ISO 18406:2017

(Main)Underwater acoustics — Measurement of radiated underwater sound from percussive pile driving

Underwater acoustics — Measurement of radiated underwater sound from percussive pile driving

ISO 18407:2017 describes the methodologies, procedures, and measurement systems to be used for the measurement of the radiated underwater acoustic sound generated during pile driving using percussive blows with a hammer. A major motivation for undertaking measurements of the sound radiated during percussive pile driving is as part of an assessment of impact on aquatic fauna required by regulatory frameworks. This document describes a generic approach to measurements that can be applied to different regulatory requirements. ISO 18407:2017 is suitable for measurement of percussive pile driving undertaken for offshore installation of foundations (monopiles, jackets, tripods, etc.) used in construction of offshore wind farms, oil and gas platforms, and other inshore structures such as bridge foundations and aquatic renewable energy devices. This document does not cover measurement of the sound radiated by vibro-piling or sheet piling. This document does not cover piling in water of depth less than 4 m or greater than 100 m. The procedures described herein provide guidance on making measurements to satisfy the following objectives: - to monitor source output during piling, for example, for regulatory purposes; - to provide consistency in comparison of piling noise from different construction projects; - for validation of modelling or predictions. ISO 18407:2017 covers only the measurement of the sound field radiated during percussive pile driving. The scope of this document does not include the assessment of exposure metrics, or the use of exposure criteria. No attempt is made to prescribe a methodology for generating maps of the acoustic field in the vicinity of the source. In the normative part of this document, requirements and procedures are described for measurement of the sound field at specific ranges from the pile being driven. In this part of the document, no procedure is provided for determination of an acoustic output metric that is independent of the propagation path between source and receiver (such as a source level). Ideally, such a metric would have some predictive utility (for example, in calculating noise impact zones and noise maps). However, some information on the determination of a possible acoustic output metric is provided in Annex A. ISO 18407:2017 covers only the measurement of sound pressure in the water column. The scope does not include measurement of sound particle velocity in the water column due to the propagating sound wave, or seabed vibration caused by waves propagating across the sea-floor. This exclusion does not imply that such measures are unimportant; indeed, their importance in assessing the impact on aquatic life is recognized. However, at the time of drafting, measurement of these quantities is not yet mature enough for standardization.

Acoustique sous-marine — Mesurage du son sous-marin émis lors de l'enfoncement de pieux marins

General Information

- Status

- Published

- Publication Date

- 24-Apr-2017

- Technical Committee

- ISO/TC 43/SC 3 - Underwater acoustics

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 07-Nov-2022

- Completion Date

- 14-Feb-2026

Overview

ISO 18406:2017 - Underwater acoustics - Measurement of radiated underwater sound from percussive pile driving - specifies standardized methodologies, procedures and measurement-system requirements for measuring the radiated underwater sound produced by percussive pile driving (hammer blows). The standard is aimed at consistent, repeatable acoustic monitoring to support environmental assessments, regulatory compliance and validation of modelling for marine construction activities.

Scope highlights

- Focuses on percussive pile driving (offshore and inshore piles for wind farms, oil & gas platforms, bridge foundations, aquatic renewable devices).

- Excludes vibro‑piling, sheet piling and operations in water depths < 4 m or > 100 m.

- Covers only sound pressure measurements in the water column (not particle velocity or seabed vibration).

- Does not prescribe exposure criteria or noise-mapping methodologies; measurement-focused.

Key topics and technical requirements

ISO 18406 defines technical and procedural requirements for reliable acoustic data collection:

- Instrumentation: hydrophone sensitivity, frequency range, sampling rate, directivity, signal‑to‑noise ratio, system self‑noise and dynamic range.

- Calibration: full system calibration and field calibration checks, plus long‑term data quality and auxiliary calibration records.

- Deployment methods: vessel‑based, static (moored) and drifting systems; guidance on hydrophone depth, number and spacing for offshore vs inshore sites.

- Noise minimization: controlling platform self‑noise sources (flow noise, cable strum, surface heave, vessel and mechanical/electrical noise).

- Measurement configuration: spatial sampling (selection of measurement locations and ranges), temporal sampling (duration), and accurate distance measurement between pile and receivers.

- Data processing and metrics: recommended processing steps and acoustic metrics to calculate for percussive impulsive sources.

- Uncertainty and reporting: identification and evaluation of measurement uncertainty (calibration, position errors, spurious signals) and mandatory/optional reporting fields (auxiliary metadata, pile characteristics, deployment configuration).

Annex A provides considerations for defining source‑output metrics; Annex B gives practical guidance on hydrophone use.

Applications and users

ISO 18406 is directly useful for:

- Environmental acoustic consultants and marine ecologists conducting monitoring for regulatory compliance.

- Acoustic and geophysical contractors performing piling noise measurements.

- Offshore wind, oil & gas, bridge and marine renewable developers planning construction and impact assessments.

