SIST EN 14585:2024

(Main)Corrugated metal hose assemblies for pressure applications

Corrugated metal hose assemblies for pressure applications

This document specifies the requirements for design, manufacture and installation of corrugated metal hose assemblies for pressure applications, i.e. maximum allowable pressure PS greater than 0,5 bar.

Gewellte Metallschlauchleitungen für Druckanwendungen

Dieses Dokument legt die Anforderungen an Auslegung, Fertigung und Einbau von gewellten Metallschlauchleitungen, z. B. für Druckanwendungen mit einem maximalen zulässigen Druck PS über 0,5 bar, fest.

Tuyauteries métalliques flexibles onduleuses pour applications sous pression

Le présent document spécifie les prescriptions relatives à la conception, fabrication et à l'installation de tuyauteries métalliques flexibles onduleuses pour applications sous pression, c'est-à-dire la pression maximale admissible PS supérieure à 0,5 bar.

Valoviti kovinski cevni sestavi za uporabo v tlačnih cevovodih

Ta evropski standard določa zahteve za načrtovanje, izdelavo in namestitev valovitih kovinskih cevnih sestavov za uporabo v tlačnih cevovodih, pri čemer je najvišji dovoljeni tlak (PS) večji od 0,5 bara.

General Information

- Status

- Published

- Public Enquiry End Date

- 12-Jul-2022

- Publication Date

- 11-Nov-2024

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Oct-2024

- Due Date

- 27-Dec-2024

- Completion Date

- 12-Nov-2024

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

Overview

EN 14585:2024 - published by CEN in 2024 - specifies requirements for the design, manufacture and installation of corrugated metal hose assemblies for pressure applications (maximum allowable pressure PS > 0.5 bar). This European Standard replaces earlier parts (EN 14585-1:2006 and related CEN/TR documents) and covers the full lifecycle from material selection and design methods to testing, documentation and operating instructions.

Key topics and technical requirements

- Scope & classification: Applies to corrugated metal hose assemblies for pressure use and includes classification categories (e.g. Categories I–III and SEP referenced for material documentation).

- Materials: Requirements for suitable materials, corrosion considerations, low-temperature applications, ductility and brittle-fracture aspects; material traceability and documentation are required.

- Design methods: Two main approaches - calculation design (with allowable stresses, fatigue and component calculations for corrugated hoses, braids, end fittings and flanges) and experimental design (type approvals, cyclic tests, validation).

- Manufacture & assembly: Requirements for corrugation forming, braiding, joining methods (welding, brazing), permanent joints, tolerances (inner diameter, ply thickness, corrugation height, overall length), repair/rework, cleaning and additional protection.

- Testing & inspection: In-process and final inspections, non‑destructive testing, leak, proof and pressure tests, cyclic testing and final documentation package.

- Documentation & marking: Final assessment, packaging, labelling, operating and safety instructions; Annexes provide material properties, derating factors and calculation coefficients.

- Regulatory linkage: Informative annex maps the relationship to EU Pressure Equipment Directive (2014/68/EU).

Applications and who uses it

EN 14585:2024 is used by:

- Design engineers and system integrators specifying metal hose assemblies for pressurized piping systems.

- Manufacturers and fabricators producing corrugated hoses, braids and end fittings.

- Quality & inspection personnel conducting tests, NDT and final acceptance.

- Procurement and asset owners requiring compliant components and documentation. Practical applications include flexible connections in pressurized piping where movement, vibration isolation or thermal expansion must be accommodated (industrial plants, process engineering, utilities and other sectors that use pressure-containing flexible metal hoses).

Related standards

- Supersedes EN 14585-1:2006, CEN/TR 14585-2:2006, CEN/TR 14585-3:2017.

- Annex ZA links EN 14585 to the essential requirements of EU Directive 2014/68/EU.

Keywords: EN 14585:2024, corrugated metal hose assemblies, pressure applications, design, manufacture, testing, CEN, pressure hose standard.

Frequently Asked Questions

SIST EN 14585:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Corrugated metal hose assemblies for pressure applications". This standard covers: This document specifies the requirements for design, manufacture and installation of corrugated metal hose assemblies for pressure applications, i.e. maximum allowable pressure PS greater than 0,5 bar.

