SIST EN 13298:2004

(Main)Railway applications - Suspension components - Helical suspension springs, steel

Railway applications - Suspension components - Helical suspension springs, steel

This standard gives guidance for: - design, - specification of technical and quality requirements, - the approval procedure and quality surveillance of production methods, - the examinations and tests to be carried out, - the delivery conditions.

Bahnanwendungen - Federungselemente - Schraubendruckfedern aus Stahl

Diese Europäische Norm gilt für Schraubendruckfedern als Federelemente von Schienenfahrzeugen.

Sie gilt insbesonders für zylindrische Druckfedern aus runden Stahl-Stäben mit konstantem Durchmesser und konstanter Federsteigung.

Sie gilt ebenfalls für Schraubendruckfedern mit anderen Formen (z. B. konisch und/oder nicht konstanter Steigung der Windung und/oder Stäben mit anderen Querschnitten, usw.).

Diese Europäische Norm gibt Anleitung zu folgenden Gebieten:

¾ Konstruktion;

¾ Spezifikation technischer und qualitativer Anforderungen;

¾ Genehmigungsverfahren und Qualitätssicherung von Fertigungsverfahren;

¾ auszuführende Prüfungen und Versuche;

Lieferbedingungen.

Applications ferroviaires - Eléments de suspension - Ressorts de compression hélicoidaux, en acier

La présente norme donne des directives pour: - la conception, - la définition des exigences techniques et qualitatives, - la procédure d'homologation et surveillance de la qualité des méthodes de production, - les vérifications et essais à effectuer, - les conditions de livraison.

Železniške naprave – Vzmetenje – Vijačna, tlačna vzmet iz jekla

General Information

- Status

- Published

- Publication Date

- 31-May-2004

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Jun-2004

- Due Date

- 01-Jun-2004

- Completion Date

- 01-Jun-2004

Overview

EN 13298:2003 - Railway applications - Suspension components - Helical suspension springs, steel is a European Standard published by CEN that provides comprehensive guidance for the specification, design, testing and delivery of steel helical suspension springs used in rail vehicle suspensions. The standard covers cylindrical compression springs made from round-section steel bars with constant coil inclination and also addresses other helical spring shapes and wire sections where relevant.

Key topics and technical requirements

EN 13298:2003 organizes requirements across design, production and verification. Major technical topics include:

Design and product specification

- Definitions of geometrical characteristics (wire diameter, mean/inner/outer diameters, free and loaded lengths).

- Design data presentation in accordance with ISO/EN spring documentation standards (EN ISO 2162 series).

Materials and mechanical characteristics

- Material selection and delivery conditions for hot-formed and quenched/tempered spring steels (see normative material annex).

- Mechanical tests referenced (tensile, impact) and required properties.

Testing methods

- Axial force–deflection (stiffness/flexibility) tests.

- Transverse stiffness and free transverse deflection (bowing) tests.

- Geometrical measurement and surface protection (corrosion) tests.

- Non-destructive examinations: inclusion checks, magnetic particle inspection and surface defect detection.

Quality assurance and production control

- Approval procedure, product qualification, sample plans and production surveillance.

- Control and monitoring of production quality, final acceptance criteria and non-conformity handling.

Surface protection, marking and delivery

- Requirements for corrosion protection (referencing ISO salt spray methods).

- Marking, packaging and delivery conditions.

Normative annexes (A–E) provide detailed requirements for cylindrical springs, materials, shot‑peening repeatability, inclusion examination and magnetic detection of surface imperfections.

Applications and who uses this standard

EN 13298:2003 is intended for practical use by:

- Rail vehicle designers and OEMs specifying suspension components.

- Spring manufacturers producing steel helical suspension springs for rolling stock.

- Procurement teams writing technical contracts and delivery specifications.

- Quality, inspection and test laboratories performing acceptance and routine tests.

- Maintenance and asset managers ensuring replacement springs meet original specifications.

- Certification bodies and railway authorities harmonizing component approval.

Use the standard to define supplier requirements, perform type approval, set in-service inspection regimes and implement production quality surveillance for critical railway suspension components.

Related standards (selection)

- EN ISO 2162 series (spring documentation)

- EN 10002-1 (tensile testing)

- EN 10045-1 (Charpy impact)

- ISO 9227 (salt spray corrosion testing)

- EN 10228-1 / magnetic particle inspection

Keywords: EN 13298:2003, helical suspension springs, railway suspension components, steel springs, spring testing, quality assurance, spring design.

Frequently Asked Questions

SIST EN 13298:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Suspension components - Helical suspension springs, steel". This standard covers: This standard gives guidance for: - design, - specification of technical and quality requirements, - the approval procedure and quality surveillance of production methods, - the examinations and tests to be carried out, - the delivery conditions.

This standard gives guidance for: - design, - specification of technical and quality requirements, - the approval procedure and quality surveillance of production methods, - the examinations and tests to be carried out, - the delivery conditions.

