ISO 10406-2:2015

(Main)Fibre-reinforced polymer (FRP) reinforcement of concrete — Test methods — Part 2: FRP sheets

Fibre-reinforced polymer (FRP) reinforcement of concrete — Test methods — Part 2: FRP sheets

ISO 10406-2:2015 specifies test methods applicable to fibre-reinforced polymer (FRP) sheets for the upgrading of concrete members.

Polymère renforcé par des fibres (PRF) pour l'armature du béton — Méthodes d'essai — Partie 2: Feuilles en PRF

General Information

- Status

- Withdrawn

- Publication Date

- 14-Jan-2015

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 13-Nov-2025

- Completion Date

- 12-Feb-2026

Relations

- Consolidated By

ISO 15630-1:2019 - Steel for the reinforcement and prestressing of concrete — Test methods — Part 1: Reinforcing bars, rods and wire - Effective Date

- 06-Jun-2022

- Effective Date

- 06-Jun-2022

- Effective Date

- 02-Mar-2013

Overview

ISO 10406-2:2015, "Fibre-reinforced polymer (FRP) reinforcement of concrete - Test methods - Part 2: FRP sheets", is an international standard that defines laboratory test methods for FRP sheets used in upgrading and strengthening concrete members. Published by ISO (second edition, 2015), it provides vocabulary, symbols, specimen requirements, test procedures, calculation rules and reporting formats to assess mechanical and durability properties of fibre‑reinforced polymer sheets.

Key Topics and Technical Requirements

The standard covers a comprehensive suite of test methods and related provisions, including:

- Terms, definitions and symbols - unified terminology for FRP sheets, bond area, effective bond length, tensile capacity, etc.

- General provisions for test pieces - specimen types, conditioning and preparation rules.

- Tensile properties - procedures to determine tensile strength, ultimate strain and Young’s modulus of FRP sheets.

- Overlap splice strength - methods for measuring splice performance of sheet overlaps used in field joints and repairs.

- Bond properties to concrete - tests to determine bond strength, effective bond length and interfacial fracture energy between FRP sheets and concrete substrates.

- Direct pull‑off strength - pull‑off test methods using steel devices bonded to FRP sheets on concrete.

- Durability and environmental resistance:

- Freeze/thaw resistance tests

- Exposure to laboratory light sources (accelerated UV/weathering)

- General durability test procedures and reporting

- Accuracy, calculation and reporting - rules for expressing results, retention rates after conditioning, and required test report contents.

Normative references cited include ISO 31-0, ISO 291, ISO 4892 series (laboratory light exposure), ISO 5725 (measurement accuracy) and ISO 7500-1 (testing machine verification).

Practical Applications and Who Uses This Standard

ISO 10406-2 is used by:

- Materials testing laboratories for quality control and certification of FRP sheets.

- FRP manufacturers to validate product mechanical properties and durability claims.

- Structural engineers and designers specifying reliable FRP reinforcement for concrete strengthening and retrofit projects.

- Contractors and installers to assess splice/bond requirements and ensure correct application procedures.

- Research & development teams developing new FRP systems or formulations.

- Standards committees and regulators referencing consistent test methods in codes and specifications.

Typical applications include external strengthening of beams, slabs and columns, seismic retrofits, and corrosion‑free reinforcement systems where FRP sheets bond to concrete surfaces.

Related Standards

- ISO 10406-1: FRP bars and grids (companion part for other FRP reinforcement forms)

- ISO 4892 (exposure to laboratory light sources) and ISO 7500-1 (testing machine verification) - both are normatively referenced.

Keywords: ISO 10406-2, FRP sheets, fibre‑reinforced polymer, test methods, tensile strength, bond strength, overlap splice, pull‑off test, durability, concrete strengthening.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Smithers Quality Assessments

US management systems and product certification.

Sponsored listings

Frequently Asked Questions

ISO 10406-2:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fibre-reinforced polymer (FRP) reinforcement of concrete — Test methods — Part 2: FRP sheets". This standard covers: ISO 10406-2:2015 specifies test methods applicable to fibre-reinforced polymer (FRP) sheets for the upgrading of concrete members.

ISO 10406-2:2015 specifies test methods applicable to fibre-reinforced polymer (FRP) sheets for the upgrading of concrete members.

