ISO 15900:2020

(Main)Determination of particle size distribution — Differential electrical mobility analysis for aerosol particles

Determination of particle size distribution — Differential electrical mobility analysis for aerosol particles

This document provides guidelines and requirements for the determination of aerosol particle number size distribution by means of the analysis of electrical mobility of aerosol particles. This measurement is usually called "differential electrical mobility analysis for aerosol particles". This analytical method is applicable to particle size measurements ranging from approximately 1 nm to 1 µm. This document does not address the specific instrument design or the specific requirements of particle size distribution measurements for different applications but includes the calculation method of uncertainty. In this document, the complete system for carrying out differential electrical mobility analysis is referred to as DMAS (differential mobility analysing system), while the element within this system that classifies the particles according to their electrical mobility is referred to as DEMC (differential electrical mobility classifier). NOTE This document does not include technical requirements and specifications for the application of DMAS, which are defined in application specific standards or guidelines, e.g. for road vehicle applications (ISO/TC 22), environmental measurements (ISO/TC 146) or nanotechnologies (ISO/TC 229).

Détermination de la distribution granulométrique — Analyse de mobilité électrique différentielle pour les particules d'aérosol

General Information

- Status

- Published

- Publication Date

- 19-Oct-2020

- Technical Committee

- ISO/TC 24/SC 4 - Particle characterization

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Referred By

EN ISO 16571:2024 - Systems for evacuation of plume generated by medical devices (ISO 16571:2024) - Effective Date

- 09-Feb-2026

- Effective Date

- 11-Oct-2014

Overview

ISO 15900:2020 - Determination of particle size distribution - Differential electrical mobility analysis for aerosol particles - defines guidelines and requirements for measuring aerosol particle number size distribution using electrical mobility analysis. Commonly called differential electrical mobility analysis, the standard covers measurement systems (DMAS) and the mobility classifier element (DEMC) for particle sizes from approximately 1 nm to 1 µm. ISO 15900:2020 (second edition) refines calibration, uncertainty calculation and best practice compared with the 2009 edition. It does not specify instrument design or application‑specific technical limits, which are addressed by other ISO technical committees.

Key topics

- Measurement principle: relationship between electrical mobility and particle size; classification with a DEMC and measurement/inversion of raw data.

- System terminology: definitions for DMAS (differential mobility analysing system) and DEMC (differential electrical mobility classifier).

- Transfer functions and charge distributions: transfer function of the DEMC and charge distribution functions for bipolar/unipolar conditioners.

- Particle losses and corrections: Brownian diffusion losses, slip correction, and effects of non‑spherical particles.

- Size range considerations: guidance and good practices for measuring particles below 10 nm.

- System components and setup: pre‑conditioners, charge conditioners, DEMC, particle detectors (e.g., CPC), data acquisition and controller requirements.

- Measurement procedures: setup, pre‑measurement checks, flow/voltage/temperature/pressure considerations, data acquisition and maintenance.

- Calibration and tests: periodic tests (zero tests, flow and voltage checks), dynamic and static particle size calibration procedures, size resolution and number concentration calibration.

- Uncertainty and traceability: calculation methods for measurement uncertainty and traceability diagrams for DEMC/DMAS.

- Informative annexes: data inversion, slip correction, cylindrical DEMC, detector information, example calibration certificates, and good practice examples.

Applications and users

ISO 15900:2020 is intended for laboratories, instrument manufacturers, calibration and testing facilities, and researchers involved in:

- Aerosol science and instrumentation

- Environmental air monitoring and particulate research

- Nanotechnology particle characterization

- Automotive exhaust and on‑road particle measurements (used with application standards)

- Occupational hygiene and regulated emissions testing

Users will apply ISO 15900 to establish robust DMAS measurement procedures, perform calibrations, assess uncertainty, and document traceable particle size distributions.

Related standards

- Application‑specific requirements and test methods are provided by relevant ISO technical committees, e.g.:

- ISO/TC 22 (road vehicle testing)

- ISO/TC 146 (environmental measurements)

- ISO/TC 229 (nanotechnologies)

- ISO 15900:2020 supersedes ISO 15900:2009 (first edition).

