SIST EN 14944-3:2024

(Main)Influence of cementitious products on water intended for human consumption - Test methods - Part 3: Migration of substances from factory-made cementititous products

Influence of cementitious products on water intended for human consumption - Test methods - Part 3: Migration of substances from factory-made cementititous products

This European Standard specifies a method to determine the migration of substances from factory made cementitious products into test waters after contact with the products.

This European Standard is applicable to factory made cementitious products, e.g. cement mortar linings to metallic pipes, tanks, concrete pipes etc., intended to be used for the transport and storage of water intended for human consumption, including raw water used for the production of drinking water.

Einfluss von zementgebundenen Produkten auf Wasser für den menschlichen Gebrauch– Prüfverfahren– Teil3: Migration von Substanzen aus fabrikmäßig hergestellten zementgebundenen Produkten

Dieses Dokument legt ein Verfahren zur Bestimmung der Migration von Substanzen aus fabrikmäßig hergestellten zementgebundenen Produkten in Prüfwässer nach einem Kontakt mit den Produkten fest.

Dieses Dokument wird auf fabrikmäßig hergestellte zementgebundene Produkte angewendet, z. B. Zement-mörtelauskleidungen von metallischen Rohren, Behältern, Betonrohre usw., die dazu bestimmt sind, Wasser für den menschlichen Gebrauch zu transportieren und zu speichern, einschließlich Rohwasser, das für die Herstellung von Trinkwasser eingesetzt wird.

ANMERKUNG Prüfungen mit dem festgelegten Prüfwasser sind nicht unbedingt repräsentativ für Materialien, die in anderen Wasserarten und insbesondere in sehr weichem Wasser verwendet werden.

Influence des produits à base de ciment sur l'eau destinée à la consommation humaine - Méthodes d'essais - Partie 3 : Migration de substances à partir des produits à base de ciment fabriqués en usine

Le présent document spécifie une méthode permettant de déterminer la migration des substances

issues de produits à base de ciment fabriqués en usine dans les eaux d’essai après contact avec les

produits concernés.

Le présent document s’applique aux produits à base de ciment fabriqués en usine, tels que les

revêtements intérieurs de mortier de ciment appliqués sur des tubes métalliques, des réservoirs, des

tubes en béton, etc., destinés à être utilisés pour le transport et le stockage de l’eau destinée à la

consommation humaine, y compris l’eau brute utilisée pour la production de l’eau potable.

NOTE Les essais réalisés avec l’eau d’essai spécifiée ne sont pas nécessairement représentatifs des matériaux

utilisés avec différents types d’eaux et notamment les eaux très douces.

Vpliv cementnih proizvodov na pitno vodo - Preskusne metode - 3. del: Prehod snovi iz cementnih, tovarniško izdelanih proizvodov

Ta evropski standard določa metodo za ugotavljanje prehoda snovi iz cementnih, tovarniško izdelanih proizvodov v preskusne vode po stiku s takšnimi proizvodi.

Ta evropski standard se uporablja za tovarniško izdelane cementne proizvode (npr. obloge iz cementne malte za kovinske cevi, cisterne, betonske cevi itd.), namenjene za prevoz in shranjevanje pitne vode, vključno z neobdelano vodo, ki se uporablja za pripravo pitne vode.

General Information

- Status

- Published

- Public Enquiry End Date

- 06-Jul-2023

- Publication Date

- 06-Feb-2024

- Technical Committee

- IOVO - Water supply and waste water engineering

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 24-Jan-2024

- Due Date

- 30-Mar-2024

- Completion Date

- 07-Feb-2024

Relations

- Effective Date

- 01-Mar-2024

Overview

EN 14944-3:2023 - "Influence of cementitious products on water intended for human consumption - Test methods - Part 3" is a CEN standard that defines a laboratory method to determine the migration of substances from factory-made cementitious products (e.g., cement mortar linings, concrete pipes, tanks, fittings) into test waters. It applies to products intended for the transport and storage of water intended for human consumption, including raw water used in drinking water production.

Key Topics

- Scope and principle: Laboratory migration testing to quantify substances released from cementitious materials into water.

- Sample preparation: Requirements for sampling, transport, storage and preparation of test pieces from factory-made pipes, fittings and storage systems.

- Surface area to volume (S/V) ratio: Prescribed S/V ratios for representative exposure conditions and test-piece geometries.

