SIST EN 1500:2013

(Main)Chemical disinfectants and antiseptics - Hygienic handrub - Test method and requirements (phase 2/step 2)

Chemical disinfectants and antiseptics - Hygienic handrub - Test method and requirements (phase 2/step 2)

This European Standard specifies a test method simulating practical conditions for establishing whether a product for hygienic handrub reduces the release of transient microbial flora on hands when rubbed onto the artificially contaminated hands of volunteers.

NOTE 1 Attention is drawn to the fact that tests on human volunteers are the subject of legal provisions in certain European countries/regions.

This European Standard applies to products for hygienic handrub for use in areas and situations where disinfection is medically indicated. Such indications occur in patient care, for example:

- in hospitals, in community medical facilities and in dental institutions,

- in clinics of schools, of kindergartens and of nursing homes;

and may occur in the workplace and in the home. It may also include services such as laundries and kitchens supplying products directly for the patient.

EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations".

NOTE 2 This method corresponds to a phase 2, step 2 test.

Chemische Desinfektionsmittel und Antiseptika - Hygienische Händedesinfektion - Prüfverfahren und Anforderungen (Phase 2/Stufe 2)

Diese Europäische Norm legt ein Prüfverfahren fest, das praktische Bedingungen simuliert um festzustellen, ob ein Produkt für die hygienische Händedesinfektion die Abgabe der auf den Händen befindlichen transienten mikrobiellen Flora verringert, wenn es auf den künstlich kontaminierten Händen von freiwilligen Probanden verrieben wird.

ANMERKUNG 1 Es wird darauf hingewiesen, dass Versuche mit menschlichen Probanden in bestimmten europäischen Ländern/Regionen gesetzlichen Bestimmungen unterliegen.

Diese Europäische Norm gilt für Produkte zur hygienischen Händedesinfektion, die in Bereichen und unter Bedingungen angewendet werden, wo eine Desinfektion aus medizinischen Gründen angezeigt ist. Indikationen dieser Art liegen z. B. bei der Patientenbetreuung in

Krankenhäusern, kommunalen medizinischen Einrichtungen und im Dentalbereich;

medizinischen Einrichtungen in Schulen, Kindergärten und Heimen

vor und können auch am Arbeitsplatz und im häuslichen Bereich gegeben sein. Eingeschlossen sein können auch Einrichtungen wie Wäschereien und Küchen, die der direkten Versorgung von Patienten dienen.

EN 14885 legt im Einzelnen die Beziehungen der verschiedenen Prüfungen untereinander und zu den „Anwendungsempfehlungen“ fest.

ANMERKUNG 2 Das Verfahren entspricht einer Prüfung der Phase 2, Stufe 2.

Antiseptiques et désinfectants chimiques - Traitement hygiénique de mains par frictions - Méthode d'essai et prescriptions (phase 2/étape 2)

La présente Norme européenne décrit une méthode d’essai simulant des conditions pratiques afin d’établir si

un produit pour le traitement hygiénique des mains par frictions réduit la flore microbienne transitoire des

mains lorsqu’il est utilisé en frictions sur les mains artificiellement contaminées de volontaires.

NOTE 1 L’attention du lecteur est attirée sur le fait que les essais sur des sujets humains sont soumis à des

dispositions légales dans certains pays/régions d’Europe.

La présente Norme européenne s’applique aux produits destinés au traitement hygiénique des mains par

frictions utilisés dans les zones et les situations où la désinfection est médicalement préconisée. De telles

indications se rencontrent dans le cadre des soins apportés aux patients, par exemple :

⎯ dans des hôpitaux, dans des centres de soins médicaux et des cabinets dentaires,

⎯ dans des infirmeries d’écoles, de jardins d’enfants et de maisons de retraite ;

et peuvent aussi se rencontrer sur les lieux de travail ou à domicile. Elles peuvent également concerner des

secteurs tels que des blanchisseries et des cuisines qui fournissent des produits directement aux patients.

L’EN 14885 spécifie de manière détaillée la relation des différents essais entre eux et par rapport aux

« recommandations d’usage ».

NOTE 2 La présente méthode correspond à un essai de type phase 2, étape 2.

Kemična razkužila in antiseptiki - Higiensko razkuževanje rok - Preskusna metoda in zahteve (faza 2, stopnja 2)

Ta evropski standard določa preskusno metodo s simuliranjem praktičnih pogojev za ugotovitev, ali izdelek za higiensko drgnjenje rok zmanjša prenos prehodne mikrobiološke flore na roke, ki se uporablja za drgnjenje načrtno onesnaženih rok prostovoljcev. OPOMBA 1: Opozoriti je treba na dejstvo, da so preskusi s človeškimi prostovoljci predmet predpisov v določenih evropskih državah. Ta evropski standard velja za izdelke za higiensko drgnjenje rok za uporabo za področja in primere, ko obstajajo zdravstvene indikacije za dezinfekcijo. Te indikacije se pojavljajo pri negi bolnikov, na primer:

v bolnišnicah, skupnih zdravstvenih in zobozdravstvenih ustanovah;

v klinikah šol, vrtcev in domov za starejše;

in lahko nastanejo na delovnem mestu ali doma. Vključujejo lahko tudi storitvene prostore, kot so pralnice in kuhinje, ki proizvode neposredno dostavljajo bolniku. EN 14885 podrobno določa razmerje med različnimi preskusi in priporočili za uporabo. OPOMBA 2: Ta metoda ustreza preskusu stopnje 2 faze 2.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Aug-2011