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

ISO 15900:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Determination of particle size distribution — Differential electrical mobility analysis for aerosol particles". This standard covers: This document provides guidelines and requirements for the determination of aerosol particle number size distribution by means of the analysis of electrical mobility of aerosol particles. This measurement is usually called "differential electrical mobility analysis for aerosol particles". This analytical method is applicable to particle size measurements ranging from approximately 1 nm to 1 µm. This document does not address the specific instrument design or the specific requirements of particle size distribution measurements for different applications but includes the calculation method of uncertainty. In this document, the complete system for carrying out differential electrical mobility analysis is referred to as DMAS (differential mobility analysing system), while the element within this system that classifies the particles according to their electrical mobility is referred to as DEMC (differential electrical mobility classifier). NOTE This document does not include technical requirements and specifications for the application of DMAS, which are defined in application specific standards or guidelines, e.g. for road vehicle applications (ISO/TC 22), environmental measurements (ISO/TC 146) or nanotechnologies (ISO/TC 229).

This document provides guidelines and requirements for the determination of aerosol particle number size distribution by means of the analysis of electrical mobility of aerosol particles. This measurement is usually called "differential electrical mobility analysis for aerosol particles". This analytical method is applicable to particle size measurements ranging from approximately 1 nm to 1 µm. This document does not address the specific instrument design or the specific requirements of particle size distribution measurements for different applications but includes the calculation method of uncertainty. In this document, the complete system for carrying out differential electrical mobility analysis is referred to as DMAS (differential mobility analysing system), while the element within this system that classifies the particles according to their electrical mobility is referred to as DEMC (differential electrical mobility classifier). NOTE This document does not include technical requirements and specifications for the application of DMAS, which are defined in application specific standards or guidelines, e.g. for road vehicle applications (ISO/TC 22), environmental measurements (ISO/TC 146) or nanotechnologies (ISO/TC 229).

ISO 15900:2020 is classified under the following ICS (International Classification for Standards) categories: 19.120 - Particle size analysis. Sieving. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15900:2020 has the following relationships with other standards: It is inter standard links to EN ISO 16571:2024, ISO 15900:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15900:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15900

