V values taken into account

C

cfu Colony forming units

n is the number of V values taken into account

C

N Test Suspension

Nv Validation suspension

Na Test

A Control A (Experimental conditions control)

B Control B (Neutralization control)

C Control C (Dilution neutralization validation)

N Test at time 0

Nv Validation suspension at time 0

R Reduction

Vc is the number of cfu counted per sample of 1,0ml

4 Requirements

The product shall demonstrate at least a 4 decimal log (lg) reduction when diluted with hard water

(5.2.2.7) or – in the case of ready-to-use products – with water (5.2.2.2) and tested in accordance with

Table 1 and Clause 5 under simulated low-level soiling (3,0 g/l bovine albumin) or high level soiling

(10,0 g/l yeast extract and 10,0 g/l bovine albumin) or 10,0 g/l milk for teat disinfectants or 3,0 g/l

bovine albumin for pre-milking teat disinfectants in additional test conditions.

Table 1 —Test conditions

Test conditions Fungicidal activity Yeasticidal activity Yeasticidal activity for

teat disinfectants

Test organisms Aspergillus brasiliensis Candida albicans Candida albicans

Candida albicans

additional any relevant test any relevant test any relevant test organism

organism organism

Test temperature At intervals of 5°C

Minimum

5°C ± 1°C 5°C ± 1°C 20°C ± 1°C

Maximum

40°C ± 1°C 40°C ± 1°C 30°C ± 1°C

Contact time At intervals of 30 s from 30 s to 5 min and at intervals

Minimum of 5 min from 5 min to 120 min

Maximum 1 min ± 5 s 1 min ± 5 s 1 min ± 5 s for post-milking

teat disinfectants

30 s ± 5 s for pre-milking

teat disinfectants

120 min ± 10 s 120 min ± 10 s 5 min ± 10 s for post-

milking teat disinfectants

3 min ± 10 s for pre-

milking teat disinfectants

Interfering substance

low level soiling 3,0 g/l bovine albumin 3,0 g/l bovine albumin Post milking: 10,0 g/l of

reconstituted milk

high level soiling 10 g/l yeast extract plus 10 g/l yeast extract plus

10 g/l bovine albumin 10 g/l bovine albumin Pre-milking: 3,0 g/l bovine

albumin

additional any relevant substance any relevant substance any relevant substance

NOTE For the additional conditions, the concentration defined as a result can be lower than the one obtained under the

standard test conditions.

The recommended test conditions for the use of the product are within the responsibility of the manufacturer.

Any additional specific fungicidal or yeasticidal activity shall be determined in accordance with 5.2.1 and

5.5.1.1 in order to take into account intended specific use conditions.

5 Test method

5.1 Principle

5.1.1 A sample of the product as delivered and/or diluted with hard water (or water for ready-to-use

products) is added to a test suspension of fungi (yeast cells or mould spores) in a solution of an interfering

substance. The mixture is maintained at temperature θ for the test contact time t in accordance with

Table 1. At the end of this contact time, an aliquot is taken, and the fungicidal/yeasticidal and/or the

fungistatic/yeastistatic activity in this portion is immediately neutralized or suppressed by a validated

method. The method of choice is dilution-neutralization. If a suitable neutralizer cannot be found,

membrane filtration is used. The number of surviving fungi in each sample are determined and the

reduction is calculated.

5.2 Materials and reagents

5.2.1 Test organisms

The fungicidal activity shall be evaluated using the following strains as test organisms:

— Candida albicans;

— Aspergillus brasiliensis.

(formerly Aspergillus niger)

The yeasticidal activity shall be evaluated using only Candida albicans.

NOTE See Annex A for strain references in some culture collections.

The required incubation temperature for these test organisms is 30 °C± 1 °C (see 5.3.2.3). The same

temperature shall be used for all incubations performed during a test and its control and validation.

If additional test organisms are used, they shall be kept and used under optimum growth conditions

(temperature, time, atmosphere, media) and noted in the test report. If the additional test organisms

selected do not correspond to the specified strains, their suitability for supplying the required inocula

shall be verified. If these additional test organisms are not classified at a reference centre, their

identification characteristics shall be stated. In addition, they shall be held by the testing laboratory or

national culture collection under a reference for five years.