- Preconditioning and curing: Defined procedures for curing and preconditioning test specimens prior to migration testing.

- Migration procedure: Stepwise contact periods (first, second, third and additional migration periods), preparation of migration water and options for testing at 23 °C or elevated temperature (see normative annexes).

- Apparatus and reagents: Equipment for forming test pieces, attaching cylinders, and controlling test conditions.

- Analysis and calculations: Methods to determine concentration, migration rate and mean migration rate of measured substances.

- Reporting: Mandatory test report content - sample ID, product information, test conditions, analytical results and calculation method.

- Annexes: Normative and informative annexes cover additional procedures for pipes, fittings, storage systems, elevated-temperature testing, and discrimination between porous and non-porous coatings.

Applications

EN 14944-3:2023 is used to:

- Demonstrate material safety and compliance for cementitious linings and concrete elements in contact with drinking water.

- Support product development and quality control by quantifying leachable substances and migration rates.

- Provide data for regulatory compliance and certification where migration into drinking water is assessed.

- Inform specification writing for water utilities, utilities procurement, civil engineers and municipal authorities concerned with potable water infrastructure.

Who should use this standard

- Manufacturers of cementitious pipes, linings, fittings and storage tanks

- Accredited testing laboratories and inspectors

- Water utilities and operators

- Product certifiers and regulators

- Materials engineers and consultants specifying potable-water systems

Related standards

- Other parts of the EN 14944 series and CEN standards addressing materials and articles in contact with drinking water (see national adoption notices for linked documents).

Frequently Asked Questions

SIST EN 14944-3:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Influence of cementitious products on water intended for human consumption - Test methods - Part 3: Migration of substances from factory-made cementititous products". This standard covers: This European Standard specifies a method to determine the migration of substances from factory made cementitious products into test waters after contact with the products. This European Standard is applicable to factory made cementitious products, e.g. cement mortar linings to metallic pipes, tanks, concrete pipes etc., intended to be used for the transport and storage of water intended for human consumption, including raw water used for the production of drinking water.

This European Standard specifies a method to determine the migration of substances from factory made cementitious products into test waters after contact with the products. This European Standard is applicable to factory made cementitious products, e.g. cement mortar linings to metallic pipes, tanks, concrete pipes etc., intended to be used for the transport and storage of water intended for human consumption, including raw water used for the production of drinking water.

SIST EN 14944-3:2024 is classified under the following ICS (International Classification for Standards) categories: 13.060.20 - Drinking water; 67.250 - Materials and articles in contact with foodstuffs; 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14944-3:2024 has the following relationships with other standards: It is inter standard links to SIST EN 14944-3:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14944-3:2024 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14944-3:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2024

Nadomešča:

SIST EN 14944-3:2009

Vpliv cementnih proizvodov na pitno vodo - Preskusne metode - 3. del: Prehod

snovi iz cementnih, tovarniško izdelanih proizvodov

Influence of cementitious products on water intended for human consumption - Test

methods - Part 3: Migration of substances from factory-made cementititous products

Einfluss von zementgebundenen Produkten auf Wasser für den menschlichen

Gebrauch– Prüfverfahren– Teil3: Migration von Substanzen aus fabrikmäßig

hergestellten zementgebundenen Produkten

Influence des produits à base de ciment sur l'eau destinée à la consommation humaine -

Méthodes d'essais - Partie 3 : Migration de substances à partir des produits à base de

ciment fabriqués en usine

Ta slovenski standard je istoveten z: EN 14944-3:2023

ICS:

13.060.20 Pitna voda Drinking water

67.250 Materiali in predmeti v stiku z Materials and articles in

živili contact with foodstuffs

91.100.10 Cement. Mavec. Apno. Malta Cement. Gypsum. Lime.

Mortar

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14944-3

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 13.060.20; 67.250 Supersedes EN 14944-3:2007

English Version

Influence of cementitious products on water intended for

human consumption - Test methods - Part 3: Migration of

substances from factory-made cementititous products

Influence des produits à base de ciment sur l'eau Einfluss von zementgebundenen Produkten auf Wasser

destinée à la consommation humaine - Méthodes für den menschlichen Gebrauch- Prüfverfahren- Teil3:

d'essais - Partie 3 : Migration de substances à partir Migration von Substanzen aus fabrikmäßig

des produits à base de ciment fabriqués en usine hergestellten zementgebundenen Produkten

This European Standard was approved by CEN on 7 August 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14944-3:2023 E

worldwide for CEN national Members.

