SIST EN 1036-1:2008

(Main)Glass in building - Mirrors from silver-coated float glass for internal use - Part 1: Definitions, requirements and tests methods

Glass in building - Mirrors from silver-coated float glass for internal use - Part 1: Definitions, requirements and tests methods

This European Standard specifies minimum quality requirements (in respect of optical, visual and edge faults) and durability tests for mirrors from silvered float glass for internal use in building.

This European Standard applies only to mirrors from silvered glass manufactured from flat annealed clear or tinted float glass, 2 mm to 10 mm thickness, and supplied in stock/standard sizes and as-cut finished sizes.

This European Standard does not apply to mirrors from silvered glass manufactured from any basic glass other than float glass, any processed glass, i.e. thermally toughened safety glass, heat strengthened glass, chemically strengthened glass and laminated glass, and any bent glass.

For mirrors from silvered glass used in aggressive and/or constantly high humidity atmospheres, e.g. horse riding halls, swimming pools, medical baths, saunas etc. this European Standard is not applicable. This European Standard is not applicable to reflective glass for external glazing applications.

This European Standard does not apply to framing, fixing or other support systems.

NOTE Useful advice on these items is contained in the informative Annex B.

Glas im Bauwesen - Spiegel aus silberbeschichtetem Floatglas für den Innenbereich - Teil 1: Begriffe, Anforderungen und Prüfverfahren

Diese Europäische Norm legt Mindestqualitätsanforderungen (im Hinblick auf optische und visuelle Fehler

sowie auf Kantenfehler) an Spiegel aus silberbeschichtetem Floatglas für den Innenbereich im Bauwesen

sowie Beständigkeitsprüfungen fest.

Diese Europäische Norm gilt nur für Spiegel aus silberbeschichtetem Glas, die aus planem, spannungsfreiem,

klarem oder gefärbtem Floatglas von 2 mm bis 10 mm Dicke hergestellt sind, und in Lager-/Standardabmessungen

und in Festmaßen geliefert werden.

Diese Europäische Norm gilt nicht für Spiegel aus silberbeschichtetem Glas, die aus einem anderen Basisglas

als Floatglas, aus behandeltem Glas, d. h. aus vorgespanntem Sicherheitsglas, teilvorgespanntem Glas,

chemisch vorgespanntem Glas oder Verbundglas, oder aus gebogenem Glas hergestellt wurden.

Diese Europäische Norm gilt nicht für Spiegel aus silberbeschichtetem Glas, die in einem aggressiven Klima

und/oder in Räumen mit ständig hoher Luftfeuchte, z. B. in Reithallen, Schwimmbädern, Heilbädern, Saunen

usw., verwendet werden. Des Weiteren gilt sie nicht für reflektierendes Glas für Verglasungen im

Außenbereich.

Diese Europäische Norm gilt nicht für Rahmen, Befestigungen oder sonstige Trägersysteme.

ANMERKUNG Nützliche Hinweise zu diesen Positionen sind im informativen Anhang B enthalten.

Verre dans la construction - Miroirs en glace argentée pour l'intérieur - Partie 1: Définitions, exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences minimales de qualité (en rapport avec les défauts

optiques, d’aspect et des bords) et les essais de durabilité des miroirs en glace argentée utilisés à l’intérieur

des bâtiments.

La présente Norme européenne s’applique uniquement aux miroirs en verre argenté fabriqués à partir de

glace recuite plane, claire ou colorée, de 2 mm à 10 mm d’épaisseur, et livrés en dimensions standard et en

dimensions finies brutes de coupe.

La présente Norme européenne ne s’applique pas aux miroirs en verre argenté fabriqués à partir de verre de

base autre que la glace, ni aux verres transformés tels que les verres de sécurité trempés thermiquement, les

verres durcis thermiquement, les verres trempés chimiquement, et les verres feuilletés, ainsi que tous verres

bombés.

La présente Norme européenne n’est pas d’application pour les miroirs en glace argentée utilisés en

atmosphère agressive et/ou en atmosphère à humidité constamment élevée, comme par exemple, les centres

équestre (manèges), piscines, bains médicaux, saunas, etc. La présente Norme européenne n’est pas

applicable aux verres réfléchissants utilisés en vitrerie extérieure.

