ISO 8092-2:2023

(Main)Road vehicles — Connections for on-board electrical wiring harnesses — Part 2: Terminology, test methods and general performance requirements

Road vehicles — Connections for on-board electrical wiring harnesses — Part 2: Terminology, test methods and general performance requirements

This document provides terminology and specifies test methods for general performance requirements of voltage class A connectors used in electrical wiring harnesses on road vehicles. This document applies to connectors which, after mounting in the vehicle, are designed to only be disconnected in connection with repair and maintenance. This document does not apply to internal connections for electronic devices. This document does not apply to signal communication quality or data integrity.

Véhicules routiers — Connexions pour faisceaux de câblage électrique embarqués — Partie 2: Terminologie, méthodes d'essai et exigences de performances générales

General Information

- Status

- Published

- Publication Date

- 03-Sep-2023

- Technical Committee

- ISO/TC 22/SC 32 - Electrical and electronic components and general system aspects

- Drafting Committee

- ISO/TC 22/SC 32/WG 6 - On-board electrical connections

- Current Stage

- 6060 - International Standard published

- Start Date

- 04-Sep-2023

- Due Date

- 01-Apr-2023

- Completion Date

- 04-Sep-2023

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

- Effective Date

- 23-Apr-2020

Overview

ISO 8092-2:2023 - Road vehicles - Connections for on-board electrical wiring harnesses - Part 2 provides terminology, test methods and general performance requirements for voltage class A connectors used in on-board electrical wiring harnesses of road vehicles. The standard applies to connectors that, once mounted in the vehicle, are intended to be disconnected only for repair and maintenance. It explicitly excludes internal connections inside electronic devices and does not cover signal communication quality or data integrity.

Keywords: ISO 8092-2:2023, road vehicles connectors, on-board electrical wiring harnesses, voltage class A connectors, test methods, performance requirements.

Key topics and technical requirements

The document defines essential vocabulary and a comprehensive test regime to verify connector performance. Major technical topics include:

- Terms and definitions for consistent use of connector-related vocabulary.

- Test conditions and preconditioning (environmental and mechanical durability) and guidance on test sequences and sample quantities.

- Visual examination procedures and pass/fail criteria.

- Mechanical tests, including:

- Connection and disconnection behaviour

- Measurement/classification of mating, unmating and unlocking forces

- Locking device strength and prevention of unintentional release

- CPA (connector position assurance) and TPA (terminal position assurance) locking/disengage forces

- Effectiveness of coding and polarization

- Connector engagement sound and terminal insertion/extraction forces

- Tensile strength of terminal-to-wire connections

- Electrical tests, including:

- Connection resistance (voltage drop) measurements

- Temperature rise under load

- Current cycling at ambient temperature

- Insulation resistance tests

The standard specifies methods to carry out these tests and sets general performance expectations; it does not prescribe specific signal/data integrity assessments.

Practical applications

ISO 8092-2:2023 is used to ensure connector reliability, safety and maintainability in automotive wiring harnesses. Practical benefits include:

- Reducing field failures and warranty costs through validated connector performance

- Ensuring repeatable manufacturing and inspection criteria

- Facilitating supplier qualification and incoming inspection

- Supporting design decisions for connector selection and harness layout

Keywords: automotive connector testing, wiring harness reliability, connector performance requirements.

Who should use this standard

- Automotive OEMs and vehicle electrical system designers

- Connector and wiring-harness manufacturers and suppliers

- Test laboratories and quality assurance teams

- Regulatory and compliance personnel assessing component conformity

Related standards

ISO 8092-2:2023 is part of the broader set of standards addressing on-board connector design and testing. Users should consider other parts of the ISO 8092 series and applicable vehicle electrical system standards when specifying or qualifying connectors.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 8092-2:2023 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Connections for on-board electrical wiring harnesses — Part 2: Terminology, test methods and general performance requirements". This standard covers: This document provides terminology and specifies test methods for general performance requirements of voltage class A connectors used in electrical wiring harnesses on road vehicles. This document applies to connectors which, after mounting in the vehicle, are designed to only be disconnected in connection with repair and maintenance. This document does not apply to internal connections for electronic devices. This document does not apply to signal communication quality or data integrity.