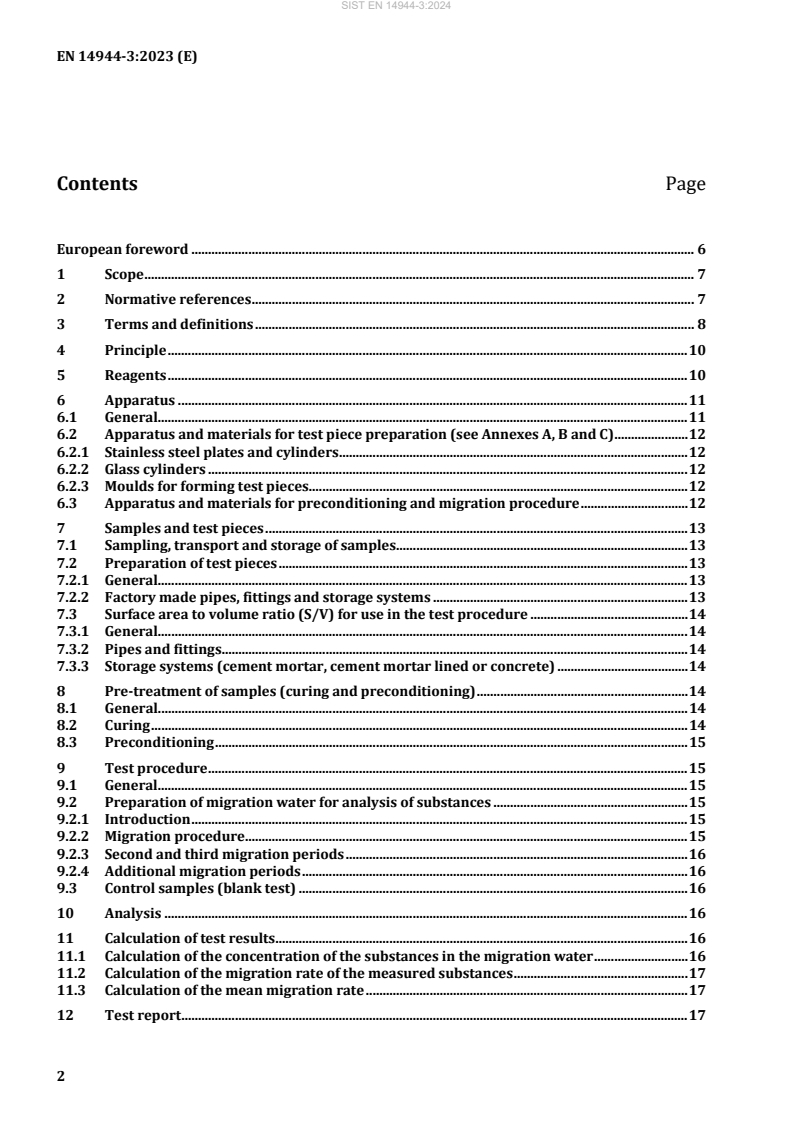

Contents Page

European foreword . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Principle . 10

5 Reagents . 10

6 Apparatus . 11

6.1 General. 11

6.2 Apparatus and materials for test piece preparation (see Annexes A, B and C) . 12

6.2.1 Stainless steel plates and cylinders . 12

6.2.2 Glass cylinders . 12

6.2.3 Moulds for forming test pieces . 12

6.3 Apparatus and materials for preconditioning and migration procedure . 12

7 Samples and test pieces . 13

7.1 Sampling, transport and storage of samples. 13

7.2 Preparation of test pieces . 13

7.2.1 General. 13

7.2.2 Factory made pipes, fittings and storage systems . 13

7.3 Surface area to volume ratio (S/V) for use in the test procedure . 14

7.3.1 General. 14

7.3.2 Pipes and fittings . 14

7.3.3 Storage systems (cement mortar, cement mortar lined or concrete) . 14

8 Pre-treatment of samples (curing and preconditioning) . 14

8.1 General. 14

8.2 Curing . 14

8.3 Preconditioning . 15

9 Test procedure . 15

9.1 General. 15

9.2 Preparation of migration water for analysis of substances . 15

9.2.1 Introduction . 15

9.2.2 Migration procedure . 15

9.2.3 Second and third migration periods . 16

9.2.4 Additional migration periods . 16

9.3 Control samples (blank test) . 16

10 Analysis . 16

11 Calculation of test results. 16

11.1 Calculation of the concentration of the substances in the migration water . 16

11.2 Calculation of the migration rate of the measured substances . 17

11.3 Calculation of the mean migration rate . 17

12 Test report . 17

12.1 General . 17

12.2 General information . 17

12.3 Information on the product . 18

12.4 Information on the test procedure . 18

12.5 Test results. 19

Annex A (normative) Additional procedures for testing factory-made pipes (cement mortar