- Researchers validating propagation models and comparing piling noise across projects.

Benefits include consistent cross‑project comparisons, regulatory monitoring support, and robust datasets for model validation.

Related standards

ISO 18406 is produced by ISO/TC 43 (Underwater acoustics) and complements national/regional regulatory guidance and other ISO/IEC standards on acoustic instrumentation and calibration. Users should consult local regulatory requirements for exposure thresholds and impact assessment methods.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO 18406:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Underwater acoustics — Measurement of radiated underwater sound from percussive pile driving". This standard covers: ISO 18407:2017 describes the methodologies, procedures, and measurement systems to be used for the measurement of the radiated underwater acoustic sound generated during pile driving using percussive blows with a hammer. A major motivation for undertaking measurements of the sound radiated during percussive pile driving is as part of an assessment of impact on aquatic fauna required by regulatory frameworks. This document describes a generic approach to measurements that can be applied to different regulatory requirements. ISO 18407:2017 is suitable for measurement of percussive pile driving undertaken for offshore installation of foundations (monopiles, jackets, tripods, etc.) used in construction of offshore wind farms, oil and gas platforms, and other inshore structures such as bridge foundations and aquatic renewable energy devices. This document does not cover measurement of the sound radiated by vibro-piling or sheet piling. This document does not cover piling in water of depth less than 4 m or greater than 100 m. The procedures described herein provide guidance on making measurements to satisfy the following objectives: - to monitor source output during piling, for example, for regulatory purposes; - to provide consistency in comparison of piling noise from different construction projects; - for validation of modelling or predictions. ISO 18407:2017 covers only the measurement of the sound field radiated during percussive pile driving. The scope of this document does not include the assessment of exposure metrics, or the use of exposure criteria. No attempt is made to prescribe a methodology for generating maps of the acoustic field in the vicinity of the source. In the normative part of this document, requirements and procedures are described for measurement of the sound field at specific ranges from the pile being driven. In this part of the document, no procedure is provided for determination of an acoustic output metric that is independent of the propagation path between source and receiver (such as a source level). Ideally, such a metric would have some predictive utility (for example, in calculating noise impact zones and noise maps). However, some information on the determination of a possible acoustic output metric is provided in Annex A. ISO 18407:2017 covers only the measurement of sound pressure in the water column. The scope does not include measurement of sound particle velocity in the water column due to the propagating sound wave, or seabed vibration caused by waves propagating across the sea-floor. This exclusion does not imply that such measures are unimportant; indeed, their importance in assessing the impact on aquatic life is recognized. However, at the time of drafting, measurement of these quantities is not yet mature enough for standardization.

ISO 18407:2017 describes the methodologies, procedures, and measurement systems to be used for the measurement of the radiated underwater acoustic sound generated during pile driving using percussive blows with a hammer. A major motivation for undertaking measurements of the sound radiated during percussive pile driving is as part of an assessment of impact on aquatic fauna required by regulatory frameworks. This document describes a generic approach to measurements that can be applied to different regulatory requirements. ISO 18407:2017 is suitable for measurement of percussive pile driving undertaken for offshore installation of foundations (monopiles, jackets, tripods, etc.) used in construction of offshore wind farms, oil and gas platforms, and other inshore structures such as bridge foundations and aquatic renewable energy devices. This document does not cover measurement of the sound radiated by vibro-piling or sheet piling. This document does not cover piling in water of depth less than 4 m or greater than 100 m. The procedures described herein provide guidance on making measurements to satisfy the following objectives: - to monitor source output during piling, for example, for regulatory purposes; - to provide consistency in comparison of piling noise from different construction projects; - for validation of modelling or predictions. ISO 18407:2017 covers only the measurement of the sound field radiated during percussive pile driving. The scope of this document does not include the assessment of exposure metrics, or the use of exposure criteria. No attempt is made to prescribe a methodology for generating maps of the acoustic field in the vicinity of the source. In the normative part of this document, requirements and procedures are described for measurement of the sound field at specific ranges from the pile being driven. In this part of the document, no procedure is provided for determination of an acoustic output metric that is independent of the propagation path between source and receiver (such as a source level). Ideally, such a metric would have some predictive utility (for example, in calculating noise impact zones and noise maps). However, some information on the determination of a possible acoustic output metric is provided in Annex A. ISO 18407:2017 covers only the measurement of sound pressure in the water column. The scope does not include measurement of sound particle velocity in the water column due to the propagating sound wave, or seabed vibration caused by waves propagating across the sea-floor. This exclusion does not imply that such measures are unimportant; indeed, their importance in assessing the impact on aquatic life is recognized. However, at the time of drafting, measurement of these quantities is not yet mature enough for standardization.

ISO 18406:2017 is classified under the following ICS (International Classification for Standards) categories: 17.140.30 - Noise emitted by means of transport. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 18406:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18406

First edition

2017-04

Underwater acoustics — Measurement

of radiated underwater sound from

percussive pile driving

Acoustique sous-marine — Mesurage du son sous-marin émis lors de

l’enfoncement de pieux marins

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

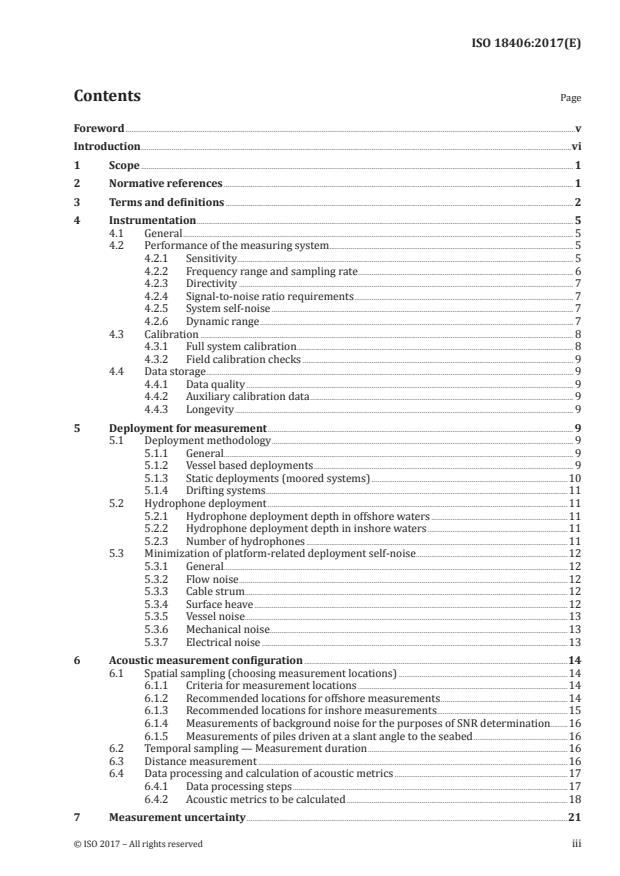

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Instrumentation . 5

4.1 General . 5

4.2 Performance of the measuring system . 5

4.2.1 Sensitivity . . . 5

4.2.2 Frequency range and sampling rate . 6

4.2.3 Directivity . 7

4.2.4 Signal-to-noise ratio requirements . 7

4.2.5 System self-noise . 7

4.2.6 Dynamic range . 7

4.3 Calibration . 8

4.3.1 Full system calibration . . 8

4.3.2 Field calibration checks . 9

4.4 Data storage . 9

4.4.1 Data quality . 9

4.4.2 Auxiliary calibration data . 9

4.4.3 Longevity . 9

5 Deployment for measurement . 9

5.1 Deployment methodology . 9

5.1.1 General. 9

5.1.2 Vessel based deployments . 9

5.1.3 Static deployments (moored systems) .10

5.1.4 Drifting systems .11

5.2 Hydrophone deployment .11

5.2.1 Hydrophone deployment depth in offshore waters .11

5.2.2 Hydrophone deployment depth in inshore waters .11

5.2.3 Number of hydrophones .11

5.3 Minimization of platform-related deployment self-noise.12

5.3.1 General.12

5.3.2 Flow noise .12

5.3.3 Cable strum.12

5.3.4 Surface heave .12

5.3.5 Vessel noise.13

5.3.6 Mechanical noise.13

5.3.7 Electrical noise .13

6 Acoustic measurement configuration .14

6.1 Spatial sampling (choosing measurement locations) .14

6.1.1 Criteria for measurement locations .14

6.1.2 Recommended locations for offshore measurements .14

6.1.3 Recommended locations for inshore measurements .15

6.1.4 Measurements of background noise for the purposes of SNR determination.16

6.1.5 Measurements of piles driven at a slant angle to the seabed .16

6.2 Temporal sampling — Measurement duration .16

6.3 Distance measurement .16

6.4 Data processing and calculation of acoustic metrics .17

6.4.1 Data processing steps .17

6.4.2 Acoustic metrics to be calculated .18

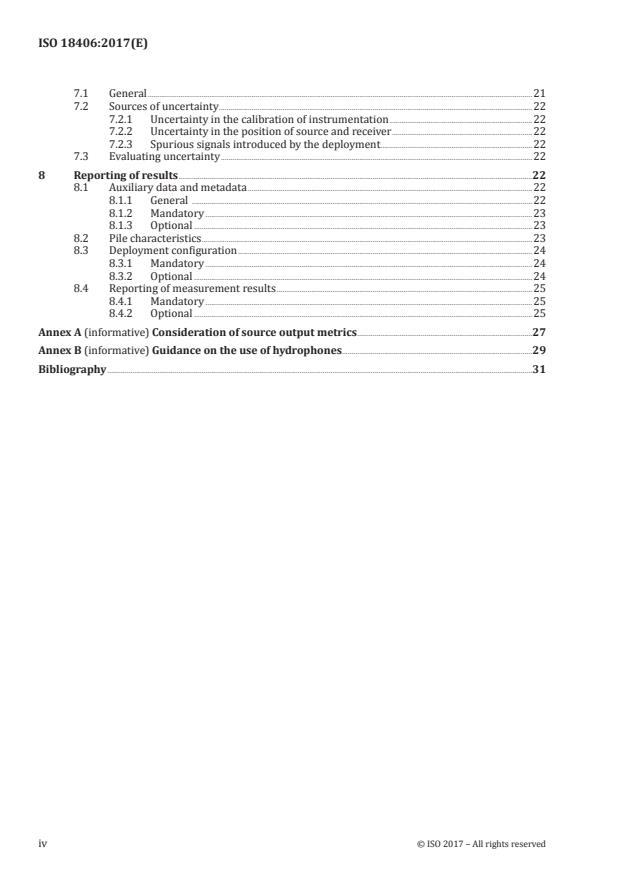

7 Measurement uncertainty .21

7.1 General .21

7.2 Sources of uncertainty .22

7.2.1 Uncertainty in the calibration of instrumentation .22

7.2.2 Uncertainty in the position of source and receiver .22

7.2.3 Spurious signals introduced by the deployment . .22

7.3 Evaluating uncertainty .22

8 Reporting of results .22

8.1 Auxiliary data and metadata .22

8.1.1 General .22

8.1.2 Mandatory .23

8.1.3 Optional .23

8.2 Pile characteristics .23

8.3 Deployment configuration .24

8.3.1 Mandatory .24

8.3.2 Optional .24

8.4 Reporting of measurement results .25

8.4.1 Mandatory .25

8.4.2 Optional .25

Annex A (informative) Consideration of source output metrics .27

Annex B (informative) Guidance on the use of hydrophones .29

Bibliography .31

iv © ISO 2017 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: w w w . i s o .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 43, Acoustics, Subcommittee SC 3,

Underwater acoustics.

Introduction

This document was written to provide a standardized measurement method for the measurement of

the radiated underwater sound during percussive pile driving.

Sound is often an unintended by-product of man-made activities, and the increasing number of sound-

producing human activities in oceans, seas, lakes, rivers and harbours have led to concern over noise

pollution from unwanted sound and its potential effect on aquatic life. In some countries, there is

already incipient regulation with regard to the impact of the radiated underwater sound, requiring

acoustic monitoring for environmental impact assessment during construction projects.

Percussive pile driving can be a significant source of low-frequency impulsive underwater sound.

During the process, a pile is driven into the seabed (or river-bed, etc.) using a hammer, which is typically

driven hydraulically. Such a technique is commonly used to position piles in shallow water construction

applications. Examples of such applications include the following:

— construction of offshore wind farms;

— construction and mooring of platforms for the offshore oil and gas industry;

— construction of bridge supports and foundations in rivers, estuaries, harbours and quays (and close

proximity to them);

— mooring and positioning of aquatic renewable energy devices.

In the scientific literature, a number of attempts to measure the water-borne noise levels have been

[1]-[13]

reported . Often, these are difficult to compare because different acoustic metrics are used, and

[14]-[16]

this has led to guidance being provided to address the need within individual countries . The

measurement of piling noise is made difficult by a number of factors.

— The source extends from the water surface to the seabed (or river-bed, etc.), generating sound waves

in water, air and seabed, and vibrating the seabed surface.

— The environment is often shallow water which gives rise to substantial reverberation, and

bathymetric features and seabed (or river-bed, etc.) interaction can strongly influence the

propagation of the sound.

Often, simple assumptions about equivalent point sources have been used in measurements and for

propagation modelling without sufficient validation. Progress with modelling the source has been

[17]-[22]

reported in the scientific literature, but a complete understanding has not yet been achieved .

The aim of this document is to provide procedures and methodologies for measurement of sound

radiation into the water, and recommend acoustic metrics to describe the sound field. The assessment

of impact of the radiated sound on marine life is not part of the scope of this document.

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 18406:2017(E)

Underwater acoustics — Measurement of radiated

underwater sound from percussive pile driving

1 Scope

This document describes the methodologies, procedures, and measurement systems to be used for the

measurement of the radiated underwater acoustic sound generated during pile driving using percussive

blows with a hammer.

A major motivation for undertaking measurements of the sound radiated during percussive pile

driving is as part of an assessment of impact on aquatic fauna required by regulatory frameworks. This

document describes a generic approach to measurements that can be applied to different regulatory

requirements.

This document is suitable for measurement of percussive pile driving undertaken for offshore

installation of foundations (monopiles, jackets, tripods, etc.) used in construction of offshore wind

farms, oil and gas platforms, and other inshore structures such as bridge foundations and aquatic

renewable energy devices. This document does not cover measurement of the sound radiated by vibro-

piling or sheet piling. This document does not cover piling in water of depth less than 4 m or greater

than 100 m.

The procedures described herein provide guidance on making measurements to satisfy the following

objectives:

— to monitor source output during piling, for example, for regulatory purposes;

— to provide consistency in comparison of piling noise from different construction projects;

— for validation of modelling or predictions.

This document covers only the measurement of the sound field radiated during percussive pile driving.

The scope of this document does not include the assessment of exposure metrics, or the use of exposure

criteria. No attempt is made to prescribe a methodology for generating maps of the acoustic field in the

vicinity of the source.

In the normative part of this document, requirements and procedures are described for measurement of

the sound field at specific ranges from the pile being driven. In this part of the document, no procedure

is provided for determination of an acoustic output metric that is independent of the propagation path

between source and receiver (such as a source level). Ideally, such a metric would have some predictive

utility (for example, in calculating noise impact zones and noise maps). However, some information on

the determination of a possible acoustic output metric is provided in Annex A.

This document covers only the measurement of sound pressure in the water column. The scope does

not include measurement of sound particle velocity in the water column due to the propagating sound

wave, or seabed vibration caused by waves propagating across the sea-floor. This exclusion does not

imply that such measures are unimportant; indeed, their importance in assessing the impact on aquatic

life is recognized. However, at the time of drafting, measurement of these quantities is not yet mature

enough for standardization.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 18405, Underwater acoustics — Terminology

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18405 (especially: sound

pressure, sound pressure level, mean-square sound pressure level, sound exposure, sound exposure

level, peak sound pressure, peak sound pressure level) and the following apply.

NOTE Although the definitions of sound exposure and sound exposure level are taken from ISO 18405,

specific nomenclature is used in this document for sound exposure level calculated over the duration of one

acoustic pulse, and over the duration of multiple acoustic pulses; this nomenclature is described in 3.2.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

3.1

pulse duration

percentage energy signal duration over the acoustic pulse

Note 1 to entry: The percentage energy signal duration is defined in ISO 18405.

Note 2 to entry: The energy percentage over which the pulse duration has been calculated should be stated with

the result. For the purposes of this document, the energy percentage for the pulse duration is 90 %.

Note 3 to entry: In general, in shallow water, the acoustic pulse includes multiple arrivals of the outgoing

acoustic waves, including multi-path signal arrivals from surface and seabed. In reverberant environments such

as harbours, where sound waves may be reflected by boundaries such as harbour walls, it may be difficult to

identify individual outgoing acoustic pulses.

3.2

sound exposure level

SEL

level of the sound exposure, for a specified reference value

Note 1 to entry: The sound exposure level is as defined in ISO 18405.

Note 2 to entry: The sound exposure level for an individual acoustic pulse (corresponding to a single hammer

strike) is calculated over the pulse duration on the basis of 100 % of the pulse energy. For the purposes of this

document, this is termed the single strike sound exposure level (abbreviated as SEL ). It is recognized that in the

ss

scientific literature, this parameter is sometimes called the single pulse sound exposure level.

Note 3 to entry: The sound exposure level over a defined period of time, which includes multiple acoustic pulses,

is, for the purposes of this document, termed the cumulative sound exposure level (abbreviated as SEL ). When

cum

reporting the cumulative sound exposure level, the number of pulses and the time duration over which the

cumulative sound exposure level has been calculated are stated.

Note 4 to entry: In the acoustic near field, sound exposure is not related to the sound intensity or energy in the

straightforward manner that applies for the acoustic far field. Therefore, care should be taken when interpreting

measurements of SEL made in the acoustic near field.

3.3

pulse repetition frequency

pulse repetition rate

number of hammer strikes per unit time

Note 1 to entry: Typically stated as the number of strikes (or acoustic pulses) per second.

Note 2 to entry: It is common for the pulse repetition frequency to be less than 1 per second.

2 © ISO 2017 – All rights reserved

3.4

background noise

all sound recorded by the hydrophone in the absence of the pile driving signal for a specified pile driving

acoustic signal being measured

3.5

measurement system

data acquisition system consisting of, but not limited to, one or more hydrophone(s), conditioning

preamplifier(s), analogue-to-digital converter(s), computer and ancillary peripherals

3.6

frequency range

span from the lowest frequency to the highest frequency over which the measurement system is able to

measure, for a given uncertainty

Note 1 to entry: The frequency range is expressed as the lowest frequency to the highest frequency.

3.7

dynamic range

amplitude range over which a measurement system is able to measure, for a given tolerance of

distortion, expressed as a range from the lowest to the highest amplitude

Note 1 to entry: Dynamic range can also be expressed in decibels representing the difference between the level of

the noise floor created by the system self-noise and the maximum level which can be measured with a specified

maximum allowable distortion. It can be expressed for a single frequency or at a range of frequencies.

3.8

field calibration

method of using known inputs, possibly using physical stimuli (such as a known and calibrated/traceable

acoustic or vibration source) or electrical input (charge or voltage signal injection) at the input (or other

stage) of a measurement system in order to ascertain that the system is, in fact, responding properly

(i.e. within the system’s stated uncertainty) to the known stimulus

[23]

[SOURCE: ISO 17208-1:2016, 3.9]

3.9

measurement uncertainty

estimate of the range (or dispersion) of values within which the true value is considered to lie to a

specified degree of confidence (for example, for a confidence level of 95 %)

[SOURCE: ISO/IEC Guide 98-3:2008]

3.10

hydrophone

underwater sound transducer that provides an electrical signal in response to fluctuations in pressure,

and is designed to respond to the pressure of a sound wave

Note 1 to entry: If the electrical signal is proportional to the incident sound pressure, the hydrophone is said to

have a linear response.

3.11

hammer energy

kinetic energy of the hammer used for the pile driving for a specific blow

Note 1 to entry: This is equal to the kinetic energy with which the hammer mass strikes the pile.

Note 2 to entry: The hammer energy is expressed in kJ.

3.12

pile dimensions

dimensions of the pile in terms of the overall length, diameter and wall thickness (if hollow)

3.13

offshore

marine area, including coastal areas, regional seas and continental shelf, but excluding harbours,

coastal inlets, inland waterways, river estuaries, and rivers

3.14

inshore

marine or aquatic region, including harbours, coastal inlets, inland waterways, river estuaries, and

rivers, but excluding regional seas, continental shelf and coastal areas

3.15

equivalent bandwidth noise pressure

p

w

ratio of the root-mean-square noise voltage at a specified central frequency in the relevant frequency

band present at the electrical terminals of the hydrophone, in the absence of pressure fluctuations at the

hydrophone input, to its free-field open-circuit hydrophone voltage sensitivity at a specified frequency

Note 1 to entry: Equivalent bandwidth noise pressure is expressed in pascals, Pa.

[24]

[SOURCE: IEC 60500:—]

3.16

equivalent bandwidth noise pressure level

ten times the logarithm to the base 10 of the ratio of the square of the value of equivalent bandwidth

noise pressure, p , of a hydrophone to the square of a reference pressure, p , in decibels

w 0

Note 1 to entry: Equivalent bandwidth noise pressure level is expressed in decibels, dB.

Note 2 to entry: The value of the reference pressure, p , is 1 μPa.

[24]

[SOURCE: IEC 60500:—]

3.17

signal-to-noise ratio

ratio of the mean-square broadband signal voltage after all processing to the mean-square broadband

noise voltage after all processing

Note 1 to entry: The noise voltage is the voltage caused by non-acoustic noise and background noise.

Note 2 to entry: The time duration for the mean-square operation on the signal voltage and the background noise

voltage shall be the same. This averaging time is specified with the value of signal-to-noise ratio.

Note 3 to entry: As a broadband quantity, the signal-to-noise ratio is evaluated over a specified frequency band.

This may be the entire range of interest, which for this document is a minimum of 20 Hz to 20 kHz, or a specific

frequency band such as a third-octave band. The applicable frequency band is stated with the value of the signal-

to-noise ratio.

Note 4 to entry: The signal-to-noise may be expressed as a level difference in decibels.

3.18

system sensitivity

quotient of the root-mean-square open-circuit voltage at a specified point in the measurement system

(usually the electrical output terminals) to the incident root-mean-square sound pressure that would

be present at the position of the reference centre of the hydrophone in the undisturbed free field if the

hydrophone was removed for specified frequency and specified direction of plane wave sound

Note 1 to entry: The system sensitivity is defined here for an acoustic measurement system designed to measure

sound pressure signals in water. The measurement system will typically consist of hydrophone(s) connected to

amplifier(s) and filter(s), and will feed an output voltage into a digital acquisition and storage system. Note that

the response of the hydrophone(s), amplifier(s) and filter(s) will in general vary with acoustic frequency.

4 © ISO 2017 – All rights reserved

Note 2 to entry: The system sensitivity is defined here as an acoustic free-field sensitivity using the free-field

sensitivity of the hydrophone. If the hydrophone is physically attached to the body of an acoustic recorder (rather

than deployed on an extension cable), diffraction and scattering of sound by the recorder body may affect the

free-field sensitivity at kilohertz frequencies, causing enhanced directivity compared to the response of the free

hydrophone.

Note 3 to entry: The system sensitivity is described in terms of the electrical voltage developed per pascal of

acoustic pressure, and is stated in units of V/Pa. The sensitivity level is sometimes expressed in decibels as dB re

1 V/μPa. The system sensitivity accounts for the response of the hydrophone(s), gain of amplifiers, and insertion

loss of filters within the system.