ISO 10406-2:2015 is classified under the following ICS (International Classification for Standards) categories: 83.120 - Reinforced plastics; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10406-2:2015 has the following relationships with other standards: It is inter standard links to ISO 15630-1:2019, ISO 10406-2:2025, ISO 10406-2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 10406-2:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10406-2

Second edition

2015-01-15

Fibre-reinforced polymer (FRP)

reinforcement of concrete — Test

methods —

Part 2:

FRP sheets

Polymère renforcé par des fibres (PRF) pour l’armature du béton —

Méthodes d’essai —

Partie 2: Feuilles en PRF

Reference number

©

ISO 2015

© ISO 2015

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2015 – All rights reserved

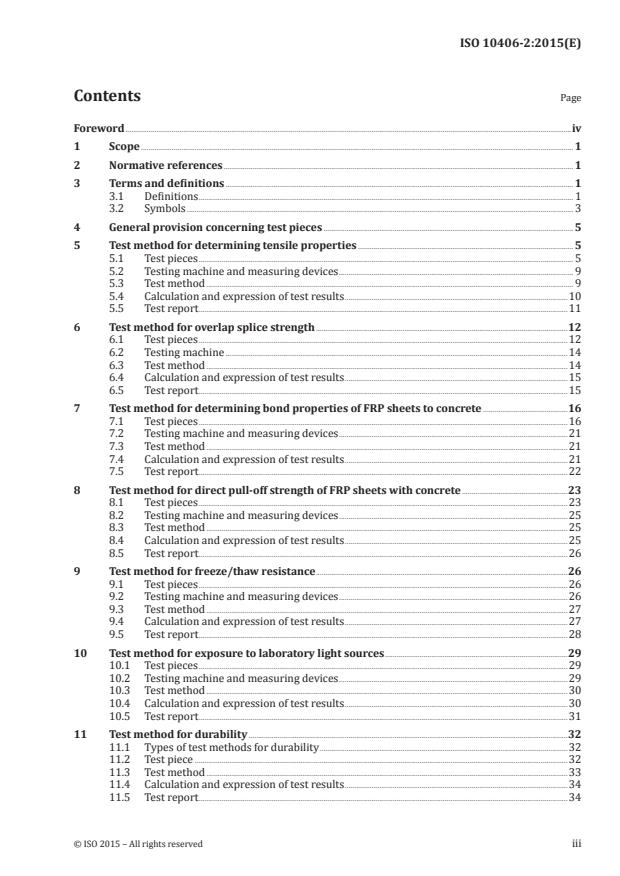

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Definitions . 1

3.2 Symbols . 3

4 General provision concerning test pieces . 5

5 Test method for determining tensile properties . 5

5.1 Test pieces . 5

5.2 Testing machine and measuring devices . 9

5.3 Test method . 9

5.4 Calculation and expression of test results .10

5.5 Test report .11

6 Test method for overlap splice strength .12

6.1 Test pieces .12

6.2 Testing machine .14

6.3 Test method .14

6.4 Calculation and expression of test results .15

6.5 Test report .15

7 Test method for determining bond properties of FRP sheets to concrete .16

7.1 Test pieces .16

7.2 Testing machine and measuring devices .21

7.3 Test method .21

7.4 Calculation and expression of test results .21

7.5 Test report .22

8 Test method for direct pull-off strength of FRP sheets with concrete .23

8.1 Test pieces .23

8.2 Testing machine and measuring devices .25

8.3 Test method .25

8.4 Calculation and expression of test results .25

8.5 Test report .26

9 Test method for freeze/thaw resistance .26

9.1 Test pieces .26

9.2 Testing machine and measuring devices .26

9.3 Test method .27

9.4 Calculation and expression of test results .27

9.5 Test report .28

10 Test method for exposure to laboratory light sources .29

10.1 Test pieces .29

10.2 Testing machine and measuring devices .29

10.3 Test method .30

10.4 Calculation and expression of test results .30

10.5 Test report .31

11 Test method for durability .32

11.1 Types of test methods for durability .32

11.2 Test piece .32

11.3 Test method .33

11.4 Calculation and expression of test results .34

11.5 Test report .34

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT), see the following URL: Foreword — Supplementary information.

The committee responsible for this document is ISO/TC 71, Concrete, reinforced concrete and pre-stressed

concrete, Subcommittee SC 6, Non-traditional reinforcing materials for concrete structures.

This second edition cancels and replaces the second edition (ISO 10406:2008), which has been technically

revised.