This document specifies the requirements for design, manufacture and installation of corrugated metal hose assemblies for pressure applications, i.e. maximum allowable pressure PS greater than 0,5 bar.

SIST EN 14585:2024 is classified under the following ICS (International Classification for Standards) categories: 23.040.70 - Hoses and hose assemblies; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14585:2024 has the following relationships with other standards: It is inter standard links to SIST-TP CEN/TR 14585-2:2006, SIST EN 14585-1:2006, SIST-TP CEN/TR 14585-3:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14585:2024 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14585:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Valoviti kovinski cevni sestavi za uporabo v tlačnih cevovodih

Corrugated metal hose assemblies for pressure applications

Gewellte Metallschlauchleitungen für Druckanwendungen

Tuyauteries métalliques flexibles onduleuses pour applications sous pression

Ta slovenski standard je istoveten z: EN 14585:2024

ICS:

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14585

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 23.040.70 Supersedes EN 14585-1:2006, CEN/TR 14585-2:2006,

CEN/TR 14585-3:2017

English Version

Corrugated metal hose assemblies for pressure

applications

Tuyauteries métalliques flexibles onduleuses pour Gewellte Metallschlauchleitungen für

applications sous pression Druckanwendungen

This European Standard was approved by CEN on 26 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14585:2024 E

worldwide for CEN national Members.