La présente Norme européenne ne concerne pas les encadrements, la fixation ou tout autre système de

support.

NOTE Des informations utiles sur la pose et la fixation des miroirs sont données dans l’Annexe informative B.

Steklo v gradbeništvu - Ogledala iz stekla s srebrno prevleko za uporabo v notranjosti stavb - 1. del: Definicije, zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 26-Mar-2008

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Jan-2008

- Due Date

- 11-Mar-2008

- Completion Date

- 27-Mar-2008

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

SIST EN 1036:1999 - Glass in building - Mirrors from silver-coated float glass for internal use - Effective Date

- 01-May-2007

Overview - EN 1036-1:2007 (Mirrors from silver-coated float glass)

EN 1036-1:2007 is the CEN European standard that sets definitions, minimum quality requirements and test methods for mirrors manufactured from silver-coated float glass for internal building use. It applies to flat, annealed clear or tinted float glass mirrors (2 mm–10 mm thickness), supplied in stock/standard sizes or as-cut finished sizes. The standard covers optical, visual and edge faults and durability testing for silvered mirrors, but excludes tempered/heat‑strengthened/laminated/bent glass, mirrors intended for aggressive/high-humidity atmospheres (e.g., pools, saunas) and external reflective glazing. Framing and fixing systems are outside its scope (informative guidance in Annex B).

Keywords: EN 1036-1:2007, mirrors, silver-coated float glass, definitions requirements test methods, durability tests, optical quality.

Key topics and technical requirements

- Materials and construction

- Mirrors must be produced from monolithic float glass conforming to EN 572‑2 (flat annealed clear/tinted float glass).

- Reflective silver layer: minimum silver content specified (≥ 0.7 g/m²).

- Protective system: metallic copper or alternative barrier plus one or more protective coatings (paint/lacquer) to protect the silver layer.

- Dimensional requirements

- Thickness measurement method and tolerances (nominal 2–10 mm with specified tolerances).

- Length, width and squareness tolerances for stock/standard and as‑cut finished sizes.

- Optical and visual quality

- Definitions and classification of faults: optical faults (image distortion), glass appearance faults (spots, linear defects, halos), reflective coating faults (stains, colour spots, edge deterioration), protective coating faults, and edge faults.

- Inspection and acceptance levels for spot, linear and cluster defects.

- Durability and test methods

- Durability testing protocols for silvered mirrors (e.g., condensation water test described in Annex A).

- Adhesion testing of protective coatings and references to corrosion/salt‑spray and cross‑cut test standards (EN ISO 9227, EN ISO 2409).

- Terminology

- Clear definitions for terms such as float glass, stock/standard sizes, as‑cut finished sizes, cluster, halo, etc.

Applications and practical value

- Ensures consistent manufacturing quality and repeatable acceptance criteria for interior mirrors used in residential, commercial and public buildings.

- Guides product specification for architects, interior designers, specifiers and building contractors when selecting interior mirrors.

- Provides test methods and acceptance levels for manufacturers, quality control laboratories, and certification bodies to verify optical performance, edge quality and durability.

- Helps suppliers ensure compliance with European market requirements and supports contractual procurement and inspection processes.

Related standards

- EN 1036-2 (evaluation of conformity; product standard)

- EN 572-2 (float glass)

- EN 410 (luminous/solar characteristics)

- EN ISO 2409 (cross-cut test)

- EN ISO 9227 (salt spray/corrosion tests)

Use EN 1036-1:2007 when specifying or testing interior mirrors to ensure defined optical quality, dimensional tolerances and protective system durability for silver‑coated float glass mirrors.