- Publication Date

- 05-Jun-2013

- Technical Committee

- KDS - Cosmetics, chemical disinfectants and surface active agents

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-May-2013

- Due Date

- 06-Jul-2013

- Completion Date

- 06-Jun-2013

Relations

- Effective Date

- 01-Jul-2013

Overview

EN 1500:2013 - published by CEN - is the European test standard for hygienic handrub products (phase 2 / step 2). It specifies a laboratory method that simulates practical use to determine whether a handrub product reduces the release of transient microbial flora from artificially contaminated volunteers’ hands. The standard requires comparison with a specified reference handrub (60% v/v propan‑2‑ol) and is intended for products used where disinfection is medically indicated (e.g., hospitals, dental clinics, care homes, schools).

Key topics and requirements

- Test scope: Evaluation of bactericidal activity on volunteers’ hands under simulated practical conditions (phase 2, step 2).

- Test organism: Escherichia coli K12 (non‑pathogenic strain; e.g., NCTC 10538 / NCIMB 10083).

- Reference product: 60% (v/v) propan‑2‑ol; the product under test must be shown to be at least not inferior to this reference in mean reduction of E. coli release.

- Volunteer testing: Precision is achieved by repeated tests on a group of volunteers (the standard defines the required number and conditions).

- Neutralization: Use and validation of a neutralizer (based on Tryptone Soya Broth) to stop residual antimicrobial activity in sampling fluids is mandatory; Annexes provide guidance and verification procedures.

- Culture media and enumeration: Methods specify TSA, TSSA and TSB for preparation, sampling and colony counting; hard water and diluted soft soap preparation and quality control are included.

- Statistical evaluation: Updated statistical methods (including non‑inferiority testing - Annex F) determine significance and acceptability of results.

- Ethical/legal note: Tests on human volunteers may be subject to national legal or ethical regulations.

Applications and who uses it

EN 1500:2013 is used by:

- Manufacturers of hand disinfectants for product development, formulation optimization and performance claims.

- Independent testing laboratories and clinical microbiology labs performing product validation and conformity testing.

- Regulatory bodies and procurement teams assessing product performance for healthcare settings.

- Infection prevention and control professionals requiring evidence-based selection of handrub products. Practical uses include demonstrating efficacy for market entry, supporting labeling/claims, and comparing formulations against the European reference.

Related standards

- EN 14885 - Application of European standards for chemical disinfectants and antiseptics (relationship and use recommendations).

- EN 12353 - Preservation of test organisms used in disinfectant testing. These referenced standards guide test organism handling, method relationships and overall conformity assessment.

Keywords: EN 1500:2013, hygienic handrub, handrub test, chemical disinfectants, antiseptics, E. coli K12, CEN, phase 2/step 2, neutralizer validation, reference propan‑2‑ol, infection prevention.

Frequently Asked Questions

SIST EN 1500:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Chemical disinfectants and antiseptics - Hygienic handrub - Test method and requirements (phase 2/step 2)". This standard covers: This European Standard specifies a test method simulating practical conditions for establishing whether a product for hygienic handrub reduces the release of transient microbial flora on hands when rubbed onto the artificially contaminated hands of volunteers. NOTE 1 Attention is drawn to the fact that tests on human volunteers are the subject of legal provisions in certain European countries/regions. This European Standard applies to products for hygienic handrub for use in areas and situations where disinfection is medically indicated. Such indications occur in patient care, for example: - in hospitals, in community medical facilities and in dental institutions, - in clinics of schools, of kindergartens and of nursing homes; and may occur in the workplace and in the home. It may also include services such as laundries and kitchens supplying products directly for the patient. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE 2 This method corresponds to a phase 2, step 2 test.

This European Standard specifies a test method simulating practical conditions for establishing whether a product for hygienic handrub reduces the release of transient microbial flora on hands when rubbed onto the artificially contaminated hands of volunteers. NOTE 1 Attention is drawn to the fact that tests on human volunteers are the subject of legal provisions in certain European countries/regions. This European Standard applies to products for hygienic handrub for use in areas and situations where disinfection is medically indicated. Such indications occur in patient care, for example: - in hospitals, in community medical facilities and in dental institutions, - in clinics of schools, of kindergartens and of nursing homes; and may occur in the workplace and in the home. It may also include services such as laundries and kitchens supplying products directly for the patient. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendations". NOTE 2 This method corresponds to a phase 2, step 2 test.

SIST EN 1500:2013 is classified under the following ICS (International Classification for Standards) categories: 11.080.20 - Disinfectants and antiseptics; 71.100.35 - Chemicals for industrial and domestic disinfection purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1500:2013 has the following relationships with other standards: It is inter standard links to SIST EN 1500:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1500:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Chemische Desinfektionsmittel und Antiseptika - Hygienische Händedesinfektion - Prüfverfahren und Anforderungen (Phase 2/Stufe 2)Antiseptiques et désinfectants chimiques - Traitement hygiénique de mains par frictions - Méthode d'essai et prescriptions (phase 2/étape 2)Chemical disinfectants and antiseptics - Hygienic handrub - Test method and requirements (phase 2/step 2)71.100.35Kemikalije za dezinfekcijo v industriji in domaChemicals for industrial and domestic disinfection purposes11.080.20Dezinfektanti in antiseptikiDisinfectants and antisepticsICS:Ta slovenski standard je istoveten z:EN 1500:2013SIST EN 1500:2013en,fr,de01-julij-2013SIST EN 1500:2013SLOVENSKI