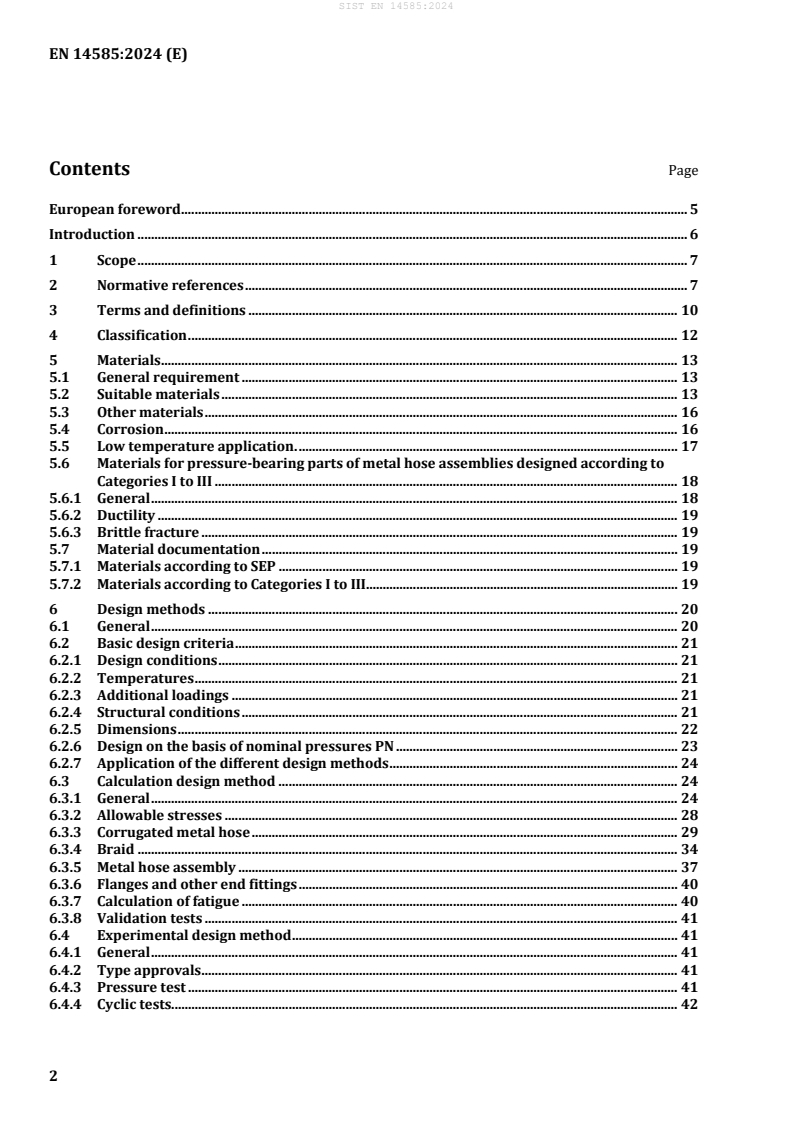

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 10

4 Classification . 12

5 Materials . 13

5.1 General requirement . 13

5.2 Suitable materials . 13

5.3 Other materials . 16

5.4 Corrosion . 16

5.5 Low temperature application. . 17

5.6 Materials for pressure-bearing parts of metal hose assemblies designed according to

Categories I to III . 18

5.6.1 General . 18

5.6.2 Ductility . 19

5.6.3 Brittle fracture . 19

5.7 Material documentation . 19

5.7.1 Materials according to SEP . 19

5.7.2 Materials according to Categories I to III . 19

6 Design methods . 20

6.1 General . 20

6.2 Basic design criteria . 21

6.2.1 Design conditions . 21

6.2.2 Temperatures . 21

6.2.3 Additional loadings . 21

6.2.4 Structural conditions . 21

6.2.5 Dimensions . 22

6.2.6 Design on the basis of nominal pressures PN . 23

6.2.7 Application of the different design methods . 24

6.3 Calculation design method . 24

6.3.1 General . 24

6.3.2 Allowable stresses . 28

6.3.3 Corrugated metal hose . 29

6.3.4 Braid . 34

6.3.5 Metal hose assembly . 37

6.3.6 Flanges and other end fittings . 40

6.3.7 Calculation of fatigue . 40

6.3.8 Validation tests . 41

6.4 Experimental design method . 41

6.4.1 General . 41

6.4.2 Type approvals . 41

6.4.3 Pressure test . 41

6.4.4 Cyclic tests. 42

6.5 Application of hose assemblies. 46

6.5.1 General . 46

6.5.2 Allowable pressure . 46

6.5.3 Flow velocity . 46

6.5.4 Pressure drop. 47

6.5.5 Hose configurations . 47

6.5.6 Documentation of the design methods . 53

7 Manufacturing . 54

7.1 General . 54

7.2 Materials . 54

7.2.1 General . 54

7.2.2 Material traceability for hose assemblies . 54

7.3 Permanent joints . 54

7.3.1 General . 54

7.3.2 Welding . 55

7.3.3 Brazing . 55

7.4 Metal hose assembly . 56

7.4.1 Corrugated hose . 56

7.4.2 Hose joining . 56

7.4.3 Braiding . 56

7.4.4 Additional protection . 57

7.5 Tolerances . 59

7.5.1 General . 59

7.5.2 Inner diameter . 59

7.5.3 Ply thickness e . 59

p

7.5.4 Corrugation height w . 59

7.5.5 Overall length . 59

7.5.6 End fittings . 59

7.6 Repair and rework . 59

7.7 Cleaning . 60

8 Testing, inspection and documentation . 60

8.1 Introduction. 60

8.1.1 General . 60

8.1.2 Documents . 60

8.1.3 Documents for category I, II and III hose assemblies . 60

8.2 In-process inspection, testing and documentation . 60

8.2.1 Materials . 60

8.2.2 Non-destructive in-process testing . 61

8.3 Final assessment . 61

8.3.1 General . 61

8.3.2 Final inspection . 61

8.3.3 Non-destructive testing . 61

8.3.4 Visual and dimensional examination . 62

8.3.5 Leak test . 62

8.3.6 Proof test . 62

8.3.7 Final documentation package . 63

8.3.8 Packaging . 64

9 Marking and labelling . 64

10 Operating instructions . 65

10.1 General . 65

10.2 Content of operating instructions . 65

10.3 Content of safety instructions . 66

Annex A (informative) Categories of corrugated metal hose assemblies . 67

Annex B (informative) Information to be supplied to the hose manufacturer . 74

Annex C (normative) Material properties and derating factors . 75

Annex D (informative) Calculation coefficients C , C , . 80

p f

Annex E (informative) Significant technical changes between this document and the

previous edition . 84

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2014/68/EU aimed to be covered. 85

Bibliography . 87

European foreword

This document (FprEN 14585:2024) has been prepared by Technical Committee CEN/TC 342 “Metal

hose, hose assemblies, bellows and expansion joints”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14585-1:2006, CEN/TR 14585-2:2006, CEN/TR 14585-3:2017.

