SIST EN 1013:2013+A1:2015

(Main)Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction.

It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und Prüfverfahren

Diese Europäische Norm legt die Anforderungen an lichtdurchlässige, einschalige, profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Wänden, Dächern und Decken fest. Sie ist anwendbar auf einschalige Platten, die als eine Lage oder zum Herstellen eines mehrlagigen Aufbaus verwendet werden.

Die Norm legt auch die Prüfverfahren fest und dient der Konformitätsbewertung und Kennzeichnung der Platten.

Plaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences relatives aux plaques d'éclairement profilées, simple paroi, en matière plastique pour toitures, bardages et plafonds, intérieurs et extérieurs. Elle est applicable aux plaques simple paroi qui sont mise en oeuvre sous forme d'une couche unique ou assemblées pour former une construction à plusieurs couches.

Elle spécifie également les méthodes d'essai ainsi que l'évaluation de la conformité et le marquage des plaques.

Prosojne enoslojne profilirane polimerne plošče za notranje in zunanje strehe, stene in stropove - Zahteve in preskusne metode

Ta evropski standard določa zahteve za prosojne enoslojne profilirane polimerne plošče za notranje in zunanje strehe, stene in strope. Velja za enoslojne plošče, ki se uporabljajo kot posamezen sloj ali so zložene skupaj in tvorijo večslojno tvorbo.

Določa tudi preskusne metode ter podaja vrednotenje skladnosti in označevanje plošč.

General Information

- Status

- Published

- Publication Date

- 01-Feb-2015

- Technical Committee

- IKER - Ceramics

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 07-Jan-2015

- Due Date

- 14-Mar-2015

- Completion Date

- 02-Feb-2015

Relations

- Effective Date

- 01-Mar-2015

- Effective Date

- 01-Mar-2015

Overview

EN 1013:2012+A1:2014 is a European standard from CEN that defines requirements and test methods for light transmitting single skin profiled plastics sheets used in internal and external roofs, walls and ceilings. It applies to single‑skin sheets used alone or assembled into multi‑layer constructions and covers product characteristics, testing, conformity assessment (AVCP) and marking - supporting the EU Construction Products Regulation where applicable.

Key topics and technical requirements

The standard addresses a comprehensive set of product characteristics and associated test methods, including:

- Visual appearance - surface quality, bubbles, inclusions, edge finish and optional diffusion classification (diffusing / non‑diffusing).

- Dimensional tolerances and mass per m² - profile and sheet geometry controls.

- Light transmission and yellowness / colour stability - optical performance and ageing indicators.

- Mechanical properties - flexural and tensile strength, impact resistance, resistance to deflection and resistance to fixings.

- Durability and ageing - thermal ageing, UV exposure (xenon / fluorescent lamps) and profile retention (thermoplastics).

- Hygro‑thermal properties - water vapour and air permeability, and linear thermal expansion.

- Fire performance - reaction to fire and external fire performance classifications (references to EN 13501 series).

- Glass‑fibre reinforced sheet checks - glass content, Barcol hardness, coating presence and adhesion.

- Factory production control (FPC) and AVCP - initial type testing, ongoing FPC, marking and conformity documentation.

- Test methods referenced - EN/ISO methods such as EN ISO 178 (flexural), EN ISO 4892 (artificial weathering), EN ISO 13468 (light transmittance) and others.

Applications and who uses this standard

EN 1013 is relevant to stakeholders involved in design, manufacture, specification, testing and regulatory compliance of translucent roofing and cladding systems:

- Manufacturers of polycarbonate (PC), PMMA, GRP, PVC-U and other profiled light‑transmitting sheets

- Specifiers, architects and façade/roofing system designers selecting rooflights and daylighting solutions

- Roofing and cladding contractors installing single‑skin profiled sheets or multi‑layer assemblies

- Test laboratories and certification bodies performing AVCP, type testing and fire classification

- Authorities and procurement teams requiring compliance with EU Construction Products Regulation

Related standards

EN 1013 references and works alongside other standards, for example:

- EN 13501‑1 / EN 13501‑5 (fire classification)

- EN ISO 4892‑2 / EN ISO 4892‑3 (artificial weathering)

- EN ISO 178, EN ISO 527 (mechanical tests)

- ETAG 010 (translucent roof kits)

For manufacturers and specifiers, EN 1013:2012+A1:2014 is the authoritative reference for ensuring optical performance, mechanical durability and regulatory conformity of light‑transmitting single skin profiled plastic sheets.

Frequently Asked Questions

SIST EN 1013:2013+A1:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods". This standard covers: This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction. It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

This European Standard specifies the requirements for light transmitting single skin profiled plastics sheets for internal and external walls, roofs and ceilings. It is applicable to single skin sheets which are used as a single layer or when assembled to form a multiple layer construction. It also specifies the test methods and provides for the evaluation of conformity and marking of the sheets.