This document provides terminology and specifies test methods for general performance requirements of voltage class A connectors used in electrical wiring harnesses on road vehicles. This document applies to connectors which, after mounting in the vehicle, are designed to only be disconnected in connection with repair and maintenance. This document does not apply to internal connections for electronic devices. This document does not apply to signal communication quality or data integrity.

ISO 8092-2:2023 is classified under the following ICS (International Classification for Standards) categories: 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 8092-2:2023 has the following relationships with other standards: It is inter standard links to FprEN ISO 8092-2, ISO 21250-1:2020, ISO 8092-2:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 8092-2:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 8092-2

Fifth edition

2023-09

Road vehicles — Connections for on-

board electrical wiring harnesses —

Part 2:

Terminology, test methods and

general performance requirements

Véhicules routiers — Connexions pour faisceaux de câblage électrique

embarqués —

Partie 2: Terminologie, méthodes d'essai et exigences de performances

générales

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

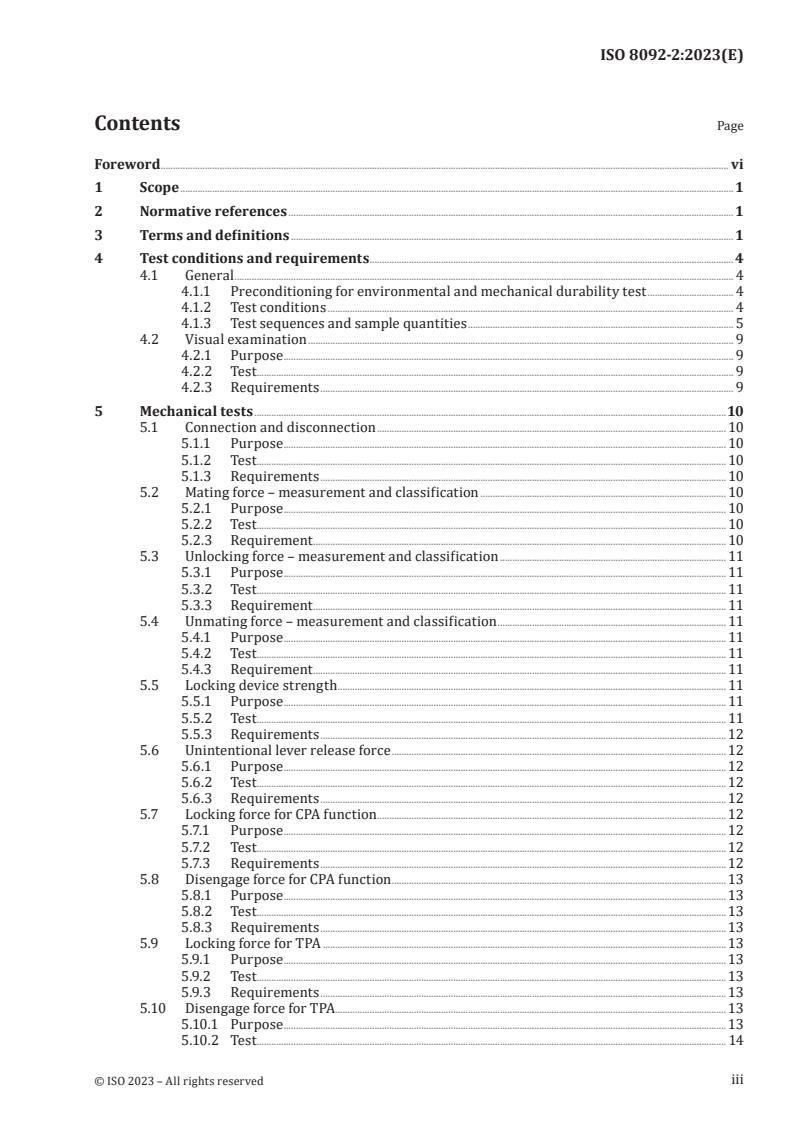

Contents Page

Foreword . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Test conditions and requirements . 4