STANDARDSIST EN 1500:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1500

April 2013 ICS 11.080.20; 71.100.35 Supersedes EN 1500:1997English Version

Chemical disinfectants and antiseptics - Hygienic handrub - Test method and requirements (phase 2/step 2)

Antiseptiques et désinfectants chimiques - Traitement hygiénique de mains par frictions - Méthode d'essai et prescriptions (phase 2/étape 2)

Chemische Desinfektionsmittel und Antiseptika - Hygienische Händedesinfektion - Prüfverfahren und Anforderungen (Phase 2/Stufe 2) This European Standard was approved by CEN on 1 March 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1500:2013: ESIST EN 1500:2013

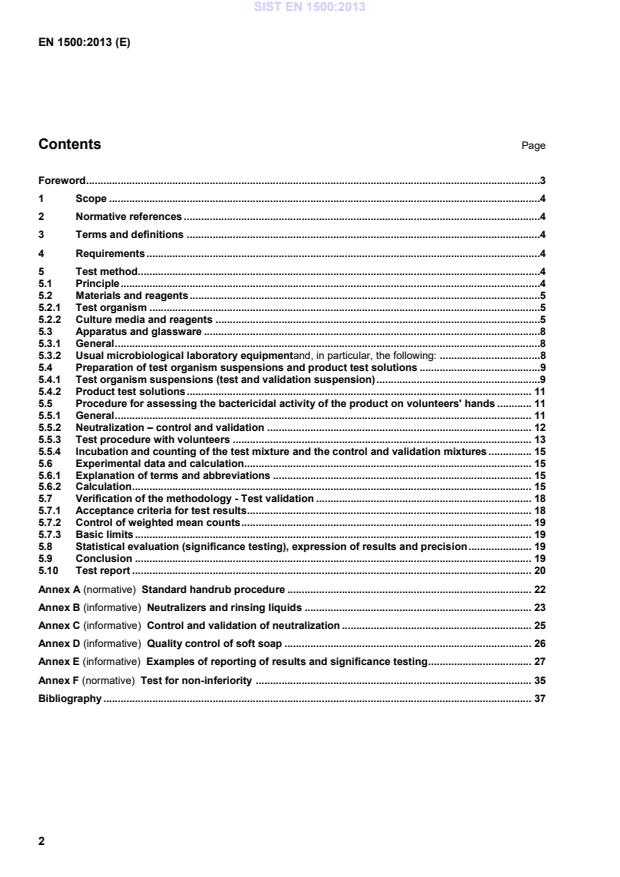

Standard handrub procedure . 22 Annex B (informative)

Neutralizers and rinsing liquids . 23 Annex C (informative)

Control and validation of neutralization . 25 Annex D (informative)

Quality control of soft soap . 26 Annex E (informative)

Examples of reporting of results and significance testing . 27 Annex F (normative)

Test for non-inferiority

................................................................................................ 35 Bibliography ..................................................................................................................................................... 37

The following technical changes have been made:

Neutralization (5.5.1.2).

The number of volunteers (5.5.1.4).

The statistical evaluation (5.8).

The annexes have been completely revised. Data obtained using the former version of EN 1500 may still be used, if it is supplemented by data on neutralization, additional results from more volunteers and the new statistical evaluation of the “mixed” (old and new) set of data. The additional results will be obtained preferably in the same laboratory and with volunteers not having participated in the previous (“old”) study. If the neutralizer used in the test using the former version is not sufficiently neutralizing, a complete new test will be run. The changed procedure in Annex A is regarded as having no (or negligible) influence on the results. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 1500:2013

NOTE 1 Attention is drawn to the fact that tests on human volunteers are the subject of legal provisions in certain European countries/regions. This European Standard applies to products for hygienic handrub for use in areas and situations where disinfection is medically indicated. Such indications occur in patient care, for example: in hospitals, in community medical facilities and in dental institutions, in clinics of schools, of kindergartens and of nursing homes; and may occur in the workplace and in the home. It may also include services such as laundries and kitchens supplying products directly for the patient.

EN 14885 specifies in detail the relationship of the various tests to one another and to “use recommendations”. NOTE 2 This method corresponds to a phase 2, step 2 test. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 12353, Chemical disinfectants and antiseptics — Preservation of test organisms used for the determination of bactericidal (including Legionella), mycobactericidal, sporicidal, fungicidal and virucidal (including bacteriophages) activity

EN 14885, Chemical disinfectants and antiseptics — Application of European Standards for chemical disinfectants and antiseptics 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 14885 apply. 4 Requirements

When tested in accordance with Clause 5, the mean reduction of the release of the test organism Escherichia coli K12 achieved by the hygienic handrub with the product under test shall be at least not inferior to that achieved by a specified reference hygienic handrub (60 % volume concentration of propan-2-ol). 5 Test method

5.1 Principle Hands of volunteers are artificially contaminated with test organisms. The number of test organisms released from their fingertips into sampling fluids is assessed before and after the hygienic handrub. The ratio of the SIST EN 1500:2013

5.2.1 Test organism Escherichia coli

K12

NCTC 10538; CIP 54.117; NCIMB 100831) NOTE This test organism has been specifically chosen to meet health and safety guidance and ethical committee considerations. It is a K12 strain of E. coli of normal flora origin internationally recognised as being non-pathogenic. According to the UK catalogue of the National Collections of Industrial & Marine Bacteria (see [2]), NCIMB strain 10083 is classified as a risk group 1 organism. The German Safety Ordinance on Gene Technology [3] also assigns the K12 strain to group 1.

