SIST EN 16907-5:2019

(Main)Earthworks - Part 5: Quality control

Earthworks - Part 5: Quality control

This European Standard provides recommendations and guidance on the quality assurance and quality control of earthworks construction forming part of general civil engineering and building works. It provides guidance on the techniques to be used to give clients, contractors and designers confidence that the earthworks have been constructed in accordance with their requirements.

Erdarbeiten - Teil 5: Qualitätskontrolle und Überwachung

Diese Europäische Norm enthält Empfehlungen und Leitlinien für die Qualitätssicherung und die Qualitäts-kontrolle von Erdarbeiten im üblichen Hoch- und Tiefbau. Sie gibt Hinweise zu den Verfahren, die anzu-wenden sind, damit Auftraggeber, Auftragnehmer und Planer sicher gehen können, dass die ausgeführten Erdarbeiten die von ihnen gestellten Anforderungen erfüllen.

Terrassement - Partie 5: Contrôle qualité et surveillance

Zemeljska dela - 5. del: Kontrola kakovosti

Ta evropski standard zajema priporočila in vodila glede zagotavljanja kakovosti ter nadzora kakovosti konstrukcije zemeljskih del, ki so del splošnih gradbenih inženirskih objektov in gradbenih del. Zajema vodila glede tehnik, s katerimi se lahko naročniki, pogodbeniki in projektanti prepričajo, da so bila zemeljska dela izvedena v skladu z njihovimi zahtevami.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Jan-2016

- Publication Date

- 14-Mar-2019

- Technical Committee

- ZEM - Earthworks

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Feb-2019

- Due Date

- 04-May-2019

- Completion Date

- 15-Mar-2019

Overview

EN 16907-5:2018 - Earthworks: Part 5 - Quality control (CEN) provides recommendations and guidance for quality assurance (QA) and quality control (QC) of earthworks within civil engineering and building projects. The standard helps clients, contractors and designers ensure earthworks are constructed to specified requirements by describing QA programmes, QC plans, material checking, compaction control approaches and compliance testing methods.

Key topics and requirements

- Quality Assurance Programme

- QA is the overall system; QC is one element. Core elements include QC, acceptance procedures, and non‑conformance resolution. Independent QA may be required for impartial evaluation.

- Quality Control Plan (minimum content)

- Sampling and testing procedures (locations, frequency, methods, acceptance criteria).

- Organisation and responsibilities.

- Visual inspection, document control and corrective actions for non‑conformance.

- Material checking

- Characterisation per EN 16907‑2 before bulk works. Sampling at excavation or deposition, testing imported materials at source/deposition where practical. Chemical testing where manufactured or recycled materials are used.

- Compaction control approaches

- Method specification: prescriptive requirements for equipment, layer thickness, number of passes and recording (e.g., Q/S method, tachographs, GNSS-equipped compactors). Trial embankments recommended.

- End product specification: performance-based criteria (e.g., required in‑place density or stiffness); constructor chooses means to comply. Trial embankment and routine compliance testing recommended.

- Compliance testing methods

- In situ density testing (acceptance of compaction).

- Stiffness and bearing capacity tests: plate loading, deflectometer, penetration tests.

- Continuous Compaction Control (CCC) with vibrating rollers (see CEN/TS 17006).

- Geometry/tolerances, testing frequency, result evaluation methods (single result, attributes, variables) and record‑keeping are covered.

- Documentation

- Daily records, presentation of test results, as‑built records and procedures for non‑conformance tracking.

Applications and users

- Practical for: civil engineers, geotechnical engineers, earthworks contractors, site supervisors, quality managers and clients procuring earthworks.

- Typical uses: embankments, road subgrades, foundation fill, land reclamation (note: dredged hydraulic fill is specified by end product).

- Helps establish contractual QC regimes, on‑site testing programs, acceptance criteria and traceable records for regulatory and design compliance.

Related standards

- EN 16907‑1 to EN 16907‑4, EN 16907‑6 (Earthworks series)

- EN 1997‑1 (Eurocode 7: Geotechnical design)

- CEN/TS 17006 (Continuous Compaction Control)

- EN ISO 22476 series (field testing)

Keywords: EN 16907-5:2018, earthworks quality control, compaction control, Quality Control Plan, continuous compaction control, in situ density testing, CEN earthworks standards.

