SIST-TP CEN/TR 16787:2015

(Main)Industrial Gas Installation - Guideline

Industrial Gas Installation - Guideline

This Technical Report applies to safety and operational topics for equipment and pipework systems installed within industrial premises which may be used for process and non-process applications such as Heating, Power Generation, Incineration, etc.

It is applicable to a range of combustible gases used within an industrial environment. The gas plant may include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery).

The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of plant operation and plant maintenance.

For piped supplies of gas to a site this Technical Report applies to the system downstream of the ‘point of delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation valve) located before or after the metering station, as will be defined by the particular EU member state national legislation.

The guidance in this Technical Report may also apply to gases generated for the sites own use, such as coke oven gas, site bio-gas plant, site LPG/air plant etc.

Industrielle Gasinstallationen - Leitlinien

This Technical Report applies to safety and operational topics for equipment and pipework systems installed within industrial premises which may be used for process and non-process applications such as Heating, Power Generation, Incineration, etc.

It is applicable to a range of combustible gases used within an industrial environment. The gas plant may include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery).

The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of plant operation and plant maintenance.

For piped supplies of gas to a site this Report applies to the system downstream of the ‘point of delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation valve) located before or after the metering station, as will be defined by the particular EU member state national legislation.

The guidance in this Report may also apply to gases generated for the sites own use, such as coke oven gas, site bio-gas plant, site LPG/air plant etc.

Installation gaz dans le domaine industriel - Lignes directrices

Le présent Rapport technique s’applique à la sécurité et aux aspects opérationnels des équipements et systèmes de tuyauterie installés sur des sites industriels et qui peuvent être employés pour des applications de procédés ou non, comme le chauffage, la production d’électricité, l’incinération, etc.

Il couvre une grande diversité de gaz combustibles utilisés en environnement industriel. L’usine à gaz peut employer des procédés de combustion normale à l’air et/ou à l’oxygène, d’oxydation catalytique ou de craquage (par exemple, dans le cas d’une raffinerie).

Il incombe à l’utilisateur d’équipements à gaz et de systèmes de tuyauterie de garantir la sécurité de la conception, de l’exploitation de l’usine et de l’entretien de l’usine.

Dans le cadre de l’approvisionnement en gaz d’un site par des canalisations, le présent Rapport technique s’applique au système en aval du « point de livraison ». Le terme « point de livraison » renvoie à la vanne de coupure (ou à l’ensemble régulateur et vanne de coupure) qui se trouve avant ou après la station de comptage, telle que définie par la législation nationale applicable à l’État-membre de l’UE concerné.

Les recommandations formulées dans le présent Rapport technique peuvent également s’appliquer aux gaz générés pour l’usage interne des sites, par exemple le gaz de cokerie, l’installation de biogaz du site, l’installation de mélange GPL/air du site, etc

Industrijska plinska napeljava - Smernica

To tehnično poročilo velja za varnostne vidike in vidike obratovanja za opremo in cevovodne sisteme, nameščene v industrijskih objektih, ki se lahko uporabljajo za namene procesov ali pa ne (kot so gretje, proizvajanje energije, sežiganje itd.).

Velja za vrsto vnetljivih plinov, ki se uporabljajo v industrijskem okolju. Naprava za uplinjanje lahko vključuje normalno zgorevanje z zrakom in/ali kisikom, katalitično oksidacijo ali razbijanje (npr. kot v rafinerijah).

Uporabnik opreme in cevovodnih sistemov za plin je odgovoren za zagotavljanje varnosti projektiranja, delovanja in vzdrževanja naprave.

Za dobavo plina po ceveh to tehnično poročilo velja za smer toka sistema do »točke dostave«. Izraz »točka dostave« se nanaša na ločilni ventil (ali kombinacijo regulatorja in ločilnega ventila) pred merilno postajo ali za njo, kot bo določeno v nacionalni zakonodaji posamezne države članice EU.

Navodila iz tega tehničnega poročila se lahko uporabljajo tudi za pline, proizvedene za lastno uporabo na lokacijah, kot so plin za koksarne, bioplinske naprave, obrat LPG/zrak.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Oct-2014

- Publication Date

- 02-Feb-2015

- Technical Committee

- DPL - Gas supply

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Jan-2015

- Due Date

- 12-Mar-2015

- Completion Date

- 03-Feb-2015

Overview

CEN/TR 16787:2014 - Industrial Gas Installation (Guideline) is a CEN Technical Report that provides guidance on safety and operational aspects of gas equipment and pipework installed within industrial premises. It covers systems used for process and non‑process applications (for example heating, power generation, incineration, catalytic oxidation and cracking) and applies to a range of combustible gases including natural gas, LPG, site bio‑gases and other industrial fuel gases. The Report applies to plant downstream of the point of delivery (as defined by national legislation) and to gases generated on‑site (coke oven gas, LPG/air mixes, bio‑gas).

Key topics and technical requirements

- Scope and definitions: common industry terms and definitions for components, jointing methods, tests, pressure regulating and metering.

- Safety management: responsibilities for designers, installers and users; maintenance of records; technical file, construction file, explosion protection document and the declaration of conformity.

- Gas composition & characteristics: properties of natural gas, LPG and non‑conventional gases; influence of composition on combustion; Wobbe index and non‑combustion parameters.

- Installation pipework: functional recommendations for design, materials, construction, inspection and testing of pipework systems.

- Industrial thermal equipment: guidance on equipment sensitivity (gas engines, turbines, burners) and control of air/gas flows vs energy content.

- Environment & regulatory context: environmental considerations, emissions control and relation to EU Directives and national implementation.

- Inspections & general safety: commissioning, operation, maintenance and inspection practices.

- Annexes: practical material on flow metering technologies, reverse flow, emissions, national data and references.

Practical applications

CEN/TR 16787 is intended to help ensure safe, compliant and efficient operation of industrial gas installations by:

- Guiding plant engineers on design and selection of pipework and components.

- Supporting installers and contractors with commissioning, testing and documentation practices.

- Assisting safety managers and maintenance teams in record keeping, inspections and conformity assessment.

- Helping regulatory bodies and gas suppliers understand responsibilities at the point of delivery and downstream systems.

Who should use this standard

- Industrial plant designers and engineers

- Installation and commissioning contractors

- Health & safety and maintenance managers

- Gas suppliers and utility interface engineers

- Regulators and compliance officers

Related standards & references

Normative references cited include EN 1775, EN 15001‑1, EN 15001‑2 and EN ISO 6976 (Wobbe index and calorific calculations). These documents are relevant for detailed design, materials, testing and gas property calculations.

Keywords: industrial gas installation, CEN/TR 16787, gas safety, pipework systems, Wobbe index, gas composition, industrial thermal processing, point of delivery.

Frequently Asked Questions

SIST-TP CEN/TR 16787:2015 is a technical report published by the Slovenian Institute for Standardization (SIST). Its full title is "Industrial Gas Installation - Guideline". This standard covers: This Technical Report applies to safety and operational topics for equipment and pipework systems installed within industrial premises which may be used for process and non-process applications such as Heating, Power Generation, Incineration, etc. It is applicable to a range of combustible gases used within an industrial environment. The gas plant may include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery). The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of plant operation and plant maintenance. For piped supplies of gas to a site this Technical Report applies to the system downstream of the ‘point of delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation valve) located before or after the metering station, as will be defined by the particular EU member state national legislation. The guidance in this Technical Report may also apply to gases generated for the sites own use, such as coke oven gas, site bio-gas plant, site LPG/air plant etc.