Directive 93/88/EEC [4] (Annex III to Directive 90/679/EEC [5]) explicitly states that non-pathogenic strains of Escherichia coli are excluded from the group 2 assignment.

5.2.2 Culture media and reagents 5.2.2.1 General All weights of chemical substances given in this European Standard refer to the anhydrous salts. Hydrated forms may be used as an alternative, but the weights required shall be adjusted to allow for consequent molecular weight differences. The reagents shall be of analytical grade and/or appropriate for microbiological purposes. They shall be free from substances that are toxic or inhibitory to the test organisms. To improve reproducibility, it is recommended that commercially available dehydrated material is used for the preparation of culture media. The manufacturer's instructions relating to the preparation of these products should be rigorously followed. For each culture medium and reagent, a time limitation for use should be fixed.

5.2.2.2 Water The water shall be freshly glass-distilled water and not demineralised water. If distilled water of adequate quality is not available, water for injections (see bibliographic reference [1]) may be used. Sterilise in the autoclave [5.3.2.1 a)]. Sterilisation is not necessary if the water is used e.g. for preparation of culture media and subsequently sterilised. NOTE See 5.2.2.7 for the procedure to prepare hard water. 5.2.2.3 Tryptone soya agar and tryptone soya selective agar a) Tryptone Soya Agar (TSA) Tryptone soya agar, consisting of:

1) The NCTC, CIP and NCIMB numbers are the collection numbers of this strain supplied by these cultures collections. This information is given for the convenience of users of this European Standard and does not constitute an endorsement by CEN of the product named.

15,0 g Soya peptone, papaic digest of soybean meal

5,0 g Sodium chloride (NaCl)

5,0 g Agar

15,0 g Water (5.2.2.2) to 1 000,0 ml Sterilise in the autoclave [5.3.2.1 a)]. After sterilisation, the pH of the medium shall be equivalent to 7,2 ± 0,2 when measured at (20 ± 1) °C. NOTE 1 TSA is used for preparing and counting N, Nv and NvB (5.4.1.4, 5.4.1.5). b) Tryptone Soya Selective Agar (TSSA) Tryptone soya selective agar, consisting of: Tryptone, pancreatic digest of casein

15,0 g Soya peptone, papaic digest of soybean meal

5,0 g Sodium chloride (NaCl)

5,0 g Sodium-desoxycholate

0,5 g Agar

15,0 g Water (5.2.2.2) to 1 000,0 ml Sterilise in the autoclave [5.3.2.1 a)]. After sterilisation, the pH of the medium shall be equivalent to 7,2 ± 0,2 when measured at (20 ± 1) °C. NOTE 2 TSSA is used for quantitative cultures of the sampling fluids and their dilutions (5.5.3.2, 5.5.3.3.4).

5.2.2.4 Tryptone Soya Broth (TSB)

Tryptone soya broth, consisting of: Tryptone, pancreatic digest of casein

15,0 g Soya peptone, papaic digest of soybean meal 5,0 g Sodium chloride (NaCl)

5,0 g Water (5.2.2.2)

to 1 000,0 ml

Sterilise in the autoclave [5.3.2.1 a)]. After sterilisation, the pH of the medium shall be equivalent to 7,0 ± 0,2 when measured at (20 ± 1) °C. 5.2.2.5 Neutralizer

The neutralizer shall be chosen, controlled and validated for the product under test in accordance with 5.5.1.2, 5.5.2.1 and 5.5.2.2. Only neutralizers using TSB (5.2.2.4) as diluent are allowed. It shall be sterile. The reference product is neutralized by dilution only. SIST EN 1500:2013

5.2.2.6 Diluted soft soap Linseed oil 50,0 parts by weight Potassium hydroxide [1] 9,5 parts by weight Ethanol (min. 95 %) [1] 7,0 parts by weight Hot distilled water (75 ± 5) °C

as needed

Prepare a solution of 9,5 parts potassium hydroxide in 15 parts water (5.2.2.2) and add 50 parts linseed oil. Heat up to approximately 70 °C while constantly stirring. Add the ethanol and continue heating while stirring until the saponification process is completed and a sample dissolves clearly in water and almost clearly in alcohol. The weight of the soft soap is then brought up to 100 parts by addition of water (5.2.2.2), and heated up to

(75 ± 5) °C to dilute the soft soap. Take 200 g of the soft soap, fill up to 1 000 g with water (5.2.2.2) and sterilise in the autoclave (5.5.2.1). The pH of the final diluted soft soap shall range between 10,0 and 11,0.