5.2.2 Culture media and reagents

5.2.2.1 General

All weights of chemical substances given in this Standard refer to the anhydrous salts. Hydrated forms

may be used as an alternative, but the weights required shall be adjusted to allow for consequent

molecular weight differences.

The reagents shall be of analytical grade and/or appropriate for microbiological purposes. They shall be

free from substances that are toxic or inhibitory to the test organisms.

If additional strains do not grow on the media (5.2.2.3) or cannot be used with diluent (5.2.2.4) alternative

media shall be used and shall be reported as well as alternative incubation conditions.

To improve reproducibility, it is recommended that commercially available dehydrated material (if

appropriate) is used for the preparation of culture media. The manufacturer's instructions relating to the

preparation of these products should be rigorously followed.

Ready to use media may be used if it complies with the required specification.

For each culture medium and reagent, a time limitation for use should be fixed.

All specified pH values are measured at 20 °C± 1 °C.

5.2.2.2 Water

The water shall be freshly glass-distilled water and not demineralized water. If distilled water of adequate

quality is not available, water for injections (see bibliographic reference [1]) can be used.

Sterilize in the autoclave [5.3.2.1 a)]. Sterilization is not necessary if the water is used e.g. for preparation

of culture media and subsequently sterilized.

NOTE 1 See 5.2.2.7 for the procedure to prepare hard water.

5.2.2.3 Malt extract agar (MEA)

Malt extract agar, consisting of:

a

Malt extract 30,0 g

Agar 15,0 g

Water (5.2.2.2) to 1 000,0 ml

a

The malt extract should be of food grade (Cristomalt poudre from Difal is recommended) or equivalent that is

not highly purified and not only based on maltose (Malt extract from OXOID is recommended) .

Sterilize in the autoclave [5.3.2.1 a)]. After sterilization, the pH of the medium shall be equivalent to

5,6 ± 0,2 when measured at 20 °C ± 1 °C.

In case of encountering problems with neutralization (5.5.1.2 and 5.5.1.3), it may be necessary to add

neutralizer to the MEA. Annex B gives guidance on the neutralizers that may be used.

5.2.2.4 Diluent

Tryptone sodium chloride solution, consisting of:

Tryptone, pancreatic digest of casein 1,0 g

Sodium chloride (NaCl) 8,5 g

Water (5.2.2.2) to 1 000,0 ml

Sterilize in the autoclave [5.3.2.1 a)]. After sterilization, the pH of the diluent shall be equivalent to

7,0 ± 0,2 when measured at 20 °C ± 1 °C.

5.2.2.5 Neutralizer

The neutralizer shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and

5.5.2. It shall be sterile.

NOTE Information on neutralizers that have been found to be suitable for some categories of products is given

in Annex B.

5.2.2.6 Rinsing liquid (for membrane filtration)

The rinsing liquid shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and

5.5.3. It shall be sterile, compatible with the filter membrane and capable of filtration through the filter

membrane under the test conditions described in 5.5.3.

NOTE Information on rinsing liquids that have been found to be suitable for some categories of products is

given in Annex B.

5.2.2.7 Hard water for dilution of products

For the preparation of 1 l of hard water, the procedure is as follows:

This information is given for the convenience of users of this European Standard and does not constitute an endorsement by

CEN of the product named. Equivalent products may be used if they can be shown to lead to the same results.

— prepare solution A: dissolve 19,84 g magnesium chloride (MgCl ) and 46,24 g calcium chloride

(CaCl ) in water (5.2.2.2) and dilute to 1 000 ml. Sterilize by membrane filtration (5.3.2.7) or in the

autoclave [5.3.2.1 a)].

Autoclaving – if used – may cause a loss of liquid. In this case make up to 1 000 ml with water (5.2.2.2)

under aseptic conditions. Store the solution in the refrigerator (5.3.2.8) for no longer than one month;

— prepare solution B: dissolve 35,02 g sodium bicarbonate (NaHCO ) in water (5.2.2.2) and dilute to 1

000 ml.