ISO 10406 consists of the following parts, under the general title Fibre-reinforced polymer (FRP)

reinforcement of concrete — Test methods:

— Part 1: FRP bars and grids

— Part 2: FRP sheets

iv © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 10406-2:2015(E)

Fibre-reinforced polymer (FRP) reinforcement of

concrete — Test methods —

Part 2:

FRP sheets

1 Scope

This part of ISO 10406 specifies test methods applicable to fibre-reinforced polymer (FRP) sheets for

the upgrading of concrete members.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 31-0:1992, Quantities and units — Part 0: General principles

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 4892 (all parts), Plastics — Methods of exposure to laboratory light sources

ISO 5725 (all parts), Accuracy (trueness and precision) of measurement methods and results

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — Part 1: Tension/compression

testing machines — Verification and calibration of the force-measuring system

3 Terms and definitions

3.1 Definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

accelerated artificial exposure testing machine

machine that creates reproducible standard test conditions to accelerate weathering artificially

3.1.2

ambient temperature

environmental conditions corresponding to the usual atmospheric conditions in laboratories with

uncontrolled temperature and humidity

3.1.3

anchorage block

block corresponding to the test block to prevent bond failure of the FRP sheet

Note 1 to entry: Additional FRP sheet circumferentially jackets the block with sheets being tested to provide

higher bond strength (in this block).

3.1.4

anchoring portion

end parts of a test piece fitted with anchoring devices to transmit loads from the testing machine to the

test portion

3.1.5

bond strength

strength calculated by dividing the maximum load by the effective bond area

3.1.6

concrete block

rectangular block of concrete used to study the bond properties of FRP sheets to concrete

Note 1 to entry: Steel reinforcement or steel bars are embedded in the axial direction at the centre of the cross-

sectional area of the concrete block in order to transmit tensile strength. Concrete blocks are made up of a test

block and an anchorage block.

3.1.7

conditioning

storage of test pieces at a prescribed temperature and humidity to keep them under identical conditions

before testing

3.1.8

coupon test piece

test piece selected from the same lot that is unexposed and subjected to the tensile strength and overlap

splice strength tests

3.1.9

effective bond area

area estimated using the effective bond length and the bond width of the FRP sheet

3.1.10

effective bond length

length of the portion in which the bond stress between the FRP sheet and the concrete acts effectively

at maximum load before the FRP sheet comes loose from the concrete

3.1.11

fibre bundle

several fibre filaments bound together to form a bundle

3.1.12

fibre mass per unit area

mass of fibre in the direction of reinforcement in dry sheet (fibre sheets before impregnation with resin)

Note 1 to entry: Expressed as mass per square metres.

3.1.13

interfacial fracture energy

amount of energy per unit bond area necessary to produce interfacial fracture

3.1.14

overlap splice strength retention rate

ratio of the overlap splice strength after accelerated artificial exposure or freezing/thawing compared

with the overlap splice strength before accelerated artificial exposure or freezing/thawing

Note 1 to entry: The overlap splice strength retention is rate expressed as a percentage.

3.1.15

plate

FRP sheet impregnated with resin from which the test pieces are cut

2 © ISO 2015 – All rights reserved

3.1.16

pull-out strength

strength calculated by dividing the maximum load by the cross-sectional area of the bond surface of the

steel device

3.1.17

steel device

mechanism made of steel connected to a loading machine to apply tensile force

Note 1 to entry: Adhesive is used to mount the device to the FRP sheet attached to the concrete surface. The shape

of the bond surface is either square or circular.

3.1.18

tab

plate made of fibre-reinforced polymer, aluminium, or any other suitable material bonded to the test

piece to transmit loads from the testing machine to the test portion

3.1.19

tensile capacity

maximum tensile load which the test piece bears during the tensile test

3.1.20

tensile strength retention rate

ratio of the tensile strength after accelerated artificial exposure or freezing/thawing compared with

the tensile strength before accelerated artificial exposure or freezing/thawing

Note 1 to entry: The tensile strength retention rate is expressed as a percentage.

3.1.21

test block

block used to study the bond properties of FRP sheets

3.1.22

test portion

part of a test piece that is in between the anchoring portions and is subjected to testing

3.1.23

ultimate strain

strain corresponding to the tensile capacity

3.1.24

weathering

physical and chemical changes of material properties due to exposure to sunlight, rain, snow, and other

outdoor natural conditions

3.2 Symbols

See Table 1.