Note 4 to entry: For digital systems, where the system records the sound as a digital waveform (rather than

providing an analogue voltage output), the calibration of the digitiser (analogue to digital converter) may be

incorporated into the overall sensitivity of the whole system including the digitizer. This may be termed the

-1

digital system sensitivity, which is the number of digital counts per unit change in sound pressure (unit Pa ).

Note 5 to entry: In general, the measuring system may introduce a phase delay into the measured signal. This

may be accounted for by representing the system sensitivity as a complex valued quantity, the modulus of which

represents the magnitude-only response (and is described by the definition above), and the phase of which

describes the phase response of the system. Note that the complex-valued system sensitivity will in general vary

with acoustic frequency.

[24]

[SOURCE: IEC 60500:—]

4 Instrumentation

4.1 General

This clause deals with the choice of measuring instrumentation and the key performance specifications,

system calibration, and data quality assurance.

The measuring system generally consists of the following instruments:

— hydrophone(s);

— amplifier(s) and signal conditioning equipment;

— digitization and storage equipment.

The amplifier can be a separate element in the system with an adjustable gain, or may be an integral

part of the hydrophone with no possibility for gain adjustment. Digitization is provided by an analogue

to digital converter (ADC) and the electronic storage is typically provided by a computer hard drive or

flash drive memory.

The measuring system may consist of individual components, as listed above, or an integrated system

forming part of an autonomous recorder that provides a self-contained recording system.

4.2 Performance of the measuring system

4.2.1 Sensitivity

The sensitivity of the measuring system should be chosen to be an appropriate value for the amplitude

of the sound being measured. The aim in the choice of the system sensitivity is to

— avoid poor signal-to-noise ratio for low amplitude signals, and

— avoid nonlinearity, clipping and system saturation for high amplitude signals.

NOTE 1 It is the latter of these two criteria that is most important for measurement of percussive pile driving

because it is a high amplitude source, and distortion of the measured signal will render the results of no value.

To build in some flexibility, it is preferable to have some selectable gain in the amplification stages, or in the

settings of the ADC. These can then be set to appropriate values once the sound levels are known after some

initial measurements. However, note that for autonomous recorders and hydrophones which have integral

preamplifiers, the gain cannot usually be modified after deployment.

NOTE 2 If measurements of background noise are necessary then it might not be appropriate to use the

same hydrophone or gain setting for the background noise measurements as those used for the measurement

of the noise radiated from the pile-driving. For measurement of background noise, a hydrophone with low-noise

performance and high sensitivity is generally preferred.

NOTE 3 The sensitivity is described in terms of the electrical voltage developed per pascal of acoustic

pressure, and is stated in units of V/Pa. The sensitivity level is often expressed in decibels as dB re 1 V/μPa.

Where the system records the sound as a digital waveform (rather than providing an analogue voltage), the

sensitivity is expressed in digital counts per pascal. Note that the range of numerical values produced by an ADC

relate to the number of bits used in the conversion, the full voltage range allowed for the analogue signal being

N

represented by values covering a range equal to 2 where N is the number of bits of the ADC. For example, a 16

bit ADC represents the full scale voltage range with 2 values (e.g. -32 768 to +32 767), which is equivalent to a

dynamic range of approximately 96 dB.

NOTE 4 Note also that if extra cable is added to a hydrophone which does not have an integral preamplifier,

this will reduce the overall sensitivity for the hydrophone due to the extra electrical loading caused by the

capacitance of the extension cable. Either the hydrophone is calibrated with the extension cable connected, or

the effect of the electrical loading is calculated. See Annex B for details. For hydrophones that have an integral

preamplifier within the hydrophone body, adding extension cable will not affect the sensitivity.

4.2.2 Frequency range and sampling rate

The frequency response of the measuring system shall extend to a high enough frequency to faithfully

record all frequency components of interest within the measured signals. This requires that the

hydrophone, and any amplifier and filter, be sufficiently broadband.

For the measurement of percussive pile driving, at minimum the system frequency range shall extend

from no more than 20 Hz to no less than 20 kHz.

NOTE 1 In general, when selecting a suitable minimum frequency range for the measurements, consideration

of the hearing abilities of the relevant receptors is given on a case by case basis. However, note that measurements

at acoustic frequencies of less than 20 Hz are difficult in very shallow water where low frequency waves do not

propagate. In addition, at such low acoustic frequencies, contaminating signals due to artefacts such as flow

noise and cable strum become more prevalent (see 5.3).

NOTE 2 The requirement for unambiguous representation of the signals within the desired frequency range

requires the sampling rate, f , of the ADC within the recording system to be greater than the Nyquist rate of the

s

signal which is input to the ADC. Where the measured data are to be represented in one-third octave bands,

the maximum frequency of interest will be the upper limit of the maximum one-third octave frequency band of

interest.