— Sterilize by membrane filtration (5.3.2.7). Store the solution in the refrigerator (5.3.2.8) for no longer

than one week;

— place 600 ml to 700 ml of water (5.2.2.2) in a 1 000 ml volumetric flask (5.3.2.12) and add 6,0 ml

(5.3.2.9) of solution A, then 8,0 ml of solution B. Mix and dilute to 1 000 ml with water (5.2.2.2). The

pH of the hard water shall be 7,0 ± 0,2, when measured at 20 °C ± 1 °C (5.3.2.4). If necessary, adjust

the pH by using a solution of approximately 40 g/l (about 1 mol/l) of sodium hydroxide (NaOH) or

approximately 36,5 g/l (about 1 mol/l) of hydrochloric acid (HCl).

The hard water shall be freshly prepared under aseptic conditions and used within 12 h.

NOTE When preparing the product test solutions (5.4.2), the addition of the product to the hard water

produces a different final water hardness in each test tube. In any case the final hardness is lower than 375 mg/l of

calcium carbonate (CaCO ) in the test tube.

5.2.2.8 Interfering substances

5.2.2.8.1 General

The interfering substance shall be chosen according to the conditions of use laid down for the product.

The interfering substance shall be sterile and prepared at 10 times its final concentration in the test.

For any additional interfering substance the ionic composition (e.g. pH, calcium and/or magnesium

hardness) and chemical composition (e.g. mineral substances, protein, carbohydrates, lipids and

detergents) shall be defined.

NOTE The term “interfering substance” is used even if it contains more than one substance.

5.2.2.8.2 Low-level and pre-milking soiling (bovine albumin solution)

Dissolve 3,0 g of bovine albumin fraction V (suitable for microbiological purposes) in 90 ml of water

(5.2.2.2) in a 100ml volumetric flask (5.3.2.12). Make up to the mark with water.

Sterilize by membrane filtration (5.3.2.7), keep in the refrigerator (5.3.2.8) and use within one month.

The final concentration of bovine albumin in the test procedure (5.5) is 3,0 g/l.

5.2.2.8.3 High-level soiling (mixture of bovine albumin solution with yeast extract)

Dissolve 50,0 g yeast extract powder in 150 ml of water (5.2.2.2) in a 250 ml volumetric flask (5.3.2.12)

and allow foam to collapse. Make up to the mark with water (5.2.2.2). Transfer to a clean dry bottle and

sterilize in an autoclave [5.3.2.1 a)]. Allow to cool to 20 °C ± 1 °C.

Pipette 25 ml of this solution into a 50 ml volumetric flask (5.3.2.12) and add 10 ml of water (5.2.2.2).

Dissolve 5,0 g of bovine albumin fraction V (suitable for microbiological purposes) in the solution with

shaking and allow foam to collapse. Make up to the mark with water (5.2.2.2), sterilize by membrane

filtration (5.3.2.7), keep in the refrigerator (5.3.2.8) and use within one month.

The final concentration in the test procedure (5.5) is 10,0 g/l yeast extract and 10,0 g/l bovine albumin.

5.2.2.8.4 Milk for teat disinfectants

Skimmed milk, guaranteed free of antibiotics and additives and reconstituted at a rate of 100 g powder

per litre of water (5.2.2.2), shall be prepared as follows:

— prepare a solution of 10,0 % (v/v) in water (5.2.2.2) by adding 10 parts of reconstituted milk to 90

parts of water. Heat for 30 min at (105 ± 3) °C [or 5 min at (121 ± 3) °C].

The final concentration of reconstituted milk in the test procedure (5.5) is 1,0 % (v/v) of reconstituted

milk.

5.3 Apparatus and glassware

5.3.1 General

Sterilize all glassware and parts of the apparatus that will come into contact with the culture media and

reagents or the sample, except those which are supplied sterile, by one of the following methods:

a) by moist heat, in the autoclave [5.3.2.1 a)];

b) by dry heat, in the hot air oven [5.3.2.1 b)].

5.3.2 Usual microbiological laboratory equipment and, in particular, the following

5.3.2.1 Apparatus for sterilization

+3

a) for moist heat sterilization, an autoclave capable of being maintained at ( 121 ) °C for a minimum

holding time of 15 min;

+5

b) for dry heat sterilization, a hot air oven capable of being maintained at ( 180 ) °C for a minimum

+5 +5

holding time of 30 min, at ( ) °C for a minimum holding time of 1 h or at ( ) °C for a

170 160

0 0

minimum holding time of 2 h.