For quality control of the soft soap, see Annex D. 5.2.2.7 Hard water for dilution of products For the preparation of 1 l of hard water, the procedure is as follows: prepare solution A: dissolve 19,84 g magnesium chloride (MgCl2) and 46,24 g calcium chloride (CaCl2) in water (5.2.2.2) and dilute to 1 000 ml. Sterilise by membrane filtration (5.3.2.7) or in the autoclave

[5.3.2.1 a)]. Autoclaving – if used - may cause a loss of liquid. In this case make up to 1000 ml with water (5.2.2.2) under aseptic conditions. Store the solution in the refrigerator (5.3.2.8) for no longer than one month; prepare solution B: dissolve 35,02 g sodium bicarbonate (NaHCO3) in water (5.2.2.2) and dilute to 1000 ml. Sterilise by membrane filtration (5.3.2.7). Store the solution in the refrigerator (5.3.2.8) for no longer than one week; place 600 ml to 700 ml of water (5.2.2.2) in a 1 000 ml volumetric flask (5.3.2.12) and add 6,0 ml (5.3.2.9) of solution A, then 8,0 ml of solution B. Mix and dilute to 1000 ml with water (5.2.2.2). The pH of the hard water shall be 7,0 ± 0,2, when measured at 20 °C ± 1 °C (5.3.2.4). If necessary, adjust the pH by using a solution of approximately 40 g/l (about 1 mol/l) of sodium hydroxide (NaOH) or approximately 36,5 g/l (about 1 mol/l) of hydrochloric acid (HCl).

The hard water shall be freshly prepared under aseptic conditions and used within 12 h. NOTE When preparing the product test solutions (5.4.2), the addition of the product to the hard water produces a different final water hardness in each test tube. In any case, the final hardness, expressed as calcium carbonate (CaCO3) in the test tube, is lower than 375 mg/l. 5.2.2.8 Propan-2-ol as reference handrub [52,3 % (weight concentration) corresponding to 60 % (volume concentration) at 20 °C]

Fill 471 g propan-2-ol [1] with a purity of min. 99,5 % V/V (determined by gas chromatography; density 0,785) in a 1000 ml flask equipped with a glass stopper on the weighing platform of a scale (precision 0,1 g). Add

429 g water (5.2.2.2). This will give a volume of approximately 1 000 ml. Close the flask with the matching glass stopper and shake the contents of the flask thoroughly. NOTE This solution can be kept indefinitely at approximately room temperature if protected from light. SIST EN 1500:2013

5.3.1 General Sterilise all glassware and parts of the apparatus that will come into contact with the culture media and reagents or the sample, except those which are supplied sterile, by one of the following methods: a) by moist heat, in the autoclave [5.3.2.1 a)]; b) by dry heat, in the hot air oven [5.3.2.1 b)].

5.3.2 Usual microbiological laboratory equipment2) and, in particular, the following: 5.3.2.1 Apparatus for sterilisation a) for moist heat sterilisation, an autoclave capable of being maintained at (12130+) °C for a minimum

holding time of 15 min;

b) for dry heat sterilisation, a hot air oven capable of being maintained at (18050+) °C for a minimum holding time of 30 min, at (170 50+) °C for a minimum holding time of 1 h or at (16050+) °C for a minimum holding time of 2 h. 5.3.2.2 Water baths, capable of being controlled at 20 °C ± 1 °C and at 45 °C ± 1 °C (to maintain melted TSA and TSSA in case of pour plate technique) 5.3.2.3 Incubator, capable of being controlled either at 36 °C ± 1 °C or 37 °C ± 1 °C (5.2.1). The same temperature shall be used for incubations performed during a test and its control and validation. 5.3.2.4 pH-meter, having an inaccuracy of calibration of no more than ± 0,1 pH units at 20 °C ± 1 °C. A puncture electrode or a flat membrane electrode should be used for measuring the pH of the agar media (5.2.2.3). 5.3.2.5 Stopwatch 5.3.2.6 Shakers a) electromechanical agitator, e.g. Vortex® mixer3); b) mechanical shaker. 5.3.2.7 Membrane filtration apparatus, constructed of a material compatible with the substances to be filtered The apparatus shall have a filter holder of at least 50 ml volume. It shall be suitable for use with filters of diameter 47 mm to 50 mm and 0,45 µm pore size for sterilisation of hard water (5.2.2.7).

The vacuum source used shall give an even filtration flow rate. To prevent overlong filtration, the device shall be set so as to obtain the filtration of 100 ml of rinsing liquid in 20 s to 40 s.

2) Disposable equipment is an acceptable alternative to reusable glassware. 3)

Vortex® in an example of a suitable product available commercially. This information is given for the convenience of users of this European Standard and does not constitute an endorsement by CEN of this product. SIST EN 1500:2013

maximum 1 l TSB (5.2.2.4) each and incubate again (5.3.2.3) for 18 h to 24 h. Pool the resulting bacterial suspensions in a container (5.3.2.14). b) Adjust the number of cells in the suspension to 1,5 x 108 cfu/ml4) to 5,0 x 108 cfu/ml using TSB

(5.2.2.4), estimating the number of cfu by any suitable means. Maintain this test suspension in the water bath at 20 °C and use within 4 h as contamination fluid and to prepare the validation suspensions (5.4.1.5). The use of a spectrophotometer for adjusting the number of cells is highly recommended (about

4) cfu/ml = colony forming unit(s) per millilitre. SIST EN 1500:2013

A colorimeter is a suitable alternative. c) For counting, prepare 10-6 and 10-7 dilutions of the test suspension using TSB (5.2.2.4).

