SIST EN 13482:2014

(Main)Rubber hoses and hose assemblies for asphalt and bitumen - Specification

Rubber hoses and hose assemblies for asphalt and bitumen - Specification

This European Standard specifies requirements for two types of hose and hose assembly (Type 1 and Type 2) identified by their maximum working pressures (Type 1 7 bar and Type 2 15 bar) and main use, i.e. Type 1 is for road and rail tanker use and Type 2 is for dockside use. The types are further divided into two classes related to the maximum temperature of the product to be conveyed (Class A up to 175 °C and Class B up to 200 °C). The hose constructions may be smooth bore (SB) or rough bore (RB).

NOTE These types of hose or hose assemblies are not necessarily suitable for all types of petroleum based products or coal tar, or products containing coal tar.

Gummischläuche und -schlauchleitungen für Asphalt und Bitumen - Spezifikation

Diese Europäische Norm legt Anforderungen für zwei Typen von Schläuchen und Schlauchleitungen fest (Typ 1 und Typ 2), die nach maximalem Betriebsdruck (Typ 1 7 bar und Typ 2 15 bar) und Hauptanwendung unterschieden werden, d. h. Typ 1 für Tankfahrzeuge auf Straße und Schiene sowie Typ 2 für die Verwendung an Kaianlagen. Die Typen werden weiter unterteilt in zwei Klassen, bezogen auf die maximale Temperatur des zu fördernden Produktes (Klasse A bis 175 °C und Klasse B bis 200 °C). Die Schläuche können im Aufbau eine glatte oder rauere Innenschicht aufweisen.

ANMERKUNG Diese Schlauchtypen sind nicht unbedingt einsetzbar für alle Produkttypen auf der Basis von Erdöl oder Kohlenteer oder für Produkte, die Kohlenteer enthalten.

Tuyaux et flexibles en caoutchouc pour asphalte et bitume - Spécification

La présente Norme européenne spécifie les exigences relatives à deux types de tuyaux et assemblages flexibles (Type 1 et Type 2) identifiés par leur pression maximale de service (Type 1 7 bar et Type 2 15 bar) et leur usage principal, c’est-à-dire que le Type 1 est destiné aux citernes routières et ferroviaires et le Type 2 aux utilisations portuaires. Les Types sont ensuite divisés en deux classes selon la température maximale du produit à acheminer (Classe A jusqu’à 175 °C et Classe B jusqu’à 200 °C). Ces tuyaux peuvent être à spirale intérieure noyée (SB) ou saillante (RB).

NOTE Ces types de tuyaux ou d’assemblages flexibles ne conviennent pas nécessairement à tous les produits à base de pétrole, au goudron de houille ou aux produits contenant du goudron de houille.

Gumene cevi in cevni priključki za asfalt in bitumen - Specifikacija

Ta evropski standard določa zahteve za dve vrsti cevi in cevnih priključkov, ki ju določa najvišji delovni tlak in glavna uporaba: tip 1 za uporabo pri cestnih in železniških cisternah, tip 2 pa za uporabo v pristaniščih. Tipa sta nadalje razdeljena v dva razreda glede na najvišjo temperaturo izdelka za transport. Cevni sestavi so lahko gladki ali grobi.

General Information

- Status

- Published

- Public Enquiry End Date

- 24-May-2012

- Publication Date

- 02-Apr-2014

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 20-Mar-2014

- Due Date

- 25-May-2014

- Completion Date

- 03-Apr-2014

Relations

- Replaces

SIST EN 13482:2002 - Rubber hoses and hose assemblies for asphalt and bitumen - Specification - Effective Date

- 01-May-2014

Overview

EN 13482:2013 is a CEN European standard that specifies requirements for rubber hoses and hose assemblies for conveying asphalt and bitumen. It defines two hose types by maximum working pressure and intended use:

- Type 1 - road and rail tanker use, 7 bar maximum working pressure

- Type 2 - dockside use, 15 bar maximum working pressure

Each type is split into temperature classes: Class A (up to 175 °C) and Class B (up to 200 °C). Hose constructions may be smooth bore (SB) or rough bore (RB). The standard replaces EN 13482:2001 and is intended for manufacturers, purchasers and safety/specification professionals working with hot bituminous materials.

Key Topics

- Classification and application: Type (1/2), Class (A/B), SB or RB construction.

- Construction requirements:

- Smooth bore: synthetic rubber lining (min. 2.0 mm), reinforcing plies, steel wire helix, ozone‑resistant rubber cover (min. 2.0 mm).

- Rough bore: internal steel wire helix, rubber/textile lining matrix, reinforcing plies, ozone‑resistant cover.