This Technical Report applies to safety and operational topics for equipment and pipework systems installed within industrial premises which may be used for process and non-process applications such as Heating, Power Generation, Incineration, etc. It is applicable to a range of combustible gases used within an industrial environment. The gas plant may include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery). The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of plant operation and plant maintenance. For piped supplies of gas to a site this Technical Report applies to the system downstream of the ‘point of delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation valve) located before or after the metering station, as will be defined by the particular EU member state national legislation. The guidance in this Technical Report may also apply to gases generated for the sites own use, such as coke oven gas, site bio-gas plant, site LPG/air plant etc.

SIST-TP CEN/TR 16787:2015 is classified under the following ICS (International Classification for Standards) categories: 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TP CEN/TR 16787:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

kSIST-TP FprCEN/TR 16787:2014

01-oktober-2014

Industrijska plinska napeljava - Smernica

Industrial Gas Installation - Guideline

Industrielle Gasinstallationen - Leitlinien

Installation gaz dans le domaine industriel - Lignes directrices

Ta slovenski standard je istoveten z: FprCEN/TR 16787

ICS:

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

kSIST-TP FprCEN/TR 16787:2014 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

kSIST-TP FprCEN/TR 16787:2014

kSIST-TP FprCEN/TR 16787:2014

TECHNICAL REPORT

FINAL DRAFT

FprCEN/TR 16787

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

July 2014

ICS

English Version

Industrial Gas Installation - Guideline

Installation gaz dans le domaine industriel - Lignes Industrielle Gasinstallationen - Leitlinien

directrices

This draft Technical Report is submitted to CEN members for Technical Committee Approval.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a Technical Report. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a Technical Report.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUR O P Ä IS CHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2014 CEN All rights of exploitation in any form and by any means reserved Ref. No. FprCEN/TR 16787:2014 E

worldwide for CEN national Members.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

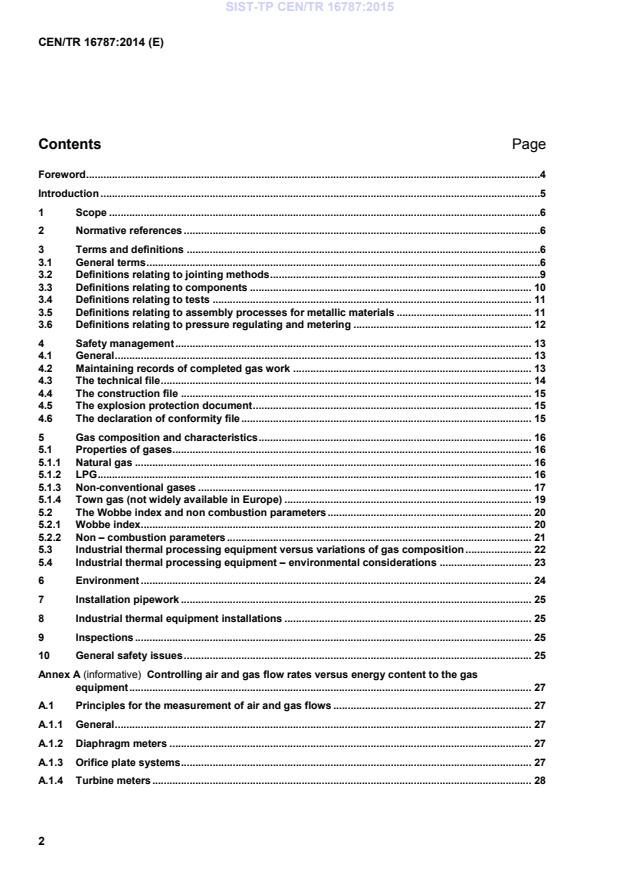

Contents Page

Foreword .4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .6

3.1 General terms .6

3.2 Definitions relating to jointing methods .9

3.3 Definitions relating to components . 10

3.4 Definitions relating to tests . 11

3.5 Definitions relating to assembly processes for metallic materials . 11

3.6 Definitions relating to pressure regulating and metering . 12

4 Safety management . 13

4.1 General . 13

4.2 Maintaining records of completed gas work . 13

4.3 The technical file . 14

4.4 The construction file . 15

4.5 The explosion protection document . 15

4.6 The declaration of conformity file . 15

5 Gas composition and characteristics . 16

5.1 Properties of gases. 16

5.1.1 Natural gas . 16

5.1.2 LPG . 16

5.1.3 Non-conventional gases . 17

5.1.4 Town gas (not widely available in Europe) . 19

5.2 The Wobbe index and non combustion parameters . 20

5.2.1 Wobbe index . 20

5.2.2 Non – combustion parameters . 21

5.3 Industrial thermal processing equipment versus variations of gas composition . 22

5.4 Industrial thermal processing equipment – environmental considerations . 23

6 Environment . 24

7 Installation pipework . 25

8 Industrial thermal equipment installations . 25

9 Inspections . 25

10 General safety issues . 25

Annex A (informative) Controlling air and gas flow rates versus energy content to the gas

equipment . 27

A.1 Principles for the measurement of air and gas flows . 27

A.1.1 General . 27

A.1.2 Diaphragm meters . 27

A.1.3 Orifice plate systems . 27

A.1.4 Turbine meters . 28

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

A.1.5 Rotating piston meters (roots) . 28

A.1.6 Vortex flow meters . 29

A.1.7 Ultrasonic flow meter . 29

A.1.8 Mass flow meters . 29

A.2 Flow calculation . 30

A.3 Control energy content . 30

A.4 Flow metering and meter performance . 31

Annex B (informative) Industrial thermal processing equipment . 33

B.1 Sensitivity of gas engines and gas turbines . 33

B.2 Sensitivity of some industrial thermal processes . 33

Annex C (informative) Reverse flow of gases . 36

Annex D (informative) Industrial thermal processing equipment and Environmental issues . 37

Annex E (informative) National implementation . 38

E.1 General/introduction . 38

E.2 Safety and health of workers at work regulations . 38

E.3 Specifications from utilities and gas suppliers . 38

E.4 Protection of buildings and equipment against fire . 38

Annex F (informative) European Directives . 40

F.1 EU Safety Directives . 40

F.1.1 General . 40

F.1.2 Safety European Directives concerning products . 40

F.1.3 Safety European Directives concerning general public and workers . 42

F.1.4 Introduction to Directives . 43

F.1.5 Synthesis of Directives . 44

F.2 Environment EU Directives for industrial end-users . 46

F.2.1 General . 46

F.2.2 Emissions Trading Scheme ETS . 46

F.2.3 Measures to reduce emissions (CO , CO, NO , CH ) . 47

2 x 4

F.2.4 Industrial Emissions Directive (IED) . 47

Annex G (informative) Natural gas overview . 48

Annex H (informative) National data . 50

Bibliography . 53

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

Foreword

This document (FprCEN/TR 16787:2014) has been prepared by CEN Sector Forum Gas.

This document is currently submitted to the Technical Committee Approval.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

Introduction

Gas industry leaders acknowledge the strategic role of European and National Standards in their efforts to

ensure the safety of gas installations in industrial premises. This Technical Report has been prepared to

explain to those involved with industrial premises some of the relevance of a range of Directives that affect

their operations. In addition guidance is given on the terms and definitions widely in use throughout the

European Union, together with some important information on how a consumer of gas can ensure safety in

operating their site. Minimizing the adverse effects on the environment is also an important consideration.