lined and concrete) . 20

A.1 Sampling, test piece preparation and storage . 20

A.1.1 Sampling . 20

A.1.2 Test piece preparation and storage . 20

A.2 Surface area to volume (S/V) ratio . 24

A.3 Preconditioning of test pieces . 24

A.4 Test procedure . 24

A.4.1 Migration procedure at 23 °C . 24

A.4.2 Migration procedure at elevated temperature . 24

A.5 Expression of results . 24

A.6 Reporting . 24

Annex B (normative) Additional procedures for testing factory made fittings (cement

mortar lined and concrete) . 25

B.1 Sampling, test piece preparation and storage . 25

B.1.1 Sampling of factory-made fittings. 25

B.1.2 Test piece preparation and storage . 25

B.2 Surface area to volume (S/V) ratio . 29

B.3 Preconditioning of test pieces . 29

B.4 Test procedure . 29

B.4.1 Migration procedure at 23 °C . 29

B.4.2 Migration procedure at elevated temperature . 29

B.5 Expression of results . 29

B.6 Reporting . 29

Annex C (normative) Additional procedures for testing factory-made storage systems

(cement mortar, cement mortar lined and concrete) . 30

C.1 Sampling, test piece preparation and storage . 30

C.1.1 Sampling . 30

C.1.2 Test piece preparation and storage . 30

C.2 Surface area to volume (S/V) ratio . 34

C.3 Preconditioning of test pieces . 34

C.4 Test procedure . 34

C.4.1 Migration procedure at 23 °C . 34

C.4.2 Migration procedure at elevated temperature . 34

C.5 Expression of results . 34

C.6 Reporting . 34

Annex D (informative) Examples of typical test pieces and test conditions as a function of

S/V ratio . 35

D.1 General. 35

D.2 Pipes and fittings . 35

D.3 Test pieces to which a cylinder of stainless steel or glass is to be attached . 36

D.4 Square test plates coated with mortar . 37

D.5 Moulded test pieces where all faces are exposed to test water . 37

Annex E (informative) Test arrangements for testing factory-made cement-based products . 40

Annex F (normative) Additional procedures for testing factory-made cement based

products at elevated temperature . 47

F.1 General. 47

F.2 Test procedure at elevated temperature . 47

F.2.1 General. 47

F.2.2 Preparation of migration water for analysis of substances . 47

F.3 Control samples (blank test) . 47

F.4 Expression of results . 47

F.5 Reporting . 48

Annex G (informative) Discrimination between porous and non-porous coatings on

factory-made products . 49

G.1 Principle . 49

G.2 Apparatus . 49

G.3 Materials and reagents . 49

G.4 Test procedure . 49

G.4.1 General. 49

G.4.2 Laboratory blank . 49

G.4.3 Coated product . 50

G.5 Determination of pH . 50

G.6 Expression of results . 50

G.7 Classification criteria . 51

Annex H (informative) Schematic description of the test procedure . 52

H.1 Preconditioning . 52

H.2 Production of migration water at 23 °C . 53

H.3 Typical Schedule . 54

H.3.1 Preconditioning . 54

H.3.2 Production of migration waters . 54

Annex I (informative) Procedural tests using standard additions (positive controls) . 55

Bibliography . 56

European foreword

This document (EN 14944-3:2023) has been prepared by Technical Committee CEN/TC 164 “Water

supply”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2024, and conflicting national standards shall be

withdrawn at the latest by June 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14944-3:2007.

In comparison with EN 14944-3:2007, the following changes have been made:

— provisions for testing the influence of materials on the migration of organic substances (TOC) have

been shifted to EN 14944-1;

— requirements for disinfection (preconditioning with 50 mg/l chlorine) have been removed;

— a procedure for extending the number of migration periods has been included.

This document describes a test method to determine the migration of inorganic substances in water

intended for human consumption.