Second edition

2020-10

Determination of particle size

distribution — Differential electrical

mobility analysis for aerosol particles

Détermination de la distribution granulométrique — Analyse de

mobilité électrique différentielle pour les particules d'aérosol

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

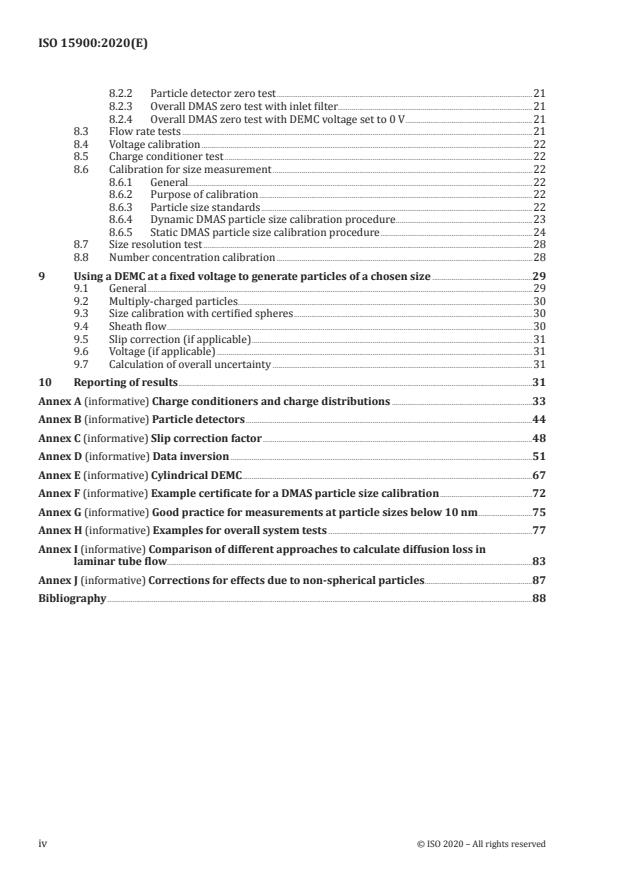

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 4

5 General principle . 5

5.1 Particle size classification with the DEMC . 5

5.2 Relationship between electrical mobility and particle size . 6

5.3 Measurement and data inversion . 7

5.4 Transfer function of the DEMC . 8

5.5 Charge distribution function . 9

5.5.1 General. 9

5.5.2 Charge distribution function for radioactive bipolar charge conditioners . 9

5.5.3 Charge distribution functions for other bipolar and unipolar charge

conditioners .10

5.6 Particle losses in the DMAS .11

5.7 Effects due to non-spherical particles.11

5.8 Measurement of particle sizes below 10 nm .11

5.9 Traceability of measurement results .11

6 System and apparatus .13

6.1 General configuration .13

6.2 Components .14

6.2.1 Pre-conditioner .14

6.2.2 Charge conditioner .14

6.2.3 DEMC .15

6.2.4 Aerosol particle detector .15

6.2.5 System controller, data acquisition and analysis .15

7 Measurement procedures .16

7.1 Setup and preparation of the instrument .16

7.1.1 General.16

7.1.2 Aerosol pre-conditioning: Adapting the aerosol to be measured to the

requirements of the DMAS .16

7.1.3 Aerosol pre-conditioning: Separation of large particles .16

7.1.4 Charge conditioning .17

7.1.5 DEMC: Flows .17

7.1.6 DEMC: Voltage .18

7.1.7 DEMC: Temperature and pressure .18

7.1.8 Particle detection: CPC . . .18

7.1.9 Particle detection: FCAE .18

7.1.10 Data acquisition .18

7.2 Pre-measurement checks.18

7.2.1 General.18

7.2.2 Overall DMAS check .19

7.2.3 Data acquisition check .19

7.3 Measurement .19

7.4 Maintenance .19

8 Periodic tests and calibrations .20

8.1 Overview .20

8.2 Zero tests .21

8.2.1 General.21

8.2.2 Particle detector zero test .21

8.2.3 Overall DMAS zero test with inlet filter .21

8.2.4 Overall DMAS zero test with DEMC voltage set to 0 V .21

8.3 Flow rate tests .21

8.4 Voltage calibration .22

8.5 Charge conditioner test .22

8.6 Calibration for size measurement .22

8.6.1 General.22

8.6.2 Purpose of calibration .22

8.6.3 Particle size standards .22

8.6.4 Dynamic DMAS particle size calibration procedure .23

8.6.5 Static DMAS particle size calibration procedure .24

8.7 Size resolution test .28

8.8 Number concentration calibration .28

9 Using a DEMC at a fixed voltage to generate particles of a chosen size .29

9.1 General .29

9.2 Multiply-charged particles .30

9.3 Size calibration with certified spheres .30

9.4 Sheath flow .30

9.5 Slip correction (if applicable) .31

9.6 Voltage (if applicable) .31

9.7 Calculation of overall uncertainty .31

10 Reporting of results .31

Annex A (informative) Charge conditioners and charge distributions .33

Annex B (informative) Particle detectors .44

Annex C (informative) Slip correction factor .48

Annex D (informative) Data inversion .51

Annex E (informative) Cylindrical DEMC .67

Annex F (informative) Example certificate for a DMAS particle size calibration .72

Annex G (informative) Good practice for measurements at particle sizes below 10 nm .75

Annex H (informative) Examples for overall system tests .77

Annex I (informative) Comparison of different approaches to calculate diffusion loss in

laminar tube flow.83

Annex J (informative) Corrections for effects due to non-spherical particles.87

Bibliography .88

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 24, Particle characterization including

sieving, Subcommittee SC 4, Particle characterization.

This second edition cancels and replaces the first edition (ISO 15900:2009), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— subclauses on particle losses due to Brownian diffusion, effects due to non-spherical particles, and

measurement of particles below 10 nm have been added in Clause 5;

— traceability diagrams for DEMC and DMAS have been added in Clause 5;

— calibration for size measurement in Clause 8 has been refined;

— Clause 9 for “Using a DEMC at a fixed voltage to generate particles of a chosen size” has been added;

— Annex D for “Data inversion” has been rewritten completely;

— Annex F for “Example certificate for a DMAS particle size calibration” has been added;

— former Annex G for “Uncertainty” in the previous edition has been deleted;

— new Annex G for “Good practice for measurements at particle sizes below 10 nm” has been added;

— Annex H for “Examples for overall system tests” has been added;

— Annex I for “Comparison of different approaches to calculate diffusion loss in laminar tube flow” has

been added;

— Annex J for “Corrections for effects due to non-spherical particles” has been added.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

Introduction

Differential electrical mobility classification and analysis of airborne particles has been widely used

to measure a variety of aerosol particles ranging from nanometre-size to micrometre-size in the gas

phase. In addition, the electrical mobility classification of charged particles can be used to generate

mono-disperse particles of known size for calibration of other instruments. One notable feature of these

techniques is that they are based on simple physical principles. The techniques have become important

in many fields of aerosol science and technology, e.g. aerosol instrumentation, production of materials

from aerosols, contamination control in the semiconductor industry, atmospheric aerosol science,

characterization of engineered nanoparticles, and so on. However, in order to use electrical mobility

classification and analysis correctly, several issues, such as the slip correction factor, the ion-aerosol

attachment coefficients, the size-dependent charge distribution on aerosol particles and the method

used for inversion of the measured mobility distribution to the aerosol particle size distribution, need

due caution.