European and National legislation and the related framework of standards are complex and changing at an

ever increasing pace. For industrial plant engineers, finding the relevant standards can be a difficult task,

demands specific knowledge, and can consume a considerable amount of time. A number of the principal

standards are highlighted in this Technical Report, but EU Member States may have similar or equivalent

standards covering the application. Additionally, member states may have slightly different legal systems and

requirements that demand compliance.

Both designers and installers play an important role in applying the current standards for design, construction,

testing, commissioning and operation of all industrial gas installations. Safety is therefore improved and the

full energy efficiency potential of industrial thermal processes can be utilized.

It is recognized that the main reference is this Technical Report is to Natural Gas but many standards equally

apply directly to LPG and LPG/Air mixtures. This Technical Report is also applicable to many bio-gases, and

other flammable gases, and the user will need to ensure they are aware of any different requirements needed

to ensure safety. For example some gases may be very hot or corrosive, some may be ‘wet’ and others may

contain significant quantities of toxic gases such as carbon monoxide. Hydrogen rich gases may also require

special attention to material selection.

Finally, due to the complexities and special needs of some types of process plant, it may be necessary to

adopt higher standards of safety and to use risk assessments to ensure reliable judgements on plant safety.

In applying the recommendations contained within this Report it is important that the relevant requirements of

national guidance standards and legislation are considered.

In some cases where a lack of information is available in a member state, guidance from other member states

or by other recognized national bodies such as ASME or API may be used.

The range of industrial thermal process and heating equipment providing energy solutions to customers for a

diverse range of applications is significant.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

1 Scope

This Technical Report applies to safety and operational topics for equipment and pipework systems installed

within industrial premises which may be used for process and non-process applications such as Heating,

Power Generation, Incineration, etc.

It is applicable to a range of combustible gases used within an industrial environment. The gas plant may

include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery).

The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of

plant operation and plant maintenance.

For piped supplies of gas to a site this Technical Report applies to the system downstream of the ‘point of

delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation

valve) located before or after the metering station, as will be defined by the particular EU member state

national legislation.

The guidance in this Technical Report may also apply to gases generated for the sites own use, such as coke

oven gas, site bio-gas plant, site LPG/air plant etc.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 1775, Gas supply ― Gas pipework for buildings ― Maximum operating pressure less than or equal to 5

bar ― Functional recommendations

EN 15001-1, Gas Infrastructure ― Gas installation pipework with an operating pressure greater than 0,5 bar

for industrial installations and greater than 5 bar for industrial and non-industrial installations ― Part 1:

Detailed functional requirements for design, materials, construction, inspection and testing

EN 15001-2, Gas infrastructure ― Gas installation pipework with an operating pressure greater than 0,5 bar

for industrial installations and greater than 5 bar for industrial and non-industrial installations ― Part 2:

Detailed functional requirements for commissioning, operation and maintenance

EN ISO 6976, Natural gas ― Calculation of calorific values, density, relative density and Wobbe index from

composition (ISO 6976)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE These terms and definitions are given for information as they are widely used in the gas industry.

3.1 General terms

3.1.1

air gas ratio

ratio between the flow of combustion air and the flow of the fuel gas

Note 1 to entry: Sometimes fuel/air ratio is used. It can either be expressed in terms of volume or mass flows.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.1.2

air factor

ratio between the actual flow of combustion air and the stoichiometric flow of combustion air

Note 1 to entry: It can be expressed in terms of volume or mass flows.

3.1.3

components

any item from which a gas supply system or installation is constructed

Note 1 to entry: A distinction is drawn between the following groups of components:

— ancillaries (for example; pressure regulators, valves, safety devices, expansion joints, and insulating joints);

— pipes, including bends made from pipe;

— instrumentation pipework;

— fittings (for example; reducers, tees, factory-made elbows, flanges, dome ends, welding stubs, and mechanical

joints).

3.1.4

flexible appliance connector

fitting of flexible pipe to be fitted between the end of fixed pipework and the appliance inlet connection

3.1.5

gas appliances

appliances burning gaseous fuels used for cooking, heating, hot water production, refrigeration, lighting or

washing and having, where applicable, a normal water temperature not exceeding 105 °C, except those

specifically designed for use in industrial processes carried out on industrial premises

3.1.6

HAZOP

hazard and operability study (HAZOP) is a structured and systematic examination of a planned or existing

process or operation in order to identify and evaluate problems that may represent risks to personnel or

equipment, or prevent efficient operation

3.1.7

industrial appliances

appliances burning gaseous fuels installed in industrial premises and are subject to specific national health

and safety regulations

3.1.8

pressure

gauge pressure of the fluid inside the system, measured in static conditions

3.1.9

design pressure

DP

pressure at which the design calculations are based

Note 1 to entry: This is equivalent to the maximum allowable pressure (PS) as given in the PED.

3.1.10

maximum allowable pressure

PS

maximum pressure for which pipework is designed in accordance with the strength requirements

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.1.11

maximum incidental pressure

MIP

maximum pressure at which a system can experience during a short time, limited by the safety devices

3.1.12

operating pressure

OP

pressure which occurs within a system under normal operating conditions

3.1.13

maximum operating pressure

MOP

maximum pressure at which a system can be operated continuously under normal operating conditions

Note 1 to entry: Normal operating conditions are: no fault in any device or stream.

3.1.14

tightness test pressure

TTP

pressure applied to a system during tightness testing

3.1.15

strength test pressure

STP

pressure applied to a system during strength testing

3.1.16

combined test pressure

CTP

pressure applied to a system during combined testing

3.1.17

risk assessment

identification, evaluation, and estimation of the levels of risks involved in a situation, their comparison against

benchmarks or standards, and determination of an acceptable level of risk

Note 1 to entry: In this sense Risk is, ‘the likelihood and consequence of a hazard being realised’.

3.1.18

point of delivery

point of transfer of ownership of gas from the supplier to the customer

Note 1 to entry: This can be at a means of isolation or at the meter outlet connection.

Note 2 to entry: This can be isolation valve (or combination of regulator and isolation valve) located before or after the

metering station, as defined by the particular EU member state.

3.1.19

user(s)

person (s) responsible for the safety of the gas installation and associated risks on a site

Note 1 to entry: Normally the user will be the site occupier or owner. It should be assumed that every user has a

responsibility for work performed on their site, whether or not the work is performed directly for the user or not. This does

not mean that they cannot take advice from an independent specialist.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.1.20

pipework

assembly of pipes and fittings

3.1.21

installation pipework

pipework downstream of the point of delivery terminating at the appliance inlet connection

Note 1 to entry: This pipework is normally the property of the customer.

3.1.22

ventilated space

space where the air is continuously changed by natural or mechanical means

3.1.23

safety zone

area around the pipework from which persons who are not involved in the strength test are excluded during

testing

3.1.24

equipotential bond

means of ensuring that metallic gas pipework and other metallic parts of the building are at the same electrical

potential

Note 1 to entry: For safety reasons, this equipotential bonding is connected to earth.

3.1.25

duct

space specifically designed and constructed for the passage of building services

EXAMPLE Building services include gas pipework, water systems, power and telecommunication cables.

3.1.26

ventilation duct

duct forming part of the structure of the building and intended exclusively for ventilation purposes

3.1.27

means of isolation

device which is intended to interrupt the gas flow in pipework

EXAMPLE Manually operable valve.