Frequently Asked Questions

SIST EN 1036-1:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Mirrors from silver-coated float glass for internal use - Part 1: Definitions, requirements and tests methods". This standard covers: This European Standard specifies minimum quality requirements (in respect of optical, visual and edge faults) and durability tests for mirrors from silvered float glass for internal use in building. This European Standard applies only to mirrors from silvered glass manufactured from flat annealed clear or tinted float glass, 2 mm to 10 mm thickness, and supplied in stock/standard sizes and as-cut finished sizes. This European Standard does not apply to mirrors from silvered glass manufactured from any basic glass other than float glass, any processed glass, i.e. thermally toughened safety glass, heat strengthened glass, chemically strengthened glass and laminated glass, and any bent glass. For mirrors from silvered glass used in aggressive and/or constantly high humidity atmospheres, e.g. horse riding halls, swimming pools, medical baths, saunas etc. this European Standard is not applicable. This European Standard is not applicable to reflective glass for external glazing applications. This European Standard does not apply to framing, fixing or other support systems. NOTE Useful advice on these items is contained in the informative Annex B.

This European Standard specifies minimum quality requirements (in respect of optical, visual and edge faults) and durability tests for mirrors from silvered float glass for internal use in building. This European Standard applies only to mirrors from silvered glass manufactured from flat annealed clear or tinted float glass, 2 mm to 10 mm thickness, and supplied in stock/standard sizes and as-cut finished sizes. This European Standard does not apply to mirrors from silvered glass manufactured from any basic glass other than float glass, any processed glass, i.e. thermally toughened safety glass, heat strengthened glass, chemically strengthened glass and laminated glass, and any bent glass. For mirrors from silvered glass used in aggressive and/or constantly high humidity atmospheres, e.g. horse riding halls, swimming pools, medical baths, saunas etc. this European Standard is not applicable. This European Standard is not applicable to reflective glass for external glazing applications. This European Standard does not apply to framing, fixing or other support systems. NOTE Useful advice on these items is contained in the informative Annex B.

SIST EN 1036-1:2008 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1036-1:2008 has the following relationships with other standards: It is inter standard links to SIST EN 1036:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1036-1:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1036-1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

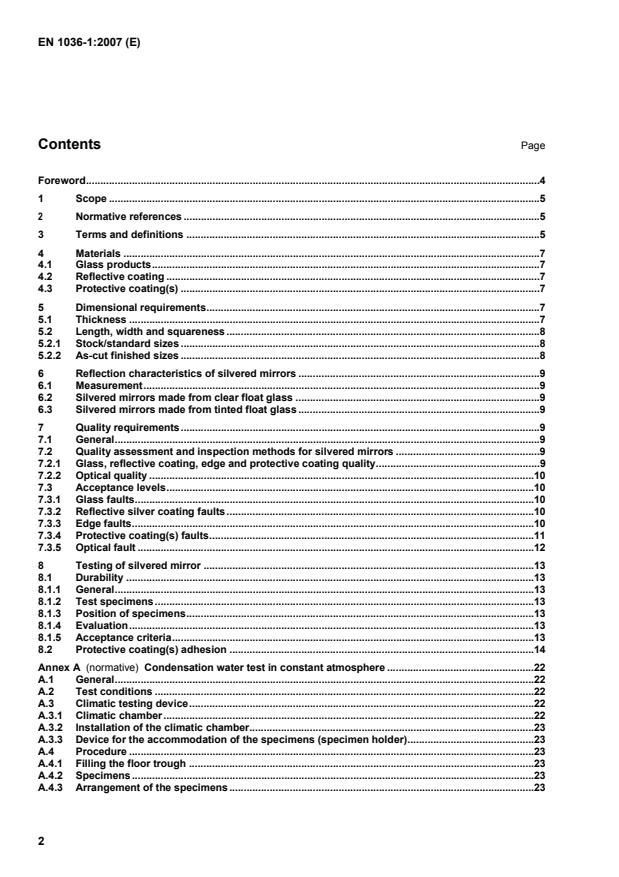

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Glass in building - Mirrors from silver-coated float glass for internal use - Part 1: Definitions, requirements and tests methodsSteklo v gradbeništvu - Ogledala iz stekla s srebrno prevleko za uporabo v notranjosti stavb - 1. del: Definicije, zahteve in preskusne metodeVerre dans la construction - Miroirs en glace argentée pour l'intérieur - Partie 1: Définitions, exigences et méthodes d'essaiGlas im Bauwesen - Spiegel aus silberbeschichtetem Floatglas für den Innenbereich - Teil 1: Begriffe, Anforderungen und PrüfverfahrenTa slovenski standard je istoveten z:EN 1036-1:2007SIST EN 1036-1:2008en,fr,de81.040.20ICS:SIST EN 1036:19991DGRPHãþDSLOVENSKI