5.3.2.2 Water baths, capable of being controlled at the specified temperatures and at 45 °C ± 1 °C (to

maintain melted MEA in case of pour plate technique).

5.3.2.3 Incubator, capable of being controlled at the specified temperatures ± 1 °C.

5.3.2.4 pH-meter, having an inaccuracy of calibration of no more than ± 0,1 pH units at 20 °C ± 1 °C.

A puncture electrode or a flat membrane electrode should be used for measuring the pH of the agar media

(5.2.2.3).

5.3.2.5 Stopwatch

Disposable sterile equipment is an acceptable alternative to reusable glassware.

5.3.2.6 Shakers

a) Electromechanical agitator, e.g. Vortex® mixer

b) Mechanical shaker

5.3.2.7 Membrane filtration apparatus, constructed of a material compatible with the substances

to be filtered.

The apparatus shall have a filter holder of at least 50 ml volume. It shall be suitable for use with filters of

diameter 47 mm to 50 mm and 0,45 µm pore size for sterilization of hard water (5.2.2.7) and bovine

albumin (5.2.2.8), and if the membrane filtration method is used (5.5.3).

The vacuum source used shall give an even filtration flow rate. In order to obtain a uniform distribution

of the microorganisms over the membrane and to prevent overlong filtration, the device shall be set so

as to obtain the filtration of 100 ml of rinsing liquid in 20 s to 40 s.

5.3.2.8 Refrigerator, capable of being controlled at 2 °C to 8 °C.

5.3.2.9 Graduated pipettes, of nominal capacities 10 ml, 1 ml and 0,1 ml, or calibrated automatic

pipettes.

5.3.2.10 Petri dishes (plates), of size 90 mm to 100 mm.

5.3.2.11 Glass beads, 3 mm to 4 mm in diameter.

5.3.2.12 Volumetric flasks.

5.3.2.13 Fritted filter, with porosity of 40 µm to 100 µm according to ISO 4793.

5.3.2.14 Flasks with ventilated caps.

5.3.2.15 Microscope capable of x 400 magnification

5.3.2.16 Containers; test tubes, culture bottles or flasks of suitable capacity.

5.4 Preparation of test organism suspensions and product test solutions

5.4.1 Test organism suspensions (test and validation suspension)

5.4.1.1 General

For each test organism, two suspensions have to be prepared; the “test suspension” to perform the test

and the “validation suspension” to perform the controls and method validation.

5.4.1.2 Preservation and working stock cultures of test organisms

The test organisms and their stock cultures shall be prepared and kept in accordance with EN 12353.

Vortex® is an example of a suitable product available commercially. This information is given for the convenience of users of

this European Standard and does not constitute an endorsement by CEN of this product.

5.4.1.3 Working culture of test organisms

5.4.1.3.1 Candida albicans (yeast)

In order to prepare the working culture of Candida albicans (5.2.1), prepare a subculture from the stock

culture (5.4.1.2) by streaking onto MEA (5.2.2.3) slopes or plates (5.3.2.10) and incubate (5.3.2.3). After

42 h to 48 h prepare a second subculture from the first subculture in the same way and incubate for 42 h

to 48 h. From this second subculture, a third subculture may be produced in the same way. The second

and (if produced) third subcultures are the working cultures.

If it is not possible to prepare the second subculture on a particular day, a 72 h subculture may be used

for subsequent subculturing, provided that the subculture has been kept in the incubator (5.3.2.3) during

the 72 h period.

Never produce and use a fourth subculture.

5.4.1.3.2 Aspergillus brasiliensis (mould)

For Aspergillus brasiliensis (5.2.1), use only the first subculture grown on MEA (5.2.2.3) in Petri dishes or

flasks with ventilated caps (5.3.2.14) and incubate for 7 days to 9 days at 30 °C ± 1°C. No further

subculturing is needed. Do not stack the Petri dishes during the incubation to improve the temperature

homogenization. At the end of incubation, all the cultures have to show a dark brown or black surface.

Cultures with rare and small white or grey areas may be used (see Figure 1).