There is, therefore, a need to establish an International Standard for the use of differential electrical

mobility analysis for classifying aerosol particles. Its purpose is to provide a methodology for adequate

quality control in particle size and number concentration measurement with this method.

vi © ISO 2020 – All rights reserved

INTERNATIONAL STANDARD ISO 15900:2020(E)

Determination of particle size distribution — Differential

electrical mobility analysis for aerosol particles

1 Scope

This document provides guidelines and requirements for the determination of aerosol particle number

size distribution by means of the analysis of electrical mobility of aerosol particles. This measurement

is usually called “differential electrical mobility analysis for aerosol particles”. This analytical method

is applicable to particle size measurements ranging from approximately 1 nm to 1 µm. This document

does not address the specific instrument design or the specific requirements of particle size distribution

measurements for different applications but includes the calculation method of uncertainty. In this

document, the complete system for carrying out differential electrical mobility analysis is referred to as

DMAS (differential mobility analysing system), while the element within this system that classifies the

particles according to their electrical mobility is referred to as DEMC (differential electrical mobility

classifier).

NOTE This document does not include technical requirements and specifications for the application of DMAS,

which are defined in application specific standards or guidelines, e.g. for road vehicle applications (ISO/TC 22),

environmental measurements (ISO/TC 146) or nanotechnologies (ISO/TC 229).

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

aerosol

system of solid and/or liquid particles suspended in gas

3.2

attachment coefficient

attachment probability of ions and aerosol particles

3.3

bipolar charging

process which attains a conditioned charge distribution of both positive and negative charges on

aerosol particles

3.4

bipolar charge conditioner

device which attains a conditioned charge distribution of both positive and negative charges on aerosol

particles

3.5

charging

processes that leave aerosol particles with size dependent specific distributions of unipolar or bipolar

electrical charges

3.6

charge conditioner

device (or component of a DMAS) which establishes a known conditioned size dependent charge

distribution on aerosol particles which are passed through it

3.7

charge distribution function

mathematical and/or empirical description of a conditioned particle size dependent charge distribution

3.8

condensation particle counter

CPC

instrument that measures the particle number concentration of an aerosol

Note 1 to entry: The sizes of particles detected are usually smaller than several hundred nanometres and larger

than a few nanometres.

Note 2 to entry: A CPC is one possible detector for use with a DEMC.

Note 3 to entry: In some cases, a condensation particle counter may be called a condensation nucleus counter (CNC).

3.9

conditioned charge distribution

distribution of unipolar or bipolar electrical charges on aerosol particles defined by a charge

distribution function, which is in a steady state for a sufficiently long period of time in an aerosol

instrument downstream of a unipolar or bipolar charge conditioner

3.10

critical mobility

instrument parameter of a DEMC (3.11) that defines the electrical mobility of aerosol particles that exit

the DEMC in aerosol form, which may be defined by the geometry, sample and sheath flow rates, and

electrical field intensity

Note 1 to entry: Particles larger or smaller than the critical mobility migrate to an electrode or exit with the

excess flow and do not exit from the DEMC in aerosol form.

3.11

differential electrical mobility classifier

DEMC

classifier able to select aerosol particles according to their electrical mobility and pass them to its exit

Note 1 to entry: A DEMC classifies aerosol particles by balancing the electrical force on each particle with its

aerodynamic drag force in an electrical field. Classified particles are in a narrow range of electrical mobility

determined by the operating conditions and physical dimensions of the DEMC, while they can have different sizes

due to difference in the number of charges that they have.

Note 2 to entry: Another common acronym for the DEMC is DMA.

3.12

differential mobility analysing system

DMAS

system to measure the size distribution of submicrometre aerosol particles consisting of a charge

conditioner, a DEMC, flow meters, a particle detector, interconnecting plumbing, a computer and

suitable software

Note 1 to entry: Another common acronym for the DMAS is MPSS (mobility particle size spectrometer).