This European Standard will result in one of a series of standards that support standards for the

approval of products and materials in contact with water intended for human consumption.

This European Standard is part of a series dealing with the influence of cement based and associated

non-cement-based products/materials on water intended for human consumption, including:

— Part 1: Influence of factory-made cement-based products on organoleptic parameters and migration

of organic substances (TOC)

— Part 2: Influence of site-applied cement-based materials and associated non-cement-based

products/materials on organoleptic parameters and migration of organic substances (TOC)

— Part 3: Migration of substances from factory-made cement-based products

— Part 4: Migration of substances from site-applied cement-based materials and associated non-cement-

based products/materials

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

1 Scope

This document specifies a method to determine the migration of substances from factory-made cement-

based products into test waters after contact with the products.

This document is applicable to factory-made cement based, e.g. cement mortar linings to metallic pipes,

tanks, concrete pipes, etc., intended to be used for the transport and storage of water intended for

human consumption, including raw water used for the production of drinking water.

NOTE Tests with the specified test water will not necessarily be representative of materials used in different

kinds of waters and especially very soft waters.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 196-1, Methods of testing cement - Part 1: Determination of strength

EN 1015-2, Methods of test for mortar for masonry - Part 2: Bulk sampling of mortars and preparation of

test mortars

EN 1015-11, Methods of test for mortar for masonry - Part 11: Determination of flexural and compressive

strength of hardened mortar

EN 10088-1, Stainless steels - Part 1: List of stainless steels

EN 12350-1, Testing fresh concrete - Part 1: Sampling and common apparatus

EN 12390-1, Testing hardened concrete - Part 1: Shape, dimensions and other requirements for specimens

and moulds

EN 12390-2, Testing hardened concrete - Part 2: Making and curing specimens for strength tests

EN ISO 7393-1, Water quality - Determination of free chlorine and total chlorine - Part 1: Titrimetric

method using N, N-diethyl-1,4-phenylenediamine (ISO 7393-1)

EN ISO 7393-2, Water quality - Determination of free chlorine and total chlorine - Part 2: Colorimetric

method using N,N-dialkyl-1,4-phenylenediamine, for routine control purposes (ISO 7393-2)

EN ISO 10523, Water quality - Determination of pH (ISO 10523)

ISO/TS 13530, Water quality — Guidance on analytical quality control for chemical and physicochemical

water analysis

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

appropriate body

certification body, inspection body or testing laboratory, as relevant to a particular requirement

3.2

cement based product

factory-made product containing a cement-based material supplied in the hardened state with a formed

surface prior to its incorporation into the construction works

3.3

cement based material

material that contains a hydraulic cement in sufficient proportion to act as the main binder by forming a

hydrate structure which governs the performance of the material

3.4

associated non-cement-based product

product which is applied to the surface of a cement-based product, directly or indirectly, during

manufacture (or construction) and which either provides a porous seal to the product or which remains

as a residue in contact with water, e.g. porous seal coats, formwork release agents and curing

compounds

3.5

porous seal coat

polymeric (usually organic) materials applied in a thin (25 μm – 200 μm thickness) surface layer to a

cement mortar lining in order to restrict (but not prevent) interactions between the mortar and

conveyed water

Note 1 to entry: See ISO 16132:2016, 3.6 [1].

3.6

proxy sample

sample of fresh mortar or fresh concrete taken from material to be used for the production of a factory-

made product, either applied to one face of a stainless steel plate (6.2.1.1) using the same process of

application used in the factory (mortar only) or cast into a mould (mortar or concrete) of appropriate

dimensions (e.g. standard cube, cylinder or prism etc.) and compacted (where appropriate), cured and

hardened under conditions representative of those intended for the product

3.7

fresh concrete

concrete that is fully mixed and still in a condition capable of being compacted by the chosen method

3.8

fresh mortar

cement mortar that is fully mixed and still in a condition of being applied by the chosen method

3.9

test

technical operation that consists of the determination of one or more characteristics of a given product

3.10

test procedure

specified technical method for performing a test

3.11

sample

one or more units, or a specified quantity, drawn from a batch or lot, selected at random for inspection,

e.g. at the factory or in a laboratory

3.12

test piece

sample or portion which is to be conditioned, treated or otherwise prepared to be tested to obtain a

single test result

3.13

nominal diameter

DN/ID

DN/OD

numerical designation of the size of a component, which is a whole number approximately equal to the

actual dimensions in millimetres

Note 1 to entry: This applies to either the internal diameter (DN/ID) or the external diameter (DN/OD).