Mix [5.3.2.6 a)]. Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the pour plate or the spread plate technique. 1) When using the pour plate technique, transfer each 1 ml sample into separate Petri dishes and add 15 ml to 20 ml melted TSA [5.2.2.3 a)], cooled to 45 °C ± 1 °C.

2) When using the spread plate technique, spread each 1,0 ml sample – divided into portions of approximately equal size – on an appropriate number (at least two) of surface dried plates containing TSA [5.2.2.3 a)]. For incubation and counting, see 5.4.1.6. 5.4.1.5 Validation suspension (“Nv”,“NvB”) a) To prepare the validation suspension (Nv), dilute the test suspension (5.4.1.4) with TSB (5.2.2.4) to obtain 3,0 x 102 cfu/ml to 1,6 x 10³ cfu/ml [about one-fourth (1+3) of the 10-5 dilution]. b) To prepare the validation suspension (NvB) for the neutralizer control (5.5.2.1), dilute the test suspension (5.4.1.4) with TSB

(5.2.2.4) to obtain 3,0 x 104 cfu/ml to 1,6 x 105 cfu/ml [about one-fourth (1+3) of the 10-3 dilution] (NvB). c) Maintain and use these validation suspensions (Nv and NvB) the same way as the test suspension [5.4.1.4 b)]. d) For counting, prepare a 10-1 dilution with TSB (5.2.2.4), but prepare a 10-3 dilution of the validation suspension to count the neutralizer control [see b)]. Mix [5.3.2.6 a)]. Take a sample of 1,0 ml in duplicate and inoculate using the pour plate or the spread plate technique [5.4.1.4 c)]. For incubation and counting, see 5.4.1.6.

5.4.1.6 Incubation and counting of the test and the validation suspensions

a) Incubate (5.3.2.3) the plates for 20 h to 24 h. Discard any plates that are not countable for

any reason. Count the plates and determine the number of cfu. Incubate the plates for a further 20 h to 24 h. Do not recount plates that no longer show well-separated colonies. Recount the remaining plates. If the number has increased, use only the higher number for further evaluation. b) Note for each plate the exact number of colonies but record > 330 for any counts higher than 330 and determine the VC-values according to 5.6.2.2.

c) Calculate the numbers of cfu/ml in the test suspension “N” and in the validation suspensions “Nv” and “NvB” using the methods given in 5.6.2.3 and 5.6.2.5. Verify according to 5.7. SIST EN 1500:2013

For solid products, dissolve the product as received by weighing at least 1,0 g ± 10 mg of the product in a volumetric flask and filling up with hard water (5.2.2.7). Subsequent dilutions (= lower concentrations) shall be prepared in volumetric flasks (5.3.2.12) on a volume/volume basis in hard water (5.2.2.7).

For liquid products, dilutions of the product shall be prepared with hard water in volumetric flasks (5.3.2.12) on a volume/volume basis. The product test solutions shall be prepared freshly and used in the test within 3 h. They shall give a physically homogenous preparation, stable during the whole procedure. If during the procedure a visible inhomogeneity appears due to the formation of a precipitate or flocculant, it shall be recorded in the test report. NOTE Counting micro-organisms embedded in a precipitate or flocculant is difficult and unreliable. Record the test concentration in terms of mass per volume or volume per volume and details of the product sample as received. 5.5 Procedure for assessing the bactericidal activity of the product on volunteers' hands 5.5.1 General 5.5.1.1 Experimental conditions

a) temperature: The temperature for the control and validation of the neutralizer and the test suspension (contamination fluid) is 20 °C ± 1 °C. b) contact time t (in s): The contact time to be tested is to be chosen according to the manufacturer’s recommendation, but not shorter than 30 s and not longer than 60 s. Contact time is the total rubbing time. For the reference hygienic handrub [propan-2-ol (5.2.2.8)] it is 60 s.

The allowed deviation for each chosen contact time is ± 5 s. NOTE

Due to the standardised rub procedure (Annex A), a contact time shorter than 30 s is not feasible and cannot be verified. c) test organism: The test organism is Escherichia coli K12 (5.2.1). 5.5.1.2 Neutralization The product under test has to be neutralized during the test. A suitable neutralizer (5.2.2.5) has to be found before the test procedure (5.5.3) is performed. For that purpose carry out the validation of the neutralization (5.5.2.1 and 5.5.2.2) in connection with 5.5.4 using a neutralizer, chosen according to laboratory experience and published data. For certain products, TSB (5.2.2.4) may act as a suitable neutralizer. If this neutralizer is not valid, repeat the validation test using an alternative neutralizer taking into account the information given in Annex B. SIST EN 1500:2013

5.5.1.3 Equilibration of temperature Prior to testing, equilibrate all reagents [product test solutions (5.4.2), propan-2-ol (5.2.2.8), diluted soft soap (5.2.2.6), test suspension (5.4.1.4), validation suspension (5.4.1.5), TSB (5.2.2.4), the neutralizer (5.2.2.5) and – if necessary - hard water (5.2.2.7)] to the test temperature of 20 °C using the water bath (5.3.2.2) controlled at 20 °C. Check that the temperature of the reagents is stabilised at 20 °C. 5.5.1.4 Selection of volunteers The test shall be performed on 18 to 22 healthy persons who have hands with healthy skin, without cuts or abrasions, and with short and clean fingernails. Although, in general, age is not a limiting factor, volunteers should be at least 18 years of age. As it may happen that values of volunteers cannot be used for calculation, it is recommended to do the test rather with a higher number than 18 volunteers. On the day of test, the volunteers should not wear any jewellery or other items on the hands and wrists.