3.2 Definitions relating to jointing methods

3.2.1

joint

means of connecting elements of a gas installation

3.2.2

flanged joint

joint in which gas tightness is achieved by compression of a gasket between the faces of two flanges

3.2.3

threaded joint

joint in which gas tightness is achieved by metal-to-metal contact within threads with the assistance of a

sealant

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.2.4

mechanical joint

joint in which gas tightness is achieved by compression, with or without a seal and which can be

disassembled and reassembled

Note 1 to entry: This definition includes twin ferrule type joints.

3.2.5

pressed joint

joint in which tightness is achieved by using a specific tool for either compressing a fitting to form the joint or

expanding a pipe to enable forming the joint

3.2.6

brazed joint

joint formed by brazing

3.2.7

welded joint

joint formed by welding

3.2.8

electro fusion joint

joint formed between polyethylene components using fittings which have an integrated electric heating

element

3.2.9

butt fusion joint

joint formed between polyethylene components where the two pipe ends are heated and brought together to

be fused directly without the use of a separate fitting or filler material

3.2.10

compression joint

type of joint in which gas tightness is achieved by compression within a socket with or without a seal

3.3 Definitions relating to components

3.3.1

regulator

device which reduces the gas pressure to a set value and maintains it within prescribed limits

3.3.2

appliance connection

flexible pipe or length of rigid pipework connecting an appliance’s means of isolation with the appliance inlet

connection

3.3.3

insulating joint

fitting installed to insulate electrically one section of pipework from another

3.3.4

sleeve

protective pipe through which a gas pipe passes

3.3.5

vent pipe

pipework connected to a safety or control device to release gas at a safe location

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.3.6

creep relief valve

device designed to release a limited flow of gas in the event of an unacceptable pressure being detected

within the system it protects

3.3.7

safety slam-shut device

device designed to quickly shut off the gas flow in the event of an unacceptable pressure being detected

within the system it protects. This often referred to an over-pressure or under-pressure shut off device

3.3.8

instrumentation pipework

pipework required for the proper functioning of the ancillaries installed within the pressure regulating

installation

EXAMPLE Sensing, measuring, auxiliary and sampling lines.

3.3.9

DN

alphanumeric designation of size for components of a pipework system, which is used for reference purposes

Note 1 to entry: It comprises the letters DN followed by a dimensionless whole number, which is indirectly related to

the physical size, in millimetres, of the bore or outside diameter of the end connections.

Note 2 to entry: The number following the letters DN does not represent a measurable value and should not be used

for calculation purposes except where specified.

Note 3 to entry: Where DN designation is used, any relationship between DN and component dimensions are given,

e.g. DN/OD or DN/ID.

3.4 Definitions relating to tests

3.4.1

strength test

specific procedure intended to verify that the pipework meets the requirements for mechanical strength

3.4.2

leak-tightness test

specific procedure intended to verify that the pipework meets the requirements for leak-tightness

3.4.3

combined test

specific procedure to verify that the pipework and/or installation meets the requirements for mechanical

strength and leak-tightness

3.4.4

leak detection fluid

specially formulated fluid and foaming product that gives a clear indication that a leak exists when applied to

an element of pipework

3.5 Definitions relating to assembly processes for metallic materials

3.5.1

welding

joining (union) of two or more parts by heat or pressure or a combination of both, (fusion, arc or oxy-

acetylene) such that the materials form a continuity

Note 1 to entry: A filler metal having a melting point similar to that of the materials to be welded can be used.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

3.5.2

brazing

operation in which metal parts are joined by means of capillary action of a filler metal in the liquid state with a

melting temperature, higher than 450 °C, lower than that of the parts to be joined and wetting the parent

metal(s), which does not participate in the making of the joint

Note 1 to entry: This is often referred to as hard soldering.

3.5.3

hot tapping

procedure involving the safe use of heat, e.g. welding or fusion, to affix an attachment to a section of pipework

containing gas at pressure

3.6 Definitions relating to pressure regulating and metering

3.6.1

compressors

complete unit for raising the gas pressure within installation pipework above 0,5 bar to an OP greater than

5 bar

3.6.2

station

gas pressure regulating and/or metering system including (where applicable) the housing, the odourisation

facilities and the fenced site

3.6.3

gas pressure regulating and metering system

system comprising all equipment, together with inlet and outlet pipework up to and including the isolating

valves, which together performs the functions of pressure regulation, pressure safety and/or quantitative gas

measurement, whether or not including pressure boosting and/or gas mixing facilities

3.6.4

monitor

second regulator used as a safety device in series with the active regulator which assumes control of the

pressure at a higher set value in the event of the active regulator failing open

3.6.5

excess air ratio (λ)

ratio between the effectively introduced quantity of air and the theoretically required quantity of air

Note 1 to entry: The terms Lambda and air factor are also used to describe this ratio.

3.6.6

Wobbe index

Gross Wobbe index W ; net Wobbe index W , ratio of the calorific value of a gas per unit volume and the

s i

square root of its relative density under the same reference conditions

Note 1 to entry: The Wobbe index is said to be gross or net according to whether the calorific value used is the gross

or net calorific value.

3.6.7

gas family

group of gaseous fuels with similar burning behaviour, linked together by a range of Wobbe indices

3.6.8

gas group

group of gases with same specified range of Wobbe index

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

4 Safety management

4.1 General

To ensure the safety of an Industrial Installation, the equipment used shall be fit for purpose.

There is a legal requirement for equipment used in European installations to bear a CE mark as required by

the various applicable Directives. A CE mark may not be required in all cases.

It is important to consider at the initial design stage of an installation, the maintenance requirements of

equipment. If it is dangerous, or unacceptable to shut down parts of a plant to carry out maintenance at the

required interval, redundant systems may need to be implemented.

To ensure the safety of the design and its operational suitability it is normal to carry out some form of risk

assessment or HAZOP during the design and prior to commissioning. These should highlight any risk and

operational issues and enable design modifications to be made at an early stage.

Maintenance procedures should be such that the release of a flammable or toxic gas during maintenance

does not lead to a dangerous condition.

4.2 Maintaining records of completed gas work

In the context of Quality Management, it is important that the Technical File, Construction File, Explosion

Protection Document and Conformity File are maintained and updated regularly to match with activities

concerning the industrial gas installation. Here below there is an example scheme.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

Figure 1 — Flow chart for maintaining records

4.3 The technical file

Technical files should be generated that contain some or all of the following:

— operators manual containing the equipment specification and operational procedures;

— service and maintenance manual;

— declarations stating compliance with the required European Directives, i.e. GAD, PED, ATEX, LVD, EMC,

Machinery Directive etc.;

— information related to lifetime of parts used in the equipment where failure may lead to danger e.g. seals,

diaphragms, flexible pipes;

— details of all settings of safety devices and controls upon completion of commissioning. Includes control

safeguards (leak tightness check, gas valve closed position proving, maximum gas pressure, minimum

gas pressure, combustion air pressure/flow, maximum medium temperature, maximum medium pressure,

minimum medium level, flame detection and E.S.D. (Emergency Shut Down));

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

— details of as commissioned combustion settings such as composition of the flue gas (O , CO , CO and

2 2

NO ), flue gas temperatures;

x

— if necessary, a maintenance schedule for the equipment.