4.1 General . 4

4.1.1 Preconditioning for environmental and mechanical durability test . 4

4.1.2 Test conditions . 4

4.1.3 Test sequences and sample quantities . 5

4.2 Visual examination . 9

4.2.1 Purpose . 9

4.2.2 Test . . . 9

4.2.3 Requirements . 9

5 Mechanical tests .10

5.1 Connection and disconnection . 10

5.1.1 Purpose . 10

5.1.2 Test . . . 10

5.1.3 Requirements . 10

5.2 Mating force – measurement and classification . 10

5.2.1 Purpose . 10

5.2.2 Test . . . 10

5.2.3 Requirement . 10

5.3 Unlocking force – measurement and classification . 11

5.3.1 Purpose . 11

5.3.2 Test . . . 11

5.3.3 Requirement . 11

5.4 Unmating force – measurement and classification . 11

5.4.1 Purpose . 11

5.4.2 Test . . . 11

5.4.3 Requirement . 11

5.5 Locking device strength . 11

5.5.1 Purpose . 11

5.5.2 Test . . . 11

5.5.3 Requirements .12

5.6 Unintentional lever release force .12

5.6.1 Purpose .12

5.6.2 Test . . .12

5.6.3 Requirements .12

5.7 Locking force for CPA function . .12

5.7.1 Purpose .12

5.7.2 Test . . .12

5.7.3 Requirements .12

5.8 Disengage force for CPA function . 13

5.8.1 Purpose . 13

5.8.2 Test . . .13

5.8.3 Requirements .13

5.9 Locking force for TPA .13

5.9.1 Purpose . 13

5.9.2 Test . . .13

5.9.3 Requirements .13

5.10 Disengage force for TPA. 13

5.10.1 Purpose .13

5.10.2 Test . . . 14

iii

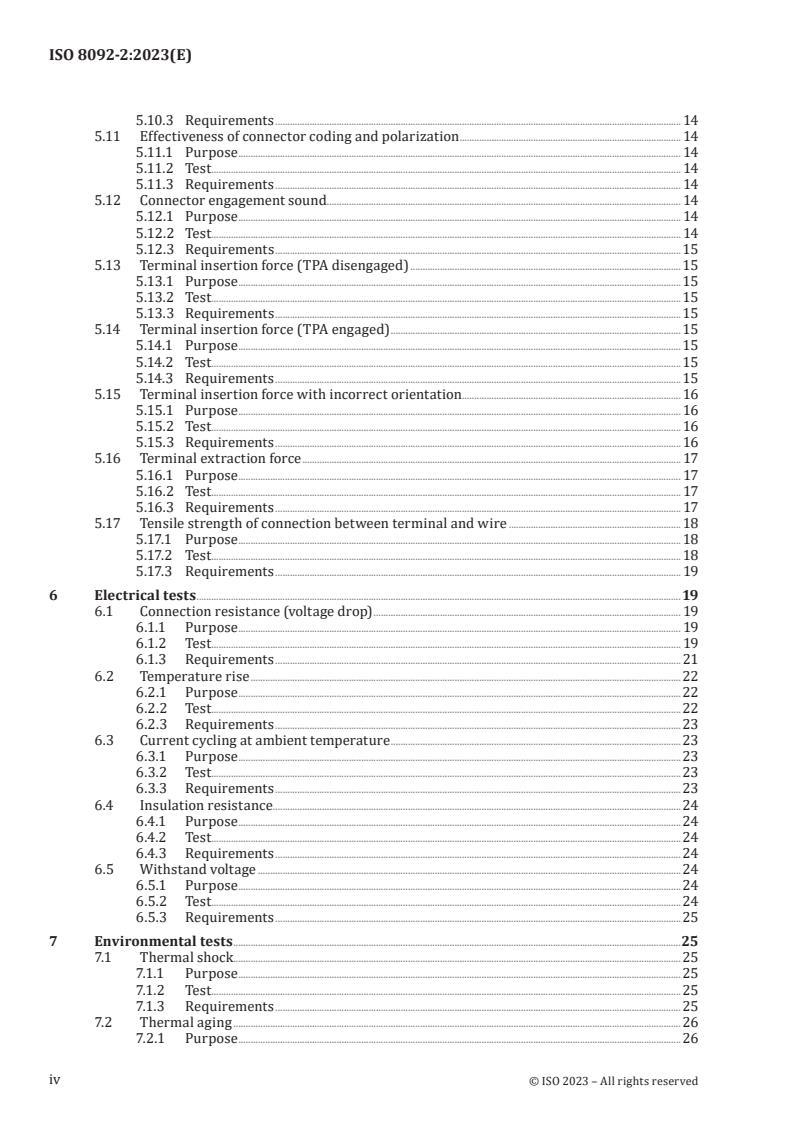

5.10.3 Requirements . 14

5.11 Effectiveness of connector coding and polarization . 14

5.11.1 Purpose . 14

5.11.2 Test . . . 14

5.11.3 Requirements . 14

5.12 Connector engagement sound . 14

5.12.1 Purpose . 14

5.12.2 Test . . . 14

5.12.3 Requirements .15

5.13 Terminal insertion force (TPA disengaged) . 15

5.13.1 Purpose .15

5.13.2 Test . . . 15

5.13.3 Requirements .15

5.14 Terminal insertion force (TPA engaged) . 15

5.14.1 Purpose . 15

5.14.2 Test . . . 15

5.14.3 Requirements .15

5.15 Terminal insertion force with incorrect orientation . 16

5.15.1 Purpose . 16

5.15.2 Test . . . 16

5.15.3 Requirements . 16

5.16 Terminal extraction force . 17

5.16.1 Purpose . 17

5.16.2 Test . . . 17

5.16.3 Requirements . 17

5.17 Tensile strength of connection between terminal and wire . 18

5.17.1 Purpose . 18

5.17.2 Test . . . 18

5.17.3 Requirements . 19

6 Electrical tests .19

6.1 Connection resistance (voltage drop) . 19

6.1.1 Purpose . 19

6.1.2 Test . . . 19

6.1.3 Requirements . 21

6.2 Temperature rise . 22

6.2.1 Purpose . 22

6.2.2 Test . . .22

6.2.3 Requirements . 23

6.3 Current cycling at ambient temperature . 23

6.3.1 Purpose .23

6.3.2 Test . . . 23

6.3.3 Requirements . 23

6.4 Insulation resistance. 24

6.4.1 Purpose . 24

6.4.2 Test . . . 24

6.4.3 Requirements . 24

6.5 Withstand voltage . 24

6.5.1 Purpose . 24