Table 1 — Symbols

Symbol Unit Description Reference

A mm Nominal cross-sectional area (general) 5.4

A mm Nominal cross-sectional area of type A test piece 5.4, 6.4

A

A mm Nominal cross-sectional area of type B test piece 5.4, 6.4

B

A mm Area of steel device 8.4

s

b mm Average width of FRP sheet 7.4

av

Table 1 (continued)

Symbol Unit Description Reference

b mm Minimum width of test piece 5.4, 6.4

t,min

E N/mm Young’s modulus 5.4, 7.4

f

f N/mm Bond strength 8.4

au

f N/mm Tensile strength 5.4

fu

N/mm Average value for tensile strength before treating, e.g. 9.4, 10.4

f

fu0

freezing and thawing or accelerated artificial exposure

f N/mm Average value for tensile strength after treating, e.g. freez- 9.4, 10.4

fu1

ing and thawing or accelerated artificial exposure

f N/mm Overlap splice strength 6.4

fus

N/mm Average value for overlap splice strength before treating, 9.4, 10.4

f

fus0

e.g. freezing and thawing or accelerated artificial exposure

N/mm Average value for overlap splice strength after treating, 9.4, 10.4

f

fus1

e.g. freezing and thawing or accelerated artificial exposure

F N Maximum load 8.4

au

F N The load included in the last simultaneously recorded pair 5.4.5

last

of values of the load and the strain when determining the

ultimate strain

F N Tensile capacity 5.4, 6.4

u

G N/mm Interfacial fracture energy 7.4

f

L mm Anchoring portion length 5.1.1

A1

L mm Anchorage thickness 5.1.1

A2

L mm Anchorage length 5.1.1

A3

L mm Width at both ends 5.1.1

end

L mm Gauge length 5.1.1

ga

L mm Thickness 5.1.1

th

L mm Total length 5.1.1

tot

l mm Effective bond length in test portion of FRP sheet 7.4

N — Number of fibre bundles in test piece 5.4

t

n — Number of plies of the sheet 7.4

n strands/mm Number of fibre bundles per unit area of the sheet 5.4

u

P N Maximum load 7.4

max

R % Overlap splice strength retention 9.4

ets

R % Tensile strength retention 9.4

ett

−3

t mm 7.4

Thickness of sheet, equal to n·ρρ ×10

Ssh

ΔF N Difference between loads at two points at 20 % and 50 % 5.4

of tensile capacity

ρ g/m Fibre mass per unit area of dry sheet 5.4, 6.4, 7.4

S

ρ g/cm Density of dry sheet 5.4, 6.4, 7.4

sh

ε — The strain included in the last simultaneously recorded 5.4.5

last

pair of values of the load and the strain when determining

the ultimate strain

4 © ISO 2015 – All rights reserved

Table 1 (continued)

Symbol Unit Description Reference

ε — Difference in strain between the two points used to calcu- 5.4.5

fu

late ΔF

Δε

— Ultimate strain 5.4

τ N/mm Bond strength 7.4

u

4 General provision concerning test pieces

Unless otherwise agreed upon, test pieces shall be taken from the sheet in the “as delivered” condition.

For the determination of the mechanical properties in the tensile, bond, and anchorage tests, the

test piece may be artificially aged (after straightening, if applicable) depending on the performance

requirements of the product.

When a test piece is “aged”, the conditions of the ageing treatment shall be stated in the test report.

5 Test method for determining tensile properties

5.1 Test pieces

5.1.1 Types and dimensions

Two types of test pieces may be used (see Figure 1 and Table 2).

a) Type A test pieces: Prepare type A test pieces in accordance with the method described in 6.1.2.1

and use them for the general tension test. The shape and the dimensions of type A test pieces are

given in Figure 1 and Table 2, respectively.

b) Type B test pieces: Prepare type B test pieces in accordance with the method described in 6.1.2.2.

These test pieces are suitable for FRP sheets in which the fibre bundles consist of a number of

filaments that can be easily separated into individual bundles.

L

tot

L

ga

L L

A1 A1

L L

A3 A3

NOTE See Table 2 for definitions of symbols and dimensions.

Figure 1 — Shape of type A and type B test pieces

L L

th end

L

A2

Table 2 — Dimensions of test pieces

Dimensions in millimetres

Dimension for the types of test piece

Symbol

Type A Type B

L total length ≥200

tot

L width at both ends 12,5 ± 0,5 10 to 15

end

L thickness Recommended not to exceed 2,5

th

L gauge length ≥100

ga

L anchoring portion length ≥35

A1

L anchorage thickness 1 to 2

A2

L anchorage length ≥50

A3

NOTE When the peeling off at tabs and the pull-out in the chuck do not occur, the thickness

of the test piece can exceed 2,5 mm. When the thickness of the test piece is less than 2,5 mm

and fracture at anchoring section occurs, the specification of the anchoring section should be

reconsidered.