5.5.1.5 Experimental design

For testing a single product, a cross-over design is used. The volunteers are randomly divided into two groups of approximately the same size. Group 1 uses the reference hygienic handrub (RP, 5.5.3.3.2), group 2 the product under test (PP, 5.5.3.3.3). The test is then repeated on the same day with group 1 using the handrub procedure with the test product and group 2 using the reference handrub procedure. Before every reference handrub procedure and every handrub procedure with the product under test, the procedures described in 5.5.3.1 and 5.5.3.2 shall be carried out.

For testing more than one product at a time, a Latin square design is used with as many groups of volunteers and as many experimental runs as there are products to be tested (including the reference propan-2-ol). In each run, all handrub procedures are employed in parallel. At the end of the whole series, every subject shall have used each product under test once, including the reference propan-2-ol. For each product under test, the hands have to be cleaned for 1 min between the testing of the different products with tap water and diluted soft soap (5.2.2.6) because residual neutralizer or product on the volunteers’ hands may influence the performance of the subsequently tested product. Finally, the hands shall be thoroughly dried with a clean (paper) towel. After the reference hand rub a rinsing with tap water is enough. NOTE 1 In a Latin square design, only products can be simultaneously tested for which the same neutralizer can be used.

NOTE 2 Due to the sample size (too small for Latin Square design) it may happen that a product is evaluated as not passing the standard (5.9) although it might pass in a cross over design. 5.5.2 Neutralization – control and validation5) 5.5.2.1 Neutralizer control "B" – verification of the absence of toxicity of the neutralizer To verify the absence of toxicity of the neutralizer, the procedure is as follows: a) Pipette 9,0 ml of the neutralizer – used in the test (5.5.3) – into a tube. Add 1,0 ml of the validation suspension (NVB) [5.4.1.5 b)] containing 3,0 x 104 cfu/ml to 1,6 x 105 cfu/ml. Start the stopwatch at the beginning of the addition, mix [5.3.2.6 a)]. Transfer 0,5 ml of this mixture into a tube containing

4,5 ml of neutralizer to obtain 10-1 dilution of NVB; repeat this procedure to obtain 10-2 dilution of NVB.

5) For a graphical representation of this method see Annex C. SIST EN 1500:2013

neutralizer. b) At the end of this time, take a sample of 1,0 ml of this mixture “B” (10-2 dilution of NVB) in duplicate and inoculate TSA plates [5.2.2.3 a)] using the pour plate or the spread plate technique [5.4.1.4 c)].

For incubation and counting, see 5.5.4. 5.5.2.2 Method validation "C"

To validate the neutralization method, the procedure is as follows:

a) Pipette 2,0 ml of TSB (5.2.2.4) into a tube. Starting a stopwatch, add 8,0 ml of the product test solution. Mix [5.3.2.6 a)] and place the tube in a water bath controlled at 20 °C for t. Just before the end of t, mix

[5.3.2.6a)] again. b) At the end of t, transfer 1,0 ml of the mixture into a tube containing 8,0 ml of neutralizer (used in 5.5.3). Restart the stopwatch at the beginning of the addition. Mix [5.3.2.6 a)] and place the tube in a water bath controlled at (20 ± 1) °C for 10 s ± 1 s (neutralization time). Add 1,0 ml of the validation suspension (5.4.1.5). Start a stopwatch at the beginning of the addition and mix [5.3.2.6 a)]. Place the tube in a water bath controlled at (20 ± 1) °C for 30 min ± 1 min. Just before the end of this time, mix [5.3.2.6 a)] again. At the end of this time, take a sample of 1,0 ml of the mixture "C" in duplicate and inoculate TSA plates [5.2.2.3 a)] using the pour plate or the spread plate technique [5.4.1.4 c)]. For incubation and counting, see 5.5.4.

5.5.3 Test procedure with volunteers 5.5.3.1 Application of the contamination fluid

Volunteers’ hands are prepared by washing for 1 min with 5 ml diluted soft soap (5.2.2.6) without use of a brush. After being rinsed with running tap water, they are thoroughly dried with paper towels for at least 30 s. The contamination fluid [5.4.1.4 b)] is poured into a container (5.3.2.14) and both hands are immersed up to the mid-metacarpals for 5 s with fingers spread apart. Carefully allow surplus liquid to drain back into the container for a maximum of 30 s. Allow the hands to dry in the air for 3 min, holding them in a horizontal position with the fingers spread out and rotating them to and fro to avoid the formation of droplets. During this procedure care should be taken to avoid contamination of the surrounding work area. One batch of contamination fluid shall be used no longer than 3 h after the first volunteer's hands have been contaminated. Additionally, it shall be ensured that, in a test, all subjects' hands shall be treated with the same batch of contamination fluid, even if various products are tested against the reference handrub. The container with the contamination fluid should be used for all volunteers. 5.5.3.2 Sampling of the test organisms before treatment (“Prevalue”)

Immediately after drying, rub the fingertips (including that of the thumb) for 1 min on the base of a Petri dish (5.3.2.10) containing 10 ml of TSB (5.2.2.4) as sampling fluid in order to assess the release of test organisms before treatment of the hands (prevalues).