SIST EN 13298:2004 is classified under the following ICS (International Classification for Standards) categories: 21.160 - Springs; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13298:2004 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC; Standardization Mandates: M/024. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13298:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Federungselemente - Schraubendruckfedern aus StahlApplications ferroviaires - Eléments de suspension - Ressorts de compression hélicoidaux, en acierRailway applications - Suspension components - Helical suspension springs, steel45.060.01Železniška vozila na splošnoRailway rolling stock in general21.160VzmetiSpringsICS:Ta slovenski standard je istoveten z:EN 13298:2003SIST EN 13298:2004en01-junij-2004SIST EN 13298:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13298March 2003ICS 21.160; 45.060.01English versionRailway applications - Suspension components - Helicalsuspension springs, steelApplications ferroviaires - Eléments de suspension -Ressorts de compression hélicoïdaux, en acierBahnanwendungen - Federungselemente - Schrauben-Druckfedern aus StahlThis European Standard was approved by CEN on 29 November 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13298:2003 ESIST EN 13298:2004

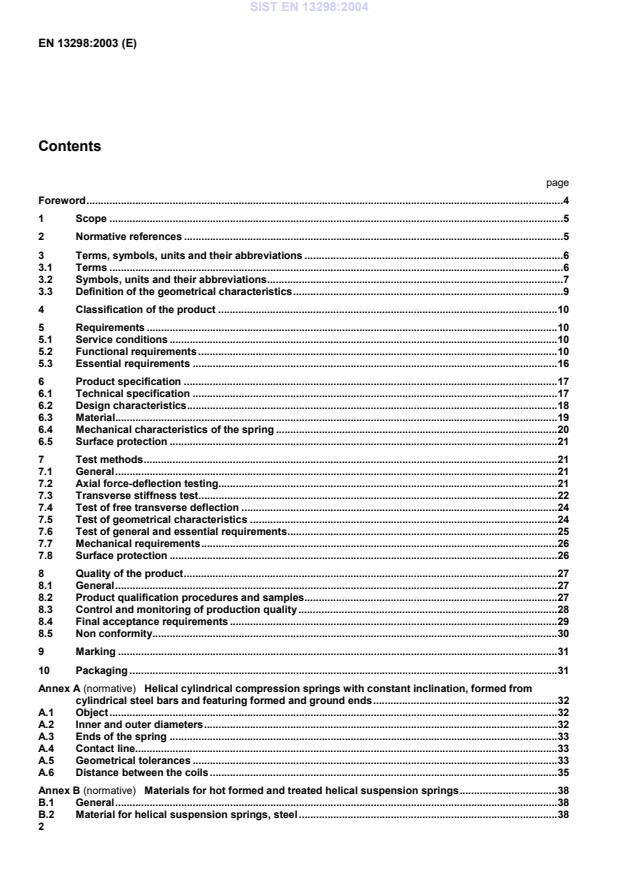

Helical cylindrical compression springs with constant inclination, formed fromcylindrical steel bars and featuring formed and ground ends.32A.1Object.32A.2Inner and outer diameters.32A.3Ends of the spring.33A.4Contact line.33A.5Geometrical tolerances.33A.6Distance between the coils.35Annex B (normative)

Materials for hot formed and treated helical suspension springs.38B.1General.38B.2Material for helical suspension springs, steel.38SIST EN 13298:2004

Repeatability of prestressing by means of shot peening.39C.1Object.39C.2Check of the intensity.39C.3Check of the covering.42Annex D (normative)

Examination for inclusions.43D.1Object.43D.2Test methods.43Annex E (normative)

Magnetic detection of surface imperfections of helical springs formed fromcylindrical steel bars.45E.1Object.45E.2Methods.45E.3Special precautions.45Bibliography.46SIST EN 13298:2004

1)Can be obtained from: UIC Direction Générale, 16 rue Jean Rey, F-75015 Paris.2)Can be purchased from: Beuth Verlag GmbH, Burggrafenstr. 6, 10772 D-Berlin.3)Can be purchased from: Association

de normalisation (AFNOR), 11, av. Francis de Pressensé, F-93571 Aint-Denis La Plaine CEDEX.4)Can be purchased from: SIS-Standardiseringen i Sverige, box 64 55, S-11 3 82 Stockholm.SIST EN 13298:2004