Frequently Asked Questions

SIST EN 16907-5:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Earthworks - Part 5: Quality control". This standard covers: This European Standard provides recommendations and guidance on the quality assurance and quality control of earthworks construction forming part of general civil engineering and building works. It provides guidance on the techniques to be used to give clients, contractors and designers confidence that the earthworks have been constructed in accordance with their requirements.

This European Standard provides recommendations and guidance on the quality assurance and quality control of earthworks construction forming part of general civil engineering and building works. It provides guidance on the techniques to be used to give clients, contractors and designers confidence that the earthworks have been constructed in accordance with their requirements.

SIST EN 16907-5:2019 is classified under the following ICS (International Classification for Standards) categories: 03.120.99 - Other standards related to quality; 93.020 - Earthworks. Excavations. Foundation construction. Underground works. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16907-5:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zemeljska dela - 5. del: Kontrola kakovostiErdarbeiten - Teil 5: Qualitätskontrolle und ÜberwachungTerrassement - Partie 5: Contrôle qualité et surveillanceEarthworks - Part 5: Quality control93.020Zemeljska dela. Izkopavanja. Gradnja temeljev. Dela pod zemljoEarthworks. Excavations. Foundation construction. Underground works03.120.99Drugi standardi v zvezi s kakovostjoOther standards related to qualityICS:Ta slovenski standard je istoveten z:EN 16907-5:2018SIST EN 16907-5:2019en,fr,de01-april-2019SIST EN 16907-5:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16907-5

December

t r s z ICS

{ uä r t r English Version

Earthworks æ Part

wã Quality control Terrassement æ Partie

wã Contrôle qualité et surveillance

Erdarbeiten æ Teil

wã Qualitätskontrolle und Überwachung This European Standard was approved by CEN on

s v May

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x { r yæ wã t r s z ESIST EN 16907-5:2019

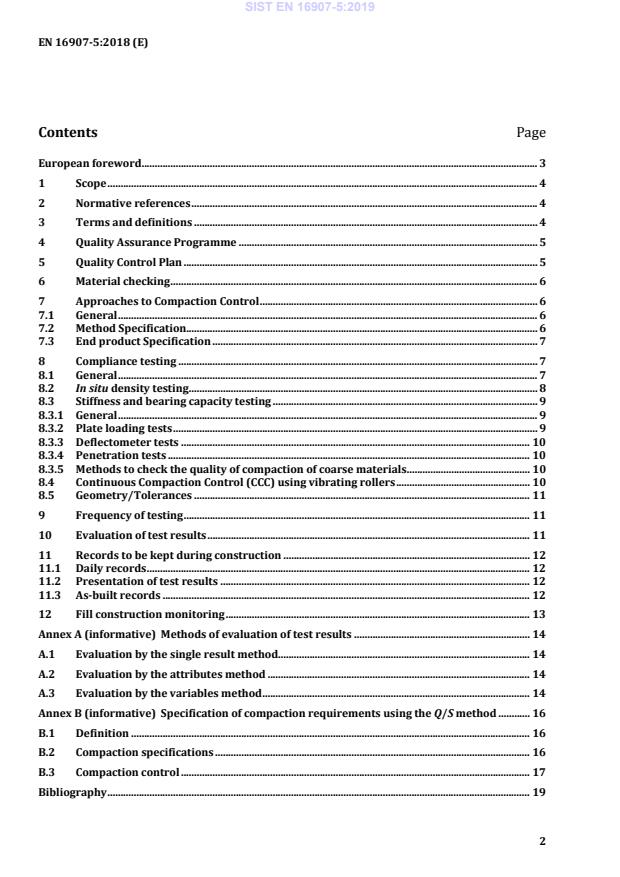

Methods of evaluation of test results . 14 A.1 Evaluation by the single result method. 14 A.2 Evaluation by the attributes method . 14 A.3 Evaluation by the variables method . 14 Annex B (informative)

Specification of compaction requirements using the Q/S method . 16 B.1 Definition . 16 B.2 Compaction specifications . 16 B.3 Compaction control . 17 Bibliography . 19 SIST EN 16907-5:2019

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp Note See also Clause 3 in EN 16907-1:2018 for general terms and definitions for use in earthworks. 3.1 quality assurance all those planned and systematic actions necessary to provide confidence that the earth-structure will perform satisfactorily in service i.e. that it has been constructed to the specified requirements SIST EN 16907-5:2019

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...