A separate Petri dish is used for each hand. Dilutions of 10-2, 10-3 and 10-4 of these sampling fluids are prepared with the sampling fluid, i.e. TSB (5.2.2.4). From each dilution, 0,1 ml is spread on surface dried plates containing TSSA [5.2.2.3 b)] using spreaders SIST EN 1500:2013

[5.2.2.3 b)], cooled to 45 °C ± 1 °C. See the procedure in 5.4.1.4 c) 1). NOTE 1 The sampling fluid for the prevalues does not contain neutralizer (5.2.2.5) as this may influence the performance of the product under test. The different sampling procedures for pre- and postvalues will not influence the evaluation of the product since the reference handrub is treated the same way. NOTE 2 Sodium-desoxycholate in TSSA is used to inhibit the growth of skin staphylococci. As TSSA may influence the growth in the contamination fluid (5.4.1.4) and the susceptibility of the test organisms against the products, it is not used for the preparation of the prevalue sampling fluid.

For incubation and counting, see 5.5.4. 5.5.3.3 Hygienic handrub procedure 5.5.3.3.1 General

After sampling for the prevalues (5.5.3.2) let the hands dry. Immediately after drying and without recontaminating the hands, perform the handrub in accordance with either 5.5.3.3.2 or 5.5.3.3.3, as applicable (5.5.1.5).

5.5.3.3.2 Reference hygienic handrub procedure (RP)

Pour 3 ml of propan-2-ol (5.2.2.8) into the cupped dry hands and rub vigorously for 30 s onto the skin up to the wrists in accordance with the standard handrub procedure shown in Annex A, to ensure total coverage of the hands. As a first step, distribute the propan-2-ol (5.2.2.8) all over the hands including the wrists palm to palm; continue with five times right palm over left dorsum and left palm over right dorsum, then continue with five strokes backwards and forwards, palm to palm with fingers interlaced; continue with five times rubbing the backs of fingers to opposing palms with fingers interlocked, then five times rotational rubbing of right thumb clasped in left palm and left thumb clasped in right palm; then rub five times rotationally with clasped fingers of the right hand in the wet palm of the left hand and clasped fingers of the left hand in the wet palm of the right hand. Repeat the whole procedure with a further 3 ml propan-2-ol (5.2.2.8), to give a total rubbing time of 60 s. For sampling, see 5.5.3.3.4. 5.5.3.3.3 Hygienic handrub procedure with product under test (PP) This procedure shall be performed according to the recommendation provided by the manufacturer, which shall include volume of product, frequency of application and the contact time [between 30 s and 60 s, 5.5.1.1 b)]. In any case, the steps of the standard handrub procedure as described in Annex A shall be followed.

NOTE Due to the standardised rub procedure (Annex A) a contact time shorter than 30 s is not feasible and cannot be verified. For sampling, see 5.5.3.3.4. 5.5.3.3.4 Sampling of the test organisms after treatment (“Postvalue”)

Immediately after treatment (5.5.3.3.2 and 5.5.3.3.3) a similar sampling procedure is used as described for the prevalues (5.5.3.2), but volumes of 1,0 ml and 0,1 ml of undiluted sampling fluid and 0,1 ml from its 10-1 dilution are plated out for quantitative culture on surface dried plates containing TSSA [5.2.2.3 b)] to obtain 100, 10-1 and 10-2 dilutions. The interval between sampling and plating shall not exceed 30 min. As an alternative technique to the spread plate technique the pour plate technique may be used by transferring each SIST EN 1500:2013

For incubation and counting, see 5.5.4. 5.5.4 Incubation and counting of the test mixture and the control and validation mixtures For incubation and counting of the test mixture and the control and validation mixtures, the procedure is as follows:

a) Incubate (5.3.2.3) the plates for 20 h to 24 h. Discard any plates which are not countable (for any reason). Count the plates and determine the number of cfu. Incubate the plates for a further 20 h to 24 h. Do not recount plates which no longer show well separated colonies. Recount the remaining plates. If the number has increased, use only the higher number for further evaluation. b) Note for each plate the exact number of colonies but record > 330 for any counts higher than 330 and determine the VC-values according to 5.6.2.2.

c) Calculate the numbers of cfu/ml in the test mixtures of prevalue and postvalue (5.6.2.6) and in the validation mixtures B and C using the method given in 5.6.2.4 and 5.6.2.5. Verify according to 5.7. 5.6 Experimental data and calculation

5.6.1 Explanation of terms and abbreviations 5.6.1.1 Overview of the different suspensions and test mixtures N, Nv and NvB represent the bacterial suspensions, B (neutralizer control) and C (method validation) represent the different control test mixtures.

5.6.1.2 VC-values

All experimental data are reported as VC-values. A VC-value is the number of cfu counted per 1,0 ml sample. 5.6.2 Calculation 5.6.2.1 General The first step in the calculation is the determination of the VC-values, the second the calculation of N, Nv, Nv0,, NvB, B and C. The third step is the calculation of the reduction R (5.6.2.6). 5.6.2.2 Determination of VC-values The VC-values are determined as follows.

a) The usual limits for counting bacteria on agar plates are between 15 and 300. In this European Standard a deviation of 10 % is accepted, so the limits are 14 and 330. NOTE

The lower limit (14) is based on the fact that the variability increases the smaller the number counted in the sample (1 ml or 0,1 ml) is and therefore subsequent calculations may lead to wrong results. The lower limit refers only to the sampl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...