6.5.2 Test . . . 24

6.5.3 Requirements .25

7 Environmental tests .25

7.1 Thermal shock. 25

7.1.1 Purpose . 25

7.1.2 Test . . . 25

7.1.3 Requirements . 25

7.2 Thermal aging . 26

7.2.1 Purpose . 26

iv

7.2.2 Test . . . 26

7.2.3 Requirements .26

7.3 Temperature and humidity cycle . 26

7.3.1 Purpose . 26

7.3.2 Test . . . 26

7.3.3 Requirements .29

7.4 Vibration with thermal cycling .29

7.4.1 Purpose .29

7.4.2 Test . . .29

7.4.3 Requirements .30

7.5 Mechanical shock . 31

7.5.1 Purpose . 31

7.5.2 Test . . . 31

7.5.3 Requirements . 31

7.6 Drop . 31

7.6.1 Purpose . 31

7.6.2 Test . . . 31

7.6.3 Requirements . 32

7.7 Water tightness . 32

7.7.1 Purpose . 32

7.7.2 Test . . . 32

7.7.3 Requirements .34

7.8 Water tightness, dynamic .34

7.8.1 Purpose .34

7.8.2 Test . . .34

7.8.3 Requirement .36

7.9 High-pressure/steam-jet cleaning . 36

7.9.1 Purpose . 36

7.9.2 Test . . .36

7.9.3 Requirements . 37

7.10 Salt spray .38

7.10.1 Purpose .38

7.10.2 Test . . .38

7.10.3 Requirements .38

7.11 Dust resistance .38

7.11.1 Purpose .38

7.11.2 Test . . .38

7.11.3 Requirements .38

7.12 Chemical loads .38

7.12.1 Purpose .38

7.12.2 Test . . .39

7.12.3 Requirements . 39

7.13 Fretting corrosion .39

7.13.1 Purpose . 39

7.13.2 Test . . .39

7.13.3 Requirements . 39

7.14 Friction corrosion . 39

7.14.1 Purpose .39

7.14.2 Test . . .40

7.14.3 Requirements .40

Bibliography .41

v

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 32,

Electrical and electronic components and general system aspects.

This fifth edition cancels and replaces the fourth edition (ISO 8092-2:2005), which has been technically

revised.

The main changes are as follows:

— adoption of the content according to new technical requirements,

— adoption of the content according to the new version of the ISO guidelines,

— alignment of the content regarding to the referred standards,

— subclause 4.24 "Flowing gas corrosion test" has been removed due to its technical irrelevance,

— former Annex A is adopted as an informative part under 4.1.2,

— Annex B has been removed due to its technical irrelevance.

A list of all parts in the ISO 8092 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

vi

INTERNATIONAL STANDARD ISO 8092-2:2023(E)

Road vehicles — Connections for on-board electrical

wiring harnesses —

Part 2:

Terminology, test methods and general performance

requirements

1 Scope

This document provides terminology and specifies test methods for general performance requirements

of voltage class A connectors used in electrical wiring harnesses on road vehicles.

This document applies to connectors which, after mounting in the vehicle, are designed to only be

disconnected in connection with repair and maintenance.