4.4 The construction file

The user should ensure that a Construction File is available and that it contains the following information (with

parts lists where appropriate):

— type of pressure equipment, phase condition and physical properties;

— design pressure(s) PS, temperature(s) maximum and minimum and nominal size diameter;

— conformity assessment, declaration of conformity;

— welders qualification (EN 15001);

— specification and qualification of welding procedures (EN 15001);

— specification and approval of welding procedures for metallic materials (EN 15001);

— non-destructive testing (EN 15001).

4.5 The explosion protection document

The user should ensure that an Explosion Protection Document is available in order to comply with ATEX

User Directive and that it contains the following information:

— risk assessment;

— list of hazard sources;

— zone classification of hazardous areas;

— technical and organisational measures taken;

— drawings with hazard sources and classified zones;

— operational procedures to maintain safety.

4.6 The declaration of conformity file

Where necessary, the user should ensure that a declaration of Conformity File is available and that it contains

the following information:

— Gas pipe line:

— examination of joints;

— verification of materials and components;

— the route and construction of pipework;

— the correct use of safety markings and signs;

— verification of corrosion protecting measurements;

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

— test results (non-destructive tests, strength test, leakage test and visual inspection); and

— Inspection report(s) with the above mentioned check and tests.

— Thermal process equipment / industrial appliances:

— boiler/furnace location (setting, combustion air intake, flue gas exhaust);

— setting of pressure regulator and safety devices;

— CE-marking burner and installation and there specifications;

— start-up sequence (purge-/ventilation time, ignition time, opening safety shut-off valves and flame

detection);

— safety times (safety time main/pilot burners, reaction time flame detection, closing time safety shut-off

valves main burners);

— execute measurements on various burner loads (e.g. minimum, maximum and two in between)

measuring gas flow, gas supply pressure, gas pressure after reduction, burner pressure, combustion

air pressure/flow; medium quantity (temperature, pressure), composition of the flue gas (O , CO , CO

2 2

and NO ); and

x

— inspection report(s) with the above mentioned check and tests.

5 Gas composition and characteristics

5.1 Properties of gases

5.1.1 Natural gas

Natural gas is a mixture of light hydrocarbons including methane (>70 %), ethane, propane, butane and

pentanes and other compounds including CO and nitrogen.

Natural gas is neither corrosive, nor toxic, its ignition temperature is high, and it has a narrow flammability

range, making it an inherently safe compared to other fossil fuel sources.

In addition, because of its specifics gravity lower than that of air, natural gas rises if escaping, thus dissipating

upwards from the site of the leak.

The specific characteristics of the natural gas being delivered to the gas consumer are available within the gas

industry.

5.1.2 LPG

This normally covers commercial Butane or commercial Propane. Both of these gases may be mixtures with

other gases. For propane this may typically be 85 %+ Propane, up to 10 % Propylene/Propane, 5 % to 7 %

Isobutene, 5 % to 7 % Ethane and up to 5 % Butane. The specific characteristics of the gas being delivered

should be available from the supplier.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

5.1.3 Non-conventional gases

5.1.3.1 Bio gas

5.1.3.1.1 Basic definitions

Bio gas is a methane rich gas with a balance of carbon dioxide produced by bacteria in anaerobic (air-free)

conditions.

For most purposes it can be divided into two categories, anaerobic digestion type and land-fill type.

The anaerobic digestion type gas is generated from organic waste which is suspended in water in an air free

chamber so that there is no oxygen present in the resulting gas.

Bio-gas is normally a product of a microbiological degradation processes. The primary sources of bio-gas for

many years have been from waste treatment systems utilizing anaerobic digesters or solid waste landfills.

Both of these waste treatment systems rely upon anaerobic bacteria to convert organic matter to methane

(CH ) 60 %–70 % and carbon dioxide (CO ) 30 %–40 %. The major differences between these processes are

4 2

that landfill sites are established over a period of years rather than days. Anaerobic digesters are typically

used for treating biological sludges, manures, and other high solids wastes.

From a safety perspective, however produced, one has to remember that Bio-gases can be odour free.

Most systems generate a methane based gas with levels varying between say about 40 % and 90 %. Typical

biogas has a distinctive odour but not as pungent as natural gas odours. Since its specific gravity varies it

should be treated for safety as a gas that can rise or fall in air. This means ventilation shall be considered for

both heavy and light gases at the same time. Equally the location of flammable gas detectors may be

preferred at low rather than high levels.

Landfill gas, when not utilized as a fuel, is usually flared at high temperatures – a process that destroys most

of the toxic and odorous components. Passive venting of landfill gas to atmosphere is no longer acceptable.

At all landfill sites, some landfill gas will escape to atmosphere through the surface and lining of the site. The

percentage of fugitive gas escaping will depend primarily on the collection efficiency on-site, the design of the

lining, the capping of the site and the volume of gas generated.

Table 1 — A typical gas is produced from a woodchip fuelled bio-mass gasifier (pyrolisis)

Constituent %

Hydrogen H 16

Methane CH 3,3

Ethane C H 0,7

2 6

Propane C H 0,4

3 8

Butane C H trace

4 10

Pentane C H trace

5 12

Hexane C H trace

6 14

Carbon Monoxide CO 20,8

Carbon Dioxide CO 11,4

Nitrogen N 45,8

Bio-mass gasification processes generate organic contaminants in the exit gases that are generally referred to

as tar. Before use of the gases in a boiler, engine or turbine, particulate matter and the organic tar shall be

removed, or reduced to a level that is acceptable to end user requirements.

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

One of the most significant hurdles leading to the development and subsequent scale up of bio-mass

gasification is gas cleaning for particulate and organic contaminant removal prior to use in boilers and

particularly power generation plant such as engines and turbine applications.

Bio-gas from anaerobic digesters can be upgraded to bio-methane and injected into a gas grid. This can be

the national high pressure gas transmission grid or a local low pressure gas distribution network. To be used

in the gas grid, the bio-gas needs to be cleaned of impurities, dried and upgraded to a higher methane content

(about 95 %) so that it resembles the qualities of natural gas. This approach is already being used in many

countries including Germany, France, Austria and the USA.

Some of the fuels may also contain sulphur that can lead to acid corrosion in the flues and appliances. Some

landfill may contain compounds of silicon (as a white powder in the exhaust system) that can be carcinogenic.

Anaerobic digesters can produce a wet and dusty gas even after filtration and drying.

5.1.3.1.2 Materials

If the gas has been sulphur stripped and properly dried conventional steel pipework can be used otherwise a

basic stainless steel or PE materials should be considered.

5.1.3.2 Carbon monoxide rich gases

5.1.3.2.1 Blast furnace gas and coke oven gas

Blast furnace gas (BFG) and coke oven gas (COG) are by-products of thermal processes operated in steel

industry. BFG is generated when the iron ore is reduced with coke to metallic iron in blast furnaces. COG is

produced by the process of converting coal into coke.

Both are gaseous fuels used locally to supply different thermal equipment such as steam boilers, reheating

furnaces or coke ovens. Because of its very low heating value, BFG is often combined with more calorific fuels

(natural gas, COG) and sometimes directly flared by torch burners.

However when its combustion temperature is increased by preheating or by burning with O , then its utilization

is widened.