2 © ISO 2020 – All rights reserved

3.13

electrical mobility

ratio of migration velocity (3.18) to electrical field for particles and ions in a gas

3.14

equivalent diameter

d

diameter of a sphere with defined characteristics which behaves under defined conditions in exactly

the same way as the particle being described

Note 1 to entry: Particle diameter (or simply diameter) used throughout this document always refers to the

electrical mobility equivalent diameter, which defines the size of charged particles with the same electrical

mobility or the same terminal migration velocity in still air under the influence of a constant electrical field.

3.15

Faraday cup aerosol electrometer

FCAE

electrometer designed for the measurement of electrical charge concentration carried by an aerosol

Note 1 to entry: A Faraday cup aerosol electrometer consists of an electrically conducting and electrically grounded

cup as a guard to cover the sensing element that includes aerosol filtering media to capture charged aerosol

particles, an electrical connection between the sensing element and an electrometer circuit, and a flow meter. An

FCAE measures electrical current ranging from about one femtoampere (fA) to about ten picoamperes (pA).

3.16

Knudsen number

Kn

ratio of gas molecular mean free path to the radius of the particle, which is an indicator of free molecular

flow versus continuum gas flow

3.17

laminar flow

gas flow with no temporally or spatially irregular activity or turbulent eddy flow

3.18

migration velocity

steady-state velocity of a charged airborne particle within an externally applied electric field

3.19

particle diameter

electrical mobility equivalent diameter

Note 1 to entry: Also, just called diameter.

3.20

plateau detection efficiency

mean detection efficiency of a CPC in the size range which is not biased by particle size

[SOURCE: ISO 27891:2015, 3.27, modified — term “plateau efficiency” has been changed to "plateau

detection efficiency.]

3.21

Reynolds number

Re

dimensionless number expressed as the ratio of the inertial force to the viscous force

Note 1 to entry: For example, applied to an aerosol particle or a tube carrying aerosol particles

3.22

slip correction

S

C

dimensionless factor used to correct the drag force acting on a particle for non-continuum effects that

become important when the particle size is comparable to or smaller than the mean free path of the gas

molecules

3.23

Stokes's drag

drag force acting on a particle that is moving relative to a continuum fluid in the creeping flow limit

(low Reynolds number)

3.24

transfer function

ratio of particle concentration at the outlet of a DEMC to the particle concentration at the inlet of the DEMC

Note 1 to entry: It is normally expressed as a function of electrical mobility.

3.25

unipolar charge conditioner

device which attains a conditioned charge distribution of either positive or negative charges on aerosol

particles

3.26

unipolar charging

process which attains a conditioned charge distribution of positive or negative charges on aerosol

particles

4 Symbols

For the purposes of this document, the following symbols apply.

Symbol Quantity SI Unit

A, B, C elements of the slip correction factor defined in Formula (2) dimensionless

−1

c thermal velocity of an ion or molecule m s

2 −1

D diffusion coefficient m s

d aerosol particle diameter m

−1

E electric field strength in a DEMC V m

−19

e elementary charge = 1,602 176 634 × 10 C

Kn Knudsen number (dimensionless)

−23 −1

k Boltzmann constant = 1,380 649 × 10 J K

effective active length of a DEMC, approximated by the axial distance be-

L tween the midpoint of the aerosol entrance and the midpoint of the exit slit m

of a cylindrical DEMC

L length of a tube m

Tube

M molecular mass of air amu

m mass of an ion amu

−3

N number concentration of aerosol particles, note that C is widely used as well. m

N

23 –1

N Avogadro constant = 6,022 140 76 × 10 mol

A

−3

N number concentration of ions m

I

P atmospheric pressure Pa

p number of elementary charges on a particle (dimensionless)

3 −1

q , q , q , q flow rates of air (or gas) and of aerosol entering and exiting a DEMC m s

1 2 3 4

3 −1

Q aerosol air flow rate m s

a

4 © ISO 2020 – All rights reserved

Symbol Quantity SI Unit

r outer radius of inner cylinder of a cylindrical DEMC m

r inner radius of outer cylinder of a cylindrical DEMC m

Re Reynolds number (dimensionless)

S Sutherland constant (=110,4 K at 23 °C and standard atmospheric pressure)

S slip correction (dimensionless)

C

T absolute temperature K

t residence time of an ion s

U DC voltage used to establish an electrical field in a DEMC V

V volume m

2 −1 −1

Z electrical mobility m V s

2 −1 −1

Z , Z , Z , Z critical electrical mobilities that describe the transfer function of a DEMC m V s