This document does not apply to internal connections for electronic devices.

This document does not apply to signal communication quality or data integrity.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 8092-5:2021, Road vehicles — Connections for on-board electrical wiring harnesses — Part 5: Test

methods and general performance requirements for wiring harness connector operation

ISO 16750-3:2023, Road vehicles - Environmental conditions and testing for electrical and electronic

equipment - Part 3: Mechanical loads

ISO 16750-4:2023, Road vehicles - Environmental conditions and testing for electrical and electronic

equipment - Part 4: Climatic loads

ISO 16750-5:2023, Road vehicles - Environmental conditions and testing for electrical and electronic

equipment - Part 5: Chemical loads

ISO 20653:2023, Road vehicles — Degrees of protection (IP-code) — Protection against foreign objects,

water and access –Electrical equipment

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

voltage class A

classification of an electric component or circuit with a maximum working voltage of ≤ 30 V a.c. (rms)

or ≤ 60 V d.c., respectively

[SOURCE: ISO 21498-1:2021, 3.12]

3.2

housing

non-conducting feature for inserting the terminal and providing insulation between terminals

3.3

cable attachment

permanent junction of cable to terminal

Note 1 to entry: Crimp and weld are typical methods.

Note 2 to entry: For terms related to cables, see ISO 19642-1.

3.4

connector

assembly of terminal, housing (3.2) and related parts that terminate cable for the purpose of providing

connection and disconnection to a suitable mating connector

3.5

connector coding

mechanical feature to provide differentiation, preventing mating of connectors (3.4) not intended to be

mated

3.6

connector polarization

method or design feature, which prevents connectors (3.4) that are intended to mate from mating in an

unintended orientation, rotation, or angular position, whilst allowing mating in the intended manner

3.7

CPA

connector position assurance

device that prevents accidental release of the connector (3.4) lock and serves as an indicator of full

connector mating

3.8

TPA

terminal position assurance

feature installed or seated after the terminals are inserted into their housing (3.2) to assure that the

terminals are properly positioned, and which reinforces the primary terminal locking mechanism or

provides a separate, redundant terminal lock

3.9

socket terminal

terminal, including means for cable attachment (3.3), designed for electrical engagement on its inner

surface, and to accept entry of a pin terminal (3.11), thus forming an electrical connection

Note 1 to entry: See Figure 1 for an example.