Typical compositions (dry gas) and main characteristics of BFG and COG are given in the following table:

kSIST-TP FprCEN/TR 16787:2014

FprCEN/TR 16787:2014 (E)

Table 2 — Typical compositions (dry gas) and main characteristics of BFG and COG

BFG COG

Carbon monoxide 18 – 22 % 4 – 8 %

Hydrogen 2 – 4 % 50 – 60 %

Methane < 1 % 20 – 30 %

Ethane and other C H Trace < 2 %

n m

Carbon dioxide 20 – 24 % < 3 %

Nitrogen 50 – 60 % 3 – 10 %

NCV (MJ/Nm ) 2,7 – 3,3 15,5 – 17,5

Relative density Approx. 1,06 0,3 – 0,4

Wobbe Index (MJ/Nm ) 2,6 – 3,2 26 – 30

a 259,4 44,7

FCO2 (tCO /TJ)

a

CO emission factor: reference values given in the guidelines of the Directive 2003/87/EC. To

be compared to reference value for natural gas (56,1 tCO /TJ)

5.1.3.2.2 Pyrolysis

Some installations use thermo-chemical processes such as pyrolysis as a means to convert the waste to a

gas, similar to the old gas works. This gas can have totally different compositions to those generated by

anaerobic means. Pyrolysis is thermal decomposition occurring in the absence of oxygen, a bit like a charcoal

production plant.

Gasifiers are usually used to produce the gas rather than anaerobic digesters. More recently gas has been

produced from waste such as woodchips or solid waste materials which produce hydrogen and carbon

monoxide rich gases with only small quantities of methane. Hydrogen is very high flame speed gas and CO is

potentially very dangerous. It has explosive/flammable limits that are wider than for a methane based gas,

about 3 % to 30 % gas in air. The very high level of inert gases (CO and N ) has a significant effect on the

2 2

performance of all gas fired plant as they delay ignition and slow down the flame speed to a great extent

causing flames to be far longer than normal.

5.1.4 Town gas (not widely available in Europe)

Town gas (also “coal gas” or “manufactured gas”), typically made by the destructi

...

SLOVENSKI STANDARD

01-marec-2015

Industrijska plinska napeljava - Smernica

Industrial Gas Installation - Guideline

Industrielle Gasinstallationen - Leitlinien

Installation gaz dans le domaine industriel - Lignes directrices

Ta slovenski standard je istoveten z: CEN/TR 16787:2014

ICS:

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/TR 16787

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

November 2014

ICS 23.040.01; 91.140.40

English Version

Industrial Gas Installation - Guideline

Installation gaz dans le domaine industriel - Lignes Industrielle Gasinstallationen - Leitlinien

directrices

This Technical Report was approved by CEN on 3 December 2014. It has been drawn up by the Technical Committee CEN/SS B25.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2014 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 16787:2014 E

worldwide for CEN national Members.

Contents Page

Foreword .4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .6

3.1 General terms .6

3.2 Definitions relating to jointing methods .9

3.3 Definitions relating to components . 10

3.4 Definitions relating to tests . 11

3.5 Definitions relating to assembly processes for metallic materials . 11

3.6 Definitions relating to pressure regulating and metering . 12

4 Safety management . 13

4.1 General . 13

4.2 Maintaining records of completed gas work . 13

4.3 The technical file . 14

4.4 The construction file . 15

4.5 The explosion protection document . 15

4.6 The declaration of conformity file . 15

5 Gas composition and characteristics . 16

5.1 Properties of gases. 16

5.1.1 Natural gas . 16

5.1.2 LPG . 16

5.1.3 Non-conventional gases . 17

5.1.4 Town gas (not widely available in Europe) . 19

5.2 The Wobbe index and non combustion parameters . 20

5.2.1 Wobbe index . 20

5.2.2 Non – combustion parameters . 21

5.3 Industrial thermal processing equipment versus variations of gas composition . 22

5.4 Industrial thermal processing equipment – environmental considerations . 23

6 Environment . 24

7 Installation pipework . 25

8 Industrial thermal equipment installations . 25

9 Inspections . 25

10 General safety issues . 25

Annex A (informative) Controlling air and gas flow rates versus energy content to the gas

equipment . 27

A.1 Principles for the measurement of air and gas flows . 27

A.1.1 General . 27

A.1.2 Diaphragm meters . 27

A.1.3 Orifice plate systems . 27

A.1.4 Turbine meters . 28

A.1.5 Rotating piston meters (roots) . 28

A.1.6 Vortex flow meters . 29

A.1.7 Ultrasonic flow meter . 29

A.1.8 Mass flow meters . 29

A.2 Flow calculation . 30

A.3 Control energy content . 30

A.4 Flow metering and meter performance . 31

Annex B (informative) Industrial thermal processing equipment . 33

B.1 Sensitivity of gas engines and gas turbines . 33

B.2 Sensitivity of some industrial thermal processes . 33

Annex C (informative) Reverse flow of gases . 36

Annex D (informative) Industrial thermal processing equipment and Environmental issues . 37

Annex E (informative) National implementation . 38

E.1 General/introduction . 38

E.2 Safety and health of workers at work regulations . 38

E.3 Specifications from utilities and gas suppliers . 38

E.4 Protection of buildings and equipment against fire . 38

Annex F (informative) European Directives . 40

F.1 EU Safety Directives . 40

F.1.1 General . 40

F.1.2 Safety European Directives concerning products . 40

F.1.3 Safety European Directives concerning general public and workers . 42

F.1.4 Introduction to Directives . 43

F.1.5 Synthesis of Directives . 44

F.2 Environment EU Directives for industrial end-users . 46

F.2.1 General . 46

F.2.2 Emissions Trading Scheme ETS . 46

F.2.3 Measures to reduce emissions (CO , CO, NO , CH ) . 47

2 x 4

F.2.4 Industrial Emissions Directive (IED) . 47

Annex G (informative) Natural gas overview . 48

Annex H (informative) National data . 50

Bibliography . 53

Foreword

This document (CEN/TR 16787:2014) has been prepared by CEN Sector Forum Gas.

Introduction

Gas industry leaders acknowledge the strategic role of European and National Standards in their efforts to

ensure the safety of gas installations in industrial premises. This Technical Report has been prepared to

explain to those involved with industrial premises some of the relevance of a range of Directives that affect

their operations. In addition guidance is given on the terms and definitions widely in use throughout the

European Union, together with some important information on how a consumer of gas can ensure safety in

operating their site. Minimizing the adverse effects on the environment is also an important consideration.

European and National legislation and the related framework of standards are complex and changing at an

ever increasing pace. For industrial plant engineers, finding the relevant standards can be a difficult task,

demands specific knowledge, and can consume a considerable amount of time. A number of the principal

standards are highlighted in this Technical Report, but EU Member States may have similar or equivalent

standards covering the application. Additionally, member states may have slightly different legal systems and

requirements that demand compliance.

Both designers and installers play an important role in applying the current standards for design, construction,

testing, commissioning and operation of all industrial gas installations. Safety is therefore improved and the

full energy efficiency potential of industrial thermal processes can be utilized.

It is recognized that the main reference is this Technical Report is to Natural Gas but many standards equally

apply directly to LPG and LPG/Air mixtures. This Technical Report is also applicable to many bio-gases, and

other flammable gases, and the user will need to ensure they are aware of any different requirements needed

to ensure safety. For example some gases may be very hot or corrosive, some may be ‘wet’ and others may

contain significant quantities of toxic gases such as carbon monoxide. Hydrogen rich gases may also require

special attention to material selection.

Finally, due to the complexities and special needs of some types of process plant, it may be necessary to

adopt higher standards of safety and to use risk assessments to ensure reliable judgements on plant safety.

In applying the recommendations contained within this Technical Report it is important that the relevant

requirements of national guidance standards and legislation are considered.