5.1.2 Preparation

5.1.2.1 Type A test pieces

Type A test pieces shall be prepared using the following method.

a) Prepare a dry sheet cut to a sufficient length for the test piece.

b) Apply the bottom coat of impregnation resin to the separation film and attach the aforementioned

sheet, fastening it so that the fibre axis of the sheet is in a straight line.

c) Apply the top coat of impregnation resin then smooth the surface so that the thickness of the

impregnation resin layer is even, to form a plate. Covering with separation film and smoothing

would be best.

d) Cure the plate for the prescribed duration considering manufacturer’s instructions, then cut in

widths of 12,5 mm as shown in Figure 2. The cut length should be at least 200 mm. Use a diamond

cutter for cutting.

e) Attach the anchorages to the anchorage portions to form the test pieces.

f) Prior to testing, the test pieces shall be conditioned as prescribed in 5.1.5 considering manufacturer’s

instructions.

6 © ISO 2015 – All rights reserved

Dimensions in millimetres

ab

12,5

Key

1 direction of fibre axis

2 section used to prepare test piece: ≥200 (area impregnated with resin)

3 test piece portion

4 cut-away portion

5 marking

a, b

Location of the two straight-line marks perpendicular to the fibre axis that define a length of at least 200 mm.

Figure 2 — Dimensions of plate used to prepare type A test pieces

5.1.2.2 Type B test pieces

Type B test pieces shall be prepared using the following method.

a) Prepare a dry sheet cut to a sufficient length for the test piece. Fasten the sheet so that the fibre axis

is in a straight line.

b) In the centre of the fastened sheet, mark two straight lines (footnotes a and b in Figure 3)

perpendicular to the fibre axis that define a length of at least 200 mm. Mark two other straight lines

(footnotes c and d in Figure 3) approximately 100 mm on either side of the area defined by lines a

and b.

c) Working along the fibre axis between lines c and d, remove one to three fibre bundles from each side

of the test piece sections. The width measures 10 mm to 15 mm. When preparing several test pieces

from the same FRP sheet, the portions to be used as test pieces should be separated by intervals of

at least 50 mm in the direction perpendicular to the fibre axis.

d) Apply the bottom coat of impregnation resin to the separation film and attach the aforementioned

sheet onto the film.

e) Apply the topcoat of impregnation resin. Then smooth the surface, so that the thickness of the

impregnation resin layer is even, to form a plate. Covering with separation film and smoothing

would be best.

f) Cure the plate for the prescribed duration, then cut the fibre bundle portions that are to be the test

pieces at widths of 10 mm to 15 mm. The cut length shall be at least 200 mm.

g) Attach the anchorages to the anchorage portions to form the test pieces.

Dimensions in millimetres

100 3 100

c ab d

10-15 5

6 50

4 4

Key

1 direction of fibre axis

2 area impregnated with resin: ≥400

3 section used to prepare test piece: ≥200

4 marking

5 cut-away portion

6 test piece portion

a, b

Location of the two straight-line marks perpendicular to the fibre axis that define a length of at least 200 mm.

c, d

Location of the two straight-line marks at least 100 mm on either side of lines a and b.

Figure 3 — Dimensions of plate used to prepare type B test pieces

h) Prior to testing, condition the test pieces as prescribed in 5.1.5 considering manufacturer’s

instructions.

A tracer thread may be added to uncured, wet-laid material to help identify the fibre direction and

to somehow specify how accurately the specimens should be cut from the larger piece of material,

specifically with respect to the fibre direction.

5.1.3 Curing of test pieces

Establish the curing period needed to give the test piece the desired strength and cure the test piece

considering manufacturer’s instructions.

5.1.4 Anchorage portion of test pieces

The anchorage portion of the test piece shall not have a shape that causes the test piece to twist or bend.

An anchorage made of fibre-reinforced polymer or aluminium shall be attached to the anchorage portion

using resin or adhesive at a suitable pressure so that the thickness of the adhesive layer is constant. The

adhesive or resin shall ensure that the adhesive layer does not experience shear fracture before the test

piece breaks.

8 © ISO 2015 – All rights reserved

5.1.5 Conditioning of test pieces

The most appropriate condition from ISO 291 shall be selected, unless otherwise agreed upon by the

interested parties. If it is confirmed by prior tests under equivalence conditions at the testing room that

humidity has a negligible or no influence on the properties, it is not necessary to control the relative

humidity. Similarly, if it is confirmed by prior tests under equivalence conditions at the testing room

that neither temperature nor humidity has any noticeable influence on the properties, it is not necessary

to control either the temperature or the relative humidity. In this case, the atmospheric condition is

termed “ambient temperature”.

5.1.6 Number of test pieces

Determine the number of test pieces suitable for the objective of the test. It shall be no fewer than five.

5.2 Testing machine and measuring devices

5.2.1 Testing machine

The testing machine shall conform to ISO 7500-1. The testing machine shall have a loading capacity in

excess of the tensile capacity of the test piece and shall be capable of applying loading at the required

loading rate.