STANDARDSIST EN 1036-1:200801-maj-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1036-1December 2007ICS 81.040.20Supersedes EN 1036:1999

English VersionGlass in building - Mirrors from silver-coated float glass forinternal use - Part 1: Definitions, requirements and test methodsVerre dans la construction - Miroirs en glace argentée pourl'intérieur - Partie 1: Définitions, exigences et méthodesd'essaiGlas im Bauwesen - Spiegel aus silberbeschichtetemFloatglas für den Innenbereich - Teil 1: Begriffe,Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 12 November 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1036-1:2007: E

(normative)

Condensation water test in constant atmosphere.22 A.1 General.22 A.2 Test conditions.22 A.3 Climatic testing device.22 A.3.1 Climatic chamber.22 A.3.2 Installation of the climatic chamber.23 A.3.3 Device for the accommodation of the specimens (specimen holder).23 A.4 Procedure.23 A.4.1 Filling the floor trough.23 A.4.2 Specimens.23 A.4.3 Arrangement of the specimens.23

Fixing and cleaning of mirrors.26 B.1 General.26 B.2 Factors affecting durability.26 B.3 Factors affecting image distortion.27 Bibliography.28

Useful advice on these items is contained in the informative Annex B. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 410, Glass in building — Determination of luminous and solar characteristics of glazing EN 572-2, Glass in building — Basic soda lime silicate glass products — Part 2: Float glass EN ISO 2409, Paints and varnishes - Cross-cut test (ISO 2409:2007) EN ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2006) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 float glass flat, transparent, clear or tinted soda-lime silicate glass having parallel and polished faces obtained by continuous casting and flotation on a metal bath (see EN 572-1 and EN 572-2) 3.2 mirror from silver-coated float glass flat annealed clear or tinted float glass whose rear surface has been coated with a protected reflective silver deposit 3.3 copper-free mirror from silver-coated float glass flat annealed clear or tinted float glass whose rear surface has been coated with a protected reflective silver deposit without use of copper

0,7 g/m² of silver. 4.3 Protective coating(s) The reflective coating described in 4.2 shall be protected by a layer of metallic copper or another material and one or more protective coatings e.g. paint, lacquer. 5 Dimensional requirements 5.1 Thickness The actual thickness shall be the average of four measurements, taken to the nearest 0,01 mm, one taken at the centre of each side. Measurement shall be by means of an instrument of the calliper micrometer type. The actual thickness, rounded to the nearest 0,1 mm shall not vary from the nominal thickness by more than the tolerances shown in Table 1.

5.2 Length, width and squareness 5.2.1 Stock/standard sizes Length, H, and width, B, are defined with reference to the direction of draw of the float glass ribbon as shown in Figure 1. The nominal dimensions for length, H, and width, B, being given, the pane shall not be larger than a prescribed rectangle resulting from the nominal dimensions increased by the tolerance, nor smaller than a rectangle defined by their nominal dimensions reduced by the tolerance. The sides of the prescribed rectangles shall be parallel to one another and these rectangles shall have a common centre. For stock/standard sizes the tolerances on nominal dimensions length, H, and width, B, are ± 5 mm. The limits of squareness shall also be described by these rectangles (see Figure 2). 5.2.2 As-cut finished sizes For dimensions less than or equal to 2 000 mm, the standard tolerance range is 2 mm, to be stated as ± 1 mm of the nominal dimension. For dimensions greater than 2 000 mm, the standard tolerance range is 3 mm to be stated as ± 1,5 mm of the nominal value. The standard tolerance range to be applied shall be determined by the largest dimension of the pane. The squareness tolerance shall be expressed as the difference in length between the diagonal dimensions of the pane. For plates with both dimensions less than or equal to 2 000 mm the difference shall not exceed 3 mm. For plates with one (or both) dimensions greater than 2 000 mm the difference shall not exceed 4 mm. NOTE The method of determining squareness tolerance is different from that applied to standard or stock sizes or in standards for other types of glass products.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...