SIST EN 1013:2013+A1:2015 is classified under the following ICS (International Classification for Standards) categories: 83.140.10 - Films and sheets; 91.060.10 - Walls. Partitions. Facades; 91.060.20 - Roofs; 91.060.30 - Ceilings. Floors. Stairs. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1013:2013+A1:2015 has the following relationships with other standards: It is inter standard links to SIST EN 1013:2013, SIST EN 1013:2013/kFprA1:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1013:2013+A1:2015 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/121, M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1013:2013+A1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

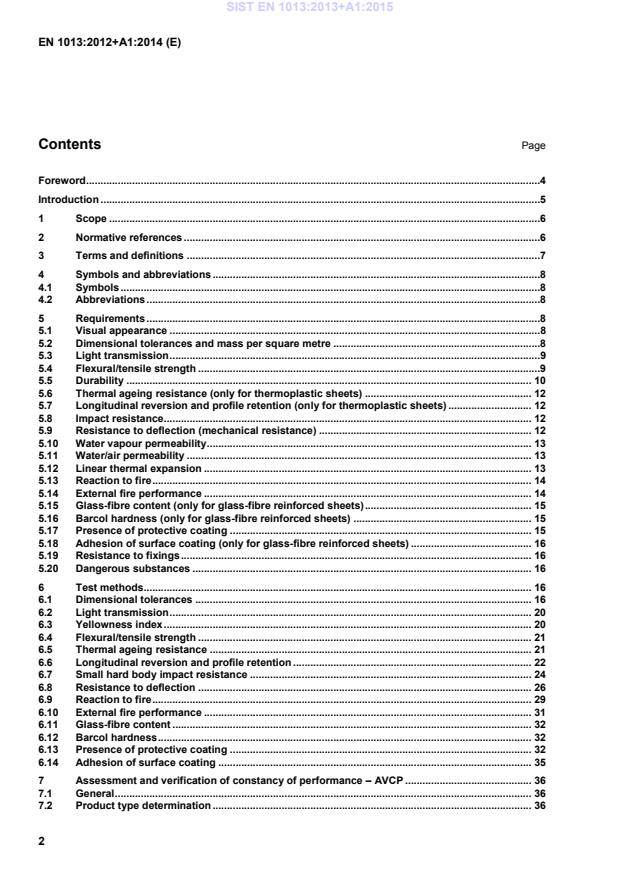

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und PrüfverfahrenPlaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essaiLight transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods91.060.20StreheRoofs91.060.30Stropi. Tla. StopniceCeilings. Floors. Stairs83.140.10Filmi in folijeFilms and sheets91.060.10Stene. Predelne stene. FasadeWalls. Partitions. FacadesICS:Ta slovenski standard je istoveten z:EN 1013:2012+A1:2014SIST EN 1013:2013+A1:2015en,fr,de01-marec-2015SIST EN 1013:2013+A1:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1013:2012+A1

December 2014 ICS 83.140.10; 91.060.01 Supersedes EN 1013:2012English Version

Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings - Requirements and test methods

Plaques d'éclairement profilées, simple paroi, en matière plastique, pour toitures, bardages et plafonds intérieurs et extérieurs - Exigences et méthodes d'essai

Lichtdurchlässige, einschalige profilierte Platten aus Kunststoff für Innen- und Außenanwendungen an Dächern, Wänden und Decken - Anforderungen und Prüfverfahren This European Standard was approved by CEN on 20 October 2012 and includes Amendment 1 approved by CEN on 22 August 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1013:2012+A1:2014 ESIST EN 1013:2013+A1:2015

Profile terminology . 42 Annex B (normative)

Glass content by density of laminate . 45 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation . 47 Bibliography . 58

EN 508-3 [5] and EN 494 [6]. They do not necessarily have the same span capabilities and alternative fixing specifications are generally required. Reference should be made to national regulations and the manufacturer's literature for requirements concerning design, storage and installation, including all safety aspects, according to the material. SIST EN 1013:2013+A1:2015

4 Symbols and abbreviations 4.1 Symbols An class for the exposure to artificial accelerated weathering using xenon-arc lamps Bn class for the exposure to artificial accelerated weathering using fluorescent UV lamps H radiant exposure YI yellowness index of a test specimen exposed to ageing YI0 yellowness index of a test specimen unexposed to ageing ûYI change of the yellowness index after ageing 4.2 Abbreviations FPC factory production control GRA glass-fibre reinforced acrylic (PMMA) GRP glass-fibre reinforced polyester ITT initial type testing PC polycarbonate PET poly(ethylene terephthalate) PMMA poly(methyl methacrylate) PVC-U unplasticised poly(vinyl chloride) PVF poly(vinyl fluoride) 5 Requirements 5.1 Visual appearance Both sides of the sheets shall be of regular appearance. Visual or tactile examination shall reveal no evidence of any hole, cracking or splitting, and no cluster of bubbles greater than 1 mm in diameter, or inclusions that are likely to affect properties. For GRP sheets, any defects such as resin ribs, glass folds or glass knots shall not exceed 5 mm in diameter. The edges of the sheet shall be straight and clean. Further requirements concerning the visual aspects of the sheets can be agreed upon between the manufacturer and the customer. Where required, the sheet shall be declared as “diffusing” or “non-diffusing” depending on whether the image of an object placed 1 m behind the sheet appears blurred or sharp, respectively. 5.2 Dimensional tolerances and mass per square metre The dimensional tolerances and mass per square metre shall be assessed when subject to regulatory requirement. When measured in accordance with the test methods as specified in 6.1.1 to 6.1.3 and Table 1, the dimensional tolerances and mass per square metre of the sheets shall conform to the requirements given in Table 1. SIST EN 1013:2013+A1:2015