1 2 3 4

3 −1

β attachment coefficient of ions onto aerosol particles m s

γ recombination coefficient of ions (dimensionless)

δ radius of a limiting sphere m

ε relative error

−1 −1

μ coefficient of dynamic viscosity of a gas kg m s

gas

λ mean free path m

−3

ρ mass density kg m

5 General principle

5.1 Particle size classification with the DEMC

The measurement of particle size distributions with a DMAS is based on particle classification by

electrical mobility in a DEMC. The DEMC may be designed in many different ways; for example, coaxial

cylindrical DEMC, radial DEMC, parallel plate DEMC, etc. The coaxial cylindrical DEMC shown in

Figure 1 is an example of a widely used design. It consists of two coaxial, cylindrical electrodes with

two inlets. One inlet (marked q in Figure 1) is for filtered clean sheath air. The other inlet (marked q )

1 2

is for the sample aerosol.

The sample aerosol, some of whose particles are electrically charged, enters the DEMC as a thin annular

cylinder around a core of filtered, particle-free sheath air. By applying a voltage, an electric field is

created between the inner and outer electrodes. A charged particle in the presence of an electric field

will migrate within the field and reach a terminal migration velocity when the fluid dynamic drag on

the particle balances the driving force of the electric field. Charged particles of the correct polarity

within the sample aerosol begin to drift across the sheath air flow towards the inner electrode. At the

same time, the clean sheath air flow carries the charged airborne particles downward. A small fraction

of the charged particles enters the thin circumferential slit near the bottom of the centre electrode and

is carried by the air flow to the detector (in the direction marked q ). By varying the voltage, particles

of different electrical mobility are selected. The remaining (not extracted) air flow leaves the DEMC as

excess flow (q ).

When used within a DMAS, measurements of relevant parameters such as voltage, flow and their

timings need to be combined with other measurements such as the output from the particle detector.

These parameters are usually controlled using a system controller as shown in Figure 5.

Key

q sheath flow a Trajectory of particles trapped in the DEMC due to high electrical

mobility.

q sample aerosol flow b Trajectory of particles leaving the DEMC with q .

2 3

q mobility selected aerosol flow c Trajectory of particles trapped in the DEMC due to low electrical

mobility.

q excess flow

Figure 1 — Schematic diagram of coaxial cylindrical DEMC

5.2 Relationship between electrical mobility and particle size

The electrical mobility of a particle depends on its size and its electric charge. The relationship between

electrical mobility and particle size for spherical particles can be described by Formula (1):

pe

Zd(), p = S (1)

C

3πμ d

gas

The slip correction, S , extends the Stokes's drag force on a spherical particle moving with low Reynolds

C

number in a gas phase to nanometre-sized particles. It is approximated by the expression given in

Formula (2):

C

SK=+1 nA+−Bexp (2)

C

Kn

For a detailed discussion of the slip correction, see Annex C.

6 © ISO 2020 – All rights reserved

The dynamic viscosity and the mean free path of gas molecules used within Formulae (1) and (2),

respectively, depend on both the temperature and the pressure of the carrier gas. Formulae (3) and (4)

shall be used to calculate the viscosity and the mean free path for temperatures and pressures different

from the reference temperature and pressure, T and P , specified in Table 1, respectively.

0 0

2 TS+

T

μμ= ⋅⋅ (3)

gasgas,0

T TS+

0

P TS+

T

λλ= ⋅⋅ ⋅ (4)

T P TS+

0

where S, the Sutherland constant, has the value given in Table 1.

Unless explicitly specified differently in the measurement report, Formulae (1) to (4) and the set of

parameters given in Table 1 shall be used for the calculation of the relation between electrical mobility

and particle size in air.

Table 1 — Values of parameters for the calculation of the electrical mobility

[33]

from the particle size in dry air at T = 296,15 K and P = 101,3 kPa

0 0

Parameter Value

−5 −1 −1

µ 1,832 45 × 10 kg m s

gas,0

−8

λ 6,730 × 10 m

S 110,4 K

A 1,165

B 0,483

C 0,997

5.3 Measurement and data inversion

For a given supply voltage, U, the response, R(U), of the particle detector to aerosol particles entering

the DEMC is given by Formula (5), which is called the basic equation for the response of the electrical

mobility measurement:

∞

∞

RU()=qn()dP⋅⋅()df ()dZ⋅ΔΩΦ()()dp,, ()UW⋅ ()dp,dd (5)

∑

2 p

∫

p=1

d=0

For condensation particle counters (CPCs), the response is particle number concentration, while it is

charge concentration for Faraday cup aerosol electrometers (FCAEs).