Figure 1 — Photo No 1: A. brasiliensis ATCC 16404 after 7 d of incubation at 30°C

Figure 2 — Photo No.2: Example of inappropriate (not usable) culture of A. brasiliensis

ATCC 16404 after 7 d of incubation at 30°C

5.4.1.3.3 Other test organisms (yeasts or moulds)

For additional test organisms, any departure from this method of culturing the yeast or the mould or of

preparing the suspensions shall be noted, giving the reasons in the test report.

5.4.1.4 Test suspension (“N”)

5.4.1.4.1 Candida albicans

The procedure for preparing the Candida albicans test suspension is as follows:

a) take 10 ml of diluent (5.2.2.4) and place in a 100 ml flask with 5 g of glass beads (5.3.2.11). Take the

working culture (5.4.1.3.1) and transfer loopfuls of the cells into the diluent (5.2.2.4). The cells should

be suspended in the diluent by rubbing the loop against the wet wall of the flask to dislodge the cells

before immersing in the diluent. Shake the flask for 3 min using a mechanical shaker [5.3.2.6b)].

Aspirate the suspension from the glass beads and transfer to a tube;

7 4 7

b) adjust the number of cells in the suspension to 1,5 × 10 cfu/ml to 5,0 × 10 cfu/ml using diluent

(5.2.2.4), estimating the number of cfu by any suitable means. Maintain this test suspension in the

water bath at 20 °C ± 1 °C [5.3.2.2] and use within 2 h.

The use of a spectrophotometer for adjusting the number of cells is highly recommended (approximately

620 nm wavelength – cuvette 10 mm path length). Each laboratory should therefore produce calibration

data for each test organism knowing that suitable values of optical density are generally found between

0,200 and 0,350. A colourimeter is a suitable alternative.

−5 −6

c) For counting, prepare 10 and 10 dilutions of the test suspension using diluent (5.2.2.4). Mix

[5.3.2.6a)].

Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the pour plate or the spread plate

technique.

1) When using the pour plate technique, transfer each 1,0 ml sample into separate Petri dishes and add

15 ml to 20 ml melted MEA (5.2.2.3), cooled to 45 °C ± 1 °C.

cfu/ml = colony-forming unit(s) per millilitre

2) When using the spread plate technique, spread each 1,0 ml sample – divided into portions of

approximately equal size – on an appropriate number (at least two) of surface dried plates containing

MEA (5.2.2.3).

For incubation and counting, see 5.4.1.6.

5.4.1.4.2 Aspergillus brasiliensis

The procedure for preparing the Aspergillus brasiliensis test suspension is as follows.

a) Take the working culture (5.4.1.3.2) and suspend the spores in 10 ml of sterile 0,05 % (w/v)

polysorbate 80 solution in water (5.2.2.2). Using a sterile glass rod or spatula, detach the

conidiospores from the culture surface. Transfer the suspension into a flask and gently shake by hand

for one minute together with 5 g of glass beads (5.3.2.11). Filter the suspension through a fritted filter

(5.3.2.13).

b) Carry out a microscopic examination under x 400 magnification (5.3.2.15) immediately after the

preparation to show:

1) the presence of a high concentration (at least 75 %) of characteristic mature spores i.e. spiny

spores (versus smooth spores) [see Figures 3 and 4];

If there are less than 75 % spiny conidiospores it may be due to the Aspergillus brasiliensis

culture or the media used to produce the spores. In this situation, it will be necessary to obtain

the culture from another culture collection and/or use a MEA from a different supplier.

2) the absence of spore germination (check at least 10 fields of view);

3) If germinated spores are present, discard the suspension;

4) the absence of mycelia fragments (check at least 10 fields of view).

If mycelia are present, proceed to a 2nd fritted filtration.

If mycelia are still present, discard the suspension.

Figure 3 — Photo No 3: Observation of conidiospores under light microscope: presence of

smooth (a) and spiny (b) spores (insufficient spiny spores)

Figure 4 — Photo No 4: Observation of conidiospores under light microscope: High

concentration of characteristic mature spores with spiny aspect (sufficient spiny spores)

7 7

c) Adjust the number of spores in the suspension to 1,5 × 10 cfu/ml to 5,0 × 10 cfu/ml using the

diluent (5.2.2.4), estimating the number of cfu by any suitable means. Use the suspension within 4 h,

maintain in a water bath controlled at 20°C ± 1°C (5.3.2.2). In any case, adjust the temperature

according to 5.5.1.4 only immediately before the start of the test (5.5.2 or 5.5.3).