(for Qj and rj , see Table 1)This characteristic shall be measured in a plane which is parallel to the support bases (force surface) of the spring.It is defined by the relation between a force variation and the corresponding displacement variation for a givenstatic axial force Fj, applied to the spring.NOTEThe transverse stiffness is not an independent value but it is cross related to the axial stiffness and other springcharacteristics and shall be defined with this in mind.The technical specification shall define the nominal value of the transverse static stiffness Kt (with its tolerance)together with relative axial force Fj to be taken into account.In addition to that, the direction in which is defined the transverse stiffness of the spring shall be specified.Unless a different tolerance is indicated in the technical specification, the transverse static stiffness shall lie within atolerance of ± 15 % versus the specified value.It is possible to define the transverse static flexibility instead of the transverse static stiffness, whereby flexibility isthe inversion of stiffness (1/Kt ).5.2.3.3 Free transverse deflection or bowingThis item shall be specified only if a defined behaviour of the free transverse deflection is essential for the operationof the suspension system.The value and direction of free deflection depend on the axial force applied and exhibit similar scatter to thetransverse stiffness value.The direction of bowing is defined by the AB straight line (see Figure 5) which is the projection to the straight linebetween the two loading surface centres of the spring.The direction of bowing of a spring submitted to a static axial force FCO shall be marked on the spring by apermanently visible system. The FC0 value shall be defined in the technical specification. The position of markingtowards the spring centre shall indicate the direction of bowing.Any limitation of the bowing force FC, when the spring undergoes an axial Force FC0 shall be stipulated in thetechnical specification. Due to the requirements in connection with the installation of the spring on the vehicle (towhich it belongs) it can be necessary to specify the FC force figure on the spring. If the case arises, thisrequirement shall be stipulated in the technical specification under the specific marking conditions (see clause 9).The maximum permissible angle qC between bowing directions of a spring which undergoes an axial force FC0 onthe one hand, and an axial force FC1 on the other hand (see example, Figure 5) shall be defined in the technicalspecification, together with the values of FC0 and FC1.SIST EN 13298:2004

vehicle to which it belongs, (see definitions in 3.2).Figure 5 — Bowing of a spring (example)While the spring is submitted to a static axial force FC0, the value of the bowing force FC shall lie within the limitsindicated in the technical specification. Unless a different value is indicated in the technical specification, the angleqC between the bowing directions of a spring submitted to an axial force FC0 on one hand and to an axial force FC1on the other hand shall be £ 30°.5.2.3.4 EnduranceThe springs shall resist the static and dynamic requirements to which they are subjected in service. The life of thespring is limited either by rupture or by creep.It depends specifically on:— the stress level and the stress range applied;— physical characteristics of the spring (internal and external integrity);— material and mechanical characteristics;— corrosion resistance.Freedom from rupture by varying cyclic loads will be achieved by keeping the stress level and the stress rangewithin allowable limits (see 6.1).SIST EN 13298:2004

be defined6.2.1---Cross-section of the material6.2.27.5.1Diameter Di and De6.2.3---Number of coils6.2.4----Unloaded (free) length6.2.5----Solid length6.2.6----Distance between coils6.2.7Annex APerpendicularity6.3.27.6.5Internal integrity6.3.37.6.6Chemical composition6.3.4Annex DInclusion cleanliness6.4.17.7.1Hardness6.4.27.7.2Tensile strength6.4.37.7.3Resilience6.57.8Surface protection9----Marking6.2 Design characteristics6.2.1 Cross section of the materialUsually the cross section of the material is round. The dimension and its tolerance shall be defined in the technicalspecification.6.2.2 DiameterThe mean diameter D shall be specified.SIST EN 13298:2004

and/or the outer diameter De

shall be specified depending on the kind of installation. If notolerance is specified reference shall be made to annex A.6.2.3 Number of coilsThe number of active coils n and the number of total coils shall be specified.6.2.4 Unloaded (free) lengthIf the free length L0 is different from the reference length, the free length is only specified as indicative. In this caseno tolerance is applicable.6.2.5 Solid lengthThe solid length LC may be specified as indicative. The minimum length LM shall always be larger than LC. Notolerance shall apply to LC.6.2.6 Distance between coilsIn order to achieve acceptable behaviour of the spring it is necessary to define the minimum distance between theactive coils emin, while the spring is subjected to a force Fj.Depending on design practice, Fj

may be the maximal force FB.The minimum distance may be defined as¾ the coefficient of aeration a, see A.6, method 1;¾ the remaining deflection Se between the length of the spring subjected to the forceFj and the solid length, see A.6, method 2.In any case the distance shall be proved by design calculation.Fj

and coefficient a

or Se

shall be specified.6.2.7 Perpendicularity of the spring axis versus the support baseIf there are special requirements, the acceptable deviation shall be specified, otherwise the provisions of annex Ashall apply.6.3 Material6.3.1 GeneralThe alloy to be used for the manufacture of the spring shall be defined in the technical specification.It is recommended to use the alloys defined in prEN 10089 (see also annex B of this standard.) It is permitted touse alloys different to those defined in prEN 10089. In this case, the chemical and mechanical characteristics shallbe completely defined in the technical specification.6.3.2 Internal integrityThe material of the springs shall not exhibit internal faults which would prove detrimental in use. In case where it isnecessary to establish that the internal integrity is acceptable, then tests as defined in 7.6.5 are to be carried out.SIST EN 13298:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...