3.14

preconditioning

succession of contact periods of a test piece with the preconditioning water (3.15) before contact with

the test water

3.15

preconditioning water

water used for preconditioning

Note 1 to entry: Prepared as described in 5.3.1

3.16

test water

water used for testing purposes

Note 1 to entry: Prepared as described in 5.3.2 and used in accordance with 5.3.3 and 5.3.4

3.17

migration water

test water which has been in contact with a test piece under specified conditions

3.18

blank water

test water which has been kept at the same specified conditions as migration water but without contact

with the test piece

3.19

tap water

drinking water distributed by a public supplier

Note 1 to entry: Tap water is used as a lubricant/coolant for the sawing and coring operations used to obtain test

pieces generally from products of large dimensions. See Annexes A, B and C.

3.20

demineralized water

water of which the mineral matter or salts have been removed by deionization

[SOURCE: ISO 23321:2019, 3.1]

4 Principle

Each test piece is subjected to a specified preconditioning procedure where the surface which, in

practice will be exposed to water intended for human consumption, is brought into contact with

preconditioning water during five sequential periods: three periods of 24 h, 1 period of 72 h and a final

period of 24 h.

The preconditioned test piece is then brought into contact with test water, chlorinated and/or chlorine-

free during three sequential migration periods. A migration period is either:

a) 72 h at (23 ± 2) °C for products intended to come into contact with chlorinated or chlorine-free cold

water;

b) 24 h at a specified elevated temperature for products intended to come into contact with warm or

hot chlorine-free water.

Migration rates are calculated after each contact period by determination of the content of specified

substances in the corresponding migration water.

NOTE 1 The test is carried out under conditions that ensure that reliable migration rates are calculated. These

conditions are not meant to simulate any service condition. Relating the results obtained from this document to

the service condition is carried out using a conversion procedure. This procedure will be specified in regulations.

NOTE 2 The selection of:

a) the appropriate test water, chlorinated and/or chlorine-free, from those made available in this

document,

b) the temperature of the test water

is specified in product or system standards or in national or European regulations, as appropriate.

5 Reagents

5.1 Chlorine neutralization reagents

5.1.1 Ascorbic acid solution, prepared by dissolving (4,0 ± 0,1) g of ascorbic acid in one litre of test

water (5.3.2).

This ascorbic acid solution shall be replaced on a monthly basis.

5.1.2 Sodium thiosulfate solution, comprising a solution of 3,5 g/l of sodium thiosulfate

pentahydrate (Na S O 5 * H O) and stored in the absence of light at a temperature below 10 °C, for a

2 2 3 2

maximum of 4 months.

5.2 Sodium hypochlorite solution

5.2.1 Sodium hypochlorite solution, prepared from a commercial solution of sodium hypochlorite

(NaOCl) and have a known concentration of about 0,1 % by mass of free chlorine determined in

accordance with either EN ISO 7393-1 or EN ISO 7393-2.

This sodium hypochlorite solution is unstable and shall be prepared on the day of use.

5.3 Waters to be used for testing

5.3.1 Preconditioning water shall be unchlorinated test water (see 5.3.2).

5.3.2 Test water, prepared by dissolving (110 ± 1) mg anhydrous calcium chloride (CaCl ),

(140 ± 1) mg sodium hydrogen carbonate (NaHCO3) and (48 ± 1) mg sodium silicate nonahydrate

(Na SiO ·9·H O) in one litre of demineralized water (3.20).

2 3 2

The pH is determined in accordance with EN ISO 10523 and adjusted to 7,0 ± 0,1 by bubbling air and/or

CO into the solution.

NOTE The target total hardness is 100 mg/l as CaCO , the target alkalinity is 122 mg/l as HCO - and the silica

3 3

concentration is 10 mg/l as SiO2.

5.3.3 Test water without chlorine content (chlorine-free), shall consist of a batch of test

water (5.3.2) used for contact with test pieces and preparation of the blank water (3.18).

5.3.4 Test water with chlorine content (chlorinated), shall consist of test water (5.3.2) with a free

chlorine content of (1,0 ± 0,2) mg/l as Cl , determined in accordance with either EN ISO 7393-1 or

EN ISO 7393-2, after addition of sodium hypochlorite solution (5.2).