NOTE 3 It is desirable that the system sensitivity be invariant with frequency over the frequency range of

interest (i.e. that it possess a “flat response”), to within a tolerance of 2 dB. Note that it is possible to correct for

the variation in the sensitivity with frequency with better accuracy than the above tolerance if the hydrophone

and measuring system is calibrated over the full frequency range of interest.

NOTE 4 The one-third octave bands are calculated using either base-10 or base-2, and the choice is stated

when presenting the results. The two calculation methods will give slightly different results, and base-10 is the

preferred method (IEC 61260-1). (Note that the base-10 representation of a one-third octave band is referred to

as a “decidecade” in ISO 18405).

6 © ISO 2017 – All rights reserved

4.2.3 Directivity

The hydrophone used shall have an omnidirectional response such that its sensitivity is invariant with

the direction of the incoming sound wave to within a tolerance of 2 dB over the frequency range of

interest.

NOTE 1 This requirement is not difficult to satisfy at frequencies up to 20 kHz. However, one issue that can

cause enhanced directionality is where the hydrophone is deployed close to another structure that is capable of

reflecting the sound waves. The combination of the direct and reflected waves causes interference, the nature

of which will change depending on the arrival angle for the sound wave. This effect can be evident at kilohertz

frequencies if the hydrophone is deployed close to a support structure such as a heavy mooring or support, or

a recorder case that houses electronics and batteries but is mostly air-filled. Similarly, if the hydrophone has a

guard deployed around it (a protective cage to prevent damage of the element by impacts), this can influence

the directivity at kilohertz frequencies. If necessary, the above effects can be quantified by directional response

measurements of the hydrophone together with the mounting, in a free-field environment.

4.2.4 Signal-to-noise ratio requirements

A signal-to-noise ratio of at least 10 dB (expressed as a level difference) shall be required for

measurements.

NOTE 1 When considering signal-to-noise ratio, all contributions to noise are relevant. These include system

self-noise (4.2.5) and platform-related deployment noise (5.3.1) as well as background noise (3.4).

NOTE 2 For measurements of percussive pile driving where high amplitude signals are commonplace, this

criterion is only likely to be challenging at significant range from the source (tens of kilometres).

4.2.5 System self-noise

To achieve acceptable signal-to-noise ratio when measuring acoustic signals, the system self-noise

(expressed as the equivalent bandwidth noise pressure level) shall be at least 10 dB below the lowest

signal level (expressed as the mean-square signal voltage after all processing) to be measured in the

frequency band of interest.

NOTE 1 In the context considered here, the system self-noise is considered to be the noise originating from

the hydrophone and recording system (for considerations of deployment and platform noise, see 5.3). The system

self-noise is the noise generated by the system in the absence of any signal due to an external acoustic stimulus.

This noise is electrical in nature and is generated by the hydrophone itself and any electronic components such as

amplifiers and ADCs. This is normally expressed as an equivalent bandwidth noise pressure level. With a typical

recording system, it is possible for the spectral density of the equivalent bandwidth noise pressure to approach

the Knudsen sea-state zero levels (which include distant shipping noise) at 63 Hz and 125 Hz, the values for which

2 2 [25]

are approximately 64 dB re 1 μPa /Hz and 59 dB re 1 μPa /Hz respectively .

NOTE 2 For good quality measurements of background noise, a measuring system with sufficiently low self-

noise is used. It might not be appropriate to use the same hydrophone for the background noise measurements

as that used for the measurement of the sound radiated from the pile-driving. For measurement of background

noise, a hydrophone with low-noise performance and high sensitivity is generally required. For a system designed

to measure very low sound levels, a maximum system self-noise of 47 dB re 1 μPa /Hz at 63 Hz and 43 dB re 1

2 [25]

μPa /Hz at 125 Hz is preferred .

4.2.6 Dynamic range

The system dynamic range shall be chosen to be sufficient to enable the highest expected sound

pressure, at the measurement position, to be recorded faithfully without distortion or saturation

caused by the hydrophone, amplifier, and ADC.

NOTE 1 The dynamic range of the measuring system is the amplitude range over which the system can

faithfully measure the sound pressure. This ranges from the noise floor of the system (which defines the lowest

measurable signal) to the highest amplitude of signal that can be measured without significant distortion.

NOTE 2 High amplitude sounds which are beyond the maximum capability of the measuring system will cause

distortions in the measured data. For example, clipping can occur where the peaks of the signal are missing from

the data (the peaks being truncated at the full-scale value of the system ADC). The measuring system is required

to be linear over the full dynamic range, requiring that the system sensitivity is constant over the full range of

measurable sound pressure. Systems with dynamic ranges of in excess of 60 dB are preferred for measurement

of pile driving noise. For some systems, when approaching the high amplitude limit, the response might no longer

be linear due to limits in the performance of components such as amplifiers. Therefore, it is advisable that a

measurement system is not used close to the limit of its dynamic range unless the linearity has been checked.

NOTE 3 A metho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...