Note 2 to entry: Socket terminals are sometimes referred to as female terminals.

a) socket b) receptacle

Figure 1 — Example of a socket and a receptacle terminal

3.10

receptacle terminal

terminal, including means for cable attachment (3.3), designed for electrical engagement on its inner

surface, and to accept entry of a tab terminal (3.12), thus forming an electrical connection

Note 1 to entry: See Figure 1 for an example.

Note 2 to entry: Receptacle terminals are sometimes referred to as female terminals.

3.11

pin terminal

terminal, including means for cable attachment (3.3), designed for electrical engagement on its outer

surface and to enter a socket terminal (3.9), thus forming an electrical connection

Note 1 to entry: Pin terminals are sometimes referred to as male terminals.

Note 2 to entry: See Figure 2 for an example.

a) pin b) tab

Figure 2 — Example of a pin and a tab terminal

3.12

tab terminal

terminal, including means for cable attachment (3.3), designed for electrical engagement on its outer

surface and to enter a receptacle terminal (3.10), thus forming an electrical connection

Note 1 to entry: Tab terminals are sometimes referred to as male terminals.

Note 2 to entry: Tab terminals are sometimes referred to as blade terminals.

Note 3 to entry: See Figure 2 for an example.

3.13

multipole connector

two mated connectors (3.4) halves with more than one terminal pair [e.g. one receptacle and one tab

terminal (3.12)]

4 Test conditions and requirements

4.1 General

4.1.1 Preconditioning for environmental and mechanical durability test

All test samples shall be preconditioned at a standard ambient temperature of (23 ± 5) °C, and (25–

75) % relative humidity for 24 h before the start of any test sequence.

4.1.2 Test conditions

All tests shall be carried out at a standard ambient temperature of (23 ± 5) °C and (25–75) % relative

humidity unless otherwise stated in the test procedure. This is referred to as room temperature (RT).

A cable in compliance with applicable part of the ISO 19642 series is recommended. The cable or cables

used shall be specified in the test report.

The cross-sectional area of the wire mentioned in this specification refers to wires with a copper

conductor.

When the wire conductor is of a material other than copper, the cross–sectional area of the wire shall

be specified by agreement between customer and supplier.

Cable attachment shall be performed in accordance with the terminal manufacturer's specifications, or

as agreed between customer and supplier.

Care shall be taken so that test samples do not influence each other (e.g. in a heat chamber).

Each connector shall have the full complement of terminals fitted unless otherwise specified.

The terminals and connectors used in the test shall be fully assembled unless otherwise specified.

Connectors shall be tested in mated condition unless otherwise stated. In the case of a connector

connecting directly to a device, a mating dummy may be used to carry out tests. This dummy shall

represent the intended device’s interface and electrical properties.

For connector mechanical tests, unless otherwise specified, fix the pin or tab housing of the unmated

or mated connector in the appropriate fixture on the tension or force tester. Secure the other side in the

appropriate fixture and insert or pull the socket or receptacle housing straight in/out. Straight-in or

straight-out engagement is critical to avoid side loads and binding which can affect force measurements.

For terminal mechanical tests, unless otherwise specified, fix the pin or tab terminal of the unmated

or mated terminal in the appropriate fixture on the tension or force tester. Secure the other side in

the appropriate fixture and insert/pull the socket receptacle terminal straight in/out. Straight-in or

straight-out engagement is critical to avoid side loads and binding which can affect force measurements.

Measurements shall be taken on all terminals regardless of the number of poles per connector, unless

otherwise specified in the test methods or by agreement between customer and supplier.

Lubrication or other means of attaining better test results shall not be added to any surface unless

representative of assembly conditions. Production-related remains of lubricants on the terminals are

permitted.

Unless otherwise specified, all forces shall be applied at a constant speed of (50 ± 10) mm/min.

Unless otherwise specified, when a temperature of T is specified in a test, the applicable “highest

max

value” temperature as per Table 1 shall be used. When a temperature of T is specified in a test, the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...