- End fittings: permitted as built‑in, swaged‑on (internal/external) or clamped‑on (clamped fittings not recommended for dockside hoses). Helix must be electrically connected to fittings to meet electrical continuity requirements.

- Mechanical & dimensional limits:

- Designated nominal bores (50–203 mm range in Table 1) with specified tolerances and minimum bend radii.

- Concentricity limits and finished length tolerances (+2% / -1%).

- Performance and test requirements:

- Proof pressure: Type 1 = 10.5 bar, Type 2 = 22.5 bar.

- Burst pressure (minimum): Type 1 = 40 bar, Type 2 = 90 bar.

- Change in length at proof pressure: temporary ≤ 7.5%, permanent ≤ 1.5%.

- Resistance to vacuum, electrical resistance (≤ 10^2 Ω per assembly), bend and burst tests.

- Rubber compound properties: tensile ≥ 7 MPa, elongation ≥ 200%, bitumen resistance (volume swell ≤ 50%), hardness and abrasion criteria.

- Marking: mandatory marking on hose cover (manufacturer, EN number, type/class, ID, working pressure, max temp, manufacture date, and service: “ASPHALT AND BITUMEN”).

Applications

- Loading/unloading and transfer of hot asphalt/bitumen from tankers, rail wagons and dockside facilities.

- Procurement and specification of hoses for bitumen plants, paving contractors, terminals and transport operators.

- Test laboratories and manufacturers for type testing, routine production tests and quality control.

Who should use this standard

- Hose manufacturers and assemblers

- Terminal/dock operators and transport companies (road/rail)

- Procurement engineers and safety officers specifying hose assemblies for hot bituminous materials

- Test houses performing compliance and type tests

Related standards

EN 13482 references and aligns with several ISO/CEN test standards, including:

- EN ISO 4671, EN ISO 7233, EN ISO 7326, EN ISO 8031, EN ISO 8330, EN ISO 10619‑1, ISO 37, ISO 4649 and EN 14023 (bitumen specification).

EN 13482:2013 provides the specification framework to ensure safe, tested hose assemblies for high‑temperature asphalt and bitumen transfer.

Frequently Asked Questions

SIST EN 13482:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Rubber hoses and hose assemblies for asphalt and bitumen - Specification". This standard covers: This European Standard specifies requirements for two types of hose and hose assembly (Type 1 and Type 2) identified by their maximum working pressures (Type 1 7 bar and Type 2 15 bar) and main use, i.e. Type 1 is for road and rail tanker use and Type 2 is for dockside use. The types are further divided into two classes related to the maximum temperature of the product to be conveyed (Class A up to 175 °C and Class B up to 200 °C). The hose constructions may be smooth bore (SB) or rough bore (RB). NOTE These types of hose or hose assemblies are not necessarily suitable for all types of petroleum based products or coal tar, or products containing coal tar.

This European Standard specifies requirements for two types of hose and hose assembly (Type 1 and Type 2) identified by their maximum working pressures (Type 1 7 bar and Type 2 15 bar) and main use, i.e. Type 1 is for road and rail tanker use and Type 2 is for dockside use. The types are further divided into two classes related to the maximum temperature of the product to be conveyed (Class A up to 175 °C and Class B up to 200 °C). The hose constructions may be smooth bore (SB) or rough bore (RB). NOTE These types of hose or hose assemblies are not necessarily suitable for all types of petroleum based products or coal tar, or products containing coal tar.

SIST EN 13482:2014 is classified under the following ICS (International Classification for Standards) categories: 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13482:2014 has the following relationships with other standards: It is inter standard links to SIST EN 13482:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13482:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.LMDGummischläuche und -schlauchleitungen für Asphalt und Bitumen - SpezifikationTuyaux et flexibles en caoutchouc pour asphalte et bitume - SpécificationRubber hoses and hose assemblies for asphalt and bitumen - Specification83.140.40Gumene ceviHosesICS:Ta slovenski standard je istoveten z:EN 13482:2013SIST EN 13482:2014en,fr,de01-maj-2014SIST EN 13482:2014SLOVENSKI

STANDARDSIST EN 13482:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13482

October 2013 ICS 23.040.70 Supersedes EN 13482:2001English Version

Rubber hoses and hose assemblies for asphalt and bitumen - Specification

Tuyaux et flexibles en caoutchouc pour asphalte et bitume -Spécification

Gummischläuche und -schlauchleitungen für Asphalt und Bitumen - Spezifikation This European Standard was approved by CEN on 7 September 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13482:2013: ESIST EN 13482:2014