Annex E provides details of significant technical changes between this document and the previous

edition.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

This document has been produced to address the specific needs of corrugated metal hose assemblies for

pressure applications. For applications outside the scope of EU Directive 2014/68/EU, refer to

EN ISO 10380:2012.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Corrugated metal hose assemblies are used as components in piping.

The requirements of this document impact designers, manufacturers, suppliers and importers of

corrugated metal hose assemblies for pressure applications.

The unique nature of a corrugated metal hose assembly is characterized by:

— the opposing requirements of pressure resistance and flexibility;

— the interactive role of its pressure bearing parts: corrugated metal hose, braid, end fittings and its

permanent joints.

As a general rule PED [1] Annex I, Clause 2.2.2 limits the experimental design method for piping to PS · DN

less than 3000. Validation tests are, however, intended to support design of corrugated metal hose

assemblies for all practically achievable values of PS · DN.

Regarding sound engineering practice (SEP), the manufacturer is responsible for its application based on

relevant standards or other professional codes. Corrugated metal hose assemblies according to SEP are

expected to be designed, manufactured, verified and delivered with instructions for use in order to ensure

their safety during their intended life, when used in foreseeable or reasonably foreseeable conditions.

NOTE 1 EN ISO 10380:2012 or relevant professional codes answer sound engineering practice requirements.

NOTE 2 See also PED Guidelines I-01 [5] and I-09 [6].

1 Scope

This document specifies the requirements for design, manufacture and installation of corrugated metal

hose assemblies for pressure applications, i.e. maximum allowable pressure PS greater than 0,5 bar.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 764-4:2014, Pressure equipment - Part 4: Establishment of technical delivery conditions for metallic

materials

EN 764-5:2014, Pressure equipment - Part 5: Inspection documentation of metallic materials and

compliance with the material specification

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1562:2019, Founding - Malleable cast irons

EN 1591-1:2013, Flanges and their joints - Design rules for gasketed circular flange connections - Part 1:

Calculation

EN 1593:1999, Non destructive testing — Leak testing — Bubble emission techniques

EN 1652:1997, Copper and copper alloys - Plate, sheet, strip and circles for general purposes

EN 1653:1997, Copper and copper alloys — Plate, sheet and circles for boilers, pressure vessels and hot

water storage units

EN 1779:1999, Non destructive testing — Leak testing – Criteria for method and technique selection

EN 1982:2017, Copper and copper alloys - Ingots and castings

EN ISO 6892-1:2019, Metallic materials - Tensile testing - Part 1: Method of test at room temperature (ISO

6892-1:2019)

EN ISO 7369:2020, Pipework - Metal hoses and hose assemblies - Vocabulary (ISO 7369:2020)

EN ISO 9445-1:2010, Continuously cold-rolled stainless steel - Tolerances on dimensions and form - Part 1:

Narrow strip and cut lengths (ISO 9445-1:2009)

EN ISO 9445-2:2010, Continuously cold-rolled stainless steel - Tolerances on dimensions and form - Part 2:

Wide strip and plate/sheet (ISO 9445-2:2009)

As impacted by EN 1593:1999/A1:2003.

As impacted by EN 1653:1997/A1:2000.

As impacted by EN 1779:1999/A1:2003.

EN ISO 9606-1:2017, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012 and Cor 2:2013)

EN ISO 9606-4:1999, Approval testing of welders - Fusion welding - Part 4: Nickel and nickel alloys (ISO

9606-4:1999)

EN ISO 9712:2022, Non-destructive testing - Qualification and certification of NDT personnel (ISO

9712:2021)

EN 10028-2:2017, Flat products made of steels for pressure purposes - Part 2: Non-alloy and alloy steels

with specified elevated temperature properties

EN 10028-4:2017, Flat products made of steels for pressure purposes - Part 4: Nickel alloy steels with

specified low temperature properties

EN 10028-7:2016, Flat products made of steels for pressure purposes - Part 7: Stainless steels

EN 10088-3:2014, Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars,

rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10204:2004, Metallic products - Types of inspection documents