W(d, p) describes the detector response;

For CPCs, W(d, p) = η (d) q , where η (d) is the size-dependent detection efficiency of

CPC CPC−1 CPC

the CPC and q is the detection flow of the CPC.

CPC

For FCAEs, W(d, p) = p e η (d) q , where p is the number of elementary charges on a

FCAE FCAE−1

particle, e is the elementary charge, η (d) is the size-dependent detection efficiency of the

FCAE

FCAE, and q is the detection flow of the FCAE.

FCAE

n(d ) dd is the number concentration of aerosol particles in the diameter interval dd around d;

P(d) is the penetration which accounts for diffusion losses (see 5.6 and Annex I).

f (d) is the charge distribution function (see 5.5 and Annex A);

p

ΩΦZd ,,pUΔ is the transfer function of the DEMC (see 5.4 and Annex E), which uses the func-

[]() ()

tions Z(d, p) and ΔΦ(U) below as arguments;

Z(d, p) is the electrical mobility of a particle with diameter d carrying p elementary charges (see 5.2);

ΔΦ(U) is a function of the supply voltage and the geometry of the DEMC (see 5.4 and Annex E). For a

cylindrical DEMC, ΔΦ(U) is given in Formula (E.2).

If the transfer function, Ω, the charge distribution function, f (d), and the maximum particle size (see

p

6.2.1) are known, the particle size distributions can be calculated based on the measurements with a

DEMC. An example calculation is given in Annex D.

NOTE 1 Formula (5) applies to the case when the DEMC classifies positively-charged particles, since the range

of the summation is from p = +1 to +∞. For the mode of classifying negatively-charged particles, the range is from

p = −1 to -∞.

NOTE 2 A DEMC can be (electrically) described as a capacitor. ΔΦ(U) can then be linked to the DEMC’s

−12 −1

capacitance, C , where ΔΦ(U) = U·C /(2·π·ε ), ε = 8,854 × 10 F m .

E E 0 0

5.4 Transfer function of the DEMC

The transfer function, Ω, of a DEMC is defined as the probability that an aerosol particle which enters

the DEMC at the aerosol inlet will leave via the detector outlet. It can, mathematically, easily be

described in the mobility regime. Therefore, this approach is taken here. The transfer function depends

on the particle’s electrical mobility, Z, on the four volumetric flow rates, on the geometry of the DEMC

and on the electrical field strength. The influence of the geometry and the electrical field strength on

the transfer function is expressed by ΔΦ, which is a function of the geometry and the variable supply

voltage, U, of the DEMC. For a given supply voltage, ΔΦ is constant.

If particle inertia, gravimetric sedimentation, Brownian motion, space charge and its image forces are

neglected, and if the sheath flow in the DEMC is recirculated (q = q , also resulting in q = q ), the

1 4 2 3

transfer function of a DEMC can be described as an isosceles triangle with the half-width, ΔZ, centred

around the electrical mobility, Z*, as in Figure 2.

When particle diffusion due to Brownian motion is significant, the resolution of the DEMC classification

is reduced, which corresponds to a broader and shorter transfer function.

A detailed discussion of the transfer function for the example of a coaxial cylindrical DEMC can be

found in Annex E.

8 © ISO 2020 – All rights reserved

Key

Z electrical mobility Z* centre electrical mobility of the transfer function

Ω transfer function ΔZ half-width of the transfer function

Figure 2 — Transfer function of a DEMC with sheath flow re-circulation (q = q and q = q )

1 4 2 3

5.5 Charge distribution function

5.5.1 General

As stated in 5.3, the particle size-dependent charge distribution function, f (d), shall be explicitly

p

known to calculate the size distribution of airborne particles classified in a DEMC. A charge conditioner

is used at the entrance of a DEMC to achieve a conditioned charge distribution which is independent of

the initial charge state of the aerosol particles and which is - at least for typical aerosol residence times

in a DEMC - in a steady-state or stable. f (d) may then be given by a set of formulae or tabulated data,

p

approximating the size-dependent charge distribution by theoretical models and/or empirical data.