5.2.2 Strain gauges/extensometers

Strain gauges/extensometers used to measure the elongation of the test piece under loading should

be capable of recording all variations in the gauge length or elongation during testing with a strain

−6

measurement accuracy of at least 10 × 10 .

5.3 Test method

5.3.1 Dimensions of test pieces

Measure the width and thickness of the test portion of the test pieces as follows. The width and thickness

of the test piece shall be determined as the average of at least three readings taking from different

locations on the test specimen. Measurements shall be taken to the following precision:

a) test pieces of type A shall be measured to 0,01 mm;

b) test pieces of type B shall be measured to 0,1 mm.

5.3.2 Mounting of strain gauges/extensometers

Mount the strain gauges/extensometers at the centre of the test portion of the test piece in order to

determine the Young’s modulus and the ultimate strain of the test piece.

5.3.3 Mounting of test piece

Mount the test piece in such a way that the long axis of the test piece coincides with the centreline

between the two chucks.

5.3.4 Loading rate

The standard loading rate shall be a constant strain rate equivalent to 1 %/min to 3 %/min strain.

5.3.5 Test temperature

In principle, conduct the test in the same atmosphere used for conditioning the test piece, unless

otherwise agreed upon by the interested parties (e.g. for testing at elevated or low temperatures).

5.3.6 Range of test

Perform the loading test until tensile failure and record the measurements of load and strain continuously

or at regular intervals at least up to two thirds of the tensile capacity.

5.4 Calculation and expression of test results

5.4.1 General

Use only results from those pieces that undergo failure in the test portion. Reject the test results from

those pieces that show tensile failure or slippage at the anchorage portion and carry out additional tests

using test pieces from the same lot until the number of test pieces having failed in the test portion is not

less than the prescribed number.

5.4.2 Load-strain curve

When strain gauges/extensometers are mounted, plot a load-strain curve depicting the relationship

between the measured load and strain.

5.4.3 Tensile strength

Calculate the tensile strength, f , expressed in newtons per square millimetre and rounded off to three

fu

significant digits in accordance with ISO 31-0:1992, Annex B, using Formula (1):

F

u

f = (1)

fu

A

where

F is the tensile capacity, expressed in newtons;

u

A is the nominal cross-sectional area of the test piece, expressed in square millimetres.

Calculate the cross-sectional area, A , expressed in square millimetres, of the type A test piece using

A

Formula (2) and the cross-sectional area, A , expressed in square millimetres, of the type B test piece

B

using Formula (3):

ρ

−3

S

Ab=⋅ ×10 (2)

A t,min

ρ

sh

ρ N

S t −3

A =⋅ ×10 (3)

B

ρ n

sh u

where

ρ is the fibre mass per unit area of dry sheet, expressed in grams per square metres;

S

ρ is the density of dry sheet, expressed in grams per cubic centimetres;

sh

b is the minimum width of the test piece, expressed in millimetres;

t,min

N is the number of fibre bundles in the test piece;

t

n is the number of fibre bundles per unit area of the sheet, expressed in strands per millime-

u

tre.

NOTE 1 The nominal fibre mass per unit area provided by the material manufacturer can be used.

10 © ISO 2015 – All rights reserved

NOTE 2 The nominal density provided by the material manufacturer can be used.

5.4.4 Young’s modulus

Calculate the Young’s modulus, E , using Formula (4) based on the load-strain curve at 20 % and 50 %

f

tensile capacity and rounded off to three significant digits in accordance with ISO 5725 (all parts).

ΔF

E = (4)

f

Δε ⋅A

where

∆F is the difference between loads at two points at 20 % and 50 % tensile capacity, expressed in

newtons;

∆ε is the difference in strain between the two points above;

A is the nominal cross-sectional area, expressed in square millimetres, calculated as A , using

A

Formula (2), for a type A test piece and as A , using Formula (3), for a type B test piece.

B

5.4.5 Ultimate strain

In cases where strain-gauge measurements of the test piece are available up to the point of failure,

take the ultimate strain, ε , as the strain corresponding to the tensile capacity, F . In cases where the

fu u

measurements are not made up to the point of failure, calculate the ultimate strain, ε , using Formula (5),

fu

based on the tensile capacity, F , and the last simultaneously recorded values of the load, F , and

u last

strain, ε :

last

F

u

εε=⋅ (5)

fu last

F

last

Round off the results to three significant digits in accordance with ISO 5725 (all parts).