In some cases where a lack of information is available in a member state, guidance from other member states

or by other recognized national bodies such as ASME or API may be used.

The range of industrial thermal process and heating equipment providing energy solutions to customers for a

diverse range of applications is significant.

1 Scope

This Technical Report applies to safety and operational topics for equipment and pipework systems installed

within industrial premises which may be used for process and non-process applications such as Heating,

Power Generation, Incineration, etc.

It is applicable to a range of combustible gases used within an industrial environment. The gas plant may

include normal combustion with air and/or oxygen, catalytic oxidation or cracking (e.g. as in a refinery).

The user of gas equipment and pipework systems has a responsibility to ensure the safety of the design, of

plant operation and plant maintenance.

For piped supplies of gas to a site this Technical Report applies to the system downstream of the ‘point of

delivery’. The term, ‘point of delivery’ refers to the isolation valve (or combination of regulator and isolation

valve) located before or after the metering station, as will be defined by the particular EU member state

national legislation.

The guidance in this Technical Report may also apply to gases generated for the sites own use, such as coke

oven gas, site bio-gas plant, site LPG/air plant etc.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 1775, Gas supply ― Gas pipework for buildings ― Maximum operating pressure less than or equal to 5

bar - Functional recommendations

EN 15001-1, Gas Infrastructure ― Gas installation pipework with an operating pressure greater than 0,5 bar

for industrial installations and greater than 5 bar for industrial and non-industrial installations ― Part 1:

Detailed functional requirements for design, materials, construction, inspection and testing

EN 15001-2, Gas infrastructure ― Gas installation pipework with an operating pressure greater than 0,5 bar

for industrial installations and greater than 5 bar for industrial and non-industrial installations ― Part 2:

Detailed functional requirements for commissioning, operation and maintenance

EN ISO 6976, Natural gas ― Calculation of calorific values, density, relative density and Wobbe index from

composition (ISO 6976)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE These terms and definitions are given for information as they are widely used in the gas industry.

3.1 General terms

3.1.1

air gas ratio

ratio between the flow of combustion air and the flow of the fuel gas

Note 1 to entry: Sometimes fuel/air ratio is used. It can either be expressed in terms of volume or mass flows.

3.1.2

air factor

ratio between the actual flow of combustion air and the stoichiometric flow of combustion air

Note 1 to entry: It can be expressed in terms of volume or mass flows.

3.1.3

components

any item from which a gas supply system or installation is constructed

Note 1 to entry: A distinction is drawn between the following groups of components:

— ancillaries (for example; pressure regulators, valves, safety devices, expansion joints, and insulating joints);

— pipes, including bends made from pipe;

— instrumentation pipework;

— fittings (for example; reducers, tees, factory-made elbows, flanges, dome ends, welding stubs, and mechanical

joints).

3.1.4

flexible appliance connector

fitting of flexible pipe to be fitted between the end of fixed pipework and the appliance inlet connection

3.1.5

gas appliances

appliances burning gaseous fuels used for cooking, heating, hot water production, refrigeration, lighting or

washing and having, where applicable, a normal water temperature not exceeding 105 °C, except those

specifically designed for use in industrial processes carried out on industrial premises

3.1.6

HAZOP

hazard and operability study (HAZOP) is a structured and systematic examination of a planned or existing

process or operation in order to identify and evaluate problems that may represent risks to personnel or

equipment, or prevent efficient operation

3.1.7

industrial appliances

appliances burning gaseous fuels installed in industrial premises and are subject to specific national health

and safety regulations

3.1.8

pressure

gauge pressure of the fluid inside the system, measured in static conditions

3.1.9

design pressure

DP

pressure at which the design calculations are based

Note 1 to entry: This is equivalent to the maximum allowable pressure (PS) as given in the PED.

3.1.10

maximum allowable pressure

PS

maximum pressure for which pipework is designed in accordance with the strength requirements

3.1.11

maximum incidental pressure

MIP

maximum pressure at which a system can experience during a short time, limited by the safety devices

3.1.12

operating pressure

OP

pressure which occurs within a system under normal operating conditions

3.1.13

maximum operating pressure

MOP

maximum pressure at which a system can be operated continuously under normal operating conditions

Note 1 to entry: Normal operating conditions are: no fault in any device or stream.

3.1.14

tightness test pressure

TTP

pressure applied to a system during tightness testing

3.1.15

strength test pressure

STP

pressure applied to a system during strength testing

3.1.16

combined test pressure

CTP

pressure applied to a system during combined testing

3.1.17

risk assessment

identification, evaluation, and estimation of the levels of risks involved in a situation, their comparison against

benchmarks or standards, and determination of an acceptable level of risk

Note 1 to entry: In this sense Risk is, ‘the likelihood and consequence of a hazard being realized’.

3.1.18

point of delivery

point of transfer of ownership of gas from the supplier to the customer

Note 1 to entry: This can be at a means of isolation or at the meter outlet connection.

Note 2 to entry: This can be isolation valve (or combination of regulator and isolation valve) located before or after the

metering station, as defined by the particular EU member state.

3.1.19

user(s)

person (s) responsible for the safety of the gas installation and associated risks on a site

Note 1 to entry: Normally the user will be the site occupier or owner. It should be assumed that every user has a

responsibility for work performed on their site, whether or not the work is performed directly for the user or not. This does

not mean that they cannot take advice from an independent specialist.

3.1.20

pipework

assembly of pipes and fittings

3.1.21

installation pipework

pipework downstream of the point of delivery terminating at the appliance inlet connection

Note 1 to entry: This pipework is normally the property of the customer.

3.1.22

ventilated space

space where the air is continuously changed by natural or mechanical means

3.1.23

safety zone

area around the pipework from which persons who are not involved in the strength test are excluded during

testing

3.1.24

equipotential bond

means of ensuring that metallic gas pipework and other metallic parts of the building are at the same electrical

potential

Note 1 to entry: For safety reasons, this equipotential bonding is connected to earth.

3.1.25

duct

space specifically designed and constructed for the passage of building services

EXAMPLE Building services include gas pipework, water systems, power and telecommunication cables.

3.1.26

ventilation duct

duct forming part of the structure of the building and intended exclusively for ventilation purposes

3.1.27

means of isolation

device which is intended to interrupt the gas flow in pipework

EXAMPLE Manually operable valve.

3.2 Definitions relating to jointing methods

3.2.1

joint

means of connecting elements of a gas installation

3.2.2

flanged joint

joint in which gas tightness is achieved by compression of a gasket between the faces of two flanges

3.2.3

threaded joint

joint in which gas tightness is achieved by metal-to-metal contact within threads with the assistance of a

sealant

3.2.4

mechanical joint

joint in which gas tightness is achieved by compression, with or without a seal and which can be

disassembled and reassembled

Note 1 to entry: This definition includes twin ferrule type joints.