There are several types of bipolar or unipolar charge conditioners which are described in more detail

in 5.5.2. Bipolar charge conditioners produce positively and negatively charged particles while unipolar

charge conditioners produce particles of one polarity (positive or negative) only.

5.5.2 Charge distribution function for radioactive bipolar charge conditioners

For commercially available radioactive bipolar charge conditioners the charge distribution function

under standard conditions (spherical particles in air (293,15 K, 101,3 kPa) is given by Formula (6)

in combination with the coefficients given in Table 2 and Formula (7) which are derived from an

[50]

approximation (Wiedensohler (1988) to theoretical models in combination with a result from Gunn

[24]

(1956) ).

i

loglfd = ap ⋅ ogd (6)

() () ()

pi∑

i=0

NOTE 1 In Formula (6), d is given in nanometres.

Formula (6) is valid for the size range:

1 nm ≤ d ≤ 1 000 nm for p = {-2, −1, 0, +1, +2}

Table 2 — Coefficients a (p) for Formula (6) for radioactive ion sources

i

a (p)

i

i

p = −2 p = −1 p = 0 p = +1 p = +2

0 −26,332 8 −2,319 7 −0,000 3 −2,348 4 −44,475 6

1 35,904 4 0,617 5 −0,101 4 0,604 4 79,377 2

2 −21,460 8 0,620 1 0,307 3 0,480 0 −62,890 0

3 7,086 7 −0,110 5 −0,337 2 0,001 3 26,449 2

4 −1,308 8 −0,126 0 0,102 3 −0,155 3 −5,748 0

5 0,105 1 0,029 7 −0,010 5 0,032 0 0,504 9

The charge distribution function, f (d), with three or more elementary charge units can be calculated

p

using the following Formula (7), which is based on Gunn's model:

+ +

N Z

2πε dkT

I I

−−p ⋅⋅ln

2 − −

e N Z

e

I I

fd = ⋅exp (7)

()

p

2 2πε dkT

4π ε dkT 0

0 2

e

±

where N is the concentration of positive or negative small ions.

I

For this calculation, the concentration of positive and negative ions is assumed to be equal, and the

+−

ratio of ion mobilities ZZ/ was taken from Wiedensohler (1988) to be 0,875. Results of this

II

calculation are given in Table 3 and in Figure A.1.

NOTE 2 Two coefficients in Wiedensohler (1988) were later corrected. The coefficients in Table 2 contain this

correction.

Table 3 — Bipolar charge distribution function f (d) for spherical particles in air (293,15 K,

p

101,3 kPa), produced by radioactive charge conditioners; see Formulae (6) and (7)

d Charge distribution function

(nm) −6 −5 −4 −3 −2 −1 0 +1 +2 +3 +4 +5 +6

1 0 0 0 0 0 0,004 8 0,999 3 0,004 5 0 0 0 0 0

2 0 0 0 0 0 0,008 3 0,974 2 0,007 5 0 0 0 0 0

5 0 0 0 0 0 0,022 5 0,969 3 0,018 9 0 0 0 0 0

10 0 0 0 0 0 0,051 4 0,912 4 0,041 1 0 0 0 0 0

20 0 0 0 0 0,000 2 0,109 6 0,793 1 0,084 6 0,000 1 0 0 0 0

50 0 0 0 0 0,011 4 0,222 9 0,581 4 0,169 6 0,006 6 0 0 0 0

100 0 0 0,000 1 0,003 7 0,056 1 0,279 3 0,425 9 0,213 8 0,031 7 0,001 7 0 0 0

200 0 0,000 5 0,005 3 0,034 0 0,121 1 0,264 1 0,299 1 0,204 3 0,071 9 0,015 3 0,001 8 0,000 1 0

500 0,006 7 0,020 7 0,050 4 0,098 0 0,149 0 0,181 6 0,181 8 0,140 3 0,089 1 0,044 0 0,017 3 0,005 4 0,001 4

1 000 0,035 7 0,058 4 0,085 4 0,111 3 0,126 1 0,138 5 0,123 5 0,103 9 0,075 4 0,050 0 0,029 3 0,015 4 0,007 2

5.5.3 Charge distribution functions for other bipolar and unipolar charge conditioners

Calculations of the respective charge distribution functions for non-radioactive bipolar and unipolar

charge conditioners are complicated and require careful experimental verification before usage in data

inversion routines for the analysis of measured data. The theoretical concepts described in Annex A

may be helpful for the experienced user to calculate a charge distribution function for a given charge

conditioner.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...