5.5 Test report

The test report shall include the following items:

a) name of FRP sheet, date of manufacture, lot number of production run, and name of manufacturer;

b) type of FRP sheet and impregnation resin;

c) fibre mass per unit area of dry sheet and density of dry sheet;

d) fabrication date, fabrication method, and curing conditions (including temperature and duration)

for test pieces;

e) temperature, humidity, and duration of test piece conditioning;

f) test date, test temperature, and loading rate;

g) dimensions of each test piece and calculated cross-sectional area;

h) tensile capacity of each test piece and average and, if required, the standard deviation for these

values;

i) tensile strength of each test piece and average and, if required, the standard deviation for these

values;

j) Young’s modulus of each test piece and average and, if required, the standard deviation for these

values;

k) ultimate strain of each test piece and average and, if required, the standard deviation for these

values;

l) load-strain curve for each test piece.

6 Test method for overlap splice strength

6.1 Test pieces

6.1.1 Dimensions

The shape and the dimensions of the overlap splice test piece are shown in Figure 4 and Table 3,

respectively. The method of preparing test pieces is described in 6.1.2.

NOTE Test piece corresponding to the Type A test piece in Clause 5 is specified in this part of ISO 10406. Type

B test piece is not specified because of difficulties of making test piece to keep axial direction of fibres linear in

two FRP sheets.

L

tot

L

ga

L

L SPI L

A1 A1

L L

A3 A3

NOTE See Table 3 for definitions of symbols and dimensions.

Figure 4 — Shape of test pieces

Table 3 — Dimensions of test pieces

Dimensions in millimetres

Symbol Dimension

L total length Length of splice plus a minimum of 200

tot

L width at both ends 12,5 ± 2,5

end

L thickness Recommended not to exceed 2,5

th

L gauge length Length of splice plus a minimum of 100

ga

L anchoring portion length ≥35

A1

L anchorage thickness 1 to 2

A2

L anchorage length ≥50

A3

L length of splice portion Necessary length

spl

NOTE When the peeling off at tabs and the pull-out in the chuck do not occur, the thickness

of the test piece can exceed 2,5 mm. When the thickness of the test piece is less than 2,5 mm

and fracture at anchoring section occurs, the specification of the anchoring section is to be

reconsidered.

12 © ISO 2015 – All rights reserved

L

L

end

th

L

A2

6.1.2 Preparation

As a rule, prepare test pieces using the same materials as those in the actual work and under constant

temperature conditions as follows, taking sufficient care to ensure that the fibres are not dispersed or

bent in the overlap splice portion.

a) Prepare a dry sheet cut to a sufficient length for the dimensions of the test piece to be fabricated.

b) Apply the bottom coat of impregnation resin to the separation film and attach the sheet mentioned

in a), fasten it so that the fibre axis of the sheet is in a straight line.

c) Overlap two sheets so that the prescribed length of the overlap splice portion is secured.

d) Apply the top coat of impregnation resin. Smooth the surface. The thickness of the impregnation

resin layer should be even to form a plate. Covering with separation film is best.

e) Cure the plate for the prescribed duration considering manufacturer’s instructions, then cut in

widths of 12,5 mm as shown in Figure 5. The cut length should be at least 200 mm. Use a diamond

cutter.

f) Attach the anchorage to the anchorage portion to form the test piece.

g) Before performing the test, condition the test piece as prescribed.

Dimensions in millimetres

a b

12,5

Key

1 direction of fibre axis

2 section used to prepare test piece: ≥200 (area impregnated with resin)

3 test piece portion

4 cut-away portion

5 marking

6 overlap splice section

a, b

Location of the two straight-line marks perpendicular to the fibre axis that define a length of at least 200 mm.

Figure 5 — Dimensions of plate used to make test pieces

6.1.3 Curing of test pieces

Establish the curing period for the test piece to have the desired strength and cure the test piece

considering the manufacturer’s instructions.

6.1.4 Anchorage portion of test pieces

The anchorage portion of the test piece shall not have a shape that causes the test piece to twist or bend.

Attach an anchorage made of fibre-reinforced plastic or aluminium to the anchorage portion using resin

or adhesive at a suitable pressure so that the thickness of the adhesive layer is constant. Ensure that the

adhesive or resin in the adhesive layer does not experience shear fracture before the test piece breaks.

6.1.5 Conditioning of test pieces

Select the most appropriate condition from ISO 291, unless otherwise agreed upon by the interested

parties. If it is confirmed by prior tests under equivalence conditions at the testing room that humidity

has a negligible or no influence on the properties, it is not necessary to control the relative humidity.

Similarly, if it is confirmed by prior tests under equivalence conditions at the testing room that neither

temperature nor humidity has any noticeable influence on the properties, it is not necessary to control

either the temperature or the relative humidity. In this case, the atmospheric condition is termed

“ambient temperature”.

6.1.6 Number of test pieces

Determine the number of test pieces suitable for the objective of the test. It shall be no fewer than five.

6.2 Testing machine

The testing machine shall conform to ISO 7500-1. The testing machine shall have a loading capacity in

excess of the tensile capacity of the test piece and shall be capable of applying loading at the required

loading rate.

6.3 Test method

6.3.1 Dimensions of test pieces

Measure the width and thickness of the test portion of the test pieces to 0,01 mm at four locations

outside the overlap splice portion and two locations within the overlap splice portion.

6.3.2 Mounting the test piece

Mount the test piece so that the long axis of the test piece coincides with the centre line between the two

chucks.

6.3.3 Loading rate

The standard loading rate shall be a fixed strain rate equivalent to 1 %/min to 3 %/min strain.

6.3.4 Test temperature

In principle, conduct the test in the same atmosphere used for conditioning the test piece, unless

otherwise agreed upon by the interested parties (e.g. for testing at elevated or low temperatures).

6.3.5 Range of test

Perform the loading test to the point of tensile failure and measure and record the load continuously or

at regular intervals until the tensile capacity is reached.

14 © ISO 2015 – All rights reserved

6.4 Calculation and expression of test results

6.4.1 General

Assess the test data only on the basis of the test pieces undergoing failure in the test portion. In cases

where tensile failure or slippage has clearly taken place at the anchorage portion, disregard the data and

perform additional tests using test pieces from the same lot until the number of test pieces failing in the

test portion is not less than the prescribed number.

6.4.2 Failure categories

Table 4 shows the types of overlap splice failure. Shear fracture of the impregnation resin within the

overlap splice portion is called “overlap splice failure”. Failure of the FRP sheet in parts of the test portion

other than the overlap splice portion is called “base material failure”.

Table 4 — Categories of overlap-splice failure

Code Type of failure

JF Overlap splice failure

SF Base material failure

6.4.3 Overlap-splice strength

Calculate the overlap-splice strength, f , expressed in newtons per square millimetre and rounded off

fus

to three significant digits, using Formula (6) in accordance with ISO 31-0:1992, Annex B:

F

u

f = (6)

fus

A

where

F is the tensile capacity, expressed in newtons;

u

A is the nominal cross-sectional area, expressed in square millimetres, using Formula (7).

ρ

S −3

Ab=×· 10 (7)

t,min

ρ

sh

where

ρ is the fibre mass per unit area of dry sheet, expressed in grams per square metres;

S

ρ is the density of dry sheet, expressed in grams per cubic centimetres;

sh

b is the minimum width of test portion of the test piece, expressed in millimetres.

t,min

6.5 Test report

The test report shall include the following:

a) name of FRP sheet, date of manufacture, lot number of production run, and name of manufacturer;

b) type of FRP sheet and impregnation resin;

c) fibre mass per unit area of dry sheet and density of dry sheet;

d) fabrication date, fabrication method, and curing conditions (including temperature and duration)

for test pieces;

e) temperature, humidity, and duration of test piece conditioning;

f) test date, test temperature, and loading rate;

g) dimensions of each test piece and calculated cross-sectional area;

h) length of overlap splice for each test piece;

i) tensile capacity of each test piece and average and, if required, standard deviation for these values;

j) tensile strength of each test piece and average and, if required, standard deviation for these values;

k) failure type for each test piece.

7 Test method for determining bond properties of FRP sheets to concrete

7.1 Test pieces

7.1.1 Types and dimensions

a) Type A test pieces: Type A test pieces shall consist of two separate concrete blocks manufactured in

accordance with the method described in 7.1.4.2 a). The shape and the dimensions of a type A test

specimen are shown in Figure 6 and Table 5, respectively.

b) Type B test pieces: Type B test pieces shall consist of a single concrete block manufactured in

accordance with the method described in 7.1.4.2 b). The shape and the dimensions of a type B test

specimen are shown in Figure 7 and Table 5, respectively.

16 © ISO 2015 – All rights reserved

Dimensions in millimetres

b

≥ 200

≥ 200

a

≥ 300

≥ 300

Key

1 anchoring block

2 tensile load

3 separation-type film

4 test block

5 FRP sheet

6 abutted surface

7 anchoring sheet

a

Beveled.

b

Bond length.

Figure 6 — Shape of a type A test piece

Table 5 — Dimensions of test pieces

Dimensions in millimetres

Type of test piece

Element

Type A (separate block type) Type B (single block type)

Length of block ≥300 ≥600

Cross-sectional area of

100 × 100

the block

a

Bond length

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...