5.4 Cleaning liquids for apparatus

Use one of the following cleaning liquids:

— non-perfumed biodegradable detergent;

— hydrochloric acid, 2 mol/l;

— nitric acid, 10 % or 1,5 mol/l.

6 Apparatus

6.1 General

For cleaning the glassware, and appropriate apparatus, before use, the following general requirements

apply:

a) Clean the glassware to be used, using detergent (5.3). Rinse the glassware in with demineralized

water (3.20).

b) Clean the inner surface of the glassware with hydrochloric acid (5.3) and rinse it with

demineralized water. For stainless steel, clean with nitric acid (5.3) and then rinse with

demineralized water.

c) Before use, rinse the glassware, and appropriate apparatus, at least three times using

preconditioning water before preconditioning (8.3) or test water before the test procedure

(Clause 9).

6.2 Apparatus and materials for test piece preparation (see Annexes A, B and C)

6.2.1 Stainless steel plates and cylinders

6.2.1.1 Stainless steel

Stainless steel shall be austenitic, super austenitic or duplex grades in accordance with the

corresponding numerical designations, 1.4301, 1.4436, 1.4429, 1.4259 or 1.4462 in EN 10088-1 for

stainless steels.

NOTE The grades above are specified for the use of stainless steel as reinforcement in concrete. Therefore,

they are considered to be inert when used in contact with cement-based proxy samples (see Annexes A, B and C).

6.2.1.2 Plates

In order to provide a sufficient volume of migration water for assessment, the surface area of one face of

2 2

a plate should be between 10 000 mm and 90 000 mm . The length/width of the plates should be

selected to be consistent with the dimensions of the test container and the volume of test water in

which they will be immersed.

6.2.1.3 Cylinders

The diameter and length of a cylinder should be consistent with the dimensions of the test piece

(see Annexes A, B, C, D and E) and the volume of test water appropriate to the specified S/V ratio given

in 7.3.

6.2.2 Glass cylinders

The diameter and length of a glass cylinder should be consistent with the dimensions of the test piece

(see Annexes A, B, C, D and E) and the volume of test water appropriate to the specified S/V ratio given

in 7.3. Glass cylinders should be provided with suitable external (opaque) shielding for use during

migration procedures (test pieces and blanks), in order to minimize exposure of migration waters to

ambient light.

6.2.3 Moulds for forming test pieces

Moulds for forming prisms of mortar shall conform to the requirements of EN 196-1, as specified for

use in EN 1015-11, or to EN 12390-1 for forming cubes/cylinders of concrete, with modifications to

materials and dimensional tolerances as specified in Annex A, B or C, as appropriate.

Clean moulds and any filling frame used with a mould, by thoroughly washing with non-perfumed

detergent (5.3) and tap water (3.19), rinsing with copious amounts of tap water, followed by a final

rinse with demineralized water (3.20) and dry before use.

If a factory-made cement-based product has been formed in a process where its entire contact surface

has been in contact with a release agent and if proxy samples (3.6) are used, the same release agent

shall be applied to the internal surfaces of the mould, otherwise the use of release agents is not

permitted.

6.3 Apparatus and materials for preconditioning and migration procedure

6.3.1 Vessels, containers, covers, connectors and stoppers shall consist of a material, such as

glass, PTFE, steel and stainless steel that is inert under the specified test conditions (Clause 9).

6.3.2 Equipment, capable of maintaining the test temperature within ± 2 °C for the duration of the

test.

6.3.3 If required, use only sealants that do not affect the determinations under the specified test

conditions (see Clause 9).

7 Samples and test pieces

7.1 Sampling, transport and storage of samples

Carry out sampling of factory-made products in accordance with the relevant product standard, system

standard, or the relevant Annex to this document, as appropriate.

NOTE National or European regulations can also apply.

Take care that the transport conditions do not influence the test results.

If it is necessary to store samples or test pieces before testing, ensure that they are protected from

contamination taking into account any written instructions that are provided.

Where appropriate, clean storage containers using the same procedures as are used for the test

containers.

Ensure that the surfaces of the test pieces intended to come into contact with the test water are free

from any contamination, e.g. adhesive tape, labels, ink or pencil marks.

7.2 Preparation of test pieces

7.2.1 General

Prepare the test pieces in such a way that only the surface intended to come into contact with drinking

water is exposed to the test water except as given in Annex C (see C.1.2.3.2.1) where stainless steel

plates are coated with cement mortar on one face only prior to complete immersion during testing.