3.2.5

pressed joint

joint in which tightness is achieved by using a specific tool for either compressing a fitting to form the joint or

expanding a pipe to enable forming the joint

3.2.6

brazed joint

joint formed by brazing

3.2.7

welded joint

joint formed by welding

3.2.8

electro fusion joint

joint formed between polyethylene components using fittings which have an integrated electric heating

element

3.2.9

butt fusion joint

joint formed between polyethylene components where the two pipe ends are heated and brought together to

be fused directly without the use of a separate fitting or filler material

3.2.10

compression joint

type of joint in which gas tightness is achieved by compression within a socket with or without a seal

3.3 Definitions relating to components

3.3.1

regulator

device which reduces the gas pressure to a set value and maintains it within prescribed limits

3.3.2

appliance connection

flexible pipe or length of rigid pipework connecting an appliance’s means of isolation with the appliance inlet

connection

3.3.3

insulating joint

fitting installed to insulate electrically one section of pipework from another

3.3.4

sleeve

protective pipe through which a gas pipe passes

3.3.5

vent pipe

pipework connected to a safety or control device to release gas at a safe location

3.3.6

creep relief valve

device designed to release a limited flow of gas in the event of an unacceptable pressure being detected

within the system it protects

3.3.7

safety slam-shut device

device designed to quickly shut off the gas flow in the event of an unacceptable pressure being detected

within the system it protects. This often referred to an over-pressure or under-pressure shut off device

3.3.8

instrumentation pipework

pipework required for the proper functioning of the ancillaries installed within the pressure regulating

installation

EXAMPLE Sensing, measuring, auxiliary and sampling lines.

3.3.9

DN

alphanumeric designation of size for components of a pipework system, which is used for reference purposes

Note 1 to entry: It comprises the letters DN followed by a dimensionless whole number, which is indirectly related to

the physical size, in millimetres, of the bore or outside diameter of the end connections.

Note 2 to entry: The number following the letters DN does not represent a measurable value and should not be used

for calculation purposes except where specified.

Note 3 to entry: Where DN designation is used, any relationship between DN and component dimensions are given,

e.g. DN/OD or DN/ID.

3.4 Definitions relating to tests

3.4.1

strength test

specific procedure intended to verify that the pipework meets the requirements for mechanical strength

3.4.2

leak-tightness test

specific procedure intended to verify that the pipework meets the requirements for leak-tightness

3.4.3

combined test

specific procedure to verify that the pipework and/or installation meets the requirements for mechanical

strength and leak-tightness

3.4.4

leak detection fluid

specially formulated fluid and foaming product that gives a clear indication that a leak exists when applied to

an element of pipework

3.5 Definitions relating to assembly processes for metallic materials

3.5.1

welding

joining (union) of two or more parts by heat or pressure or a combination of both, (fusion, arc or oxy-

acetylene) such that the materials form a continuity

Note 1 to entry: A filler metal having a melting point similar to that of the materials to be welded can be used.

3.5.2

brazing

operation in which metal parts are joined by means of capillary action of a filler metal in the liquid state with a

melting temperature, higher than 450 °C, lower than that of the parts to be joined and wetting the parent

metal(s), which does not participate in the making of the joint

Note 1 to entry: This is often referred to as hard soldering.

3.5.3

hot tapping

procedure involving the safe use of heat, e.g. welding or fusion, to affix an attachment to a section of pipework

containing gas at pressure

3.6 Definitions relating to pressure regulating and metering

3.6.1

compressors

complete unit for raising the gas pressure within installation pipework above 0,5 bar to an OP greater than

5 bar

3.6.2

station

gas pressure regulating and/or metering system including (where applicable) the housing, the odourisation

facilities and the fenced site

3.6.3

gas pressure regulating and metering system

system comprising all equipment, together with inlet and outlet pipework up to and including the isolating

valves, which together performs the functions of pressure regulation, pressure safety and/or quantitative gas

measurement, whether or not including pressure boosting and/or gas mixing facilities

3.6.4

monitor

second regulator used as a safety device in series with the active regulator which assumes control of the

pressure at a higher set value in the event of the active regulator failing open

3.6.5

excess air ratio (λ)

ratio between the effectively introduced quantity of air and the theoretically required quantity of air

Note 1 to entry: The terms Lambda and air factor are also used to describe this ratio.

3.6.6

Wobbe index

Gross Wobbe index W ; net Wobbe index W , ratio of the calorific value of a gas per unit volume and the

s i

square root of its relative density under the same reference conditions

Note 1 to entry: The Wobbe index is said to be gross or net according to whether the calorific value used is the gross

or net calorific value.

3.6.7

gas family

group of gaseous fuels with similar burning behaviour, linked together by a range of Wobbe indices

3.6.8

gas group

group of gases with same specified range of Wobbe index

4 Safety management

4.1 General

To ensure the safety of an Industrial Installation, the equipment used shall be fit for purpose.

There is a legal requirement for equipment used in European installations to bear a CE mark as required by

the various applicable Directives. A CE mark may not be required in all cases.

It is important to consider at the initial design stage of an installation, the maintenance requirements of

equipment. If it is dangerous, or unacceptable to shut down parts of a plant to carry out maintenance at the

required interval, redundant systems may need to be implemented.

To ensure the safety of the design and its operational suitability it is normal to carry out some form of risk

assessment or HAZOP during the design and prior to commissioning. These should highlight any risk and

operational issues and enable design modifications to be made at an early stage.

Maintenance procedures should be such that the release of a flammable or toxic gas during maintenance

does not lead to a dangerous condition.

4.2 Maintaining records of completed gas work

In the context of Quality Management, it is important that the Technical File, Construction File, Explosion

Protection Document and Conformity File are maintained and updated regularly to match with activities

concerning the industrial gas installation. Here below there is an example scheme.

Figure 1 — Flow chart for maintaining records

4.3 The technical file

Technical files should be generated that contain some or all of the following:

— operators manual containing the equipment specification and operational procedures;

— service and maintenance manual;

— declarations stating compliance with the required European Directives, i.e. GAD, PED, ATEX, LVD, EMC,

Machinery Directive etc.;

— information related to lifetime of parts used in the equipment where failure may lead to danger e.g. seals,

diaphragms, flexible pipes;

— details of all settings of safety devices and controls upon completion of commissioning. Includes control

safeguards (leak tightness check, gas valve closed position proving, maximum gas pressure, minimum

gas pressure, combustion air pressure/flow, maximum medium temperature, maximum medium pressure,

minimum medium level, flame detection and E.S.D. (Emergency Shut Down));

— details of as commissioned combustion settings such as composition of the flue gas (O , CO , CO and

2 2

NO ), flue gas temperatures;

x

— if necessary, a maintenance schedule for the equipment.

4.4 The construction file

The user should ensure that a Construction File is available and that it contains the following information (with

parts lists where appropriate):

— type of pressure equipment, phase condition and physical properties;

— design pressure(s) PS, temperature(s) maximum and minimum and nominal size diameter;

— conformity assessment, declaration of conformity;

— welders qualification (EN 15001);

— specification and qualification of welding procedures (EN 15001);

— specification and approval of welding procedures for metallic materials (EN 15001);

— non-destructive testing (EN 15001).

4.5 The explosion protection document

The user should ensure that an Explosion Protection Document is available in order to comply with ATEX

User Directive and that it contains the following information:

— risk assessment;

— list of hazard sources;

— zone classification of hazardous areas;

— technical and organisational measures taken;

— drawings with hazard sources and classified zones;

— operational procedures to maintain safety.

4.6 The declaration of conformity file

Where necessary, the user should ensure that a declaration of Conformity File is available and that it contains

the following information:

— Gas pipe line:

— examination of joints;

— verification of materials and components;

— the route and construction of pipework;

— the correct use of safety markings and signs;

— verification of corrosion protecting measurements;

— test results (non-destructive tests, strength test, leakage test and visual inspection); and

— Inspection report(s) with the above mentioned check and tests.

— Thermal process equipment / industrial appliances: