IWA 15:2015

(Main)Specification and method for the determination of performance of automated liquid handling systems

Specification and method for the determination of performance of automated liquid handling systems

IWA 15:2015 specifies methods for testing the volumetric performance of air-displacement, system-liquid filled and positive displacement automated liquid handling systems (ALHS), including an estimation of measurement uncertainties and established traceability to reference standards (preferably, traceability to SI Units). The testing methods specified in this document may also be used to measure the volumetric performance of automated liquid delivery systems which do not aspirate the test liquid. IWA 15:2015 also specifies statistical methods for the determination of random and systematic errors (including intra-plate and inter-plate comparisons), analysis of measured results when using multichannel dispensing heads, and analysis depending on dispense patterns. It further defines terms and formulae to be used for summarizing test results. IWA 15:2015 also specifies the information to be provided to users of ALHS, including the display of summary results and performance claims. IWA 15:2015 is applicable to all ALHS with complete, installed liquid handling devices, including tips and other essential parts needed for delivering a specified volume, which perform liquid handling tasks without human intervention into microplates. Manipulation of the microplates on the deck of the automated liquid handling system may be achieved automatically, semi-automatically, or manually. IWA 15:2015 addresses the needs of: - suppliers of ALHS, as a basis for quality control including, where appropriate, the issuance of supplier's declarations; - test houses and other bodies, as a basis for independent certification and calibration; - users of the equipment, to enable calibration, verification, validation, and routine testing of trueness and precision. The tests established in this IWA should be carried out by trained personnel.

Spécification et méthode pour la détermination de performance des systèmes automatisés de manipulation de liquides

General Information

- Status

- Withdrawn

- Publication Date

- 14-Oct-2015

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 11-Aug-2022

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 23-Apr-2020

- Revised

ISO 23783-1:2022 - Automated liquid handling systems — Part 1: Vocabulary and general requirements - Effective Date

- 23-Apr-2020

- Effective Date

- 23-Apr-2020

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

IWA 15:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Specification and method for the determination of performance of automated liquid handling systems". This standard covers: IWA 15:2015 specifies methods for testing the volumetric performance of air-displacement, system-liquid filled and positive displacement automated liquid handling systems (ALHS), including an estimation of measurement uncertainties and established traceability to reference standards (preferably, traceability to SI Units). The testing methods specified in this document may also be used to measure the volumetric performance of automated liquid delivery systems which do not aspirate the test liquid. IWA 15:2015 also specifies statistical methods for the determination of random and systematic errors (including intra-plate and inter-plate comparisons), analysis of measured results when using multichannel dispensing heads, and analysis depending on dispense patterns. It further defines terms and formulae to be used for summarizing test results. IWA 15:2015 also specifies the information to be provided to users of ALHS, including the display of summary results and performance claims. IWA 15:2015 is applicable to all ALHS with complete, installed liquid handling devices, including tips and other essential parts needed for delivering a specified volume, which perform liquid handling tasks without human intervention into microplates. Manipulation of the microplates on the deck of the automated liquid handling system may be achieved automatically, semi-automatically, or manually. IWA 15:2015 addresses the needs of: - suppliers of ALHS, as a basis for quality control including, where appropriate, the issuance of supplier's declarations; - test houses and other bodies, as a basis for independent certification and calibration; - users of the equipment, to enable calibration, verification, validation, and routine testing of trueness and precision. The tests established in this IWA should be carried out by trained personnel.

IWA 15:2015 specifies methods for testing the volumetric performance of air-displacement, system-liquid filled and positive displacement automated liquid handling systems (ALHS), including an estimation of measurement uncertainties and established traceability to reference standards (preferably, traceability to SI Units). The testing methods specified in this document may also be used to measure the volumetric performance of automated liquid delivery systems which do not aspirate the test liquid. IWA 15:2015 also specifies statistical methods for the determination of random and systematic errors (including intra-plate and inter-plate comparisons), analysis of measured results when using multichannel dispensing heads, and analysis depending on dispense patterns. It further defines terms and formulae to be used for summarizing test results. IWA 15:2015 also specifies the information to be provided to users of ALHS, including the display of summary results and performance claims. IWA 15:2015 is applicable to all ALHS with complete, installed liquid handling devices, including tips and other essential parts needed for delivering a specified volume, which perform liquid handling tasks without human intervention into microplates. Manipulation of the microplates on the deck of the automated liquid handling system may be achieved automatically, semi-automatically, or manually. IWA 15:2015 addresses the needs of: - suppliers of ALHS, as a basis for quality control including, where appropriate, the issuance of supplier's declarations; - test houses and other bodies, as a basis for independent certification and calibration; - users of the equipment, to enable calibration, verification, validation, and routine testing of trueness and precision. The tests established in this IWA should be carried out by trained personnel.

IWA 15:2015 is classified under the following ICS (International Classification for Standards) categories: 71.040.20 - Laboratory ware and related apparatus. The ICS classification helps identify the subject area and facilitates finding related standards.

IWA 15:2015 has the following relationships with other standards: It is inter standard links to ISO 23783-3:2022, ISO 23783-1:2022, ISO 23783-2:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IWA 15:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IWA

WORKSHOP 15

AGREEMENT

First edition

2015-10-15

Specification and method for the

determination of performance of

automated liquid handling systems

Spécification et méthode pour la détermination de performance des

systèmes automatisés de manipulation de liquides

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

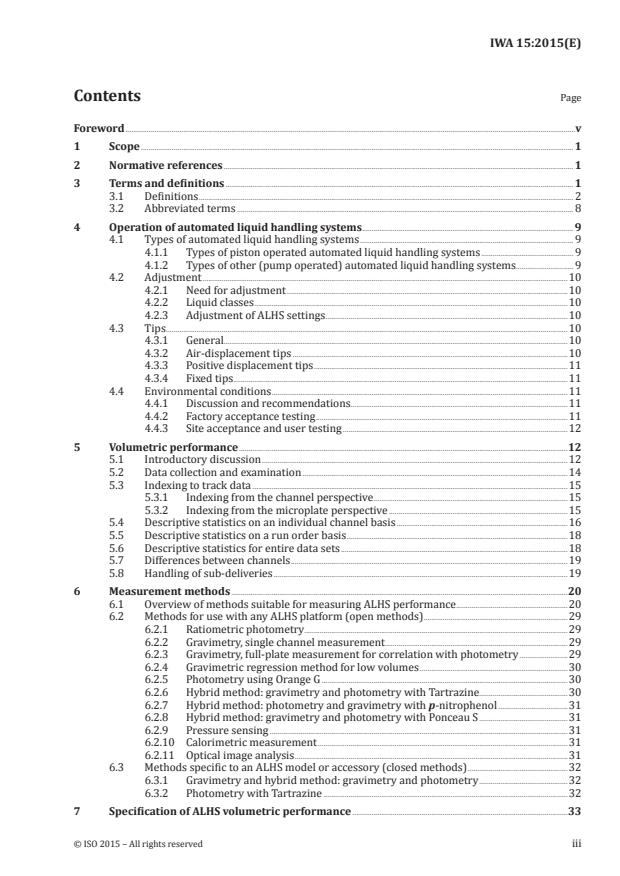

Contents Page

Foreword .v

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

3.1 Definitions . 2

3.2 Abbreviated terms . 8

4 Operation of automated liquid handling systems .9

4.1 Types of automated liquid handling systems . 9

4.1.1 Types of piston operated automated liquid handling systems . 9

4.1.2 Types of other (pump operated) automated liquid handling systems. 9

4.2 Adjustment .10

4.2.1 Need for adjustment .10

4.2.2 Liquid classes .10

4.2.3 Adjustment of ALHS settings .10

4.3 Tips .10

4.3.1 General.10

4.3.2 Air-displacement tips .10

4.3.3 Positive displacement tips .11

4.3.4 Fixed tips.11

4.4 Environmental conditions .11

4.4.1 Discussion and recommendations.11

4.4.2 Factory acceptance testing .11

4.4.3 Site acceptance and user testing .12

5 Volumetric performance .12

5.1 Introductory discussion .12

5.2 Data collection and examination .14

5.3 Indexing to track data .15

5.3.1 Indexing from the channel perspective .15

5.3.2 Indexing from the microplate perspective .15

5.4 Descriptive statistics on an individual channel basis .16

5.5 Descriptive statistics on a run order basis .18

5.6 Descriptive statistics for entire data sets .18

5.7 Differences between channels .19

5.8 Handling of sub-deliveries .19

6 Measurement methods .20

6.1 Overview of methods suitable for measuring ALHS performance .20

6.2 Methods for use with any ALHS platform (open methods) .29

6.2.1 Ratiometric photometry .29

6.2.2 Gravimetry, single channel measurement .29

6.2.3 Gravimetry, full-plate measurement for correlation with photometry .29

6.2.4 Gravimetric regression method for low volumes .30

6.2.5 Photometry using Orange G .30

6.2.6 Hybrid method: gravimetry and photometry with Tartrazine . .30

6.2.7 Hybrid method: photometry and gravimetry with p-nitrophenol .31

6.2.8 Hybrid method: gravimetry and photometry with Ponceau S .31

6.2.9 Pressure sensing .31

6.2.10 Calorimetric measurement .31

6.2.11 Optical image analysis .31

6.3 Methods specific to an ALHS model or accessory (closed methods) .32

6.3.1 Gravimetry and hybrid method: gravimetry and photometry .32

6.3.2 Photometry with Tartrazine .32

7 Specification of ALHS volumetric performance .33

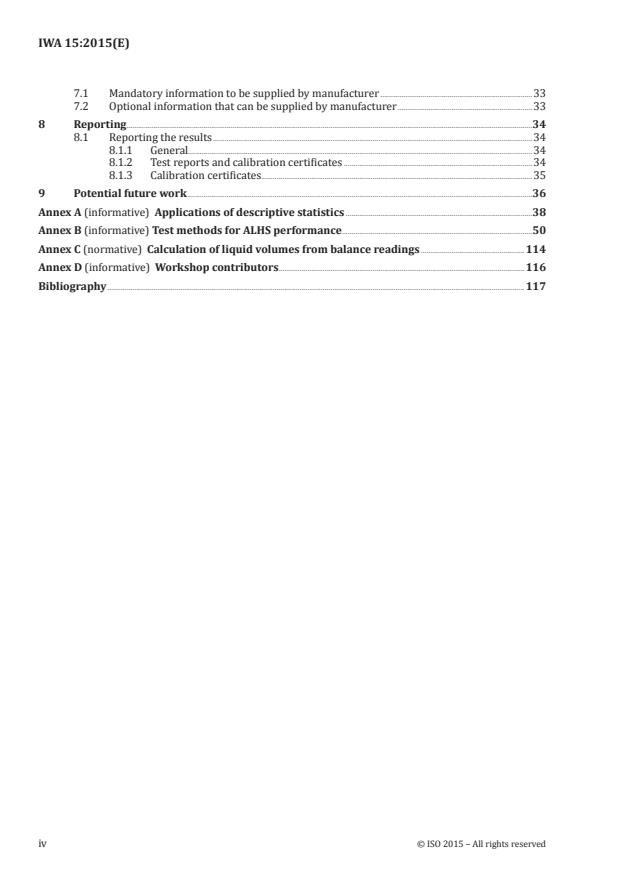

7.1 Mandatory information to be supplied by manufacturer .33

7.2 Optional information that can be supplied by manufacturer .33

8 Reporting .34

8.1 Reporting the results .34

8.1.1 General.34

8.1.2 Test reports and calibration certificates .34

8.1.3 Calibration certificates.35

9 Potential future work .36

Annex A (informative) Applications of descriptive statistics .38

Annex B (informative) Test methods for ALHS performance .50

Annex C (normative) Calculation of liquid volumes from balance readings .114

Annex D (informative) Workshop contributors .116

Bibliography .117

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TMBG, Technical Management Board Groups.

International Workshop Agreement IWA 15:2015(E)

Specification and method for the determination of

performance of automated liquid handling systems

1 Scope

This International Workshop Agreement (IWA) specifies methods for testing the volumetric

performance of air-displacement, system-liquid filled and positive displacement automated liquid

handling systems (ALHS), including an estimation of measurement uncertainties and established

traceability to reference standards (preferably, traceability to SI Units). The testing methods specified

in this document may also be used to measure the volumetric performance of automated liquid delivery

systems which do not aspirate the test liquid.

This IWA also specifies statistical methods for the determination of random and systematic errors

(including intra-plate and inter-plate comparisons), analysis of measured results when using

multichannel dispensing heads, and analysis depending on dispense patterns. It further defines terms

and formulae to be used for summarizing test results.

This IWA also specifies the information to be provided to users of ALHS, including the display of

summary results and performance claims.

This IWA is applicable to all ALHS with complete, installed liquid handling devices, including tips and

other essential parts needed for delivering a specified volume, which perform liquid handling tasks

without human intervention into microplates. Manipulation of the microplates on the deck of the

automated liquid handling system may be achieved automatically, semi-automatically, or manually.

This IWA addresses the needs of:

— suppliers of ALHS, as a basis for quality control including, where appropriate, the issuance of

supplier’s declarations;

— test houses and other bodies, as a basis for independent certification and calibration;

— users of the equipment, to enable calibration, verification, validation, and routine testing of trueness

and precision.

The tests established in this IWA should be carried out by trained personnel.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

3 Terms and definitions

For purposes of this document, the following terms and definitions apply.

3.1 Definitions

3.1.1

accuracy

closeness of agreement between a delivered volume and the

target volume

Note 1 to entry: The concept ‘accuracy’ is not a quantity and is not given a numerical quantity value. A liquid

delivery is said to be more accurate when it is accomplished with a smaller liquid handling error.

[SOURCE: ISO/IEC Guide 99:2007, 2.13, modified]

3.1.2

air displacement

liquid handling principle in which a body of air is contained between the piston and the test liquid

Note 1 to entry: It is possible to have a large air gap (piston systems), or smaller air gap between the test liquid

and the system liquid (liquid filled systems).

3.1.3

ALHS uncertainty

non-negative parameter characterizing the dispersion of the measured volumes relative to the

target volume

Note 1 to entry: Uncertainty is inversely related to accuracy, and is a quantity value. This value should be

expressed in accordance with ISO/IEC Guide 98-3.

[SOURCE: ISO/IEC Guide 99:2007, 2.26, modified]

3.1.4

aliquot

single delivery during a multi-dispense

3.1.5

automated liquid handling system

ALHS

system with a complete, installed liquid handling device, including tips and other essential parts needed

for delivering a specified volume without human intervention into microplates

Note 1 to entry: Examples of automated liquid handling systems include automated pipetting systems (APS), and

automated dispensing systems (ADS).

3.1.6

calibration

operation that, under specified conditions, establishes a relation

between the target volume of the ALHS and the delivered volume

Note 1 to entry: A calibration may be expressed by a statement, a calibration curve or a calibration table. It may

include a correction, but correction or adjustment is not a required element of a calibration.

[SOURCE: ISO/IEC Guide 99:2007, 2.39, modified]

3.1.7

dead air volume

captive air volume

air gap

air volume between the lower part of the piston

and the surface of the aspirated liquid

Note 1 to entry: It is possible to have a large air gap (piston systems), or smaller air gap for liquid filled systems.

Sometimes called captive air volume.

2 © ISO 2015 – All rights reserved

Note 2 to entry: Commonly, an air gap can be adjusted through ALHS system parameters, while the dead air

volume or captive air volume cannot be adjusted (see 4.2.1).

3.1.8

delivered volume

quantity delivered by a liquid handling system

Note 1 to entry: Delivered volume is a conceptual term and cannot be known with complete certainty due to

measurement error.

3.1.9

dispense height

height at which the test liquid is dispensed relative to a stated reference

3.1.10

dispensing system

system for delivering liquids from a pre-filled liquid reservoir

3.1.11

disposable tip

tip, which is attached once and after use, as defined by the manufacturer, detached and intended to be

discarded

Note 1 to entry: Disposable tips are usually made of plastic.

Note 2 to entry: Disposable tips are in contrast to fixed tips, which are described in 4.3.4.

3.1.12

dry contact dispensing

dispensing of liquid while tip is in contact with the dry target

3.1.13

factory acceptance testing

internal vendor testing to ensure ALHS performance to specifications

3.1.14

forward mode pipetting

direct mode pipetting

pipetting mode where the entire aspirated volume is delivered

3.1.15

immersion depth

depth of the tip below the liquid surface

Note 1 to entry: Immersion depth can be applied to both aspiration and dispensing (wet contact).

[SOURCE: Toolpoint Photometric Volume Check Procedure:2008, modified]

3.1.16

individually controlled channel

liquid handling channel that can be operated independently of other channels

3.1.17

labware

materials used in conjunction with liquid handling operations

Note 1 to entry: Labware includes disposable tips, reservoirs, receiving vessels, adapters and microplates.

3.1.18

maximum permissible error

upper or lower permitted extreme value for the deviation of the dispensed volume from the target volume

3.1.19

maximum specified volume

largest volume for which the manufacturer offers specifications

Note 1 to entry: The maximum specified volume may vary depending on instrument configuration (e.g. disposable

tip size, syringe size).

3.1.20

measured volume

quantity reported by a volume measuring system

Note 1 to entry: In practice, all measurements contain some measurement error. The measured volume is a

quantity value and serves as an estimate of the delivered volume which is not known with complete certainty.

3.1.21

measurement method

measurement procedure

detailed description of a measurement according to one or more measurement principles

Note 1 to entry: The source document (ISO/IEC Guide 99) draws a distinction between ‘measurement method’ and

‘measurement procedure’ and that distinction is ignored here. In this IWA, the terms are used interchangeably.

Note 2 to entry: The measurement method descriptions in this IWA detail the steps needed to make a volume

measurement and calculate certain descriptive statistics. Additional details needed to operate the ALHS are

part of the ‘test process’ as defined in 3.1.43. In this IWA, the measurement method is one of the components of

a ‘test process.’

[SOURCE: ISO/IEC Guide 99:2007, 2.6, modified]

3.1.22

measurement uncertainty

non-negative parameter characterizing the dispersion of the measured volumes

relative to the delivered volume

Note 1 to entry: Uncertainty is inversely related to accuracy, and is a quantity value. This value should be

expressed in accordance with the ISO/IEC Guide 98-3.

[SOURCE: ISO/IEC Guide 99:2007, 2.26, modified]

3.1.23

metrological traceability

property of a measurement result whereby the result can be related to a reference through a

documented unbroken chain of calibrations, each contributing to the measurement uncertainty

Note 1 to entry: Additional information can be found in the notes to definition (ISO/IEC Guide 99:2007, 2.41) and

the related term ‘metrological traceability chain’ (ISO/IEC Guide 99:2007, 2.42).

[SOURCE: ISO/IEC Guide 99:2007, 2.41]

3.1.24

microplate

flat plate with an array of wells

[1-5]

Note 1 to entry: Some dimensions of microplates are defined in ANSI/SLAS standards.

3.1.25

minimum specified volume

smallest volume for which the manufacturer offers specifications

Note 1 to entry: The minimum specified volume may vary depending on instrument configuration.

4 © ISO 2015 – All rights reserved

3.1.26

multichannel head

group of liquid handling channels operated in common

Note 1 to entry: Common arrangements of multichannel heads include 8, 96, 384, and 1536 channel heads. Other

arrangements are possible, e.g. 2 channel to 1536 channel configurations.

Note 2 to entry: Pipetting channels in a multichannel head may be controlled by a single, common drive, or each

channel may be controlled individually.

3.1.27

multi dispense

repeat dispense

sequential dispense

a collection of dispenses without intervening aspiration

Note 1 to entry: First dispense can be different, and is frequently wasted.

Note 2 to entry: Repeat dispenses usually dispense repeatedly the same volume, while sequential dispenses

usually dispense different volumes.

3.1.28

non-contact dispensing

contact-free dispensing

free-jet dispensing

dispensing of the liquid while tip is in air and without contacting the target or the liquid contained

in the target

3.1.29

outlier

member of a set of values which is inconsistent with the other members of that set

3.1.30

pipetting system

system for aspirating and dispensing a specified volume of liquid

[SOURCE: Toolpoint Gravimetric Volume Check Procedure:2008, modified]

3.1.31

positive displacement

direct displacement

liquid handling principle in which a mechanical actuator is in direct contact with the test liquid

3.1.32

precision

the closeness of agreement between the measured volume of independent

delivered volumes under stipulated conditions

Note 1 to entry: Precision is conceptual and not a quantity value.

Note 2 to entry: Measurement precision is usually expressed numerically by measures of random error, such as

standard deviation, variance, or coefficient of variation under the specified conditions of measurement.

Note 3 to entry: The ‘stipulated conditions’ can be, for example, repeatability conditions of measurement,

intermediate precision conditions of measurement, or reproducibility conditions of measurement (see

ISO 5725-1:1994).

[SOURCE: ISO 5725-1:1994, 3.12, modified]

3.1.33

random error

component of liquid handling error that in replicate deliveries

varies in an unpredictable manner

[SOURCE: ISO/IEC Guide 99:2007, 2.19, modified]

3.1.34

reservoir

liquid container

vessel that contains the liquid

3.1.35

reverse mode pipetting

pipetting mode in which excess volume is aspirated and remains in the tip after delivery

3.1.36

single dispense

individual dispense

single dispense per aspiration

3.1.37

site acceptance testing

in-situ testing at the user’s site, typically part of the installation process

3.1.38

supplier’s declaration

document by which a supplier gives written assurance that an ALHS conforms to the requirements of

one or more commonly accepted industry standards

Note 1 to entry: This IWA can be referenced as an applicable industry standard.

3.1.39

systematic error

component of volumetric error that in replicate deliveries remains

constant or varies in a predictable manner

Note 1 to entry: Systematic error is estimated by calculating the average volume of a series of deliveries and

comparing it to the indicated volume of the automated liquid handling system. Frequently this result is expressed

as a percentage of the indicated volume.

[SOURCE: ISO/IEC Guide 99:2007, 2.17, modified]

3.1.40

system liquid

liquid used to transmit energy between a mechanical actuator and the test liquid

Note 1 to entry: System liquids can reduce or completely eliminate system dead air volume.

Note 2 to entry: System liquid is usually deionized water. For special applications organic solvents such as DMSO

or aqueous solutions such as saline (e.g. 0,9 % NaCl) can be used.

Note 3 to entry: System liquid can be used for flushing and rinsing tips to minimize cross contamination.

3.1.41

target volume

indicated volume

selected volume

volume which is intended to be delivered

6 © ISO 2015 – All rights reserved

3.1.42

test liquid

liquid used for the volume measurement

Note 1 to entry: May be aqueous or other solvents. Aqueous test liquids can be pure water or contain other

compounds such as buffers, dyes or salts. The chemical composition of the test liquid can vary significantly

depending on method.

3.1.43

test process

detailed description of an ALHS testing procedure including

system operation and measurement method

Note 1 to entry: The test process includes all details needed to reproduce the test or interpret the results. The

measurement method is defined in 3.1.21, and is only a part of the test process.

3.1.44

test report

document reporting the result of the testing

Note 1 to entry: Details regarding information contained in test reports is specified in Clause 8.

3.1.45

test result

value of a characteristic obtained by carrying out a specified test method

Note 1 to entry: Test result is a broader concept than measured volume. The test result can be a single measured

volume, a set of measured volumes, or descriptive statistics such as the mean or standard deviation of multiple

measurements. The test method should specify what form the test results take.

[SOURCE: ISO 5725-1:1994, 3.2]

3.1.46

traceability

metrological traceability

property of a measurement result whereby the result can be related to a reference through a

documented unbroken chain of calibrations, each contributing to the measurement uncertainty

[SOURCE: ISO/IEC Guide 99:2007, 2.41]

3.1.47

trueness

closeness of agreement between the average volume delivered in a

large series of deliveries and the target volume

Note 1 to entry: Trueness is inversely related to systematic error, but is not related to random error.

[SOURCE: ISO/IEC Guide 99:2007, 2.14, modified]

3.1.48

validation

confirmation, through the provision of objective evidence, that

the requirements for a specific intended use or application have been fulfilled

Note 1 to entry: The term “validated” is used to designate the corresponding status.

Note 2 to entry: The test protocol for this testing should reflect the liquid volumes and instrument settings, at

which the ALHS will be operated.

Note 3 to entry: A product may meet all of its specifications (verification), but that does not ensure that it will

work in the operating paradigm (validation).

3.1.49

verification

confirmation, through provision of objective evidence, that

volumetric performance specifications have been fulfilled

Note 1 to entry: The term “verified” is used to designate the corresponding status.

Note 2 to entry: Volumetric performance specifications may vary depending on the environment where the ALHS

is used, e.g. factory and field specifications may be different.

[SOURCE: ISO/IEC Guide 99:2007, 2.44, modified]

3.1.50

wet contact dispensing

dispensing of the test liquid while tip is in contact with liquid present in the target

3.2 Abbreviated terms

See Table 1.

Table 1 — Abbreviated terms used in this document

Abbreviated term Explanation

ADS Automated Dispensing System

ALHS Automated Liquid Handling System

APS Automated Pipetting System

C2C Channel-to-Channel

CV Coefficient of Variation

DI De-ionized

DMSO Dimethylsulfoxide

GA Grand Average

HVAC Heating, Ventilation, and Air Conditioning

IEC International Electrotechnical Commission

IWA International Workshop Agreement

MU Measurement Uncertainty

MW Molecular weight

NaOH Sodium hydroxide

OA Over All

OD Optical Density

p.a. pro analysi (purity grade of chemicals)

p-NP para-nitrophenol

RH Relative Humidity [%]

RSE Relative Systematic Error

rcf Relative centrifugal force

rpm Revolutions per minute

SD Standard Deviation

SMOW Surface Mean Ocean Water

8 © ISO 2015 – All rights reserved

4 Operation of automated liquid handling systems

4.1 Types of automated liquid handling systems

The purpose of this clause is to provide examples of some types of ALHS. This list is not intended to be a

[6]

comprehensive list as technologies continue to evolve.

4.1.1 Types of piston operated automated liquid handling systems

Automated liquid handling systems can operate as follows:

— variable volume; designed by the manufacturer to aspirate and dispense volumes selectable by the

user within the specified useful volume range of the dispense head and selected tips, for example

between 10 µl and 100 µl.

— a larger volume may be aspirated into the tips, followed by a series of subsequent dispenses of

smaller aliquots.

The piston can

— either have a body of air contained between the piston and the surface of the liquid

(air-displacement), or

— be in direct contact with the surface of the liquid (positive or direct displacement), or

— be in contact with a system liquid.

The system can

— have a single tip, or

— have multiple tips, operated by individual pistons, or

— have multiple tips, operated by a single, common drive or moving plate with multiple pistons

simultaneously driven by a common drive.

The tip can be

— permanently attached to the dispense channel of the ALHS, or

— disposable, and used for one or more aspirate and dispense sequences.

4.1.2 Types of other (pump operated) automated liquid handling systems

Pump operated automated liquid handling systems can operate as follows:

variable volume; designed by the manufacturer to dispense volumes selectable by the user within

the specified useful volume range of the dispense head.

The dispense head can

— be permanently attached to the instrument, or

— be exchangeable, e.g. to change the usable volume range or number of channels.

The system can

— have a peristaltic or diaphragm pump to aspirate liquid from a reservoir, or

— have a pressurized liquid reservoir and separate liquid valves to control the liquid delivery.

4.2 Adjustment

4.2.1 Need for adjustment

A standard parameter set for a given fluid class may need to be adjusted for optimizing the ALHS

performance. ALHS parameters may need to be adjusted in one or more of the following situations:

— to accommodate liquid-specific properties;

— following the replacement of system components;

— following change of labware components; or

— following a change of the location of operation sites (e.g. at the factory vs. the end user’s location).

The performance of an ALHS can be corrected and optimized by adjusting system parameters such as

the aspiration and dispense speeds, immersion depth of the tip, dispense height, air gaps, and others.

The scope of adjustable system parameters varies between ALHS models and the manufacturer’s

adjustment instructions should be followed.

Some ALHS can be used at volumes outside of the volume range specified by the manufacturer for the

installed system components. In this case, the ALHS performance at these volumes shall be validated

with a test method (see Clause 6) suitable for these used volumes.

4.2.2 Liquid classes

An automated liquid handling system is adjusted by its manufacturer for the delivery of its selected

volume (or multiple volumes as specified by the manufacturer). The manufacturer shall report the

test solution, instrument settings, and environmental basis used for defining the standard liquid class.

Users of ALHS who define liquid classes and test the volumetric performance of the ALHS shall report

the test liquid, instrument settings, and environmental basis for each tested liquid class.

4.2.3 Adjustment of ALHS settings

Some automated liquid handling systems have a provision for adjustment by the user when, for

example, it is found in routine calibration that the volume delivered is not within specification. Such

user adjustment shall be made according to the manufacturer’s instructions and by reference to one of

the methods for the determination of measurement error specified in this IWA.

4.3 Tips

4.3.1 General

The dispensing orifice of the tip shall be shaped in such a way that consistent dispensing of the liquid is

achieved. When the pipetting operation is completed, any amount of liquid remaining in or around the

dispensing orifice of the tip shall be consistent.

In the case of sterilizable tips, the sterilization procedures indicated as appropriate by the manufacturer

in user information or on packaging shall not negatively affect the metrological characteristics of the

tips such as shape, seal and wettability.

NOTE This requirement can be assessed by comparing errors of measurement using tips which have and

have not been sterilized.

4.3.2 Air-displacement tips

4.3.2.1 Air-displacement tips shall be disposable parts, usually made of plastic, which fit on the ALHS

dispensing head and prevent the instrument from contact with the aspirated liquid.

10 © ISO 2015 – All rights reserved

4.3.2.2 Disposable air-displacement tips shall be fitted in accordance with the ALHS supplier’s

instructions to form a good seal between the tip and the dispensing head.

Disposable tips should not be cleaned or reused unless their metrological characteristics are confirmed

and they are shown fit for use in the specific application (validation).

NOTE Variability of the amount of externally retained liquid or an incomplete seal will contribute to poor

precision when testing with one of the methods described in this IWA.

4.3.3 Positive displacement tips

4.3.3.1 Positive displacement tips shall consist of a plunger and a capillary which fit on the tip holder

of the dispensing head of the automated liquid handling system. Various materials may be used for the

plunger, such as metal, plastic, or ceramic and for the capillary, such as plastic or glass. These pipette

tips may be reusable or disposable (both plunger and capillary are changed together, per manufacturer’s

instructions).

4.3.3.2 The shape and material of the plunger and capillary shall confer a good seal of the tip, as well as

a smooth action between the plunger and the capillary, to ensure consistent dispensing of the liquid.

4.3.4 Fixed tips

4.3.4.1 Description and materials

Fixed tips can be manufactured from various materials, such as stainless steel or polymeric materials.

These tips may be coated for inertness to pipetted fluids or for specific functionality, e.g. conductivity

to sense contact with fluids in receptacles on the deck of the ALHS.

4.3.4.2 Development of cleaning protocol and testing / confirmation of metrological

characteristics

Functionality and metrological performance of fixed tips should be tested at regular intervals. It is

recommended to follow the manufacturer’s cleaning protocol and use instructions for best performance

of fixed tips.

4.3.4.3 Maintenance and exchange of fixed tips

Fixed tips should be examined for damage and tested for proper functionality at regular intervals

according to the manufacturer’s instructions, which should contain protocols for the maintenance and

replacement of such tips.

4.4 Environmental conditions

4.4.1 Discussion and recommendations

Changes in temperature, relative humidity, and barometric pressure can cause changes in the

volumetric performance of piston-operated automated liquid handling systems. It is recommended

that temperature and relative humidity be monitored at all locations where operational performance

testing of ALHS is conducted.

4.4.2 Factory acceptance testing

It is recommended that factory acceptance testing is performed in a location where the temperature and

relative humidity can be controlled. It is good practice to equilibrate all equipment at least 2 h prior to

testing in an environment as defined by the ALHS manufacturer. Both the ALHS and the test method can

have specific sensitivity to environmental conditions. The relevant environmental conditions and their

upper and lower limits (e.g. temperature, RH, barometric pressure) shall be identified and recorded.

This equipment includes the ALHS, and may include a balance, plate reader, pipettes, test liquids, weight

calibration standards, etc. Any deviations from the recommended conditions shall be recorded and

reported with the test results. Estimates of the measurement uncertainty shall be based on the actual

test conditions.

4.4.3 Site acceptance and user testing

It is recognized that automated liquid handling systems are frequently installed and used in locations

where temperature, relative humidity, and barometric pressure differ from factory testing conditions.

It is recommended that site acceptance testing be performed at prevailing local conditions, which

should be stable within the requirements of the test method and the manufacturer’s specifications

before and during the time of testing. For reference, the temperature and relative humidity with their

minimum and maximum values during the time of testing should be recorded. At a minimum, the

temperature or temperature range during the time of testing shall be reported with the test results

for all equipment used during this testing (e.g. ALHS, balance, plate reader, test liquids, etc.), and the

estimate of measurement uncertainty shall reflect the actual test conditions.

Regardless of available environmental controls, it is recommended that automated liquid handling

systems be situated in an appropriate environment that reduces temperature extremes (e.g. away from

windows with direct sunlight exposure, or concentrated heat sources such as autoclaves, HVAC systems

and vents, or high voltage installations). Manufacturer’s recommendations for the installation and use

environment of ALHS should be followed.

Deviations from ideal/recommended test conditions need to be reflected in the measurement

uncertainty (MU) estimate.

5 Volumetric performance

5.1 Introductory discussion

Automated liquid handling systems (ALHS) are designed to deliver amounts of liquid at a target volume.

The target volume is typically set using software or other digital control. Volumetric performance is

assessed by measuring the volume of each liquid delivery and evaluating the data.

Volumetric performance is typically assessed by suppliers as part of the manufacturing process quality

control or a supplier’s service offering. Volumetric performance can also be assessed by users, as well

as by third party testing and calibration service providers.

Automated liquid handling systems are designed to handle a variety of liquids of differing physical

properties such as density, viscosity, surface tension and contact angle against solid surfaces. The

volumetric performance of the ALHS can vary depending on these physical properties, so a description

of the test liquid shall be included when reports of volumetric performance are made. This description

of the test liquid may be made in terms of chemical composition, physical properties, or both.

Manufacturers of ALHS can make performance claims at various volumes for a particular instrument

configuration. The maximum specified volume and minimum specified volume establish a liquid

handling range over which the system manufacturer has established volumetric performance

specifications. However, in some systems it is possible for the user to program the system to deliver

volumes which are outside of this range (i.e. greater than the maximum specified volume or less than

the minimum specified volume).

In preparing for a volumetric performance test, the ALHS will be set to deliver a particular target

volume. For testing by the supplier, the target volume will frequently be identical to one of the

manufacturer’s specified volumes. Operators may decide to test at any target volume they wish.

During testing each delivered volume is expected to be slightly different from the target volume. The

delivered volume is a conceptual quantity because it cannot be known with certainty and can only be

approximated by measurement.

12 © ISO 2015 – All rights reserved

In order to evaluate volumetric performance, measurements are made of individual delivered volumes.

The measured volume is a quantity which consists of a numerical value and units. The recommended

units are microlitres (µl) though related units such as millilitres (ml) and nanolitres (nl) are sometimes

used and are also acceptable. The measured volume is an estimate of the delivered volume and

departs slightly from t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...