EN 10216-1:2013, Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 1: Non-

alloy steel tubes with specified room temperature properties

EN 10216-2:2013+A1:2019, Seamless steel tubes for pressure purposes - Technical delivery conditions -

Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-3:2013, Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 3: Alloy

fine grain steel tubes

EN 10216-4:2013, Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 4: Non-

alloy and alloy steel tubes with specified low temperature properties

EN 10216-5:2021, Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 5:

Stainless steel tubes

EN 10217-3:2019, Welded steel tubes for pressure purposes - Technical delivery conditions - Part 3: Electric

welded and submerged arc welded alloy fine grain steel tubes with specified room, elevated and low

temperature properties

EN 10217-4:2019, Welded steel tubes for pressure purposes - Technical delivery conditions - Part 4: Electric

welded non-alloy steel tubes with specified low temperature properties

EN 10217-5:2019, Welded steel tubes for pressure purposes - Technical delivery conditions - Part 5:

Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10217-7:2021, Welded steel tubes for pressure purposes - Technical delivery conditions - Part 7:

Stainless steel tubes

EN 10222-2:2017+A1:2021, Steel forgings for pressure purposes - Part 2: Ferritic and martensitic steels

with specified elevated temperatures properties

EN 10222-3:2017, Steel forgings for pressure purposes - Part 3: Nickel steels with specified low temperature

properties

EN 10222-5:2017, Steel forgings for pressure purposes - Part 5: Martensitic, austenitic and austenitic-

ferritic stainless steels

EN 10253-2:2021, Butt-welding pipe fittings - Part 2: Non alloy and ferritic alloy steels with specific

inspection requirements

EN 10253-4:2008, Butt-welding pipe fittings - Part 4: Wrought austenitic and austenitic-ferritic (duplex)

stainless steels with specific inspection requirements

EN ISO 10380:2012, Pipework - Corrugated metal hoses and hose assemblies (ISO 10380:2012)

EN 12164:2016, Copper and copper alloys - Rod for free machining purposes

EN 12165:2016, Copper and copper alloys - Wrought and unwrought forging stock

EN 12166:2016, Copper and copper alloys - Wire for general purposes

EN 12167:2016, Copper and copper alloys - Profiles and bars for general purposes

EN 12168:2016, Copper and copper alloys - Hollow rod for free machining purposes

EN 12449:2023, Copper and copper alloys - Seamless, round tubes for general purposes

EN 13134:2000, Brazing - Procedure approval

EN 13184:2001, Non-destructive testing — Leak testing — Pressure change method

EN 13445-3:2021, Unfired pressure vessels - Part 3: Design

EN 13480-2:2017, Metallic industrial piping - Part 2: Materials

EN 13480-3:2017, Metallic industrial piping - Part 3: Design and calculation

EN ISO 148-1:2016, Metallic materials - Charpy pendulum impact test - Part 1: Test method (ISO 148-

1:2016)

EN ISO 13585:2012, Brazing - Qualification test of brazers and brazing operators (ISO 13585:2012)

EN ISO 14732:2013, Welding personnel - Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2013)

EN ISO 15610:2023, Specification and qualification of welding procedures for metallic materials —

Qualification based on tested welding consumables (ISO 15610:2023)

EN ISO 15613:2004, Specification and qualification of welding procedures for metallic materials -

Qualification based on pre-production welding test (ISO 15613:2004)

As impacted by EN 13184:2001/A1:2003.

EN ISO 15614-1:2017, Specification and qualification of welding procedures for metallic materials -

Welding procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1:2017, Corrected version 2017-10-01)

EN ISO 17637:2016, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO

17637:2016)

EN ISO 20485:2018, Non-destructive testing - Leak testing - Tracer gas method (ISO 20485:2017)

3 Terms and definitions

For the purposes of this document, the terms and definitions in EN ISO 7369:2020 and the following

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

metal hose assembly

assembly of a corrugated metal hose with its end fittings

3.2

maximum allowable pressure

PS

maximum pressure at the operating temperature for which the metal hose assembly is designed

Note 1 to entry: See also 6.2.1.

3.3

maximum allowable pressure at 20°C

PS

equivalent maximum pressure at ambient temperature for which the metal hose assembly is designed

3.4

minimum allowable temperature

minimum allowable temperature TS

minimum temperature for which the metal hose assembly is designed

Note 1 to entry: See also 6.2.1.

3.5

maximum allowable temperature

maximum allowable temperature TS

maximum temperature for which the metal hose assembly is designed

Note 1 to entry: See also 6.2.1.

3.6

nominal pressure

PN

dimensionless alphanumerical designation which is a convenient rounded number commonly used for

reference purposes of piping components and stock parts

Note 1 to entry: For this document PN represents the maximum allowable pressure at 20°C as specified by the

metal hose assembly manufacturer.

3.7

test pressure

PT

pressure at which the metal hose assembly is proof tested (normally at ambient temperature)

3.8

main pressure bearing parts

parts, such as corrugated metal hose, braid, pipe ends, the failure of which can result in a sudden

discharge of pressure energy

3.9

pressure bearing parts

parts, such as swivel nuts, flanges, threaded end fittings, that are not main pressure bearing parts defined

in 3.8 and the failure of which can not lead to a sudden discharge of pressure energy

3.10

attachments to pressure parts

parts, such as ferrules, that are directly welded to parts defined in 3.8 or 3.9

3.11

other parts

parts, such as external protection, anti-kink device, braid protecting spiral, which are not parts according

to 3.8 to 3.9

3.12

experimental tests

type testing

tests made to develop an experimental design method

3.13

category

classification of pressure equipment according to ascending level of hazard

Note 1 to entry: See Annex A.

3.14

equipment manufacturer

natural or legal person responsible for the values of the parameters PS and TS

Note 1 to entry: This can be the manufacturer or planner of the piping for which the metal hose assembly is

designed.

3.15

hose manufacturer

natural or legal person responsible for the design and the manufacture of the corrugated metal hose

and/or the metal hose assembly

3.16

purchaser

person or organization that orders products in accordance with this document

Note 1 to entry: The purchaser is not necessarily, but can be, a manufacturer of pressure equipment in

accordance with the EU Directive listed in Annex ZA. Where a purchaser has responsibilities under this EU Directive,

this document will provide a presumption of conformity with the essential requirements of the Directive identified

as such in Annex ZA once the reference of the Standard is published in the Official Journal of the European

Commission

3.17

hydraulic forming

longitudinal welded

corrugating a tube by pressurizing the inside against external tooling which allows this corrugated tube

to be axially shortened during the process

3.18

roll forming

longitudinal welded

corrugating a tube by rolling from the outside to the inside and allowing or forcing this corrugated tube

to be axially shortened during the process

3.19

helical crest welded

resistance welded

profiling a strip, rolling it over helically and finally welding the overlaps

3.20

strand

group of parallel wires used for plain braid or wires woven together to form a braided strand

3.21

braided braid

braid that is manufactured from previously braided strands

3.22

operating instructions

written procedure provided by the manufacturer which include all information regarding installation,

operation, safety and maintenance of the equipment within the manufacturer's scope of supply

4 Classification

For the application of this document, hose assemblies are divided into groups according to ascending

level of hazard: SEP, Category I, and Categories II and III.

The grouping is, according to the requirements of PED [1], depending on their nominal diameter DN, their

maximum allowable pressure PS, and on the type of fluid they convey.

According to the conformity assessment tables of the PED (see also Annex A) the different levels of hazard

lead to:

— SEP, covering the field of sound engineering practice according to Article 4, Clause 3 of PED; i.e.

smallest level of hazard with no CE marking;

— Category I, covering metal hose assemblies designed for a mean level of hazard and being CE marked;

— Categories II and III, covering metal hose assemblies designed for higher levels of hazard and being

CE marked.

5 Materials

5.1 General requirement

Materials for the manufacture of hose assemblies including filler metal shall be selected on the basis of

their suitability for fabrication according to Clause 7, and for the conditions under which they will be

used.

Materials used for hose assemblies according to Categories I to III shall fulfil the additional requirements

specified in 5.6.

When combining different materials, care shall be taken regarding material compatibility (e.g. galvanic

corrosion, welding compatibility).

5.2 Suitable materials

Materials suitable for hoses assemblies are given as follows:

a) Materials suitable for corrugated metal hoses and their temperature limits are given in Table 1;

b) Materials suitable for braid, end fittings, and additional parts are given in Table 2.

Table 1 — Materials for corrugated metal hoses and their temperature limits

Material Temperature °C

Document

Type Number Steel name Minimum Maximum

a

1.4306 X2CrNi19–11 – 273 550

a

1.4401 X5CrNiMo17–12–2 – 196 550

a

1.4404 X2CrNiMo17–12–2 – 273 550

Stainless

a

1.4435 X2CrNiMo18–14–3 – 273 550

austenitic EN 10028-7:2016

a

1.4539 X1NiCrMoCu25–20–5 – 196 550

steels

a

1.4541 X6CrNiTi18–10 – 273 550

a

1.4547 X1CrNiMoCuN20–18–7 – 196 500

a

1.4571 X6CrNiMoTi17–12–2 – 273 550

X10NiCrAlTi32–21 600

Heat resistant

1.4876 – 196 See Table C.2

b

austenitic steels

X10NiCrAlTi32–21 (H) (900)

Nickel 2.4360 NiCu30Fe – 196 425 See Table C.2

alloys

2.4858 NiCr21Mo – 10 540 See Table C.2

(part 1)

2.4610 NiMo16Cr16Ti – 196 400 EAM-0526–28

EAM-0526-43-1,

– 10 450

EAM-0526-43-2

2.4816 NiCr15Fe

Nickel

c b

(– 273) (900) See Table C.3

alloys

(part 2)

2.4819 NiMo16Cr15W – 196 400 EAM-0526–18

– 196 450 EAM-0526–40

2.4856 NiCr22Mo9Nb

c b

(– 273) (900) See Table C.3

a

Minimum temperature in accordance with EN 13445-2:2021, Annex B or EN 13480-2:2017, Annex B.

b

Special care should be exercised due to the risk of embrittlement when using the materials at elevated

temperatures above 550 °C. See 6.2.2 for details.

c

See 5.6.3 a) for details.

Table 2 — Materials for braid, end fittings, ferrules, and additional parts

Component Material No Document

Pressure parts

1.4301, 1.4306, 1.4401, 1.4404, 1.4541,

EN 10088-3:2014

1.4571

Braid 1.4876, 2.4360, 2.4819, 2.4856, 2.4858 Table 1

Cu-based material: CW450K, CW452K,

a

EN 12166:2016

CW508L

EN 10222-2:2017+A1:2021 and

Forged

f

EN 10222-3:2017

Carbon steel

f

Flat products EN 10028-2:2017

EN 10222-5:2017

1.4301, 1.4306, 1.4401, 1.4404, 1.4435,

Fixed flange,

1.4462, 1.4541, 1.4571

EN 10028-7:2016

Weld collar,

1.4876, 2.4360, 2.4816, 2.4819, 2.4856, Table 1

b

Floating flange

2.4858

CW024A EN 1653:1997

Copper-based

a

EN 12164:2016

material:

CW617N

a

EN 12165:2016

f

Carbon steel EN 10253-2:2021

1.4301, 1.4306, 1.4401, 1.4404, 1.4435,

EN 10253-4:2008

1.4462, 1.4541, 1.4571

1.4876, 2.4360, 2.4816, 2.4819, 2.4856,

Table 1

Thread nipple, 2.4858

Taper thread

CW024A EN 1653:1997

nipple,

a

CW602N EN 12164:2016

Threaded

a

CW608N EN 12165:2016

connection,

a

CW614N EN 12167:2016

Copper-based

Threaded fitting,

a

CW617N EN 12168:2016

material:

c

Swivel nut

CC491K

(CuSn5Zn5Pb5-C)

EN 1982:2017

CC499K

(CuSn5Zn5Pb2-C)

Malleable cast iron

EN-JM1030 EN 1562:2019

d

EN 10216-1:2013,

EN 10216-2:2013+A1:2019,

Seamless EN 10216-3:2013 and

Pipe ends Carbon steel

EN 10216-4:2013

welded

EN 10217-3:2019, EN 10217-4:2019

f

and EN 10217-5:2019

Component Material No Document

1.4301, 1.4306, EN 10216-5:2021

Seamless

1.4401, 1.4404,

EN 10217-7:2021

welded

1.4541, 1.4571

1.4876, 2.4360, 2.4816, 2.4819, 2.4856,

See Table 1

2.4858

Copper-based

a

CW024A EN 12449:2023

material:

Parts attached to pressure parts

1.4301, 1.4306, 1.4401, 1.4404, 1.4541,

EN 10028-7:2016

1.4571

Ferrule

1.4876, 2.4360, 2.4816, 2.4819, 2.4856,

See Table 1

(similar to braid

2.4858

material)

Copper-based material: CW450K,

a

EN 12166:2016

CW452K, CW508L

e

Other parts

1.4301, 1.4306, 1.4401, 1.4404, 1.4541,

EN 10028-7:2016

1.4571

End ring,

1.4876, 2.4360, 2.4816, 2.4819, 2.4856,

Protective strip-

See Table 1

2.4858

wound hose,

Anti-kink device

Copper-based material: CW450K,

EN 1652:1997

CW452K, CW508L

Braid protecting 1.4301, 1.4306, 1.4401, 1.4404, 1.4541,

EN 10088-3:2014

helix 1.4571, 1.4310

a

Not harmonized to PED; Particular Material Appraisals (PMA) are necessary for applications within the scope

of the PED.

b

Ferritic floating flanges shall be protected to avoid contamination of adjacent stainless steel parts.

c

Swivel nuts shall be made from free cutting materials.

d

Malleable cast iron parts shall be made weldable by multiple tempering. The carbon content of the welding

zones shall not exceed 0,3 %.

e

Other parts shall be preferably made from materials similar to the braid material.

f

Minimum/maximum temperature limits are indicated in the relevant normative references.

5.3 Other materials

Other materials can be used provided they fulfil the general requirements of 5.1 and conform to a

harmonized standard or comply with a European Approval for Materials (EAM) or have a Particular

Material Appraisal (PMA) as defined in EN 764-4:2014.

5.4 Corrosion

The materials selected for the metal hose assembly shall have adequate resistance to all the corrosive

agents likely to be encountered during the lifetime of the system, i.e. the transported fluid and/or the

environment. Consideration shall be given to all corrosion risks including pitting corrosion, intergranular

corrosion, crevice corrosion, contact corrosion and stress corrosion cracking.

NOTE Corrugated metal hoses generally have a wall thickness substantially less than that of the rest of the

system with which they are used. Hence, they are often manufactured from a material having a higher corrosion

resistance than that used in the associated piping.

5.5 Low temperature application.

End fittings such as weld ends, flanges, and threaded end fittings used for low temperature applications

shall not go below the temperature limits given in Table 3. The lowest allowable working temperature is

depending on the degree of load G which is defined by the maximum quotient of the stress levels

σ

resulting from the calculation of pressure resistance and the allowable stresses related to the regarded

stress components:

G max σσ/,ff/, σ+⋅σ / 1,5 f (1)

( )

( )

σ Θ mm, mm,,mb

where the definitions of terms are indicated in Table 6.

=

Table 3 — Materials for pressure-bearing parts at low temperature application

(Except corrugated hoses and braid)

Lowest allowable

working temperature in

°C

N° Description European Standard

Degree of load G

σ

a a

1,0 0,75 0,25

Non-alloy and alloy steels with

specified properties at elevated

temperatures:

— flat products EN 10028-2:2017

– 85

— seamless pipes EN 10216-2:2013+A1:2019

– 10 – 60

(– 100)

b b b

— steel forgings EN 10222-2:2017+A1:2021 (– 20) (– 70)

Flat products for pressure purpose

c

2 from Nickel alloy steels with specified EN 10028-4:2017 tmin tmin – 50 tmin – 80

low temperature properties

Seamless pipes for pressure purpose,

c

3 from non-alloy steels with specified EN 10216-4:2013 t t – 50 t – 80

min min min

low temperature properties

Forgings for pressure purpose, Nickel

c

4 steels with specified low temperature EN 10222-3:2017 t t – 50 t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...