is the total luminous transmittance, in percentage, of an unaged sample; û2t1

is the total luminous transmittance, in percentage, of an aged sample. The performance at class A3 or B3, as applicable, may be declared but the performance at higher classes of exposure shall only be declared provided that the variation of the total luminous transmission is not greater than 20 % at any higher class(es) declared. 5.5.5 Variation of the flexural/tensile strength after ageing The variation of the flexural/tensile strength after ageing shall be assessed when subject to regulatory requirement. The variation of properties after ageing shall be determined by assessing the variations of either the flexural strength and flexural modulus by a bending test, or the tensile strength and Young's modulus by a tensile test, both according to 6.4. SIST EN 1013:2013+A1:2015

is the nominal thickness of the sheet, in metres. The deflection of a sheet of any given profile can be assumed to be approximately proportional to the material stiffness factor. 5.10 Water vapour permeability The water vapour permeability coefficient shall be assessed when subject to regulatory requirement. The value of the water vapour permeability coefficient of the sheet material according to Table 4 shall be declared when a higher performance is sought for declaration, the water vapour permeability coefficient of the material used for the sheet shall be determined according to EN ISO 12572. Table 4 — Typical values for water vapour permeability coefficient Material Reference value mg/(m·h·Pa) GRA GRP PC PVC-U PMMA 3,8 x 10-5 1,5 x 10-5 3,8 x 10-5 0,8 x 10-5 3,8 x 10-5 5.11 Water/air permeability The water/air permeability shall be assessed when subject to regulatory requirement. All plastics sheets covered by this standard shall be deemed to satisfy the water/air permeability requirement without the need for testing provided that there are no defects in the sheets. The absence of defects shall be evaluated by examination of visual appearance according to 5.1. 5.12 Linear thermal expansion The linear thermal expansion in the longitudinal direction shall be assessed when subject to regulatory requirement. The value of the coefficient of linear thermal expansion in the longitudinal direction of the sheet material according to Table 5 shall be declared. When a higher performance is sought for declaration or to use another SIST EN 1013:2013+A1:2015

5.17.3 UV protection on PVC-U sheets Where a UV protection layer is provided, the thickness of that layer shall be declared. When tested in accordance with 6.13.3.2, the thickness of the UV protection layer shall not be less that the declared value. Where UV protection is throughout the thickness of the sheet, the content of the UV protective material shall be declared. When tested in accordance with 6.13.3.3, the content of the UV protective material shall not be less that the declared value. 5.17.4 Durability of coating The tests given in 5.17.2 and 5.17.3 confirm the presence of surface coatings only. The durability of such coatings shall be demonstrated by testing the variations after artificial ageing of the yellowness index and total luminous transmittance (see 5.5.3 and 5.5.4). 5.18 Adhesion of surface coating (only for glass-fibre reinforced sheets) When tested in accordance with 6.14, the adhesion of surface coating shall be considered satisfactory when the coating cannot be pried up (raised up) or peeled on a length more than 3 mm. 5.19 Resistance to fixings The principles of fixing of the sheets shall be declared. The method(s) of installation shall consider resistance to wind loads, snow loads and resistance to large soft body impact which may be assessed separately, e.g. in accordance with the requirements given in EN 14963, EN 1873, ETAG 010, or individual safety national requirements. 5.20 Dangerous substances !National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when construction products covered by this standard are placed on those markets. In the absence of European harmonized test methods, verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction website on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/" 6 Test methods 6.1 Dimensional tolerances 6.1.1 General The measurements shall be carried out either at an ambient temperature of (20 ± 5) °C or, when this is not possible, a correction factor according to 5.12 shall be applied from the test temperature to 20 °C. SIST EN 1013:2013+A1:2015

is the mass, in grams, of the sample; Wext

is the extended width, in metres, of the sample; L is the length, in metres, of the sample. Where a value of the mass per linear metre of profiled sheet, ML, is to be declared, this shall be calculated as follows: LMML= (4) where M

is the mass, in grams, of the sample; L is the length, in metres, of the sample. Where a value of the mass per square metre of profiled sheet, Mp, is to be declared, this shall be calculated as follows: pMMowL=⋅ (5) where M

is the mass, in grams, of the sample; ow is the overall width, in metres, of the sample; L is the length, in metres, of the sample. 6.1.6 Cover width of a sheet The covered width of a sheet shall be determined as follows: — position the upper template over the outer corrugation only, and use this to define the centre of the crown of the corrugation; mark this on the test piece; — repeat this operation at the other side of the sheet; — measure the distance between the centre of the crown of the outer two corrugations. The results shall be expressed as follows: the three values obtained at the middle and at both ends, expressed in mm, to the nearest millimetre. SIST EN 1013:2013+A1:2015

6.1.7 Shape of the sheet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...