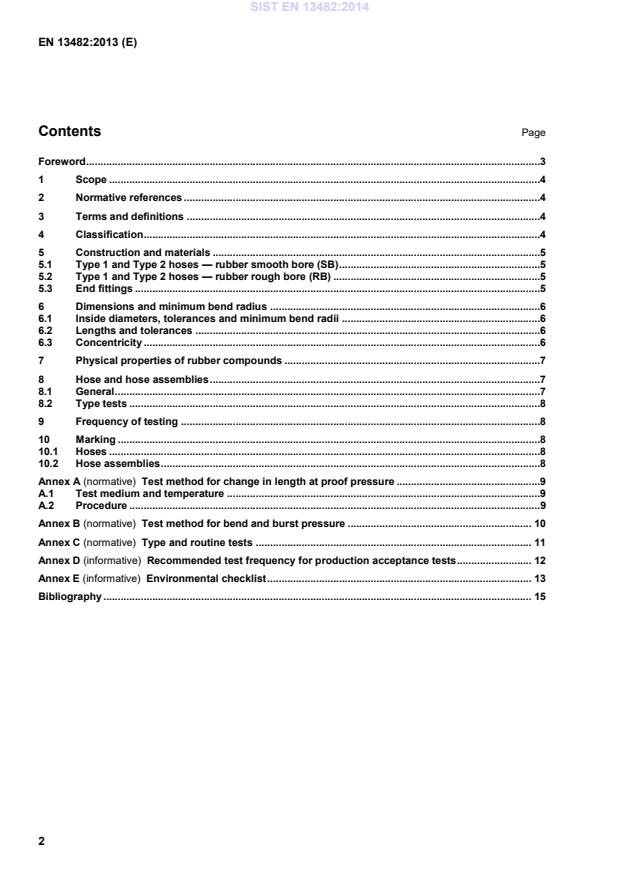

Test method for change in length at proof pressure .9 A.1 Test medium and temperature .9 A.2 Procedure .9 Annex B (normative)

Test method for bend and burst pressure . 10 Annex C (normative)

Type and routine tests . 11 Annex D (informative)

Recommended test frequency for production acceptance tests . 12 Annex E (informative)

Environmental checklist . 13 Bibliography . 15

1 Scope This European Standard specifies requirements for two types of hose and hose assembly (Type 1 and Type 2) identified by their maximum working pressures (Type

1 7 bar and Type 2 15 bar) and main use, i.e. Type 1 is for road and rail tanker use and Type 2 is for dockside use. The types are further divided into two classes related to the maximum temperature of the product to be conveyed (Class A up to 175 °C and Class B up to 200 °C). The hose constructions may be smooth bore (SB) or rough bore (RB). NOTE These types of hose or hose assemblies are not necessarily suitable for all types of petroleum based products or coal tar, or products containing coal tar. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14023, Bitumen and bituminous binders - Specification framework for polymer modified bitumens EN ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions of hoses and the lengths of hose assemblies (ISO 4671) EN ISO 7233:2008, Rubber and plastics hoses and hose assemblies — Determination of resistance to vacuum (ISO 7233:2006) EN ISO 7326, Rubber and plastics hoses — Assessment of ozone resistance under static conditions (ISO 7326) EN ISO 8031, Rubber and plastics hoses and hose assemblies — Determination of electrical resistance and conductivity (ISO 8031) EN ISO 8330:2008, Rubber and plastics hoses and hose assemblies – Vocabulary (ISO 8330:2007) EN ISO 10619-1, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness — Part 1: Bending tests at ambient temperature (ISO 10619-1) ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties ISO 4649:2010, Rubber, vulcanized or thermoplastic — Determination of abrasion resistance using a rotating cylindrical drum device 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 8330:2008 apply. 4 Classification Hoses and hose assemblies shall be one of the following types: Type 1 maximum working pressure 7 bar for road and rail tanker hose and hose assemblies; Type 2 maximum working pressure 15 bar for dockside hose and hose assemblies. Each type shall be available in SB or RB construction and these additional letters shall be part of the identification. SIST EN 13482:2014

an ozone resistant rubber cover of minimum thickness 2,0 mm. Internally, hoses shall have rubber linings that are smooth and free from delamination and blisters. 5.2 Type 1 and Type 2 hoses — rubber rough bore (RB) These hoses shall have the following construction:

an internal steel wire helix of flat or round cross-section; a synthetic rubber and/or textile lining matrix; reinforcing plies of textile or steel wire; additional helix reinforcement, if specified; and an ozone resistant rubber cover of minimum thickness 2,0 mm. Overlapped joins in the lining matrix above

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...