In the preparation of a test piece the following general principles apply:

a) ensure that test pieces are representative of the finished product;

b) during the preparation of test pieces, include any procedures which are performed in practice for

curing and cleaning;

c) ensure that the minimum age of the test piece, at test, conforms to that recommended by the

manufacturer for the product to be ready for use;

d) ensure that the surface area of the test piece is sufficient to fulfil the appropriate surface area to

volume (S/V) ratio in accordance with the requirements of 7.3.

7.2.2 Factory made pipes, fittings and storage systems

Where possible, use the product or test piece as the test vessel, with dimensions that provide sufficient

migration water for assessment. In cases where this is not practicable (e.g. large pipes, storage systems

etc.), and where alternatives are specified, use as appropriate, an alternative test piece described in the

relevant Annex A, B or C and an appropriate test arrangement given in Annex E.

Where it is required to discriminate between porous and non-porous coatings already applied to

factory-made products, use the test procedure given in Annex G.

7.3 Surface area to volume ratio (S/V) for use in the test procedure

7.3.1 General

The following general principles apply for S/V ratios:

a) the surface area to volume ratio (S/V) of the test piece exposed to the test water relates to realistic

service conditions;

b) where no difference in material composition and production process exists in the range of sizes

produced, only the largest S/V ratio is required to be tested;

c) the ratio of the surface area, S, of the test piece intended to come into contact with volume, V, of the

−1

test water is expressed per decimetre, i.e. dm .

−1 2 3 2

NOTE The unit, dm , can also be expressed as dm /dm or dm /l.

7.3.2 Pipes and fittings

The S/V ratio is calculated, in dm-1, according to the formula:

S/ V = (1)

DN / ID

[ ]

where

[DN/ID] (3.12) is the nominal internal diameter, in mm.

Test pipes and fittings of DN/ID less than 80, at the actual S/V ratio of the pipe diameter.

−1

Test pipes and fittings of DN/ID equal to 80 and less than 300, at an S/V ratio of (5,0 ± 0,2) dm .

−1

Test pipes and fittings of DN/ID 300 or greater, at an S/V ratio of (1,3 ± 0,1) dm .

NOTE See 7.3.1 (b) for the acceptable minimum requirement for testing pipes that are produced in a range of

sizes.

7.3.3 Storage systems (cement mortar, cement mortar lined or concrete)

−1

Test storage systems at an S/V ratio of (1,3 ± 0,1) dm .

8 Pre-treatment of samples (curing and preconditioning)

8.1 General

The procedures for curing cement-based products are given in 8.2.

The procedure for preconditioning at (23 ± 2) °C is given in 8.3.

8.2 Curing

Ensure that test pieces have been subject either to the curing conditions used in manufacture of the

factory-made product or, in the case of test pieces formed from proxy samples (3.6), to curing

conditions that are representative of those used in the manufacture of the factory-made product (see

the relevant Annex A, B or C).

8.3 Preconditioning

Precondition test pieces at the appropriate S/V ratio given in 7.3.

Fill test pieces with, or immerse them in, or otherwise bring them into contact with (see the test

arrangements in Annex E), preconditioning water (5.3.1) for a succession of five contact periods,

without rinsing between contact periods, at a temperature of (23 ± 2) °C as follows:

— three periods of (24 ± 1) h;

— one period of (72 ± 1) h;

— one period of (24 ± 1) h.

After the fifth contact period determine the pH of the preconditioning water in accordance with

EN ISO 10523. If the pH exceeds 9,5 stop the testing.

Where the pH exceeds 9,5 preconditioning may be repeated using new test pieces.

The results of co-normative research [2] obtained using this preconditioning water indicate that where

the pH exceeds 9,5 after the fifth contact period, then steps should be taken to first investigate and then

eliminate the cause(s) before proceeding to the test procedure (see Clause 9).

After preconditioning, test pieces shall be rinsed with drinking water; the required tests shall be carried

out immediately afterwards in accordance with 9.

9 Test procedure

9.1 General

Where testing of products is required, at 23 °C, carry out the procedures according to 9.2.

Where testing at elevated temperature is required carry out the procedure in accordance with

normative Annex F.

9.2 Preparation of migration water for analysis of substances

9.2.1 Introduction

The number of tests to be carried out e.g.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...