The use of a cell counting device for adjusting the number of cells is highly recommended. When using a

suitable counting chamber, follow the instructions explicitly. Each laboratory should therefore produce

calibration data to establish the relationship between the counts obtained using the counting device and

the counts (5.4.1.6) obtained by the pour plate or the spread plate technique. Experienced laboratories

found a better fit to the required number of spores when the spore suspension count in the device was

10 % to 50 % higher than the number aimed at.

−5 −6

d) For counting, prepare 10 and 10 dilutions of the test suspension using diluent (5.2.2.4). Mix

[5.3.2.6 a)].

Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the pour plate or the spread plate

technique.

1) When using the pour plate technique, transfer about half of each 1,0 ml sample into separate Petri

dishes (i.e. in duplicate = four plates) and add 15 ml to 20 ml of melted MEA (5.2.2.3), cooled to

45 °C ± 1 °C

2) When using the spread plate technique, spread about one quarter of each 1,0 ml sample on an

appropriate number (at least four) of surface dried plates containing MEA (5.2.2.3) (i.e. in duplicate

– at least eight plates).

For incubation and counting, see 5.4.1.6.

5.4.1.5 Validation suspension (“Nv”)

a) To prepare the validation suspension, dilute the test suspension (5.4.1.4.1 and 5.4.1.4.2) with the

2 3

diluent (5.2.2.4) to obtain the fungal count of 3,0 × 10 cfu/ml to 1,6 × 10 cfu/ml [about one-quarter

−4

(1 + 3) of the 10 dilution].

−1

b) For counting, prepare a 10 dilution with diluent (5.2.2.4). Mix [5.3.2.6a)]. Take a sample of 1,0 ml

in duplicate and inoculate using the pour plate or the spread plate technique [with Candida albicans,

5.4.1.4.1 c); with Aspergillus brasiliensis, 5.4.1.4.2 d)]. For incubation and counting, see 5.4.1.6.

5.4.1.6 Incubation and counting of the test and the validation suspensions

For incubation and counting of the test and the validation suspensions, the procedure is as follows:

a) incubate (5.3.2.3) the plates for 42 h to 48 h. Discard any plates that are not countable for any reason.

Count the plates and determine the number of cfu.

Only for Aspergillus brasiliensis: incubate the plates for a further 20 h to 24 h and – if the number of

colonies has increased – for a third additional period of 20 h to 24 h. Do not recount plates that no longer

show well-separated colonies. Recount the remaining plates. If the number has increased, use only the

higher number for further evaluation;

b) count for each plate the exact number of colonies, but record “> 165” (for moulds) or “> 330” (for

yeasts) for any counts higher than 165 and 330 respectively and determine the Vc values according

to 5.6.2.2;

c) calculate the numbers of cfu/ml in the test suspension “N” and in the validation suspension “Nv” using

the methods given in 5.6.2.3 and 5.6.2.5. Verify according to 5.7.

5.4.2 Product test solutions

The concentration of a product test solution shall be 1,25 times the desired test concentration because it

is diluted to 80 % during the test and the method validation (5.5.2 or 5.5.3). Product test solutions shall

be prepared in hard water (5.2.2.7) at minimum three different concentrations to include one

concentration in the active range and one concentration in the non-active range (5.8.2). The product as

received may be used as one of the product test solutions, in this case the highest tested concentration is

80 %.

Dilutions of ready-to-use products, i.e. products that are not diluted when applied, shall be prepared in

water (5.2.2.2).

For solid products, dissolve the product as received by weighing at least 1,0 g ± 10 mg of the product in a

volumetric flask and filling up with hard water (5.2.2.7). Subsequent dilutions (lower concentrations)

shall be prepared in volumetric flasks (5.3.2.12) on a volume/volume basis in hard water (5.2.2.7).

For liquid products, dilutions of the product shall be prepared with hard water (5.2.2.7) on a

volume/volume basis using volumetric flasks (5.3.2.12).

The product test solutions shall be prepared freshly and used in the test within 2 h. They shall give a

physically homogeneous preparation that is stable during the whole procedure. If during the procedure

a visible inhomogeneity appears due to the formation of a precipitate or flocculant (for example, through

the addition of the interfering substance), it shall be recor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...